Escolar Documentos

Profissional Documentos

Cultura Documentos

Sop For Ash Slurry Pump (r1)

Enviado por

SonratDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sop For Ash Slurry Pump (r1)

Enviado por

SonratDireitos autorais:

Formatos disponíveis

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ASP/0

Power from knowledge 1

SOP For Ash Slurry Pump

Issue No: 1 Issue Date: Revision: 01 Revision Date: File no: Page 1 of 6

STANDARD OPERATING INSTRUCTION

FOR

ASH SLURRY PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ASP/0

Power from knowledge 1

SOP For Ash Slurry Pump

Issue No: 1 Issue Date: Revision: 01 Revision Date: File no: Page 2 of 6

STANDARD OPERATING PROCEDURE FOR ASH SLURRY PUMP

OBJECTIVE: For Smooth Operation of ash slurry pump.

SCOPE: This SOP is applicable for 06 nos. of ash slurry pump.

INTRODUCTION: Ash slurry pump is needed to dispose the ash slurry from slurry sump to

ash dyke. It is obtained by 06 nos of ash slurry pump for 06 units. For 03 units 02 nos ash slurry

pump is running and another one standby).

PRE CHECKS:

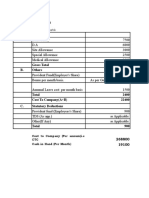

ASH SLURRY PUMP TECHNICAL DATA:-

Make Shijiazhuang Kingda Quantity O6 Nos

Pump Industry Group

Co. Ltd

Type 200ZGB Discharge Capacity 960m³/h

Discharge 1.0mpa Rotating speed 1030r/min (Max.)

Pressure

VFD DRIVEN

ASH SLURRY PUMP MOTOR

Type YKK500-42 Power 560kW

Voltage 11KV Current 36.4A

Rotating speed 1490 r/min

ASH SLURRY PUMP SCOPE COUPLING

TYPE VARIABLE SCOPE POWER 250 TO 730 KW

COUPLING

RPM 1030 TO 1500

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ASP/0

Power from knowledge 1

SOP For Ash Slurry Pump

Issue No: 1 Issue Date: Revision: 01 Revision Date: File no: Page 3 of 6

SAFTEY PRECAUTIONS: Ensure no permit to work is pending on regarding this system by

checking with EE/MRSE.

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

SPECIAL TOOLS/ EQUIPMENTS: NIL

PRECHECKS AND ACTION BY FIELD ENGINEER

SL Description Ok Not Remarks

No Ok

1 All permits and cross permits have been returned.

2 Area is clear of any other materials.

3 Check all the foundation bolt should be tight properly.

4 Check Cooling water is OK.

5 Check the coupling bolt should be tight properly.

6 Check coupling guard is not touching with coupling.

7 Check the lubrication of pump & its accessories.

8 Check Fluid Coupling Oil level is OK..

9 Check seal water pump is ready for gland sealing of pump.

Check all pipe line flange & coupling nut bolt properly

10 tight.

11 Check slurry line flushing water valve closed.

12 Check pump suction & discharge valve closed.

13 Check local push button released.

14 Check Scoop-tube position is OK.

PRECHECKS AND ACTION BY DESK ENGINEER

SL Description Ok Not Remarks

No Ok

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ASP/0

Power from knowledge 1

SOP For Ash Slurry Pump

Issue No: 1 Issue Date: Revision: 01 Revision Date: File no: Page 4 of 6

1 Check MCC panel feeder is ready.

2 Check control supply is healthy.

3 Check seal water pressure is normal.

4 Check motor bearing & winding temperature normal.

5 Check slurry sump level normal

6 Check suction & discharge valve feedback is ok.

OPERATING PROCEDURE -

Sr. RESPONSIBILITY

No Description UCE DE FE EE

.

PRE- START CHECKS:

1 All permits and cross permits have been returned.

2 Power supply and control power supply available.

3 Cooling water line Pr. NORMAL.

4 Check suction & discharge valve feedback is ok.

5 Slurry tank level normal.

START PERMISSIVE :

1 Motor bearing (DE/NDE) temp normal.

2 Motor winding temp normal.

3 Pump suction & discharge valve closed.

4 Emergency push button is in release condition.

5 Slurry sump level not in danger low

SLURRY PUMP START UP SEQUENCE :

1 Start seal water pump.

2 Open the slurry pump suction valve. Open the water inlet valve of oil

cooler.

