Escolar Documentos

Profissional Documentos

Cultura Documentos

A330 Tire Inspn PDF

Enviado por

Rithesh Ram NambiarTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

A330 Tire Inspn PDF

Enviado por

Rithesh Ram NambiarDireitos autorais:

Formatos disponíveis

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

** ON A/C ALL

TASK 32-41-00-210-803-A

General Visual Inspection of Tires, Wheels and Brakes (for Hydraulic Leaks)

WARNING: MAKE SURE THAT THE SAFETY DEVICES AND THE WARNING NOTICES ARE IN POSITION BEFORE YOU START A TASK ON OR NEAR:

- THE FLIGHT CONTROLS

- THE FLIGHT CONTROL SURFACES

- THE LANDING GEAR AND THE RELATED DOORS

- COMPONENTS THAT MOVE.

MOVEMENT OF COMPONENTS CAN KILL OR INJURE PERSONS.

WARNING: MAKE SURE THAT THE GROUND SAFETY-LOCKS ARE CORRECTLY INSTALLED ON THE LANDING GEAR.

THIS PREVENTS UNWANTED MOVEMENT OF THE LANDING GEAR.

WARNING: LET THE BRAKES AND THE WHEELS BECOME COOL BEFORE YOU GO NEAR THE LANDING GEAR. DO NOT APPLY A LIQUID OR GAS FIRE

EXTINGUISHER DIRECTLY ON A HOT WHEEL OR BRAKE UNIT. THIS COULD CAUSE AN EXPLOSION.

1. Reason for the Job

Refer to the MPD TASK: 324100-03

GENERAL VISUAL INSPECTION OF TYRES, WHEELS AND BRAKES (FOR HYDRAULIC LEAKS)

NOTE: The information that follows is given for Bias and Radial tires.

The information given is for all Airline Operators.

Make sure that the procedure is applicable to the tires installed on the aircraft.

2. Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR PENCIL

No specific AR WARNING NOTICE(S)

B. Consumable Materials

REFERENCE DESIGNATION

11-001C CLEANING AGENTS

CLEANING AGENT FOR SURFACE AND PARTS

11-010* CLEANING AGENTS

ISOPROPYL ALCOHOL

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

711 NOSE GEAR

731 LEFT MAIN GEAR

741 RIGHT MAIN GEAR

751 CENTERLINE GEAR AND DOORS

D. Referenced Information

REFERENCE DESIGNATION

32-41-00-200-802-A Mixability of Tires

32-41-00-220-801-A-01 Check Tire Pressures Using TPIS and MCDU

Radial Tire (Michelin example) - Details SHEET 1 Radial Tire (Michelin example) - Details SHEET 2 Radial Tire (Michelin example) - Details SHEET 3 Radial Tire

(Michelin example) - Details SHEET 4 Radial Tire (Michelin example) - Details SHEET 5

Bias Tire - Section SHEET 1

Radial Tire (Bridgestone example) - Details SHEET 1 Radial Tire (Bridgestone example) - Details SHEET 2 Radial Tire (Bridgestone example) - Details SHEET

3 Radial Tire (Bridgestone example) - Details SHEET 4 Radial Tire (Bridgestone example) - Details SHEET 5 Radial Tire (Bridgestone example) - Details SHEET

6 Radial Tire (Bridgestone example) - Details SHEET 7

3. Job Set-up

Subtask 32-41-00-941-055-A

A. Safety Precautions

(1) Put the WARNING NOTICE(S) in the cockpit, to tell persons not to operate the landing gear or brakes.

4. Procedure

NOTE: The key to abbreviations are as follows: CL Cut Length LL Length Limit

NOTE: You must replace a wheel immediately when its speed has been more than the tire manufacturer's speed rating. The manufacturer will complete an inspection of

the tire, to make a decision if it is serviceable.

Subtask 32-41-00-941-057-A

A. Tire Dimensions - General

Nose wheel tires - limitations of damage

Tire Size: 1050 x 395 R 16 AIR x TL 28 PR

Main wheel tires - limitations of damage

Tire Size: 1400 x 530 R 23 AIR x TL 32 PR OR 36 PR

Subtask 32-41-00-210-108-A

B. General Visual Inspection of the Tires

Print Date: Oct 11/12 Local Time Page 1 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

NOTE: The specified serviceable wear limits will make sure that the tires can be safely retreaded.

(1) Make sure that:

- the aircraft tires are in a serviceable condition and can be used on the aircraft

- there are no air leaks

- there is no friction damage

- the tires are worn equally

- there are no cuts, flat spots or bulges

- there is no contamination by chemicals, hydrocarbon based fuel or oil based products

- the wheel is replaced when the tire is worn to the base of a tread groove in one or more location

- the wheel is replaced if you can see reinforcing material (metal or fabric).

NOTE: Refer to the limits for the use of the tires. They are related to the type and make of the tire.

(2) Make sure the tire pressure is in the specified limits (Ref. AMM TASK 32-41-00-220-801) .

(3) Obey the tire mixability precautions (Ref. AMM TASK 32-41-00-200-802) .

Subtask 32-41-00-210-109-A

C. Tire Wear Deterioration Characteristics

(1) Under inflated

See pressure table (Ref. AMM TASK 32-41-00-220-801) .

If tires are not inflated to their correct value:

- their shoulders can wear too much

- the tire will flex too much and heating can occur

- the tire can move on the wheel and decrease the braking effect.

(2) Over inflated

See pressure table (Ref. AMM TASK 32-41-00-220-801)

If tires are inflated with too much pressure:

- Too much wear can occur on the center of the tire tread

- the braking effect can be reduced

- there is an increased risk of foreign object damage to the tire.

