Escolar Documentos

Profissional Documentos

Cultura Documentos

Sop For Recovery Water Pump (r1) Incomplete

Enviado por

SonratTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sop For Recovery Water Pump (r1) Incomplete

Enviado por

SonratDireitos autorais:

Formatos disponíveis

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/RWP/01 (R1)

Power from knowledge

SOP For RECOVERY WATER PUMP

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 6

STANDARD OPERATING INSTRUCTION

FOR

RECOVERY WATER

PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Assistant Manager Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/RWP/01 (R1)

Power from knowledge

SOP For RECOVERY WATER PUMP

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 6

STANDARD OPERATING PROCEDURE FOR RECOVERY WATER PUMP

OBJECTIVE: For Smooth Operation of Recovery water pump.

SCOPE: This SOP is applicable for 03 nos. of Recovery water pump.

INTRODUCTION: Recovery water pump is required for filling & make up of ash water sump. It is

obtained by 03 nos of Recovery water pump for 06 units. For 06 units 02 nos Recovery water pump is running

and another one is standby.

PRE CHECKS:

RECOVERY WATER PUMP TECHNICAL DATA:-

Make BOSHAN Quantity 03 Nos

Type 126H-19 Discharge Capacity 550m³/h

Discharge 0.2mpa Rotating speed 1480r/min

Pressure

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

1. Ensure no permit to work is pending on regarding this system.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Assistant Manager Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/RWP/01 (R1)

Power from knowledge

SOP For RECOVERY WATER PUMP

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 6

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

SPECIAL TOOLS/ EQUIPMENTS: NIL

PRECHECKS AND ACTION BY FIELD ENGINEER

S No Description Ok Not Ok Remarks

1 All permits and cross permits have been returned.

2 Area is clear of any other materials.

3 Check all the foundation bolt should be tight properly.

4 Check the coupling bolt should be tight properly.

5 Check coupling guard is not touching with coupling.

6 Check Pump is not rotate in reverse direction.

7 Check all pipe line flange & coupling nut bolt properly tight.

8 Check pump suction & discharge valve closed.

PRECHECKS AND ACTION BY DESK ENGINEER

S Description Ok Not Ok Remarks

No

1 Check MCC panel feeder is ready.

2 Check control supply is healthy.

3 Check sump level.

4 Check local push button released.

OPERATING PROCEDURE -

Sr. RESPONSIBILITY

No Description UCE DE FE E

. E

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Assistant Manager Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/RWP/01 (R1)

Power from knowledge

SOP For RECOVERY WATER PUMP

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 6

PRE- START CHECKS:

1 All permits and cross permits have been returned.

2 Power supply and control power supply available.

3 Pump suction & discharge valve closed.

4 Water Level in Recycle Water Bin is not high.

START PERMISSIVE :

1 Pump suction & discharge valve closed.

2 Sump level should be normal.

3 Emergency push button is in release condition.

PUMP START UP SEQUENCE :

1 Open the Recovery water pump suction valve.

2 Start the Recovery water pump.

3 Open the Recovery water pump discharge valve.

SHUTDOWN SEQUENCE:

1.PLANNED SHUTDOWN :

1 Insure that stand by Recovery pump is running condition.

2 Stop the Recovery water pump & closed the discharge & suction valve.

3 Rectify the probable problem, if any.

2. TRIPPING OF LP WATER PUMP :If suddenly pump trips

1 Closed the pump discharge & suction valve.

2 Try to start stand by Recovery water pump as above

3. EMERGENCY SHUT DOWN:

1 There is the apparent abnormal noise/Vibration after starting the pump.

2 The pump & motor bearing temperature is high.

3 When discharge line is leakage.

4 When endangering the safety of person and equipment.

5 Water in recovery water sump is ‘Low’.

6 Water level in Recover water Bin is ‘High’.

INTERLOCKS : Remarks

1 Sump level is danger low.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Assistant Manager Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/RWP/01 (R1)

