Escolar Documentos

Profissional Documentos

Cultura Documentos

Bavaria en BA-TIG 347si

Enviado por

cocoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Bavaria en BA-TIG 347si

Enviado por

cocoDireitos autorais:

Formatos disponíveis

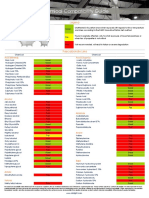

Solid Wire Rod for TIG Welding BA-TIG 347Si

Classification: EN ISO 14343-A: W 19 9 Nb Si

SFA-5.9: ER347Si

Main Application:

BA-TIG 347Si is a solid wire rod for GTAW with higher Si content than BA-TIG 347, suitable to weld 18Cr/10Ni

stabilized with Ti or Nb austenitic stainless steels grades 321 and 347. Also suitable for welding similar unstabilized

grades 304 or 304L. BA-TIG 347Si has high resistance to intergranular corrosion.

Typical analysis and chemical composition acc. to EN ISO 14343-A and AWS A5.9: (Weight Percent)

Cu

Wire rod C Si Mn Mo Ni Cr Nb P S

total

Typical analysis

0.05 0.8 1.6 0.1 9.8 19.5 0.6 0.015 0.013 0.10

BA-TIG 347Si

W 19 9 Nb Si acc. to 9.0- 10xC to

0.08 0.65-1.2 1.0-2.5 0.3 19.0-21.0 0.03 0.02 0.3

ISO 14343-A 11.0 1.0

ER347Si acc. to 9.0- 10xC to

0.08 0.65-1.0 1.0-2.5 0.75 19.0-21.5 0.03 0.03 0.75

AWS A5.9 11.0 1.0

All - Weld Metal Mechanical Properties / Welding Data:

Heat Treatment As Welded

Yield Strength Re, N/mm² (ksi) 400 (58)

Tensile Strength Rm, N/mm² (ksi) 550 (80)

Elongation A5 [%] >28

Impact Energy ISO-V, J (ft lbs) +20°C: 70 (52)

Current/polarity DC -

Shielding Gas ISO 14175: I1

Base Materials:

1.4550/ X6CrNiNb18-10, 1.4541/ X6CrNiTi18-10, 1.4552/ GX5CrNiNb19-11,1.4301/ X5CrNi18-10,1.4312/

GX10CrNi18-8, 1.4546/ X5CrNiNb18-10, 1.4311/ X2CrNiN18-10, 1.4306/ X2CrNi19-11

AISI 347, 321, 302, 304, 304L, 304LN, ASTM A296 Gr. CF 8 C, A157 Gr. C9, A320 Gr. B8C or D

Package Forms:

5 kg carton boxes as standard package form for GTAW wire rods.

Diameter:

1,0 – 3,2 mm. Sizes and tolerances acc. to ISO 544 and AWS A5.9.

Wire Rod Surface:

Smooth finish free from surface defects and foreign matter.

Você também pode gostar

- Bavaria en BA-TIG 310Documento1 páginaBavaria en BA-TIG 310cocoAinda não há avaliações

- Bavaria en BA-TIG 308LDocumento1 páginaBavaria en BA-TIG 308LcocoAinda não há avaliações

- Bavaria en BA-TIG 309LSiDocumento1 páginaBavaria en BA-TIG 309LSicocoAinda não há avaliações

- Your Reliable Welding Business Partner Worldwide"Documento70 páginasYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGAinda não há avaliações

- Bavaria en BA-MIG 307siDocumento1 páginaBavaria en BA-MIG 307siMarcel BolovedeaAinda não há avaliações

- Ok 347 AutrodDocumento2 páginasOk 347 Autrodjoao guilhermeAinda não há avaliações

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocumento1 página308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroAinda não há avaliações

- en WW FactSheet Main 01Documento1 páginaen WW FactSheet Main 01Samuel TanAinda não há avaliações

- PDS-OK Autrod 430LNbTi GMAW-rev2Documento1 páginaPDS-OK Autrod 430LNbTi GMAW-rev2joao guilhermeAinda não há avaliações

- item8-LNT NiCro60.20Documento1 páginaitem8-LNT NiCro60.20VVan TanAinda não há avaliações

- AUTROD 316LSiDocumento2 páginasAUTROD 316LSijoao guilhermeAinda não há avaliações