(3) Tread wear (worn more than the maximum limit)

When the tire is worn to the reinforcing material (metal or fabric) it is worn more than the maximum limit.

(4) Tread rubber reversion (hydroplaning on wet or frozen surfaces)

You can see this condition when there is an oval area of damage to the tire tread. It is almost the same as skid damage but the rubber shows burns.

(5) Thrown tread

This condition occurs when a tire loses part or all of its tread to the tread fabric ply.

(6) Peeled rib

This condition can start with a cut in the tread. This causes the tread rib to delaminate on the circumference.

(7) Fabric fraying

The tread frays or breaks on the ply at the base of the tread groove.

(8) Open tread splice

This is a cut or opening where the tread joint or splice separates radially on the treads.

(9) Cuts

These are cuts which extend more than 50% of a rib and deeper than 50% of the remaining groove depth.

(10) Tread flaking and chipping

You can see this condition when pieces of rubber chip or flake from the tread.

(11) Tread broken away (rib tearing)

You can see this condition when the tire has had a large side force applied during landing or taxiing.

(12) Chevron cutting

Cross grooves on runway surfaces can cause chevron shaped cuts in the tire tread.

(13) Blister or bulges

A separation or bulge on the tread or sidewall.

(14) Groove cracking

This is a crack at the bottom of the tread groove.

(15) Rib undercutting

Cracks or undercutting that occur below the tread rib.

(16) Circumferential cracks or radial cracks

Cracks in the sidewall of the shoulder area of the tire.

(17) Ozone and weather cracks

Cracks caused by weathering and ozone exposure.

(18) Skid and flat spot damage

An oval wear pattern on the tread area.

(19) Contamination

This can be caused by brake oil, tar oil, solvent, chemicals and hydrocarbon based products. The tire must be cleaned with Material No. 11-010* (CLEANING

AGENTS) , and Material No. 11-001C (CLEANING AGENTS) . After cleaning, push the rubber in the contaminated area.

If the rubber is tacky, the wheel must be changed.

(20) External object damage

Print Date: Oct 11/12 Local Time Page 2 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

WARNING: DO NOT REMOVE OBJECTS FROM A PRESSURIZED TIRE. THE PRESSURE CAN EJECT THE OBJECTS WITH MUCH FORCE AND THUS

CAUSE INJURY.

(a) If the tire has an unwanted object in the tread or sidewall:

1 Put a mark in the area where you can see the object with a crayon.

2 Remove the wheel, take care to prevent movement of the object.

NOTE: Move the wheel to a safe area. Deflate the tire before you remove an object. The tire must be inspected at the tire shop.

(21) Circular Tire Movement on the Wheel:

(a) If the circular tire movement is less than 20 degrees you can:

1 Keep the wheel on the aircraft.

2 Monitor the circular tire movement for the next 5 flight cycles.

(b) If the circular tire movement is more than 20 degrees after 5 flight cycles:

1 The wheel must be replaced.

2 The tire must be inspected at the tire shop.

NOTE: To measure the circular movement of the tire on the wheel you can:

- paint a continuous radial line on the tire and wheel when the tire is installed

- refer to the specified tire manufacturer.

Subtask 32-41-00-210-075-A

D. Visual Check of the Tires (MICHELIN)

(Ref. Fig. Radial Tire (Michelin example) - Details SHEET 1) (Ref. Fig. Radial Tire (Michelin example) - Details SHEET 2) (Ref. Fig. Radial Tire (Michelin example) -

Details SHEET 3) (Ref. Fig. Radial Tire (Michelin example) - Details SHEET 4) (Ref. Fig. Radial Tire (Michelin example) - Details SHEET 5)

(1) Do a visual check of the tires for damage.

Table 1 - Tread Wear Criteria (MICHELIN)

Defect Limit Procedure

Tread Wear 1. The groove depth is more than 1 mm (0.04 in.) on the tread. Keep the wheel on the aircraft.

Tread Wear 2. The groove depth is less than 1 mm (0.04 in.) at one point on Replace the wheel. You are permitted a return to base flight

the tread. for replacement of the wheel (at standard operating

procedures).

Tread Wear 3. The wear limit gets to the bottom of the groove for more than 1/8 Replace the wheel before the subsequent flight.

of the tire circumference.

Tread Wear 4. You can see the protector ply at a point of the tire Replace the wheel before the subsequent flight.

circumference.

Flat spot on the tread 1. The protector does not show at the flat spot and tread Keep the wheel on the aircraft (unless the pilot report shows

surface separation has not started. The flat spot has a minimum tread vibration during taxiing or landing gear retraction).

depth of 1 mm (0.04 in.)

Flat spot on the tread 2. The protector shows at the flat spot. Replace the wheel.

surface

Tread wear that is not 1. The tire is in the wear limits. The wheel can be kept on the aircraft.

symmetrical or burns

because of hydroplaning

Tread wear that is not 2. The tire is out of the wear limit or will be in a short time. Replace the wheel.

symmetrical or burns

because of hydroplaning

Subtask 32-41-00-210-076-A

E. Visual Check of the Tires

NOTE: Make sure that you use the correct data for the specified tire

(Michelin or Goodyear).

NOTE: These are the limits for MICHELIN tires:

NLG tire 1050x395R16 CL 9mm/2 plies LL 50mm

MLG tire 1400x530R23 CL 11mm/3 plies LL 60mm

(1) Do a visual check of the tires for damage (a PENCIL will be necessary).

Table 2 - Tread Inspection (MICHELIN)

Defect Limit Procedure

Cuts (Michelin) Examine the depth of the cut.

1. The cut does not touch the metallic protector or it touches the Keep the wheel on the aircraft.

metallic protector but does not damage it.

2. The metallic protector is damaged. Do an estimate of the depth

of the cut. Start at the bottom of the nearest groove.

