Escolar Documentos

Profissional Documentos

Cultura Documentos

Generon Membrane 4100

Enviado por

Javier Garcia Marquez0 notas0% acharam este documento útil (0 voto)

48 visualizações2 páginasGeneron Membrane 4100

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoGeneron Membrane 4100

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

48 visualizações2 páginasGeneron Membrane 4100

Enviado por

Javier Garcia MarquezGeneron Membrane 4100

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

4100

Nitrogen Membrane

Reliable Nitrogen Membrane Modules are the heart

of a nitrogen generation system. GENERON®

membrane modules have been at the forefront of

the industry for over 40 years. Our research and

development team in California work to continually

improve the performance and durability of our

membranes.

By supplying the GENERON® membrane modules with

compressed air, they generate a nitrogen stream

that’s suitable for industries including: commercial,

food, beverage, laboratory, controlled atmosphere,

pharmaceutical, chemical, textile, heat treatment,

electronics and many more.

Features & Benefits

Durability by Design Ease of Installation

GENERON® has been the benchmark of the industry GENERON® membrane modules allow installa-

and is proud of the track record of the lowest return- tion in any available space, whether horizontal

rate while selling >100,000 membranes or vertical. The large choice of membrane sizes

makes the fit easy.

Saving Energy

GENERON® membrane modules offer the highest Quality is Guaranteed

efficiency which reduces your compression costs to Every GENERON® membrane module is rigor-

the minimum ously QC tested before it leaves our membrane

manufacturing facility to ensure it meets the

Reducing Footprint highest flow and purity standards set in our ISO

GENERON® membrane modules with the highest 90001 procedures

productivity in the industry allow for the smallest sys-

tem size and lowest weight Suited for Tough Environments

GENERON® membrane modules are built to

Start-Up is a Breeze withstand even the roughest operating condi-

As soon as you supply compressed air to the GEN- tions, incl. vibrations, pressure– and tempera-

ERON® membrane modules you will instantaneously ture swings and harsh off-shore or roadside out-

produce nitrogen door conditions

Reduced CO2 emissions Experience Engineering

No heater required to open polymer membrane GENERON® membrane modules are designed

structure, thus reducing the energy consumption. and built for 10+ years of operation.

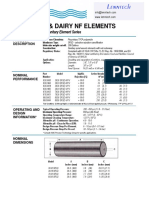

Operating Conditions Mechanical Description

Max Pressure 203 PSIG (14 barg) Outer Diameter 4.5 inch [114 mm)

Temperature (Min /Max) 40 °F (4.4 °C) / 149 °F (65 °C) Length 36.5 inch [927 mm]

Max Relative Humidity 80% (no liquid water) Weight 17 lbs [7.7 kg)

Max Particle Size 0.01 micron Case Material 6061-T6 Aluminum

Nitrogen Product Flow Rate at 25°C (77°F) vs. Product Purity

Pressure Nitrogen Product Purity in vol% and Product Flow Rate NCMH (SCFH)

barg (psig)

95.0% 96.0% 97.0% 98.0% 99.0% 99.5%

6.9 6.5 5.5 4.6 3.6 2.6 2

(100) (251.6) (213.1) (176.1) (139.8) (101.9) (78.5)

8.5 8.8 7.5 6.2 4.9 3.6 2.8

(125) (338.8) (287.5) (238.1) (189.6) (138.9) (107.7)

10.4 11.5 9.8 8.1 6.5 4.8 3.7

(150) (443.2) (376.7) (312.6) (249.8) (184) (143.3)

12.1 13.8 11.8 9.8 7.8 5.8 4.5

(175) (533.2) (453.7) (377.2) (302) (223.3) (174.7)

13.8 16.2 13.8 11.5 9.2 6.8 5.4

(200) (625.4) (532.7) (443.5) (355.9) (264.1) (207.3)