- en - WW FactSheet - Main 01Documento1 páginaen - WW FactSheet - Main 01Mario FuentesklrlyAinda não há avaliações

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocumento1 páginaTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkAinda não há avaliações

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocumento3 páginasProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLAinda não há avaliações

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocumento1 páginaThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavAinda não há avaliações

- Comparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Documento7 páginasComparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Erijanio Silva100% (1)

- Alloy 318Documento2 páginasAlloy 318Branko FerenčakAinda não há avaliações

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocumento4 páginasA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Ainda não há avaliações

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocumento1 páginaNI-182 Victory ENICRFE-3 Electrode Data SheetgianAinda não há avaliações

- Inertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsDocumento1 páginaInertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsEdison CheongAinda não há avaliações

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanAinda não há avaliações

- Weld 71T-1Documento1 páginaWeld 71T-1Luciano Alves CavalcantiAinda não há avaliações

- item11-LNT NiCroMo 59.23Documento1 páginaitem11-LNT NiCroMo 59.23VVan TanAinda não há avaliações

- Product Data Sheet - OK Tigrod 13.09 PDFDocumento2 páginasProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuAinda não há avaliações

- T - Thermanit 25 - 09 CuT - de - en - 5Documento1 páginaT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANIAinda não há avaliações

- en - GB FactSheet - Main 01Documento1 páginaen - GB FactSheet - Main 01ronaldb322Ainda não há avaliações

- OK Tigrod 316LDocumento1 páginaOK Tigrod 316Laxisd47Ainda não há avaliações

- Datasheet Sandvik 199l enDocumento3 páginasDatasheet Sandvik 199l enpedro rojasAinda não há avaliações

- Item5 LNT316LDocumento1 páginaItem5 LNT316LVVan TanAinda não há avaliações

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Documento2 páginasDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeAinda não há avaliações

- Cavitalloy: Technical Data Sheet Cored Welding WireDocumento1 páginaCavitalloy: Technical Data Sheet Cored Welding WireMAURO MORESCOAinda não há avaliações

- P91 - Modified 9crmo: Data SheetDocumento7 páginasP91 - Modified 9crmo: Data SheetpbanerjeeAinda não há avaliações

- ER316L Ss en 1Documento1 páginaER316L Ss en 1brayanAinda não há avaliações

- Thermanit GE-316L PDFDocumento1 páginaThermanit GE-316L PDFsmpoe017Ainda não há avaliações

- OK Tigrod 316LDocumento1 páginaOK Tigrod 316Lbevara santhoshkumarAinda não há avaliações

- Ficha Técnica CarborodDocumento1 páginaFicha Técnica CarborodAndres NuñezAinda não há avaliações

- Overcord R12: MMA Electrodes C-MN and Low-Alloy SteelsDocumento1 páginaOvercord R12: MMA Electrodes C-MN and Low-Alloy SteelsbrunizzaAinda não há avaliações

- Shield Bright 309L-1Documento1 páginaShield Bright 309L-1adanmeneses1Ainda não há avaliações

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Documento3 páginasProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801Ainda não há avaliações

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocumento1 páginaOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedAinda não há avaliações

- Nickel Based ElectrodeDocumento1 páginaNickel Based Electrodewalter091011Ainda não há avaliações

- Classifications: For Atmospheric Corrosion Resisting SteelDocumento1 páginaClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongAinda não há avaliações

- CM-9CB TG-S9Cb US-9CbDocumento3 páginasCM-9CB TG-S9Cb US-9Cbamit singhAinda não há avaliações

- E 8018 B2Documento1 páginaE 8018 B2ElMacheteDelHuesoAinda não há avaliações

- Boehler CN 13 4-MC FDocumento1 páginaBoehler CN 13 4-MC FFilipe CordeiroAinda não há avaliações

- FSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFDocumento2 páginasFSX-414 Datasheet, FSX-414 Chemical, FSX-414 Heat Treatment PDFJ. BangjakAinda não há avaliações

- Ok Tubrod 14.30a PDFDocumento1 páginaOk Tubrod 14.30a PDFqaAinda não há avaliações