If the depth of the cut is more than the cut limit (CL). Replace the wheel.

If the depth of the cut is less than or the same as the CL: Measure

the largest length of the cut and compare it with the limit of length

(LL).

(a) If the length of the cut is more than the LL. Replace the wheel.

(b) If the length of the cut is less than the LL. Keep the wheel on the aircraft.

The tread broken away 1. The void does not touch the metallic protector, or it touches the

Print Date: Oct 11/12 Local Time Page 3 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

(Michelin) metallic protector but does not damage it.

If the void area is less than 6sq cm (1sq in). Keep the wheel on the aircraft.

If the void area is more than 6sq cm (1sq in). Replace the wheel.

2. The metallic protector is damaged. Replace the wheel.

Open tread joint (Michelin) When the opening is seen.

Groove cracking (Michelin)

1. The metallic protector does not show. Replace the wheel.

2. The metallic protector shows:

(a)The length of the crack is less than LL. Keep the wheel on the aircraft.

(b)The length of the crack is more than the LL. Replace the wheel.

Rib undercutting (Michelin) 1. The depth of the undercut is less than 6 mm (0.25 in.). Keep the wheel on the aircraft.

2. The depth of the undercut is more than 6 mm (0.25 in.). Replace the wheel.

Subtask 32-41-00-210-077-A

F. Visual Check of the Tires

(1) Do a visual check of the tires for damage:

Table 3 - Sidewall Inspection (MICHELIN)

---------------------------------------------------------------------

! Defect ! Limit ! Procedure !

---------------------------------------------------------------------

!Radial cuts,!1. The depth is less than ! Keep the wheel on the !

!cracks or ! 2 mm (0.08 in.) and does ! aircraft. !

!splits (at ! not touch the carcass. ! !

!an angle of !----------------------------!-------------------------!

!less than !2. The depth is more than ! Replace the wheel. !

!30 deg from ! 2 mm (0.08 in.) or ! !

!the radial ! touches the carcass. ! !

!direction) ! ! !

!------------!----------------------------!-------------------------!

!Cuts, cracks!1. The carcass is not ! Keep the wheel on the !

!or splits ! touched. ! aircraft. !

!(at an angle!----------------------------!-------------------------!

!of more than!2. The carcass is touched. ! Replace the wheel. !

!30 deg from ! ! !

!the radial ! ! !

!direction) ! ! !

!------------!----------------------------!-------------------------!

!Sidewall ! No tolerance ! Replace the wheel. !

!damage or ! ! !

!separation ! ! !

!in the tire ! ! !

!sidewall ! ! !

!(not given ! ! !

!above) ! ! !

!-------------------------------------------------------------------!

! NOTE: !

! Sidewall damage can be caused by the separation or damage to the !

! sidewall cords. This can be seen, or felt, as contour distortion !

! on the sidewall compared to a new tire with no damage !

!-------------------------------------------------------------------!

!Blisters or ! No tolerances. ! Replace the wheel. !

!bulges ! ! (Tire to be inspected !

! ! ! by Michelin). !

---------------------------------------------------------------------

Subtask 32-41-00-210-078-A

G. Visual Check of the Tires

NOTE: Make sure that you use the correct data for the specified tire (Michelin or Goodyear).

(1) Do a visual check of the tires for damage:

Table 4 - Bead Inspection (MICHELIN)

Defect Limit Procedure

Rim and tire No effect for the Keep the wheel on the

marks show MICHELIN AIR X tubeless aircraft and clean the

that the tire. wheel.

tire slips

on the wheel

rim

(Michelin)

Bead wires No tolerances. Replace the wheel.

can be seen

(Michelin)

Damaged No tolerances. Replace the wheel.

beads or

bead wires

(Michelin)

Cracks in The depth of the crack Replace the wheel.

Print Date: Oct 11/12 Local Time Page 4 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

the upper is more than 1 mm

part of the (0.04 in.).

bead zone

(Michelin)

The bead The depth of the worn Keep the wheel on the

zone that area is less than 1 mm aircraft.

touches the (0.04 in.). Replace the wheel.

upper part The depth of the worn

of the area is more than 1 mm

flange is (0.04 in.).

worn

(Michelin)

Blisters in The length or diameter Replace the wheel.

the upper of the blister is more

part of the than 10 mm (0.40 in.).

bead zone

above the

rim flange

(Michelin)

Subtask 32-41-00-210-079-A

H. Visual Check of the Tires

(Ref. Fig. Bias Tire - Section SHEET 1)

NOTE: Make sure that you use the correct data for the specified tire (Michelin or Goodyear).

(1) Do a visual check of the tires for damage.

Table 1 - Tread Wear Criteria (GOODYEAR)

Defect Limit Procedure

Tread Wear (Goodyear) 1. The groove depth is more than 1 mm (0.04 in.). Keep the wheel on the aircraft.

Tread Wear (Goodyear) 2. The groove depth is less than 1 mm (0.04 in.) at one point on Replace the wheel. You are permitted a return to base flight

the tread. for replacement of the wheel (at standard operating

procedures).

Tread Wear (Goodyear) 3. The tread is worn to the bottom of a groove at one position on Replace the wheel before subsequent flight.

the tire.

Tread Wear (Goodyear) 4. The fabric shows in one position in the tread area. Replace the wheel before subsequent flight.

Tread wear is not 1. The tire is in the wear limits and the fabric does not show. Replace the wheel. The tire can be turned on the wheel thru

symmetrical (Goodyear) 180 degrees on the vertical axis / to be used again.

Subtask 32-41-00-210-080-A

J. Visual Check of the Tires

NOTE: Make sure that you use the correct data for the specified tire

(Michelin or Goodyear).