3 Start the slurry pump.

4 Open the discharge valve.

5 Set the back-up seal water pump as "standby."

6 Engage Scoope table.

SHUTDOWN SEQUENCE:

1.PLANNED SHUTDOWN :

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ASP/0

Power from knowledge 1

SOP For Ash Slurry Pump

Issue No: 1 Issue Date: Revision: 01 Revision Date: File no: Page 5 of 6

1 Proper slurry tank flushing should be done.

2 The flushing water line valve open.

3 Stop the slurry pump & closed the suction valve.

4 Close all valves.

5 Rectify the probable, if any.

2. TRIPPING OF SLURRY PUMP :If suddenly pump trips

1 Fallow the procedure as above.

2 Check the pump, close suction valve and flush the discharge line by HP

water.

3 Stop the HP water pump and try to start ash slurry pump. If not ask for

PTW

3. EMERGENCY SHUT DOWN:

1 There is the apparent abnormal noise after starting the pump.

2 The pump & motor bearing temperature is high.

3 When discharge line is chocked.

4 When endangering the safety of person and equipment.

INTERLOCKS : Remarks

1 Slurry tank level is danger low.

2 Seal water pump stopped.

3 Pump suction & discharge open feedback.

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/ASP/0

Power from knowledge 1

SOP For Ash Slurry Pump

Issue No: 1 Issue Date: Revision: 01 Revision Date: File no: Page 6 of 6

DO’s & DONT’s:

DO’s:

1. Ensure Cooling Water Pressure & Flow for Fluid Coupling Oil is sufficient before starting the Slurry

Pump.

2. Ensure all the Agitators of Slurry Sump are running before stating of Slurry Pump

3. Ensure Discharge is closed before stating of Slurry Pump.

4. Ensure Line Pressure does not goes up beyond receoomended pressure by OEM.

DONT’s:

1. Don’t run the Slurry Pump if discharge pressure becomes low.

2. Don’t run the Slurry Pump if Oil temperature is continuously high.

3. Don’t run the Slurry Pump if Oil level is continuously low.

4. Don’t start/stop the Pump frequently.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Você também pode gostar

- Sop For Eco SystemDocumento6 páginasSop For Eco SystemSonratAinda não há avaliações

- Sop For Ba-Hp Pump (r1)Documento6 páginasSop For Ba-Hp Pump (r1)SonratAinda não há avaliações

- SMP For Agitator (Slurry Sump)Documento9 páginasSMP For Agitator (Slurry Sump)SonratAinda não há avaliações

- PM WORK For Fluidizing Blower of Fly Ash SiloDocumento4 páginasPM WORK For Fluidizing Blower of Fly Ash SiloSonratAinda não há avaliações

- Sop For HCSD PumpDocumento6 páginasSop For HCSD PumpSonrat100% (2)

- PM Work For Bag Filters of Fly Ash SiloDocumento4 páginasPM Work For Bag Filters of Fly Ash SiloSonrat0% (1)

- Sop For Eco-Hp Pump (r1)Documento6 páginasSop For Eco-Hp Pump (r1)SonratAinda não há avaliações

- Sop For LP PumpDocumento5 páginasSop For LP PumpSonratAinda não há avaliações

- PM For Bottom Ash Wet System SystemDocumento7 páginasPM For Bottom Ash Wet System SystemSonratAinda não há avaliações

- Sop For LP Pump (R1)Documento6 páginasSop For LP Pump (R1)SonratAinda não há avaliações

- SMP For Supply Water PumpDocumento13 páginasSMP For Supply Water PumpSonratAinda não há avaliações

- Sop For Dry Ash Pressure Conveying SystemDocumento7 páginasSop For Dry Ash Pressure Conveying SystemSonratAinda não há avaliações

- PM FOR FLY ASH Dry SystemDocumento30 páginasPM FOR FLY ASH Dry SystemSonratAinda não há avaliações

- Sop For LP PumpDocumento5 páginasSop For LP PumpSonratAinda não há avaliações

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDocumento6 páginasKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratAinda não há avaliações

- PM Work For Dry Ash UnloaderDocumento4 páginasPM Work For Dry Ash UnloaderSonratAinda não há avaliações

- 6 Esp BlowerDocumento2 páginas6 Esp BlowerMithun Singh RajputAinda não há avaliações

- SMP For Vacuum PumpDocumento9 páginasSMP For Vacuum PumpSonratAinda não há avaliações

- OCCW Pump SOP-1Documento7 páginasOCCW Pump SOP-1SonratAinda não há avaliações

- Gland Sealing Systeam011Documento6 páginasGland Sealing Systeam011SonratAinda não há avaliações