- CSF-71T en 2014Documento1 páginaCSF-71T en 2014HoangAinda não há avaliações

- CSF-71T en 2014Documento1 páginaCSF-71T en 2014Yousab CreatorAinda não há avaliações

- QU AL ITY: Material Data SheetDocumento5 páginasQU AL ITY: Material Data SheetAlex007Ainda não há avaliações

- Datasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1Documento3 páginasDatasheet-Sandvik-188mn-En-V2017-10-17 10 - 15 Version 1szystAinda não há avaliações

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajAinda não há avaliações

- Product Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'Documento2 páginasProduct Data Sheet Pipeweld 70S-6: G 'Gas-Shielded Metal-Arc Welding'RobertoAinda não há avaliações

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-3 EN 10087Documento2 páginasEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-3 EN 10087farshid KarpasandAinda não há avaliações

- L1 8581 en Diamondspark 44 BC CU03100F 3379759 ENDocumento1 páginaL1 8581 en Diamondspark 44 BC CU03100F 3379759 ENRaviTeja BhamidiAinda não há avaliações

- ER 347 Si (Gazaltı Kaynak Teli)Documento1 páginaER 347 Si (Gazaltı Kaynak Teli)muratcanAinda não há avaliações

- B Boehler Ni 1-Ig Ss en 5Documento1 páginaB Boehler Ni 1-Ig Ss en 5Andrei UrsacheAinda não há avaliações

- Materials Data for Cyclic Loading: Low-Alloy SteelsNo EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsNota: 5 de 5 estrelas5/5 (2)

- Baisikeli DocumentationDocumento67 páginasBaisikeli DocumentationcocoAinda não há avaliações

- Exam 18Documento5 páginasExam 18cocoAinda não há avaliações

- ScenDocumento1 páginaScencocoAinda não há avaliações

- 2014-Volkswagen-Tires and WheelsDocumento27 páginas2014-Volkswagen-Tires and WheelscocoAinda não há avaliações

- Report Part 2Documento10 páginasReport Part 2cocoAinda não há avaliações

- CraftingDocumento1 páginaCraftingcocoAinda não há avaliações

- Blind Rivet Nuts VVG Fasteners 2016 2017Documento42 páginasBlind Rivet Nuts VVG Fasteners 2016 2017cocoAinda não há avaliações

- Soudotape Nicrmo4: DescriptionDocumento1 páginaSoudotape Nicrmo4: DescriptioncocoAinda não há avaliações

- Zbook 15 g5Documento54 páginasZbook 15 g5cocoAinda não há avaliações

- Robineti Sertar Pana - Pliant Date TehniceDocumento2 páginasRobineti Sertar Pana - Pliant Date TehnicecocoAinda não há avaliações

- HAUS Decanters For Oil Sludge TreatmentDocumento3 páginasHAUS Decanters For Oil Sludge TreatmentcocoAinda não há avaliações

- ConstructionDocumento10 páginasConstructioncocoAinda não há avaliações

- Böhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistanceDocumento1 páginaBöhler CM 2-Ig: Solid Wire, Low-Alloyed, Creep ResistancecocoAinda não há avaliações

- U Bolt StandardDocumento1 páginaU Bolt StandardcocoAinda não há avaliações

- Weld Summary PerformanceDocumento11 páginasWeld Summary PerformancecocoAinda não há avaliações

- Weldolet and Dimension of WeldoletDocumento10 páginasWeldolet and Dimension of WeldoletcocoAinda não há avaliações

- En 25817Documento1 páginaEn 25817RamanujadaasanAinda não há avaliações

- Cromobaz MDocumento1 páginaCromobaz McocoAinda não há avaliações

- Tabel Nominal Cu Elevii Clasei A VI-a ADocumento1 páginaTabel Nominal Cu Elevii Clasei A VI-a AcocoAinda não há avaliações

- Brosura Pistolete TIG KemppiDocumento4 páginasBrosura Pistolete TIG KemppicocoAinda não há avaliações

- PhEd-Some Basic Concepts of Chemistry-W.SDocumento18 páginasPhEd-Some Basic Concepts of Chemistry-W.SSubharna ChauhanAinda não há avaliações

- Presentation 01Documento28 páginasPresentation 01Rexona KhanomAinda não há avaliações