(1) Do a visual check of the tires for damage (a PENCIL will be necessary)

Table 2 - Tread Inspection (GOODYEAR)

Defect Limit Procedure

Cuts (Goodyear) 1. The cut goes into the fabric. Replace the wheel.

2. The cut is across more than 50% of the rib. If the depth of the Replace the wheel if: . the depth of the cut is more than the

tread remaining is: limit for the depth of the remaining tread. The maximum depth

of the cut permitted is:

. 12.7 mm thru 10.3 mm (0.50 in.). (0.41 in.). . 6.4 mm (0.25 in.).

. 9.5 mm thru 7.1 mm (0.37 in.). (0.28 in.). . 4.8 mm (0.19 in.).

. 6.4 mm thru 4.0 mm (0.25 in). (0.16 in). . 3.2 mm (0.13 in.).

. 3.2 mm thru 0 mm (0.13 in.). (0 in.). . 1.6 mm (0.06 in.).

Bulge (Goodyear) Cracks in 1. A bulge in the tire tread. Replace the wheel. Make a mark on the bulge with a crayon.

the grooves (Goodyear) Flat

Spots (Goodyear)

2. Fabric shows through the cracks in the grooves. Replace the wheel.

3. The crack undercuts the tread ribs. Replace the wheel.

4. The fabric does not show at the flat spot. Keep the wheel on the (unless the aircraft log shows vibration

during taxiing or landing gear

retraction). 2. The fabric does show at the flat spot. Replace the wheel.

Subtask 32-41-00-210-081-A

K. Visual Check of the Tires

NOTE: Make sure that you use the correct data for the specified tire (Michelin or Goodyear).

(1) Do a visual check of the tires for damage:

Table 3 - Sidewall Inspection (GOODYEAR)

---------------------------------------------------------------------

! Defect ! Limit ! Procedure !

---------------------------------------------------------------------

!Radial cuts,!1. The depth is less than ! Keep the wheel on the !

!cracks or ! 2 mm (0.08 in.) and does ! aircraft. !

Print Date: Oct 11/12 Local Time Page 5 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

!splits (at ! not touch the carcass. ! !

!an angle of !----------------------------!-------------------------!

!less than !2. The depth is more than ! Replace the wheel. !

!30 deg from ! 2 mm (0.08 in.) or ! !

!the radial ! touches the carcass. ! !

!direction) ! ! !

!(Goodyear) ! ! !

!------------!----------------------------!-------------------------!

!Cuts, cracks!1. The carcass is not ! Keep the wheel on the !

!or splits ! touched. ! aircraft. !

!(at an angle!----------------------------!-------------------------!

!of more than!2. The carcass is ! Replace the wheel. !

!30 deg from ! touched. ! !

!the radial ! ! !

!direction) ! ! !

!(Goodyear) ! ! !

!------------!----------------------------!-------------------------!

!Sidewall ! No tolerance ! Replace the wheel. !

!damage or ! ! !

!separation ! ! !

!in the tire ! ! !

!sidewall ! ! !

!(not given ! ! !

!above) ! ! !

!-------------------------------------------------------------------!

! NOTE: !

! Sidewall damage can be caused by the separation or damage to the !

! sidewall cords. This can be seen, or felt, as contour distortion !

! on the sidewall compared to a new, undamaged tire. !

!-------------------------------------------------------------------!

! ! ! !

!Blisters or ! No tolerances. ! Replace the wheel. !

!bulges ! ! (Tire to be inspected !

!(Goodyear) ! ! by Goodyear). !

---------------------------------------------------------------------

Subtask 32-41-00-210-082-A

L. Visual Check of the Tires

(1) Do a visual check of the tires for damage:

Table 4 - Bead Inspection (GOODYEAR)

Defect Limit Procedure

Bead wires No tolerances. Replace the wheel.

can be seen

Damaged No tolerances. Replace the wheel.

beads or

bead wires

Cracks in The depth of the crack Replace the wheel.

the upper is more than 1 mm

part of the (0.04 in.).

bead zone

The bead The depth of the worn Keep the wheel on the

zone that area is less than 1 mm aircraft.

touches the (0.04 in.). Replace the wheel.

upper part The depth of the worn

of the area is more than 1 mm

flange is (0.04 in.).

worn

Blisters in The length or diameter Replace the wheel.

the upper of the blister is more

part of the than 10 mm (0.40 in.).

bead zone

above the

rim flange

Subtask 32-41-00-210-085-A

M. Visual Check of the Tires (BRIDGESTONE)

(Ref. Fig. Radial Tire (Bridgestone example) - Details SHEET 1) (Ref. Fig. Radial Tire (Bridgestone example) - Details SHEET 2) (Ref. Fig. Radial Tire (Bridgestone

example) - Details SHEET 3) (Ref. Fig. Radial Tire (Bridgestone example) - Details SHEET 4) (Ref. Fig. Radial Tire (Bridgestone example) - Details SHEET 5) (Ref.

Fig. Radial Tire (Bridgestone example) - Details SHEET 6) (Ref. Fig. Radial Tire (Bridgestone example) - Details SHEET 7)

(1) Do a visual check of the tires for damage.

NOTE: For the Bridgestone tires with 6 grooves, Airbus recommends (for usual wear conditions) you use the center grooves as the wear indication point. The

outer grooves have approximately 30% less depth than the center grooves.

Table 1 - Tread Wear Criteria (BRIDGESTONE)

Defect Limit Procedure

Tread Wear 1. The groove depth is more than 1.0 mm (0.04 in.) on the tread. Keep the wheel on the aircraft.

Tread Wear 2. The groove depth is less than 1.0 mm (0.04 in) at one point on Replace the wheel. You are permitted a return to base flight

Print Date: Oct 11/12 Local Time Page 6 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

the tread surface. for replacement of the wheel (at standard operating

procedures).