- Final KSK Sop Instrument CompressorDocumento10 páginasFinal KSK Sop Instrument CompressorSonratAinda não há avaliações

- 08-SOP of ASH SLURRY PUMPDocumento5 páginas08-SOP of ASH SLURRY PUMPMithun Singh RajputAinda não há avaliações

- Sop For Concentrator (r1)Documento5 páginasSop For Concentrator (r1)Sonrat100% (1)

- Cep Sop KSKDocumento11 páginasCep Sop KSKSonratAinda não há avaliações

- Condenser Ball Cleaning SystemDocumento6 páginasCondenser Ball Cleaning SystemSonratAinda não há avaliações

- Sop For Dry Ash Vacuum Conveying SystemDocumento8 páginasSop For Dry Ash Vacuum Conveying SystemSonratAinda não há avaliações

- EH Oil Pump SOPDocumento8 páginasEH Oil Pump SOPSonratAinda não há avaliações

- Sop For Vacuum PumpDocumento7 páginasSop For Vacuum PumpSonratAinda não há avaliações

- Bahp Water PumpDocumento4 páginasBahp Water PumpMithun Singh RajputAinda não há avaliações

- List of BHEL TOP File Handed Over To DocumentationDocumento578 páginasList of BHEL TOP File Handed Over To DocumentationNaresh PattanaikAinda não há avaliações

- Technical Diary: STAGE-I (2 X 500 MW)Documento133 páginasTechnical Diary: STAGE-I (2 X 500 MW)scentpcbarauni BARAUNIAinda não há avaliações

- Control Write Up R1 - Khaperkheda PDFDocumento71 páginasControl Write Up R1 - Khaperkheda PDFAsif ShaikhAinda não há avaliações

- Fahp Water PumpDocumento9 páginasFahp Water PumpMithun Singh RajputAinda não há avaliações

- Vol III Rev 0Documento871 páginasVol III Rev 0Anonymous nwByj9LAinda não há avaliações

- Standard Operating InstructionDocumento8 páginasStandard Operating InstructionSonratAinda não há avaliações

- List of Part-3Documento2.000 páginasList of Part-3Gỗ Mộc100% (1)

- Stator CW SOP - Docx-1Documento12 páginasStator CW SOP - Docx-1SonratAinda não há avaliações

- Vertical Turbine Canal Recirculation & CT Make-Up Water PumpDocumento37 páginasVertical Turbine Canal Recirculation & CT Make-Up Water PumpSanto EAinda não há avaliações

- SESI-TSPL-OPN-SOP-BTG-012 (APH Fire)Documento9 páginasSESI-TSPL-OPN-SOP-BTG-012 (APH Fire)sourav mahapatraAinda não há avaliações

- Vol-Ii B936Documento113 páginasVol-Ii B936Anonymous uXdS9Y7Ainda não há avaliações

- MDBFP Sop KSK-1Documento12 páginasMDBFP Sop KSK-1SonratAinda não há avaliações

- ACWDocumento9 páginasACWrohit_me083Ainda não há avaliações

- CC Pump Manual-Full (Original)Documento109 páginasCC Pump Manual-Full (Original)friendbce100% (1)

- ABB 500 MW Steam TurbineDocumento11 páginasABB 500 MW Steam TurbineRama Ranjan Samantaray100% (1)

- Boiler Tube Failure Gyanendra Sharma Npti DelhiDocumento41 páginasBoiler Tube Failure Gyanendra Sharma Npti DelhiNPTIAinda não há avaliações

- List of BHEL Tur All IndiaDocumento27 páginasList of BHEL Tur All IndiaManoj SinghAinda não há avaliações

- Chapter I General Information of Pump UnitDocumento42 páginasChapter I General Information of Pump UnitRahmat Budi HartantoAinda não há avaliações

- 5 Buffer Hopper D-PumpDocumento4 páginas5 Buffer Hopper D-PumpMithun Singh RajputAinda não há avaliações

- BFP TDDocumento22 páginasBFP TDArvind ShuklaAinda não há avaliações

- Paddle Feeder (PF) Stage-1: FunctionDocumento5 páginasPaddle Feeder (PF) Stage-1: FunctionSatyaranjan mahapatraAinda não há avaliações

- Ash Handling PlantDocumento24 páginasAsh Handling Plantsekhar_ntpcAinda não há avaliações

- CEP#a Maintenance ReportDocumento17 páginasCEP#a Maintenance ReportrownnieyAinda não há avaliações

