Escolar Documentos

Profissional Documentos

Cultura Documentos

Operations-Course Theoretical

Enviado por

ANTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Operations-Course Theoretical

Enviado por

ANDireitos autorais:

Formatos disponíveis

Faculty of Design and Production Engineering

Course specification

Production and Operations Management (EDPT 904)

A-Basic Information

Semester number Ninth

Semester type Winter Semester

Study year Fifth

Department offering the course Design and Production Engineering

Specialization Production and Operations Management

Type of course Compulsory

Number of sessions/ week 1 Lecture/week, 1 Tutorial/week

Student workload 121 hrs

Credit points (ECTS) 4 CP

B- Professional Information

Theoretical Part of Production and Operations Management (EDPT 904)

Course Aim

Production and operation management course is offered to design and production engineering

students in their 5th year of study. This course gives an introduction to the functional area of production

and operations management as practiced in manufacturing and services industries. It includes basic

definitions of production, operations and operations management. It introduces the students to topics such

as Productivity Analysis, Forecasting Techniques, Regression and correlation analysis, Inventory,

management, aggregate planning, materials requirements planning (MRP), and scheduling. It also allows

more emphasis on computer solutions with excel spreadsheets.

Learning Outcomes

By the end of the theoretical part, the student will be able to:

Knowledge & Understanding

Academic Year 2011/2012

Page / 1

Faculty of Design and Production Engineering

Course specification

1. Define Productivity Analysis and its applications.

2. Describe different Forecasting Techniques.

3. Describe Regression Techniques.

4. Describe Inventory Techniques.

5. Explain Aggregate Planning.

6. Define Project scheduling.

Intellectual skills

7. Develop an understanding of the strategic importance of manufacturing systems, production and

operations systems.

8. Recognize the relationship between manufacturing and related service providers and other

business functions, such as human resources, purchasing, marketing, finance, etc

9. Calculate forecasts using different techniques.

10. Apply qualitative and quantitative methods of inventory models.

11. Apply proactive and reactive planning strategies.

12. Calculating the timing of the use of different resources in an organization.

Professional & Practical skills

13. Predict new demands of the globally competitive business environment Emphasize the

importance of change, facilitation of learning, cross-functional teamwork, knowledge capture,

and analysis in manufacturing organizations.

14. Submit a Course project, in which the project process of initiating, planning, executing,

controlling and closing the project is applied through case studies.

General and Transferrable skills

15. Work in teams for their project.

Academic Year 2011/2012

Page / 2

Faculty of Design and Production Engineering

Course specification

Topics Covered in the Theoretical Part of the Course (theoretical course content):

No. of Teaching

Hours

Topic Lecture Tutorial

1 Introduction to production and operations management 2 2

2 Productivity analysis 2 2

3 Forecasting techniques 2 2

4 Forecasting techniques (Continued) 2 2

5 Introduction to inventory management 2 2

6 Inventory Models 2 2

7 Aggregate Planning 2 2

8 Aggregate Planning (Continued) 2 2

9 MRP and scheduling 2 2

10 MRP and scheduling (Continued) 2 2

Learning and Teaching Methods

Lectures, assignments and tutorials.

References

Recommended Textbook

R.Dan Reid and Nada R. Sanders (2009).Operations Management (4th edition). Wiley.

ISBN-10: 0849309247. ISBN-13: 978-0849309243

Recommended Further Reading

Jay Heizer and Barry Render (2010). Principles of Operations Management (8th edition).

Prentice Hall. ISBN-10: 0849309247. ISBN-13: 978-0849309243

Assessment

Student Assessment Methods Assessment Weighing

3 quizzes (best 2 of 3) 10%

Assignments and course project 20%

Midterm 25%

Final 45%

Facilities Required for Teaching & Learning:

Academic Year 2011/2012

Page / 3

Faculty of Design and Production Engineering

Course specification

• Lecture hall equipped with microphone, computer, beamer and white board.