Tread Wear 3. The tread is worn to the bottom of the groove at one point on the Replace the wheel before subsequent flight.

tread.

Tread Wear 4. The aramid protector shows at one point on the tread surface. Replace the wheel before subsequent flight.

Flat spot on the tread 1. The carcass shows more than 50 sq. cm. (10 sq. ins.). Replace the wheel.

surface

Tread wear that is not 1. The tire is in the wear limits. The wheel can be kept on the aircraft.

symmetrical

2. The tire is out of the wear limit or will be in a short time. Replace the wheel.

Tread rubber Reversion 1. The tire shows an oval shaped burn (aquaplaning). Replace the wheel.

Tread Separation 1. The tread or casing is loose and can come off the wheel. Replace the wheel.

Subtask 32-41-00-210-086-A

N. Visual Check of the Tires

NOTE: Make sure that you use the correct data for the specified tire

(Michelin, Goodyear or Bridgestone).

(1) Do a visual check of the tires for damage (a PENCIL will be necessary).

NOTE: These are the cut limits for BRIDGESTONE tires:

Nose Landing Gear (NLG) tire 1050x395R16 28 PR = CL 9mm/2 plies LL 50mm

Main Landing Gear (MLG) tire 1400x530R23 32 PR (Part Number APR06900)

- CL 9mm/2 plies LL 50mm

MLG tire 1400x530R23 32 PR (Part Number APR06901)

- CL 8mm/2 plies LL 50mm

MLG tire 1400x530R23 36 PR (Part Number APR06910)

- CL 9mm/2 plies LL 50mm

MLG tire 1400x530R23 36 PR (Part Number APR06911)

- CL 8mm/2 plies LL 50mm.

Table 2 - Tread Inspection (BRIDGESTONE)

Defect Limit Procedure

Cuts Examine the depth of the Replace the wheel.

Bridgestone cut.

If the depth of the cut

is more than the CL

or the length of the cut

is more than the LL.

Rib Examine the depth of the Replace the wheel.

undercutting cut.

Bridgestone If the depth of the cut

is more than 6.5 mm

(0.25 ins.)

or the length of the cut

is more than the LL.

Chevron When the reinforced Replace the wheel.

cuts fabric or protector

Bridgestone can be seen.

Groove Examine the depth of the Replace the wheel.

cracking crack.

Bridgestone If the reinforced fabric

or aramid cord protector

can be seen or if the

crack length is more than

LL.

Open tread When the opening is Replace the wheel.

joint seen.

Bridgestone

(2) To calculate the permitted cut depth:

(a) Subtract the remaining tread wear depth (A) from the measured cut depth (B).

(b) if the result is more than the CL, the tire must be replaced.

Subtask 32-41-00-210-087-A

P. Visual Check of the Tires

(1) Do a visual check of the tires for damage:

Table 3 - Sidewall Inspection (BRIDGESTONE)

---------------------------------------------------------------------

! Defect ! Limit ! Procedure !

---------------------------------------------------------------------

!Radial cuts,! The depth shows the ! Replace the wheel. !

!cracks or ! carcass of the sidewall. ! !

!splits. ! ! !

!------------!----------------------------!-------------------------!

!Sidewall ! No tolerance ! Replace the wheel. !

!damage or ! ! !

!separation ! ! !

Print Date: Oct 11/12 Local Time Page 7 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

!in the tire ! ! !

!sidewall ! ! !

!(not given ! ! !

!above) ! ! !

!-------------------------------------------------------------------!

! NOTE: !

! Sidewall damage can be caused by the separation or damage to the !

! sidewall cords. This can be seen, or felt, as contour distortion !

! on the sidewall compared to a new, undamaged tire. !

!-------------------------------------------------------------------!

!Blisters or ! No tolerances. ! Replace the wheel. !

!bulges ! ! !

! ! ! !

---------------------------------------------------------------------

Subtask 32-41-00-210-088-A

Q. Visual Check of the Tires

NOTE: Make sure that you use the correct data for the specified tire (Michelin, Goodyear or Bridgestone).

(1) Do a visual check of the tires for damage:

Table 4 - Bead Inspection (BRIDGESTONE)

Defect Limit Procedure

Bead wires No tolerances. Replace the wheel.

can be seen

Damaged No tolerances. Replace the wheel.

beads or

bead wires

Cord shows No tolerances. Replace the wheel.

overheating

at the bead

base.

Subtask 32-41-00-210-083-A

R. General Visual Inspection of the Wheels

(1) Examine all wheels for damage, make sure that:

- the wheel is in the correct condition

- the tie-bolts are serviceable and tightened correctly

- there are no cracks on the rim

- the inflation valve cap is correctly installed.

Subtask 32-41-00-210-084-A

S. General Visual Inspection of the Wheel Brakes for Hydraulic Leaks

(1) Examine the wheel brakes for signs of:

- hydraulic leakage from the hydraulic connectors

- hydraulic fluid leakage around the brake pistons

- hydraulic fluid contamination of the carbon discs.

5. Close-up

Subtask 32-41-00-942-053-A

A. Removal of Equipment

(1) Remove the warning notice(s).