Air Recovery Rate at 25°C (77°F) [%] vs Product Purity

Pressure

95.0% 96.0% 97.0% 98.0% 99.0% 99.5%

barg (psig)

6.9

51.1% 47.7% 43.6% 38.6% 31.6% 26.2%

(100)

8.5

52.8% 49.4% 45.3% 40.3% 33.3% 27.9%

(125)

10.4

54.1% 50.7% 46.7% 41.7% 34.8% 29.4%

(150)

12.1

54.8% 51.4% 47.5% 42.6% 35.7% 30.3%

(175)

13.8

55.2% 51.9% 48.0% 43.2% 36.4% 31.1%

(200)

Porting Configuration

Connection Size 1. Seal connections with Teflon Tape or Formula 8 Thread Sealant only.

A—Feed 1/2 inch FNPT 2. Standard Conditions: 77°F (25°C) and 14.696 psi (1 atm)

3. Performance after 1 year (9,000 hours) of continuous operation

B—Product 1/2 inch FNPT 4. Recovery = Product N2 Flow / Feed Flow

C—Permeate 1 inch FNPT

GENERON

16250 Tomball Parkway

Houston, Texas 77086

713-937-5200

Sales@Generon.com

Go Direct:GENERON Delivers

Você também pode gostar

- Introduction To Building Water Supply SystemDocumento9 páginasIntroduction To Building Water Supply SystemCyrelle EscritorAinda não há avaliações

- Effect of Hole Cleaning On Drilling Rate and PerformanceDocumento7 páginasEffect of Hole Cleaning On Drilling Rate and PerformanceazeazeazeAinda não há avaliações

- As 1692 Tanks For Flammable & Combustible LiquidsDocumento19 páginasAs 1692 Tanks For Flammable & Combustible Liquidspvdang100% (13)

- Marine Surveyors Manual Part 1Documento22 páginasMarine Surveyors Manual Part 1Javier Garcia MarquezAinda não há avaliações

- Pneumatic Test ReportDocumento5 páginasPneumatic Test ReportMohd Ashraf50% (2)

- Document FileDocumento68 páginasDocument Fileso100% (1)

- BBC Engineering Training Manual - Microphones (Robertson)Documento380 páginasBBC Engineering Training Manual - Microphones (Robertson)Nino Rios100% (1)

- 4995 1Documento19 páginas4995 1Vijay YadavAinda não há avaliações

- Fluid Mechanics (MCQ)Documento17 páginasFluid Mechanics (MCQ)John WilmarAinda não há avaliações

- Polymer Foams Handbook: Engineering and Biomechanics Applications and Design GuideNo EverandPolymer Foams Handbook: Engineering and Biomechanics Applications and Design GuideAinda não há avaliações

- Science10 Q4 Week-1-Boyles LawDocumento12 páginasScience10 Q4 Week-1-Boyles LawJomelyn Arzaga80% (5)

- Processing Technology: Processing of Polymer Melts Made in GermanyDocumento24 páginasProcessing Technology: Processing of Polymer Melts Made in GermanyRobel MTAinda não há avaliações

- Cobb ManualDocumento112 páginasCobb ManualAvinash Technical ServiceAinda não há avaliações

- Datasheet For FiltersDocumento13 páginasDatasheet For FiltersAntonio MendesAinda não há avaliações

- Spare Parts Catalog 2006 PDFDocumento82 páginasSpare Parts Catalog 2006 PDFJavier Garcia Marquez100% (1)

- Medical Gas Piping SpecDocumento22 páginasMedical Gas Piping Specvvg100% (1)

- Introduction To Fiscal MeteringDocumento30 páginasIntroduction To Fiscal MeteringOkoro Kenneth100% (1)

- Generon Membrane 4100 CPDocumento2 páginasGeneron Membrane 4100 CPJavier Garcia MarquezAinda não há avaliações

- Model 7200LPHF: Membrane ModulesDocumento2 páginasModel 7200LPHF: Membrane ModulesPraveen Manikandan MuthurajAinda não há avaliações