- Description: Operation & Maintenance Manual Part 1 - Technical SpecificationDocumento22 páginasDescription: Operation & Maintenance Manual Part 1 - Technical Specificationa.jainAinda não há avaliações

- O&M Manual - Part 1 of 5 PDFDocumento58 páginasO&M Manual - Part 1 of 5 PDFYOUTH FUTUREAinda não há avaliações

- TNEB Thermal Power PlantDocumento107 páginasTNEB Thermal Power Plantvicky_hyd_130% (1)

- CHP SpecifictionDocumento36 páginasCHP SpecifictionVaibhav Jain100% (1)

- Standard Operating Instruction: Sop For Condenser Ball CleaningDocumento6 páginasStandard Operating Instruction: Sop For Condenser Ball CleaningSonratAinda não há avaliações

- Sop For Flushing Water PumpDocumento6 páginasSop For Flushing Water PumpSonratAinda não há avaliações

- Sop For Recovery Water Pump (r1) IncompleteDocumento6 páginasSop For Recovery Water Pump (r1) IncompleteSonratAinda não há avaliações

- CCCWDocumento7 páginasCCCWSonratAinda não há avaliações

- SMP For Sealing Water Pump Multi Stage.Documento13 páginasSMP For Sealing Water Pump Multi Stage.SonratAinda não há avaliações

- SMP For Fluidizing Air BlowerDocumento20 páginasSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Vacuum PumpDocumento9 páginasSMP For Vacuum PumpSonratAinda não há avaliações

- Control Write Up HCSDDocumento10 páginasControl Write Up HCSDSonratAinda não há avaliações

- SMP For Dry Ash UnloaderDocumento8 páginasSMP For Dry Ash UnloaderSonratAinda não há avaliações

- Sop For Vent FilterDocumento6 páginasSop For Vent FilterSonratAinda não há avaliações

- SMP For Supply Water PumpDocumento13 páginasSMP For Supply Water PumpSonratAinda não há avaliações

- Turbine Drains SOPDocumento6 páginasTurbine Drains SOPSonratAinda não há avaliações

- SMP For Slurry PumpDocumento14 páginasSMP For Slurry PumpSonrat100% (1)

- Pdi EspDocumento1 páginaPdi EspSonratAinda não há avaliações

- ESP-FLD. BLOWER-Model PDFDocumento1 páginaESP-FLD. BLOWER-Model PDFSonratAinda não há avaliações

- Silo Blower Compressor ModelDocumento1 páginaSilo Blower Compressor ModelSonratAinda não há avaliações

- Buffer Hopper & Air Lock Tank-ModelDocumento1 páginaBuffer Hopper & Air Lock Tank-ModelSonratAinda não há avaliações

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDocumento6 páginasKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratAinda não há avaliações

- Turbine Drains SOPDocumento6 páginasTurbine Drains SOPSonratAinda não há avaliações

- Stator CW SOP - Docx-1Documento12 páginasStator CW SOP - Docx-1SonratAinda não há avaliações

- State Nodal Officers DS GuidelinesDocumento3 páginasState Nodal Officers DS GuidelinesSonratAinda não há avaliações

- Sop For LP PumpDocumento5 páginasSop For LP PumpSonratAinda não há avaliações

- Stator CW SOP-2Documento12 páginasStator CW SOP-2SonratAinda não há avaliações

- Salary Structure Siddharth KaushikDocumento1 páginaSalary Structure Siddharth KaushikSonratAinda não há avaliações

- Curriculum Vitae: Nageshwar Prasad RathoreDocumento2 páginasCurriculum Vitae: Nageshwar Prasad RathoreSonratAinda não há avaliações

- Sop For Oil Purification SystemDocumento8 páginasSop For Oil Purification SystemSonrat100% (1)

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocumento8 páginasStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratAinda não há avaliações

- Sop For LP PumpDocumento5 páginasSop For LP PumpSonratAinda não há avaliações

- Salary AnnextureDocumento1 páginaSalary AnnextureSonratAinda não há avaliações

- Seal Oil SopDocumento18 páginasSeal Oil SopSonrat100% (1)

- Integrated CircuitsDocumento46 páginasIntegrated CircuitsSai LakshmiAinda não há avaliações

- Okan Ggcpdebottlenecking Project: Welding Procedure Specification FOR Pipe To FlangeDocumento4 páginasOkan Ggcpdebottlenecking Project: Welding Procedure Specification FOR Pipe To FlangeNilesh KabadeAinda não há avaliações

- Air Conditioning Load CalculationDocumento22 páginasAir Conditioning Load CalculationSyed Kaleem Gilani50% (2)