Print Date: Oct 11/12 Local Time Page 8 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

METALLIC

F_MM_324100_6_AEM0_01_00

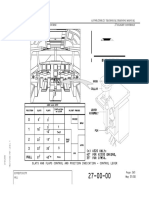

Figure 32-41-00-991-00300-06-A / SHEET 1/5 - Radial Tire (Michelin example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 9 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

BINDING LAYER N°3

BINDING LAYER N°2

BINDING LAYER N°1

PLY CASING N°3 BEAD WIRE

PLY CASING N°2

PLY CASING N°1

TURN-UP OF PLY CASING N°2

TURN-UP OF PLY CASING N°1

F_MM_324100_6_AEM0_02_00

Figure 32-41-00-991-00300-06-A / SHEET 2/5 - Radial Tire (Michelin example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 10 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

NORMAL WEAR

BELT PLIES WEAR CAUSED BY UNDERINFLATION

CASING OUTER PLY

BELT PLIES

CASING OUTER PLY

WEAR CAUSED BY OVERINFLATION

BELT PLIES WORN TO LIMITS

CASING OUTER PLY

BELT PLIES

CASING OUTER PLY

F_MM_324100_6_AEM0_03_00

Figure 32-41-00-991-00300-06-A / SHEET 3/5 - Radial Tire (Michelin example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 11 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

F_MM_324100_6_AEM0_04_00

Figure 32-41-00-991-00300-06-A / SHEET 4/5 - Radial Tire (Michelin example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 12 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

BELT PLIES

CASING OUTER PLY

A B

C

BELT PLIES

CASING OUTER PLY

F_MM_324100_6_AEM0_05_00

Figure 32-41-00-991-00300-06-A / SHEET 5/5 - Radial Tire (Michelin example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 13 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

FABRIC PLY

23 3 2P R

F_MM_324100_6_BEM0_01_00

Figure 32-41-00-991-00400-06-A / SHEET 1 - Bias Tire - Section

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 14 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

F_MM_324100_6_WEM0_01_00

Figure 32-41-00-991-00600-06-A / SHEET 1/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 15 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

F_MM_324100_6_WEM0_02_00

Figure 32-41-00-991-00600-06-A / SHEET 2/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 16 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

F_MM_324100_6_WEM0_03_00

Figure 32-41-00-991-00600-06-A / SHEET 3/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 17 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

CHEVRON CUTTING

CHEMICAL AND HYDROCARBON

HYDROPLANING WEAR

CONTANIMATION (FUEL, BRAKE OIL ETC.)

(SKID BURNS)

F_MM_324100_6_WEM0_04_00

Figure 32-41-00-991-00600-06-A / SHEET 4/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 18 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

F_MM_324100_6_WEM0_05_00

Figure 32-41-00-991-00600-06-A / SHEET 5/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 19 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

B B

F_MM_324100_6_WEM0_06_00

Figure 32-41-00-991-00600-06-A / SHEET 6/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 20 of 21

Customer : SVA Manual: AMM

Type : A330 Selected effectivity: ALL

Rev. Date : Apr 01/12

32-41-00-210-803-A - General Visual Inspection of Tires, Wheels and Brakes

(for Hydraulic Leaks)

CUT LENGTH LL

CUTS ON

THE TREAD

TREAD

GROOVES

CUT DEPTH AND LENGTH LIMITS TABLE EXAMPLE (CL AND LL)

REMAINING TREAD

WEAR DEPTH (A)

GROOVE

BOTTOM

CUT DEPTH (B)

CL

REINFORCED FABRIC/

ARAMID CORD PROTECTOR

1st CASING PLY/BELT

THE CUT DEPTH LIMIT IS MEASURED FROM THE BOTTOM

OF THE TREAD GROOVE TO THE CASING PLY OR

THE BELT PLY.

F_MM_324100_6_WEM0_07_01

Figure 32-41-00-991-00600-06-A / SHEET 7/7 - Radial Tire (Bridgestone example) - Details

** ON A/C ALL

Print Date: Oct 11/12 Local Time Page 21 of 21

Você também pode gostar

- ON A/C 051-100: Zone/Access Zone DescriptionDocumento7 páginasON A/C 051-100: Zone/Access Zone DescriptionEder LucianoAinda não há avaliações

- MLG - Removal InstallationDocumento14 páginasMLG - Removal InstallationKeilaeFrancisco ArceAinda não há avaliações

- 33 Lights System Presentation (1) : A330 Technical Training ManualDocumento34 páginas33 Lights System Presentation (1) : A330 Technical Training ManualAshik AslamAinda não há avaliações

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocumento11 páginasService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehAinda não há avaliações

- Airnavx Standalone User GuideDocumento34 páginasAirnavx Standalone User GuideUtku OzdoganAinda não há avaliações

- GVI Brake Units - 32-40-00-210-801-A PDFDocumento4 páginasGVI Brake Units - 32-40-00-210-801-A PDFpannAinda não há avaliações

- A350 - (Aircraft Maintenance Manual (AMM) ) (01001-270A-A Pressurization Retest and Leakage Rate Measurement)Documento12 páginasA350 - (Aircraft Maintenance Manual (AMM) ) (01001-270A-A Pressurization Retest and Leakage Rate Measurement)Bongyoun LeeAinda não há avaliações

- Offwing Alide InstallDocumento16 páginasOffwing Alide InstallAndreea MăgureanuAinda não há avaliações

- Ata 36 PneumaticDocumento30 páginasAta 36 PneumaticSohaib Aslam ChaudharyAinda não há avaliações

- 14WN Test 2Documento7 páginas14WN Test 2Ahsan AvioniqueAinda não há avaliações

- Ata 49 ApuDocumento77 páginasAta 49 ApuSohaib Aslam Chaudhary100% (1)

- TASK 12!13!79-610-011-A Check Oil Level and ReplenishDocumento6 páginasTASK 12!13!79-610-011-A Check Oil Level and ReplenishSatishReddyAinda não há avaliações

- 04 CH77,31 Engine IndicatingDocumento44 páginas04 CH77,31 Engine IndicatingaliAinda não há avaliações