Power from knowledge

SOP For RECOVERY WATER PUMP

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 6

2 Pump suction & discharge open feedback.

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

DO’s & DONT’s :

DO’s :

1. Ensure Discharge is closed before stating of Pump.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Assistant Manager Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/OPR/RWP/01 (R1)

Power from knowledge

SOP For RECOVERY WATER PUMP

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 6 of 6

2. Ensure Line Pressure does not goes up beyond receoomended pressure by OEM.

3. Before starting the Pump, ensure Sump Level Transmitter is working properly.

DONT’s :

1. Don’t run the Pump if discharge pressure becomes low.

2. Don’t run the Pump if Pump drawing high current continuously..

3. Don’t run the Slurry Pump if huge amount of ash laden water is coming from BA Dyke.

4. Don’t start/stop the Pump frequently.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Assistant Manager Designation: Designation:

Você também pode gostar

- SMP For Sealing Water Pump Multi Stage.Documento13 páginasSMP For Sealing Water Pump Multi Stage.SonratAinda não há avaliações

- Installation Manual for CODEL Model D-CEM1000/1001 Opacity MonitorDocumento76 páginasInstallation Manual for CODEL Model D-CEM1000/1001 Opacity MonitorshivanshAinda não há avaliações

- Handling and Use of Sulfur Hexafluoride GasDocumento8 páginasHandling and Use of Sulfur Hexafluoride GasممشطAinda não há avaliações

- Sop For Flushing Water PumpDocumento6 páginasSop For Flushing Water PumpSonratAinda não há avaliações

- Catalyst Loading Work InstructionDocumento4 páginasCatalyst Loading Work Instructionvishal bailurAinda não há avaliações

- STG Instrument ListDocumento12 páginasSTG Instrument Listhari reddyAinda não há avaliações

- SMP For Vacuum PumpDocumento9 páginasSMP For Vacuum PumpSonratAinda não há avaliações

- Sop For Eco SystemDocumento6 páginasSop For Eco SystemSonratAinda não há avaliações

- Sop For Concentrator (r1)Documento5 páginasSop For Concentrator (r1)Sonrat100% (1)

- ATEX Ex-EDocumento10 páginasATEX Ex-EBrajan's B.Ainda não há avaliações

- SMP For Supply Water PumpDocumento13 páginasSMP For Supply Water PumpSonratAinda não há avaliações

- SMP For Supply Water PumpDocumento13 páginasSMP For Supply Water PumpSonratAinda não há avaliações

- FluidizingDocumento13 páginasFluidizingSonratAinda não há avaliações

- FluidizingDocumento13 páginasFluidizingSonratAinda não há avaliações

- Instruments Index RO Plant YTMDocumento8 páginasInstruments Index RO Plant YTMNavneet SinghAinda não há avaliações

- Sop For Vent FilterDocumento6 páginasSop For Vent FilterSonratAinda não há avaliações

- IC-7100 Service ManualDocumento84 páginasIC-7100 Service ManualAndy CowleyAinda não há avaliações

- CSS Grade 10 Q3 LAS1Documento7 páginasCSS Grade 10 Q3 LAS1Rainier Doctolero100% (1)

- KSK Mahanadi Thermal Power Project Control Write UpDocumento10 páginasKSK Mahanadi Thermal Power Project Control Write UpSonratAinda não há avaliações

- SMP For Ba Overflow PumpDocumento14 páginasSMP For Ba Overflow PumpSonratAinda não há avaliações

- SMP For Fluidizing Air BlowerDocumento20 páginasSMP For Fluidizing Air BlowerSonrat100% (1)

- Transformer Trouble ShootingDocumento4 páginasTransformer Trouble ShootingRitesh JaiswalAinda não há avaliações

- SMP For Slurry PumpDocumento14 páginasSMP For Slurry PumpSonrat100% (1)

- FAT Procedure (B) 12.10.15Documento5 páginasFAT Procedure (B) 12.10.15Richard AdolfAinda não há avaliações