- Halliburton Screens: Filtration TechnologyDocumento10 páginasHalliburton Screens: Filtration TechnologyVGAinda não há avaliações

- The Premium Performance: Medical Oxygen Generators Standard SeriesDocumento2 páginasThe Premium Performance: Medical Oxygen Generators Standard SeriesPReYMOdeAinda não há avaliações

- Comet Portables and Mobile Catalog v5Documento11 páginasComet Portables and Mobile Catalog v5Hyujeii MceAinda não há avaliações

- Flares5Heftly Kristen Zeeco EmissionsTestingDocumento44 páginasFlares5Heftly Kristen Zeeco EmissionsTestingTsunYuChangAinda não há avaliações

- EWP63S Product SpecificationsDocumento2 páginasEWP63S Product SpecificationsKoro SenpaiAinda não há avaliações

- CT Catalogue - FullDocumento9 páginasCT Catalogue - FulldedeAinda não há avaliações

- EW77 Product SpecificationsDocumento3 páginasEW77 Product SpecificationsBjorn AdikAinda não há avaliações

- Aqua Series Vapor Compression DistillerDocumento1 páginaAqua Series Vapor Compression DistillerMohd Khairul Ahmad AliasAinda não há avaliações

- Pressurization Skid FilterDocumento4 páginasPressurization Skid FilterHAAinda não há avaliações

- WAVEGUIDE EW77.Aspx Elliptical Waveguide With HIGDocumento2 páginasWAVEGUIDE EW77.Aspx Elliptical Waveguide With HIGAngelo X. LinaoAinda não há avaliações

- Pall Emflon PFRW LDocumento2 páginasPall Emflon PFRW Lhamoon.jabbari.94Ainda não há avaliações

- NGP+8-130 enDocumento2 páginasNGP+8-130 enwilliambach2018Ainda não há avaliações

- Brochure - Tecnipile - Copie PDFDocumento3 páginasBrochure - Tecnipile - Copie PDFAmine ATTARAinda não há avaliações

- ECPEN11-800 D-AHU-Professional Catalogues EnglishDocumento8 páginasECPEN11-800 D-AHU-Professional Catalogues EnglishRan NAinda não há avaliações

- EVO Product Catalog v3Documento9 páginasEVO Product Catalog v3Saad AfzalAinda não há avaliações

- Nitrogen Generators Nitrogen On Wall: Series: NOW CP-211Documento2 páginasNitrogen Generators Nitrogen On Wall: Series: NOW CP-211Rajendra LabadeAinda não há avaliações

- Marine: Fire Protection SolutionsDocumento4 páginasMarine: Fire Protection SolutionsJohan VillarrealAinda não há avaliações

- Flexair T-Series-SS-2017-HRDocumento2 páginasFlexair T-Series-SS-2017-HRandres.ariasAinda não há avaliações

- Aptos DNA 365W SpecDocumento2 páginasAptos DNA 365W Specdfgdgg dagaggAinda não há avaliações

- Work FilesDocumento36 páginasWork FilesAhmed AbdullahAinda não há avaliações

- EW77Documento2 páginasEW77Vin VinAinda não há avaliações

- 3900 Prepreg SystemDocumento5 páginas3900 Prepreg SystemLiran KatzAinda não há avaliações

- SleepersDocumento8 páginasSleepersDso AnakpanahAinda não há avaliações

- Abrikam NC: Connecting The WorldDocumento8 páginasAbrikam NC: Connecting The WorldcacaAinda não há avaliações

- CLCP Product CatalogsDocumento46 páginasCLCP Product CatalogsHasan67% (3)

- New Alpha Medical Vacuum USDocumento2 páginasNew Alpha Medical Vacuum USvishal.nithamAinda não há avaliações

- Series: Positive Displacement Blowers & Vacuum PumpsDocumento12 páginasSeries: Positive Displacement Blowers & Vacuum Pumpszain140Ainda não há avaliações