- Ata 25Documento78 páginasAta 25Sohaib Aslam ChaudharyAinda não há avaliações

- Amm 32-41-00-210-002Documento26 páginasAmm 32-41-00-210-002Andrei NecuţăAinda não há avaliações

- A318/A319/A320/A321: Service BulletinDocumento54 páginasA318/A319/A320/A321: Service BulletinPradeep K sAinda não há avaliações

- Fly Away Kit BoeingDocumento9 páginasFly Away Kit BoeingVolAinda não há avaliações

- SBcontent PDFDocumento65 páginasSBcontent PDFThanh Vinh NguyenAinda não há avaliações

- Airbus Manual Freefall LGDocumento40 páginasAirbus Manual Freefall LGjoshoa fernandoAinda não há avaliações

- Boeing 737: Preflight CheckDocumento4 páginasBoeing 737: Preflight CheckDenysadenisa100% (1)

- On A/C All: Reference Qty DesignationDocumento7 páginasOn A/C All: Reference Qty DesignationRicardoBillEdwinAinda não há avaliações

- Aircraft Maintenance Services Products and ServicesDocumento7 páginasAircraft Maintenance Services Products and Servicesaedd eddaAinda não há avaliações

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 01 GeneralDocumento97 páginasA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 01 GeneralJimmyAinda não há avaliações

- A330-343 E.O Status Easa FormDocumento31 páginasA330-343 E.O Status Easa FormAmr El Kady0% (1)

- 08 Ch75 Airflow Control SystemDocumento38 páginas08 Ch75 Airflow Control SystemaliAinda não há avaliações

- 06 0005 Anti-Collision Light 400cd RedDocumento8 páginas06 0005 Anti-Collision Light 400cd RedoglasifwdAinda não há avaliações

- A380 Level I Ata 28 FuelDocumento84 páginasA380 Level I Ata 28 FuelGuyAinda não há avaliações

- A319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDocumento3 páginasA319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDavid OwenAinda não há avaliações

- 22 Auto FlightDocumento30 páginas22 Auto Flightsan2inAinda não há avaliações

- EMC 1-STN-Level 2 3-ATA 46 PDFDocumento10 páginasEMC 1-STN-Level 2 3-ATA 46 PDFbasid911Ainda não há avaliações

- 24 Electrical PowerDocumento164 páginas24 Electrical PowermarkAinda não há avaliações

- A330-200/300 Technical Training Manual Ramp & Servicing Course - M02 (Ge Cf6) Aircraft General PracticesDocumento16 páginasA330-200/300 Technical Training Manual Ramp & Servicing Course - M02 (Ge Cf6) Aircraft General PracticesWilliam Jaldin CorralesAinda não há avaliações

- 4Documento17 páginas4Jai DeepAinda não há avaliações

- Single Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) Ice & Rain ProtectionDocumento20 páginasSingle Aisle Technical Training Manual CMQ A330/A340 To A319/320/321 (IAE V2500/ME) T1 (LVL 2&3) Ice & Rain ProtectionjuanAinda não há avaliações

- ATA 79 ENG MCD Installation ProcedureDocumento6 páginasATA 79 ENG MCD Installation Procedureanarko arsipelAinda não há avaliações

- A320-232 MEL REV007 17 OCT16.compressed PDFDocumento1.336 páginasA320-232 MEL REV007 17 OCT16.compressed PDFAhsanAinda não há avaliações

- 28 FUEL (Metric Units)Documento250 páginas28 FUEL (Metric Units)Navid Khalili SafaAinda não há avaliações

- A318/A319/A320/A321: Service BulletinDocumento62 páginasA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- 3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3Documento357 páginas3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3mikeAinda não há avaliações

- 71-00-00-710-004-B - Engine Manual StartDocumento9 páginas71-00-00-710-004-B - Engine Manual StartEder LucianoAinda não há avaliações

- A320 - Training Manual - PART 2 OUT of 2Documento356 páginasA320 - Training Manual - PART 2 OUT of 2MARCELO CABRALAinda não há avaliações

- A320 PPG TB - A320Documento2 páginasA320 PPG TB - A320Jivendra Kumar100% (1)

- 32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelDocumento40 páginas32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelalfonsofelipesaraviaAinda não há avaliações

- A320 CB PDFDocumento17 páginasA320 CB PDFFaiyaz DurweshAinda não há avaliações

- FAA 2012 0721 0009 - Attachment - 5Documento119 páginasFAA 2012 0721 0009 - Attachment - 5CHIMOAinda não há avaliações

- Ajw gtcp331-500b Minipack SN p-1154Documento249 páginasAjw gtcp331-500b Minipack SN p-1154Okky Pangestoe WibowoAinda não há avaliações

- A320 SRM Oem 56Documento7 páginasA320 SRM Oem 56Jhoshua AvilaAinda não há avaliações

- CorrosionDocumento6 páginasCorrosiondonjon ellenAinda não há avaliações

- 51-49-00 - Description - Standard Torque ValuesDocumento14 páginas51-49-00 - Description - Standard Torque ValuesMarijaAinda não há avaliações

- 03 ELECTRO-MECHANICAL SYSTEMS (Airframe) Level 1Documento198 páginas03 ELECTRO-MECHANICAL SYSTEMS (Airframe) Level 1Wilson BenincoreAinda não há avaliações

- Alert Service BulletinDocumento94 páginasAlert Service BulletinFrank MasonAinda não há avaliações

- B 737 - CL - Ata 38 - B1.1Documento47 páginasB 737 - CL - Ata 38 - B1.1Vasili RafaelyanAinda não há avaliações

- Saft General PDFDocumento84 páginasSaft General PDFESAVEAinda não há avaliações

- Cf6cmm PDFDocumento85 páginasCf6cmm PDFHaithem BrebishAinda não há avaliações

- Ata25 AirbusDocumento308 páginasAta25 AirbusOliver BarrientosAinda não há avaliações