- Iso 6634 1982Documento8 páginasIso 6634 1982odota deoAinda não há avaliações

- Acids & Bases OL NotesDocumento5 páginasAcids & Bases OL NotesHooria AminAinda não há avaliações

- Cyanide Detoxification - Inco SO2-AirDocumento14 páginasCyanide Detoxification - Inco SO2-Aircjrdeleon100% (1)

- 2017 Catalog Endmills Update SmallDocumento88 páginas2017 Catalog Endmills Update SmallwisnuAinda não há avaliações

- Acids Bases and Salts WksheetDocumento2 páginasAcids Bases and Salts WksheetShakwan WatermanAinda não há avaliações

- Chapter 4b-Back TitrationDocumento9 páginasChapter 4b-Back TitrationnajwaAinda não há avaliações

- Chemistry Electrolysis Cheat Sheet: by ViaDocumento3 páginasChemistry Electrolysis Cheat Sheet: by ViaRose AimanAinda não há avaliações

- Identification of Cations and Anions Present in ToothpasteDocumento24 páginasIdentification of Cations and Anions Present in ToothpastePiyush SinghAinda não há avaliações

- Engineering Properties of Nickel and Nickel AlloysDocumento240 páginasEngineering Properties of Nickel and Nickel AlloysOR Premium FreeAinda não há avaliações

- List Bahan Kimia Di RPKADocumento4 páginasList Bahan Kimia Di RPKAReysaAinda não há avaliações

- Dialight Chemical CompatibilityDocumento16 páginasDialight Chemical CompatibilityJuan AcuñaAinda não há avaliações

- Gold and Silver Leaching Practice in The United States by Peter G. Chamberlain and Michael G. PojarDocumento52 páginasGold and Silver Leaching Practice in The United States by Peter G. Chamberlain and Michael G. PojarFerudun Akyol100% (1)

- Asma Zaghbani Publications ScientifiquesDocumento2 páginasAsma Zaghbani Publications Scientifiquesapi-227010260Ainda não há avaliações

- Tin Plating: Michael CaranoDocumento2 páginasTin Plating: Michael CaranoVaidas JukneviciusAinda não há avaliações

- Glyoxalic Acid From OxalicDocumento3 páginasGlyoxalic Acid From OxalictfosgnameAinda não há avaliações

- Is 2062Documento12 páginasIs 2062ANTONYLEOAinda não há avaliações

- Cambridge O Level: Chemistry 5070/41 October/November 2020Documento9 páginasCambridge O Level: Chemistry 5070/41 October/November 2020Islamabad ALMA SchoolAinda não há avaliações

- Mock Test 18Documento8 páginasMock Test 18KIEN NGUYENDACCHIAinda não há avaliações

- Acids & BasesDocumento4 páginasAcids & BasesGrand Meme VinesAinda não há avaliações

- Asmet Technical Introduction To Metallurgical Process Control Using ATAS Advanced Thermal Analysis System Eng v1 20062011Documento2 páginasAsmet Technical Introduction To Metallurgical Process Control Using ATAS Advanced Thermal Analysis System Eng v1 20062011fondershellAinda não há avaliações

- Copper SlagDocumento6 páginasCopper SlagpushkarAinda não há avaliações

- List of Polyatomic IonsDocumento1 páginaList of Polyatomic IonsSk. Salahuddin Ahammad100% (1)

- Inorg 2 - Tut 1 - 2018 - MemoDocumento4 páginasInorg 2 - Tut 1 - 2018 - MemoStolo SbaeAinda não há avaliações

- MGSV Unprocessed MaterialsDocumento6 páginasMGSV Unprocessed MaterialsjayAinda não há avaliações

- Cambridge IGCSE (9-1) 0973 Co-Ordinated Sciences Specimen Paper 1 For Examination From 2025Documento16 páginasCambridge IGCSE (9-1) 0973 Co-Ordinated Sciences Specimen Paper 1 For Examination From 2025mahavirhouse987Ainda não há avaliações

- By Pass System in The Dry ProcessDocumento34 páginasBy Pass System in The Dry Processfaheemqc100% (1)

- TFSP Ver3-2-02Documento74 páginasTFSP Ver3-2-02Murali Krishna ThotaAinda não há avaliações

- Balancing Equations: Practice ProblemsDocumento10 páginasBalancing Equations: Practice ProblemsAdeenaAinda não há avaliações