- Petrol Chainsaws: Owner's ManualDocumento4 páginasPetrol Chainsaws: Owner's Manualkatta ngaAinda não há avaliações

- UL 1558 LV SwitchgearDocumento2 páginasUL 1558 LV SwitchgearezpmeAinda não há avaliações

- Rapport 1Documento2 páginasRapport 1koukou kikiAinda não há avaliações

- Heat Exchange PDFDocumento3 páginasHeat Exchange PDFmunhAinda não há avaliações

- ME MotronicDocumento3 páginasME Motronicdory7dawAinda não há avaliações

- Why I Must Attack ThriveDocumento6 páginasWhy I Must Attack ThriveMatthew EhretAinda não há avaliações

- Performance Verification For Platinum Resistance ThermometersDocumento4 páginasPerformance Verification For Platinum Resistance Thermometersfawmer61Ainda não há avaliações

- 8 CL636Documento20 páginas8 CL636shubhamAinda não há avaliações

- Catalogo Invt gd100 PVDocumento10 páginasCatalogo Invt gd100 PVSergio RecabarrenAinda não há avaliações

- Pcr2019-14 PCR Construction Products v1.0Documento26 páginasPcr2019-14 PCR Construction Products v1.0marcoAinda não há avaliações

- Introduction LetterDocumento2 páginasIntroduction Letterbllimbani100% (1)

- AR05.20-P-6020QB Set Basic Position of Camshafts 2.3.10 Engine 272 in MODEL 203, 209 Engine 273 in MODEL 209Documento3 páginasAR05.20-P-6020QB Set Basic Position of Camshafts 2.3.10 Engine 272 in MODEL 203, 209 Engine 273 in MODEL 209Eko PurwantoAinda não há avaliações

- Flexible Disc Couplings: TB Wood's Form-Flex & Torsiflex-IDocumento52 páginasFlexible Disc Couplings: TB Wood's Form-Flex & Torsiflex-Ioscar.pabaAinda não há avaliações

- Luminous Eco Watt Neo 1050 InverterDocumento3 páginasLuminous Eco Watt Neo 1050 InverterSanjoms SebastianAinda não há avaliações

- Reclosers: Form 6 Microprocessor-Based Pole Mount Recloser Control Installation and Operation InstructionsDocumento48 páginasReclosers: Form 6 Microprocessor-Based Pole Mount Recloser Control Installation and Operation InstructionsTrịnh Huy ĐảmAinda não há avaliações

- AMF InstructionsDocumento4 páginasAMF Instructionspapasp105305Ainda não há avaliações

- Qualification of Compressed Air ProtocolDocumento18 páginasQualification of Compressed Air ProtocolBRIJENDRA KUMAR SINGH100% (2)

- Data Sheet For HV Motor: 4935-30001-21-EL-DS-1050Documento3 páginasData Sheet For HV Motor: 4935-30001-21-EL-DS-1050Pinaki SharmaAinda não há avaliações

- Reciprocating PumpDocumento6 páginasReciprocating PumpManish SoniAinda não há avaliações

- Dimmable Fluorescent Troubleshooting Application Note #436Documento8 páginasDimmable Fluorescent Troubleshooting Application Note #436Loretta KimAinda não há avaliações

- 4D Seminar ReportDocumento41 páginas4D Seminar ReportChandu Sunag0% (1)

- AIIMS Solved Paper 2017Documento30 páginasAIIMS Solved Paper 2017Jagmohan SinghAinda não há avaliações

- Recommendations Regarding Fuel Quality For Diesel Engines: Number 21 2003Documento36 páginasRecommendations Regarding Fuel Quality For Diesel Engines: Number 21 2003MiguelAinda não há avaliações

- Gait Analysis and Clinical ApplicationDocumento123 páginasGait Analysis and Clinical ApplicationKanhu Mallik100% (4)

- Toyota Techdoc Continuously Variable Transaxle Fluid Adjustment 1 2 PDFDocumento5 páginasToyota Techdoc Continuously Variable Transaxle Fluid Adjustment 1 2 PDFrodrivalentAinda não há avaliações

- Supplement To M6.11 - M7.07 EWIS - Bonding and Grounding Network On Carbon Structure AIrcraftDocumento54 páginasSupplement To M6.11 - M7.07 EWIS - Bonding and Grounding Network On Carbon Structure AIrcraftjamesclh100% (1)

- Subject 4. - Product Design OCW PDFDocumento33 páginasSubject 4. - Product Design OCW PDFJose Luis BarradasAinda não há avaliações