Escolar Documentos

Profissional Documentos

Cultura Documentos

Preliminary Inspection Report of Line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60 (Pipe Rack)

Enviado por

Anonymous YRyGcKPTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Preliminary Inspection Report of Line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60 (Pipe Rack)

Enviado por

Anonymous YRyGcKPDireitos autorais:

Formatos disponíveis

Preliminary inspection report of line # 80-SCL-6016600-BB31C at VCM Plant UNIT-60(Pipe rack)

Plant: VCM Unit-60

Date: 24-05-2016

Background:

Leakage was reported by VCM Operation Department from line # 80-SCL-6016600-BB31C in Pipe

rack.External visual inspection and UT thickness monitoring were carried out adjacent to location of

leaked pipe and other accessible area(with scaffolding) of connecting branch line # 25-SCL-02213-

BB31C(Steam condensate outlet line of TE-1306).The following were the observations:

Observations:

1.0 External Visual inspection :

Leakage was observed at bottom portion of 3" Ø pipe of line # 80-SCL-6016600-BB31C.

Temporarily repaired by furmanite clamp was found at 1" Ø Tee of line # 25-SCL-02213-BB31C.

2.0 UT thickness measurement :

Random UT thickness measurement was carried out on all established TMLs and reduction of

thickness recorded with a minimum of 1.3 mm & 1.6 mm thickness against the nominal thickness of

2.6 mm & 2.9 mm for 1" Ø & 3" Ø respectively (As per piping specification) with 1.2 mm corrosion

allowance.

.

LEAKAGE AT BOTTOM PORTION OF 3" Ø PIPE OF LEAKAGE AT BOTTOM PORTION OF 3" Ø PIPE OF

LINE # 80-SCL-6016600-BB31C LINE # 80-SCL-6016600-BB31C (FULL VIEW)

TEMPORARILY REPAIRED BY FURMANITE CLAMP TEMPORARILY REPAIRED BY FURMANITE CLAMP

AT 1" Ø TEE OF LINE # 25-SCL-02213-BB31C BB31C AT 1" Ø TEE OF LINE # 25-SCL-02213-BB31C BB31C

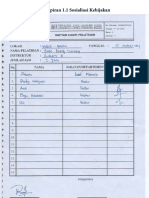

Form No.: INSP-046-02

Rev. No.: 02 EQUIPMENT / PIPING THICKNESS MEASUREMENT SHEET

Dated: 07-09-2015

SMP / WI No.: SMP-INSP-051

INSPECTION DEPARTMENT

Page: 1 of 1

Thickness Thickness Reading

Orig.

Drawing / Sketch Measurement (mm)

Thk. Remark(s)

Location *

(mm) 0 90 180 270 N E S W

(TMLs)

1- 3"Ø 2.9 2.9 2.9 2.9 3.0

NORTH 2- 3"Ø 2.9 5.0 5.0 5.1 5.1

3- 3"Ø 2.9 5.0 1.6 5.0 5.1 LEAKAGE

4- 3"Ø 2.9 5.0 5.1 5.1 5.1

5- 3"Ø 2.9 2.6 2.8 2.9 2.9

6- 1"Ø 2.6 4.1 4.2 4.1 4.2

7- 1"Ø 2.6 4.1 4.0 4.1 4.2

8- 1"Ø 2.6 1.3 - 4.0 4.1 BEND PIPE

9- 1"Ø 2.6 4.0 4.1 1.4 - BEND PIPE

10- 1"Ø 2.6 4.1 4.1 4.2 4.1

11- 1"Ø 2.6 4.1 4.2 4.1 4.2

12- 1"Ø 2.6 1.3 - 4.1 4.2 BEND PIPE

13- 1"Ø 2.6 4.1 4.0 4.0 4.1

Thickness Gauge S.R. No. : DMS 2 # 01VKH1 (INSP-TM-03)

Calibration date : 08-06-2015

Probe # and Frequency : HT 400 / 5 MHZ

Applicable Procedure : PK SHEM 7.05 & SMP-INSP-051

Criteria for passing Inspection :

Eqpt. / Piping Material : ST 35 ( CARBON STEEL )

Corrosion Allowance (mm) : 1.2 mm

Corrosion Rate (mm / Year) : 1.3 mm

Remaining Life (Year) :

Surface Temperature (ºC) : 105

Condition of Piping : Satisfactory Unsatisfactory X

Recommendation (if any) :

Plant : VCM UNIT-60 Description : Inspector(s) : MARIO / ALI Date : 24-05-2016

Eqpt / Line No. : 80-SCL-6016600-BB31C Service : STEAM CONDENSATE (SCL)

* Nozzle size to be specified

Recommendations:

Replace leaked portion of 3ӯ pipe (TML # 3) and 1ӯ bend pipe low thickness area (TML# 8,9 & 12) .