- Oxywise Nitrogen Generator SEPDocumento2 páginasOxywise Nitrogen Generator SEPlifemillion2847Ainda não há avaliações

- Archas PDFDocumento32 páginasArchas PDFEnmanuel Antony JeriAinda não há avaliações

- Lehrs: Tom HartDocumento32 páginasLehrs: Tom HartEnmanuel Antony JeriAinda não há avaliações

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDocumento4 páginasCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloAinda não há avaliações

- FirexDocumento8 páginasFirexSE KongAinda não há avaliações

- Heavy Duty FiltrationDocumento80 páginasHeavy Duty Filtrationsuphanat joomjanAinda não há avaliações

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDocumento24 páginasACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaAinda não há avaliações

- ACSEW Cast Control Centers Appleton en 7439390 PDFDocumento8 páginasACSEW Cast Control Centers Appleton en 7439390 PDFGERARDO DIAZAinda não há avaliações

- CMT Lab Report #1Documento5 páginasCMT Lab Report #1jae periasAinda não há avaliações

- Autoclave Midmark m11Documento2 páginasAutoclave Midmark m11VENTAS CIRCUIMEDAinda não há avaliações

- PEPLYN AIR Filter Cartridges: Performance CharacteristicsDocumento2 páginasPEPLYN AIR Filter Cartridges: Performance CharacteristicsDucVikingAinda não há avaliações

- 9109a8e0-1815-11e9-9c88-c51e407c53abDocumento112 páginas9109a8e0-1815-11e9-9c88-c51e407c53abSBC Law Council100% (1)

- Rugged Disc Brake SolutionsDocumento4 páginasRugged Disc Brake SolutionsNelsonParedesAinda não há avaliações

- Compressive Strength of AAC BlockDocumento11 páginasCompressive Strength of AAC BlockImran KhanAinda não há avaliações

- BEKOKAT Presentation WebDocumento32 páginasBEKOKAT Presentation WebEstefania ZamoraAinda não há avaliações

- Foam Insualtion R Value WALLTITE Eco v.3 Technical Data Sheet PDFDocumento7 páginasFoam Insualtion R Value WALLTITE Eco v.3 Technical Data Sheet PDFAl7amdlellahAinda não há avaliações

- Ce Series Filters & Moisture Separator: Compressed Air & Power SolutionsDocumento4 páginasCe Series Filters & Moisture Separator: Compressed Air & Power SolutionsTim MitchellAinda não há avaliações

- ISO 95+™ GL Insulation: Product InformationDocumento3 páginasISO 95+™ GL Insulation: Product InformationCarlos CorregidorAinda não há avaliações

- Compare Samsung Galaxy S21 5G vs. Samsung Galaxy A52 5G vs. Samsung Galaxy A72 5GDocumento3 páginasCompare Samsung Galaxy S21 5G vs. Samsung Galaxy A52 5G vs. Samsung Galaxy A72 5GShahrizad Mad SariffAinda não há avaliações

- Metric Design GuideDocumento95 páginasMetric Design GuidePicollusAinda não há avaliações

- EDI FlexAir Magnum Spec SheetDocumento2 páginasEDI FlexAir Magnum Spec SheetMurukan PadmanabhanAinda não há avaliações

- 01 Spech Sheet - SKID UF (1 Módulo)Documento3 páginas01 Spech Sheet - SKID UF (1 Módulo)mohamed salahAinda não há avaliações

- Oxywise Oxygen GeneratorDocumento2 páginasOxywise Oxygen GeneratorAbrourAinda não há avaliações

- PIYUSH SHARMA ICACMS Proceedings Vol 4Documento10 páginasPIYUSH SHARMA ICACMS Proceedings Vol 4Piyush SharmaAinda não há avaliações

- LR Magna Comp BPDocumento2 páginasLR Magna Comp BPherbster28Ainda não há avaliações