• Availability of lecture presentations on the GUC intranet that are used for data show and

explanation to students during lecture sessions

C- Administrative Information

Head of the Department

Prof. Dr. Mohamed Kamal Shoukry

Course Coordinator Contact Information

Course Coordinator Dr. Lamia Ahmed Shihata

E- Mail Lamia.shihata@guc.edu.eg

Fax +20-2-7581041

Telephone +20-2-7589990-8

Ext 1168

Room number C7.110

Academic Year 2011/2012

Page / 4

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

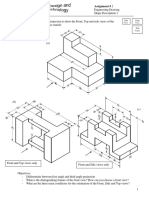

- Assignment # 2: Top ViewDocumento1 páginaAssignment # 2: Top ViewAN100% (1)

- Home Assignment 4 SectioniongDocumento2 páginasHome Assignment 4 SectioniongAN0% (1)

- Drawing PDFDocumento1 páginaDrawing PDFANAinda não há avaliações

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocumento11 páginasSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingANAinda não há avaliações

- Introduction To Materials Manufacturing and Process EDPT 302 Prof. Yasser FouadDocumento49 páginasIntroduction To Materials Manufacturing and Process EDPT 302 Prof. Yasser FouadANAinda não há avaliações

- Handrail & Balustrade Solutions: Uniclass L442 Ci/Sfb (34) X Epic D4Documento32 páginasHandrail & Balustrade Solutions: Uniclass L442 Ci/Sfb (34) X Epic D4ANAinda não há avaliações

- DrawingDocumento1 páginaDrawingANAinda não há avaliações

- Ral Chart PDFDocumento3 páginasRal Chart PDFErunerAinda não há avaliações

- Home Assignment 5 Missing ViewDocumento1 páginaHome Assignment 5 Missing ViewANAinda não há avaliações

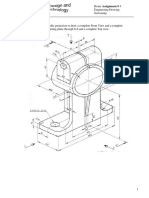

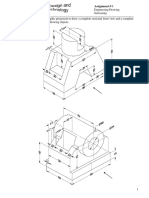

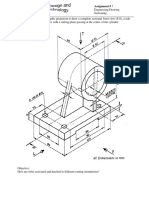

- Engineering Drawing Isometric 1: Assignment # 4Documento3 páginasEngineering Drawing Isometric 1: Assignment # 4ANAinda não há avaliações

- DrawingDocumento1 páginaDrawingAN100% (1)

- Engineering Drawing Shape Description 2 Use The First-Angle Orthographic Projection To Draw The Front, Top and Side Views of The Following ObjectsDocumento2 páginasEngineering Drawing Shape Description 2 Use The First-Angle Orthographic Projection To Draw The Front, Top and Side Views of The Following ObjectsANAinda não há avaliações

- Drawing Lec 1Documento44 páginasDrawing Lec 1ANAinda não há avaliações

- Assignment # 5Documento4 páginasAssignment # 5ANAinda não há avaliações

- DrawingDocumento1 páginaDrawingAN100% (1)

- Lecture 4 SectioningDocumento37 páginasLecture 4 SectioningANAinda não há avaliações

- Home Assignment 3 Isometric and ObliqueDocumento2 páginasHome Assignment 3 Isometric and ObliqueANAinda não há avaliações

- Lecture 5 Missing ViewDocumento32 páginasLecture 5 Missing ViewANAinda não há avaliações

- Lecture 5 Cont.: Dimensioning DimensioningDocumento58 páginasLecture 5 Cont.: Dimensioning DimensioningANAinda não há avaliações

- Home Assignment 1 Applied GeometryDocumento3 páginasHome Assignment 1 Applied GeometryANAinda não há avaliações

- Lecture 3Documento24 páginasLecture 3ANAinda não há avaliações

- Lecture 2 Orthographic ProjectionDocumento53 páginasLecture 2 Orthographic ProjectionANAinda não há avaliações

- Lecture 1 Cont.Documento60 páginasLecture 1 Cont.ANAinda não há avaliações

- Home Assignment 2 Shape DescriptionDocumento1 páginaHome Assignment 2 Shape DescriptionANAinda não há avaliações

- Lecture 4 SectioningDocumento37 páginasLecture 4 SectioningANAinda não há avaliações

- Regulations For Engineering Drawing CourseDocumento1 páginaRegulations For Engineering Drawing CourseANAinda não há avaliações

- Course Weight Distribution PDFDocumento1 páginaCourse Weight Distribution PDFANAinda não há avaliações

- June2013 Application Advanced Materials in Industry WorkshopDocumento2 páginasJune2013 Application Advanced Materials in Industry WorkshopANAinda não há avaliações

- Standard of Drawing LinesDocumento1 páginaStandard of Drawing LinesANAinda não há avaliações

- Tools To Bring With YouDocumento1 páginaTools To Bring With YouANAinda não há avaliações