Replace furmanite clamp as shown in the above sketch (line no #25-SCL-02213-BB31C) in the nearest

opportunity.

For replacement activity, Maintenance has to submit the repair / Welding Procedure Specification (WPS)

to INSP for review and approval.

Fit-up, root & final visual / Dye penetrant test (DPT), Radiographic testing & Hydro testing (if possible) will

be performed after the welding repair to ensure the quality of welding.

VCM operation has to ensure all the requirements / guidelines mentioned as per the procedure (CGPE-

012) for temporary repair (Furmanite clamp) in the line

Prepared by:

Mario, Ali

Reviewed by:

Hazaa M. Al-Harbi

Você também pode gostar

- NORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceDocumento33 páginasNORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceJose Antonio100% (1)

- PROTEM Completo PDFDocumento44 páginasPROTEM Completo PDFMarcelo AguileraAinda não há avaliações

- Recruitment, Selection and Training of Workers: Revision QuestionsDocumento1 páginaRecruitment, Selection and Training of Workers: Revision QuestionsBinSayeed100% (1)

- Electrical Design Checklist v1.2Documento39 páginasElectrical Design Checklist v1.2huangjlAinda não há avaliações

- Brosur BridgestoneDocumento12 páginasBrosur BridgestoneWahyuni SalmanAinda não há avaliações

- AM Series 45-200 D170 Rev D-W OM PDFDocumento15 páginasAM Series 45-200 D170 Rev D-W OM PDFNestor SalasAinda não há avaliações

- Hydrogen Attack PDFDocumento11 páginasHydrogen Attack PDFChanoAinda não há avaliações

- Xtreme King BulldogDocumento12 páginasXtreme King BulldogGustavo Eduardo Vargas RaynholdsAinda não há avaliações

- GSB-Form-247 Dimension Inspection Report (Nozzle)Documento1 páginaGSB-Form-247 Dimension Inspection Report (Nozzle)Made GileeAinda não há avaliações

- Annual OkDocumento22 páginasAnnual OkdennisjuntakAinda não há avaliações

- Data Ta 2017Documento131 páginasData Ta 2017Anonymous ZgxsFIe100% (1)

- DNV-OS-C501 Composite Components Oct 2010Documento164 páginasDNV-OS-C501 Composite Components Oct 2010mseymour91Ainda não há avaliações

- Full MKAPR Evidence Audit SMK3-04 MedcoDocumento114 páginasFull MKAPR Evidence Audit SMK3-04 MedcoSALIM ALI AFIFFAinda não há avaliações

- Jule A'. SchollDocumento8 páginasJule A'. SchollMario TrianaAinda não há avaliações

- 3PS Gaw 003Documento5 páginas3PS Gaw 003ravi00098Ainda não há avaliações

- GSB Form 221 Purchase RequestDocumento2 páginasGSB Form 221 Purchase RequestMade GileeAinda não há avaliações

- Joining Copper Nickel AlloysDocumento9 páginasJoining Copper Nickel AlloyshboodhaiAinda não há avaliações

- FRM-3025 (Hot Work Permit) OkeDocumento1 páginaFRM-3025 (Hot Work Permit) OkerizkiAinda não há avaliações

- SOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)Documento1 páginaSOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)FendiAinda não há avaliações

- List Perijinan Unit Mesin Pt. Medan Sugar Industry: No Nama Ijin Nomor Ijin PengesahanDocumento2 páginasList Perijinan Unit Mesin Pt. Medan Sugar Industry: No Nama Ijin Nomor Ijin PengesahanRobby DamanikAinda não há avaliações

- Sop & Jsa For Flange LeakageDocumento2 páginasSop & Jsa For Flange LeakageSoumya ChatterjeeAinda não há avaliações

- GRACO King 45-1 PartsDocumento10 páginasGRACO King 45-1 Partssamgivp2869Ainda não há avaliações

- 20 Catalog Krisbow 9 WeldingDocumento14 páginas20 Catalog Krisbow 9 WeldingEnrique da MattaAinda não há avaliações

- Msds. FSC-7CDocumento3 páginasMsds. FSC-7CSagu LempengAinda não há avaliações

- TM-81 Condenser Cleaner 5125Documento6 páginasTM-81 Condenser Cleaner 5125gshdavidAinda não há avaliações

- 2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1Documento1 página2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1BennyAinda não há avaliações

- QP-MTC-01 - Pemeliharaan & PencegahanDocumento6 páginasQP-MTC-01 - Pemeliharaan & PencegahanFendi100% (1)

- Header Plug Seal Weld ProcedureDocumento3 páginasHeader Plug Seal Weld ProcedureMohd Shafuaaz Kassim100% (1)