- Koch SR3D Food Dairy Elements LDocumento2 páginasKoch SR3D Food Dairy Elements LFacundo RiffelAinda não há avaliações

- The Science and Engineering of Thermal Spray CoatingsNo EverandThe Science and Engineering of Thermal Spray CoatingsAinda não há avaliações

- Introduction to Microsystem Technology: A Guide for StudentsNo EverandIntroduction to Microsystem Technology: A Guide for StudentsNota: 5 de 5 estrelas5/5 (1)

- Ballast WaterDocumento30 páginasBallast WaterJavier Garcia MarquezAinda não há avaliações

- Exploded View and Parts Table Codeline 40E SeriesDocumento1 páginaExploded View and Parts Table Codeline 40E SeriesJavier Garcia MarquezAinda não há avaliações

- Transverse StabilityDocumento13 páginasTransverse StabilityJavier Garcia MarquezAinda não há avaliações

- Traduccion ASMEDocumento18 páginasTraduccion ASMEraul gonzalezAinda não há avaliações

- Productivity Index Horizontal Gas WellDocumento53 páginasProductivity Index Horizontal Gas WellSasha AdiraAinda não há avaliações

- ES 65 Summer 2012-2013 Take Home 3Documento2 páginasES 65 Summer 2012-2013 Take Home 3Eddie Balansag MCheavenAinda não há avaliações

- Wind Tunnel Designs and Their Diverse Engineering Applications 14Documento2 páginasWind Tunnel Designs and Their Diverse Engineering Applications 14Dang Tien PhucAinda não há avaliações

- 4647 - EME2066 Tutorial 4, Trim.3,2014-15Documento1 página4647 - EME2066 Tutorial 4, Trim.3,2014-15Ong Teck ChongAinda não há avaliações

- Pipesim: - FPT Case StudiesDocumento6 páginasPipesim: - FPT Case StudiesMhanna AYAinda não há avaliações

- CFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserDocumento27 páginasCFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserK PedersenAinda não há avaliações

- Vacuum and Pressure Gauges For Fire Proteccion System 2311Documento24 páginasVacuum and Pressure Gauges For Fire Proteccion System 2311Anonymous 8RFzObvAinda não há avaliações

- High Performance Diaphragm Liquid End (HPD) - Low Flow: Installation, Operation, and Maintenance ManualDocumento40 páginasHigh Performance Diaphragm Liquid End (HPD) - Low Flow: Installation, Operation, and Maintenance ManualMiguel SoteloAinda não há avaliações

- Pore-Throat Sizes in Sand StonesDocumento12 páginasPore-Throat Sizes in Sand StonesSouvik DeAinda não há avaliações

- Physics PapersDocumento61 páginasPhysics PapersDanial Amjad ChohanAinda não há avaliações

- European Aviation Safety Agency: Easa Type-Certificate Data SheetDocumento9 páginasEuropean Aviation Safety Agency: Easa Type-Certificate Data SheetAlberto CisnerosAinda não há avaliações

- Hubungan Karakteristik Aktivitas Dengan Tekanan DarahDocumento16 páginasHubungan Karakteristik Aktivitas Dengan Tekanan DarahDhanis DharmaAinda não há avaliações

- 5ChED Thurs Group1 Packed ColumnDocumento15 páginas5ChED Thurs Group1 Packed ColumnThesis Group- Coronado Reyes Zapata UST ChEAinda não há avaliações

- GAS Safety: Information BulletinDocumento5 páginasGAS Safety: Information BulletinTeguh SetionoAinda não há avaliações

- 8th Science Notes by MubasirDocumento21 páginas8th Science Notes by MubasirSajidmehsud100% (1)

- Cell Mechanics and Cellular EngineeringDocumento570 páginasCell Mechanics and Cellular Engineeringlifejuice100% (1)

- Manual BombaDocumento15 páginasManual BombaHector RamírezAinda não há avaliações