- Om 1 2Documento32 páginasOm 1 2nicks1988Ainda não há avaliações

- Etextbook 978 0273776208 Operations Management 7th EditionDocumento61 páginasEtextbook 978 0273776208 Operations Management 7th Editionbenjamin.vega423100% (47)

- MBCQ722D-Operations & Materials Management-Jul19.-Assignment2Documento14 páginasMBCQ722D-Operations & Materials Management-Jul19.-Assignment2Utkarsh SinghAinda não há avaliações

- 1 - Project Management FrameworkDocumento60 páginas1 - Project Management Frameworklaxave8817Ainda não há avaliações

- Process Layout: 1. Explain Different Types of Facility Layout and Their Strength and WeaknessDocumento11 páginasProcess Layout: 1. Explain Different Types of Facility Layout and Their Strength and WeaknessSamuel DebebeAinda não há avaliações

- ASM2 - 488 - Nộp 2Documento25 páginasASM2 - 488 - Nộp 2Harry Potter100% (1)

- MB0044 Slides Unit 04Documento18 páginasMB0044 Slides Unit 04Saagar KarandeAinda não há avaliações

- BMGT25 OmDocumento4 páginasBMGT25 OmjieAinda não há avaliações

- An Overview of Operations ManagementDocumento2 páginasAn Overview of Operations ManagementPink WorkuAinda não há avaliações

- Industrial AutomationDocumento21 páginasIndustrial Automationsanju245100% (1)

- Sourcing and Supply Management: Author: B. Mahadevan Operations Management: Theory and Practice, 3eDocumento24 páginasSourcing and Supply Management: Author: B. Mahadevan Operations Management: Theory and Practice, 3eakankshaAinda não há avaliações

- Revised Thesis 3Documento94 páginasRevised Thesis 3Anthea May PansacalaAinda não há avaliações

- JIT and Lean Production - Russel and TaylorDocumento51 páginasJIT and Lean Production - Russel and Tayloranon_128262675Ainda não há avaliações

- Dmgt501 Operations ManagementDocumento337 páginasDmgt501 Operations ManagementZzzddd100% (1)

- Metal Forming OverviewDocumento120 páginasMetal Forming OverviewSang Ka KalaAinda não há avaliações

- Operational Management Assignment PDFDocumento7 páginasOperational Management Assignment PDFYonas D. EbrenAinda não há avaliações

- 22PGD205 OmDocumento5 páginas22PGD205 OmRohit KumarAinda não há avaliações

- MGMT20130 Operations Management - Assignment 3Documento4 páginasMGMT20130 Operations Management - Assignment 3Richa Deolia100% (1)

- Production and Operations ManagementDocumento29 páginasProduction and Operations ManagementAyush SinghAinda não há avaliações

- Principles of Operation and ManagementfinalDocumento15 páginasPrinciples of Operation and ManagementfinalK58 Đặng Thành VinhAinda não há avaliações

- Operations Management and TQM - An OverviewDocumento10 páginasOperations Management and TQM - An OverviewKenma ApplePiAinda não há avaliações

- Running Head: Operational Management 1Documento12 páginasRunning Head: Operational Management 1Ali AzmatAinda não há avaliações

- Manufacturing Systems Analysis (MF-630) : Course Instructor Dr. Kashif IshfaqDocumento38 páginasManufacturing Systems Analysis (MF-630) : Course Instructor Dr. Kashif Ishfaqshahid saeedAinda não há avaliações

- Operations Management MCQ With Answers PDF For MBA, BBADocumento15 páginasOperations Management MCQ With Answers PDF For MBA, BBAshot viral vedioAinda não há avaliações

- Queueing Theory and Operations ManagementDocumento11 páginasQueueing Theory and Operations ManagementMarthandeAinda não há avaliações

- 7 Functions of Operations ManagementDocumento4 páginas7 Functions of Operations ManagementMichelle AmihanAinda não há avaliações

- Source Change ProcesdDocumento7 páginasSource Change ProcesdKarthik MadhuAinda não há avaliações

- Operation Goods and ServiceDocumento11 páginasOperation Goods and ServiceFazal RaheemAinda não há avaliações

- BITS PILANI Operation Management SyllabusDocumento12 páginasBITS PILANI Operation Management Syllabussap6370Ainda não há avaliações

- Sample OPMDocumento110 páginasSample OPMnaveenAinda não há avaliações