- Sfa-5.6Documento20 páginasSfa-5.6vannie_yundaAinda não há avaliações

- Technical & Price Proposal On Line Leak Sealing On Straight Pipe 2 Inchi PDFDocumento5 páginasTechnical & Price Proposal On Line Leak Sealing On Straight Pipe 2 Inchi PDFandistwn99Ainda não há avaliações

- HPI BrochureDocumento20 páginasHPI BrochurePramod AthiyarathuAinda não há avaliações

- JNL-1241 Technical Data SheetDocumento3 páginasJNL-1241 Technical Data SheetAndrian TamsirAinda não há avaliações

- GSB-Form-58 Non Conforming Report (NCR)Documento1 páginaGSB-Form-58 Non Conforming Report (NCR)Made GileeAinda não há avaliações

- Introduction To Pressure Seal ValvesDocumento3 páginasIntroduction To Pressure Seal ValvesGanci ZebroAinda não há avaliações

- GSB-Form-245 Dimension Inspection Report (Wall Thickness)Documento1 páginaGSB-Form-245 Dimension Inspection Report (Wall Thickness)Made GileeAinda não há avaliações

- HIRAC For Project Retubing ACHEDocumento2 páginasHIRAC For Project Retubing ACHEragilAinda não há avaliações

- ASTM A106 Working PresureDocumento4 páginasASTM A106 Working PresureAnkon MukherjeeAinda não há avaliações

- QP-STR-01 - Penangan Barang Atau MaterialDocumento7 páginasQP-STR-01 - Penangan Barang Atau MaterialFendi100% (1)

- 44 File2 Friction Welding Stir Welding-Course MaterialDocumento92 páginas44 File2 Friction Welding Stir Welding-Course MaterialTeguh SulistiyonoAinda não há avaliações

- TDS - Shell Gadus S3 V460 1 - EN PDFDocumento2 páginasTDS - Shell Gadus S3 V460 1 - EN PDFdtcuongAinda não há avaliações

- Prevention Costs: Appraisal Costs: Internal Failure Costs: External Failure CostsDocumento35 páginasPrevention Costs: Appraisal Costs: Internal Failure Costs: External Failure CostsRaniaAinda não há avaliações

- FM - Hse.004 Laporan Bulanan QHSEDocumento21 páginasFM - Hse.004 Laporan Bulanan QHSEAnak SulungAinda não há avaliações

- TECOtubeexpanders BROCHUREDocumento56 páginasTECOtubeexpanders BROCHUREMontajes Industriales EOS, MIESAAinda não há avaliações

- Welding Inspection ReportDocumento1 páginaWelding Inspection ReportabdiAinda não há avaliações

- GSB-Form-246 Dimension Inspection Report (Circum)Documento1 páginaGSB-Form-246 Dimension Inspection Report (Circum)Made GileeAinda não há avaliações

- Tube Pullout Testing Experience - Final PaperDocumento9 páginasTube Pullout Testing Experience - Final PaperRavi AbuwalaAinda não há avaliações

- Air Cooler Cleaning TechniqueDocumento4 páginasAir Cooler Cleaning Techniquedinakaranpatel100% (1)

- Whitepaper Remanufacturing Liebherr enDocumento11 páginasWhitepaper Remanufacturing Liebherr enAyaz İş MakinalarıAinda não há avaliações

- Welding and Cutting ProcedureDocumento7 páginasWelding and Cutting ProceduredennisjuntakAinda não há avaliações

- TesDocumento68 páginasTesOFIAinda não há avaliações

- T 48Documento7 páginasT 48Anonymous s3xePAAinda não há avaliações

- Operation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanaDocumento7 páginasOperation Control - Powered and Hand Tools Procedure: Pt. Eskimo WieraperdanadennisjuntakAinda não há avaliações

- QP-STR-02 - Pemeriksaan Penerimaan MaterialDocumento6 páginasQP-STR-02 - Pemeriksaan Penerimaan MaterialFendiAinda não há avaliações

- Re Manufacturing Trends and IssuesDocumento14 páginasRe Manufacturing Trends and Issuescallisto69Ainda não há avaliações

- Pipe FittingDocumento71 páginasPipe FittingFharishPutraAinda não há avaliações

- TECO AESV AESU AESV LA Series Squirrel Cage Induction MotorDocumento32 páginasTECO AESV AESU AESV LA Series Squirrel Cage Induction MotorNeo Dinastian OnssalisAinda não há avaliações

- 0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDocumento11 páginas0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDenny AgusAinda não há avaliações

- Solutions Looking For Problems... : BeamsDocumento16 páginasSolutions Looking For Problems... : BeamslifeadventureAinda não há avaliações