- 71 IAE Trouble ShootDocumento22 páginas71 IAE Trouble ShootMarc Covas MartorellAinda não há avaliações

- A330 MRTT ATA 21 L1 - TM - Issue 2Documento18 páginasA330 MRTT ATA 21 L1 - TM - Issue 2RaulAinda não há avaliações

- Wheel CHKDocumento24 páginasWheel CHKvietha1990Ainda não há avaliações

- Inspection - Check of The Wheels and TiresDocumento28 páginasInspection - Check of The Wheels and TiresJorge OrtegaAinda não há avaliações

- MLG Wheel InspectionDocumento64 páginasMLG Wheel InspectionEdwin Perez100% (1)

- Queen Elizabeth Olympic Park, Stratford City and Adjacent AreasDocumento48 páginasQueen Elizabeth Olympic Park, Stratford City and Adjacent AreasRavi WoodsAinda não há avaliações

- OCES 1001 - Final Exam Instructions (Please Read BEFORE The Exam)Documento16 páginasOCES 1001 - Final Exam Instructions (Please Read BEFORE The Exam)Heihei ChengAinda não há avaliações

- 2 - Water Requirements of CropsDocumento43 páginas2 - Water Requirements of CropsHussein Alkafaji100% (4)

- Losses in Valves and FittingsDocumento17 páginasLosses in Valves and FittingsMintesnot AberaAinda não há avaliações

- Science, Technology and SocietyDocumento2 páginasScience, Technology and SocietyHamieWave TVAinda não há avaliações

- NHW Beg 4E Unit Tests - 3a PDFDocumento2 páginasNHW Beg 4E Unit Tests - 3a PDFabeer24Ainda não há avaliações

- Iwcf Section OneDocumento20 páginasIwcf Section OnesuifengniliuAinda não há avaliações

- FPO Policy-1Documento96 páginasFPO Policy-1shashanksaranAinda não há avaliações

- 1LA7070-4AB10-Z A11 Datasheet en PDFDocumento1 página1LA7070-4AB10-Z A11 Datasheet en PDFKraponis TylnessAinda não há avaliações

- BUSINESS PROPOSAL-dönüştürüldü-2Documento15 páginasBUSINESS PROPOSAL-dönüştürüldü-2Fatah Imdul UmasugiAinda não há avaliações

- UST G N 2011: Banking Laws # I. The New Central Bank Act (Ra 7653)Documento20 páginasUST G N 2011: Banking Laws # I. The New Central Bank Act (Ra 7653)Clauds GadzzAinda não há avaliações

- Improving The Passenger Experience: Monitoring Airport Quality of ServiceDocumento6 páginasImproving The Passenger Experience: Monitoring Airport Quality of ServiceParisa HadidianAinda não há avaliações

- CHAPTER 2 Principles of MarketingDocumento41 páginasCHAPTER 2 Principles of MarketingASHIMA THAPAAinda não há avaliações

- 03 Pezeshki-Ivari2018 Article ApplicationsOfBIMABriefReviewADocumento40 páginas03 Pezeshki-Ivari2018 Article ApplicationsOfBIMABriefReviewAdanes1800Ainda não há avaliações

- VMware SD WAN Google Cloud Platform Virtual Edge Deployment GuideDocumento24 páginasVMware SD WAN Google Cloud Platform Virtual Edge Deployment GuideJuan RojasAinda não há avaliações

- Hospital DocumentsDocumento17 páginasHospital DocumentsRaviraj PisheAinda não há avaliações

- BS en Iso 11114-4-2005 (2007)Documento30 páginasBS en Iso 11114-4-2005 (2007)DanielVegaNeira100% (1)

- Packages: Khidmatul A'WaamDocumento4 páginasPackages: Khidmatul A'WaamAltaaf IzmaheroAinda não há avaliações

- MSW - 1 - 2016 Munisicpal Solid Waste Rules-2016 - Vol IDocumento96 páginasMSW - 1 - 2016 Munisicpal Solid Waste Rules-2016 - Vol Inimm1962Ainda não há avaliações

- Outsourced New Product DevelopmentDocumento5 páginasOutsourced New Product Developmentvinnakota5Ainda não há avaliações

- How To Post Bail For Your Temporary Liberty?Documento5 páginasHow To Post Bail For Your Temporary Liberty?Ruel Benjamin Bernaldez100% (1)

- Amendment Notes For June 2021Documento32 páginasAmendment Notes For June 2021arohi gupta0% (2)

- CompressDocumento14 páginasCompressAnonymous gfR3btyU0% (1)

- Needs Assessment Form Company Name: HRMO Address: Sta. Barbara Agoo, La UnionDocumento2 páginasNeeds Assessment Form Company Name: HRMO Address: Sta. Barbara Agoo, La UnionAlvin LaroyaAinda não há avaliações

- Difference Between Distinct and Group byDocumento1 páginaDifference Between Distinct and Group byPavelStrelkovAinda não há avaliações

- Gen. Coll.-2014fDocumento8.152 páginasGen. Coll.-2014fVeron Golocan Sowagen JovenAinda não há avaliações

- Contractor Commissioning ProcedureDocumento61 páginasContractor Commissioning ProcedureTaras Pompiliu100% (8)

- Piston EffectDocumento11 páginasPiston EffectBK180Ainda não há avaliações

- 40th Caterpillar Performance HandbookDocumento372 páginas40th Caterpillar Performance Handbookcarlos_córdova_8100% (11)

- Avast 2050 License Faker by ZeNiX 2014-03-14 enDocumento1 páginaAvast 2050 License Faker by ZeNiX 2014-03-14 enenteryourname5Ainda não há avaliações