- Prosedur Penetran TestingDocumento11 páginasProsedur Penetran TestingIkhsan DalimuntheAinda não há avaliações

- TIAL Installation Guide M80Documento2 páginasTIAL Installation Guide M80Yan FerizalAinda não há avaliações

- Select ' ' and Choose An Select ' ' and Choose An: CRL Pipe Dimension Stainless Steel 304/304L or 316 Size ScheduleDocumento1 páginaSelect ' ' and Choose An Select ' ' and Choose An: CRL Pipe Dimension Stainless Steel 304/304L or 316 Size ScheduleDanAinda não há avaliações

- ETNA - FlowMeter - FBB SeriesDocumento2 páginasETNA - FlowMeter - FBB SeriesPrach MeanithAinda não há avaliações

- Chapter 8 - 1935 Rife Ray #4 Rife MachineDocumento2 páginasChapter 8 - 1935 Rife Ray #4 Rife MachineKhalid IbrahimAinda não há avaliações

- Improvements in Offshore Pipeline Cathodic ProtectionDocumento6 páginasImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoAinda não há avaliações

- Swot Analysis of PTCLDocumento5 páginasSwot Analysis of PTCLM Aqeel Akhtar JajjaAinda não há avaliações

- Project TimesheetDocumento2 páginasProject TimesheetAmanpreet SinghAinda não há avaliações

- Fundamentals of ElectronicsDocumento2 páginasFundamentals of ElectronicsatulzendeAinda não há avaliações

- Loupe S Dental Brochure Sur 6351Documento16 páginasLoupe S Dental Brochure Sur 6351bernadinadwiAinda não há avaliações

- Gardenia RedddDocumento44 páginasGardenia RedddYasmin Yvonne De Chavez100% (1)

- Cambridge Ordinary LevelDocumento4 páginasCambridge Ordinary LevelHaziq AfzalAinda não há avaliações

- Interrupt: ECE473/573 Microprocessor System Design, Dr. Shiue 1Documento25 páginasInterrupt: ECE473/573 Microprocessor System Design, Dr. Shiue 1shanty85Ainda não há avaliações

- Washing MachinesDocumento6 páginasWashing MachinesAnonymous wK36hLAinda não há avaliações

- Abstract Superstructure Conc - Frame WestgateDocumento2 páginasAbstract Superstructure Conc - Frame WestgateTashamiswa MajachaniAinda não há avaliações

- Computer Network-II Lab ProgramsDocumento5 páginasComputer Network-II Lab ProgramsAnshul ChauhanAinda não há avaliações

- Life-Saving Rules: Tool Box Talk SeriesDocumento86 páginasLife-Saving Rules: Tool Box Talk SeriesSalahBouzianeAinda não há avaliações

- Ignitability and Explosibility of Gases and VaporsDocumento230 páginasIgnitability and Explosibility of Gases and VaporsKonstantinKot100% (3)

- CNC Grinding Notching and Marking Machine: AT 710 ENDocumento2 páginasCNC Grinding Notching and Marking Machine: AT 710 ENsmarjanAinda não há avaliações

- Pds Maestro Alkyd Primer 12070 En-GbDocumento2 páginasPds Maestro Alkyd Primer 12070 En-GbKhyle Laurenz DuroAinda não há avaliações

- 7.sieve Analysis AhmedDocumento9 páginas7.sieve Analysis AhmedJin AhmedAinda não há avaliações

- 22KW Hydraulic Power Unit GADocumento1 página22KW Hydraulic Power Unit GAGabi GabrielAinda não há avaliações

- Tips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of PaperDocumento3 páginasTips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of Papermyco samAinda não há avaliações

- MK7850NDocumento6 páginasMK7850NkherrimanAinda não há avaliações

- G 342 Engine Part 1 PDFDocumento26 páginasG 342 Engine Part 1 PDFharley florezAinda não há avaliações

- Swifty Loudspeaker KitDocumento5 páginasSwifty Loudspeaker KitTNAinda não há avaliações

- Shock Absorber DynamometerDocumento19 páginasShock Absorber DynamometerUmanath R Poojary100% (1)

- Types of CameraDocumento18 páginasTypes of CameraVijay Ravi100% (1)

- Geothermal Project TimelinesDocumento10 páginasGeothermal Project TimelinesAldwin EncarnacionAinda não há avaliações

- Six Tsakalis Pedal ManualDocumento1 páginaSix Tsakalis Pedal ManualAdedejinfoAinda não há avaliações

- DC and AC InterferenceDocumento40 páginasDC and AC InterferenceREJI JOY ThoppilAinda não há avaliações

- Rajiv Verma CVDocumento3 páginasRajiv Verma CVrajivAinda não há avaliações