- DH3-31MA-T-SCT-0018 Commissioning Procedure of Varying Load of Turbine-Generator REV.0ADocumento6 páginasDH3-31MA-T-SCT-0018 Commissioning Procedure of Varying Load of Turbine-Generator REV.0AhungAinda não há avaliações

- SMP For Agitator (Slurry Sump)Documento9 páginasSMP For Agitator (Slurry Sump)SonratAinda não há avaliações

- GEH-6676 - EX2100 and EX2100e Excitation ControlDocumento60 páginasGEH-6676 - EX2100 and EX2100e Excitation ControlLê Trung DũngAinda não há avaliações

- Resource Dependent Activity Type in P6Documento7 páginasResource Dependent Activity Type in P6MuhammadIqbalMughalAinda não há avaliações

- ESPDocumento5 páginasESPKuntal SatpathiAinda não há avaliações

- B0700BG BDocumento64 páginasB0700BG BRodrigoCastilloAcostaAinda não há avaliações

- Sop For LP Pump (R1)Documento6 páginasSop For LP Pump (R1)SonratAinda não há avaliações

- Sop For LP PumpDocumento5 páginasSop For LP PumpSonratAinda não há avaliações

- GV Series Pumps Booster Set in EgyptDocumento144 páginasGV Series Pumps Booster Set in EgyptRheoserve Industrial SolutionsAinda não há avaliações

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDocumento6 páginasKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratAinda não há avaliações

- Fs Nice Actimize Brochure - Watch List Filtering SolutionDocumento0 páginaFs Nice Actimize Brochure - Watch List Filtering Solutionapi-245482086Ainda não há avaliações

- Motor technical specificationsDocumento2 páginasMotor technical specificationsmishtinilAinda não há avaliações

- Sop For Eco-Hp Pump (r1)Documento6 páginasSop For Eco-Hp Pump (r1)SonratAinda não há avaliações

- Introdution Multinet PakistanDocumento23 páginasIntrodution Multinet PakistanDemureAinda não há avaliações

- Maintaining Fly Ash Silo BlowersDocumento4 páginasMaintaining Fly Ash Silo BlowersSonratAinda não há avaliações

- Sop For LP PumpDocumento5 páginasSop For LP PumpSonratAinda não há avaliações

- Improved Level Control of A Feed Water ValveDocumento7 páginasImproved Level Control of A Feed Water ValveAli Bari100% (1)

- DPT Smart Pressure TransmitterDocumento15 páginasDPT Smart Pressure Transmitterprasanta_bbsrAinda não há avaliações

- MQP of PanelDocumento1 páginaMQP of Panelrahulchitrakoot123Ainda não há avaliações

- Coagulant Mixing and FlocculationDocumento6 páginasCoagulant Mixing and FlocculationOlivia NorrAinda não há avaliações

- 3M™ Activated Carbon Filters - Data Sheet (PDF 670.8 K) PDFDocumento2 páginas3M™ Activated Carbon Filters - Data Sheet (PDF 670.8 K) PDFshwethakunjilna100% (1)

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocumento24 páginasThermoplastic Flanges: Technical Information Weights & DimensionsAngs TazAinda não há avaliações

- LT Switchgear Technical SpecificationDocumento28 páginasLT Switchgear Technical SpecificationUday Sankar YadavAinda não há avaliações

- My Latest CV - EngineerDocumento3 páginasMy Latest CV - EngineersasibhushanAinda não há avaliações

- Marley Aquatower: Cooling TowerDocumento28 páginasMarley Aquatower: Cooling TowerMauricio Damián Padilla SalgadoAinda não há avaliações

- Unit Station ChangeoverDocumento6 páginasUnit Station ChangeoversambhuAinda não há avaliações

- Technical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)Documento12 páginasTechnical Bid T - 3560: (Note: Photo Copy of SSI / NSIC Certificate Is Not Acceptable)SeresdfrtAinda não há avaliações

- Double Pass Operating ManualDocumento12 páginasDouble Pass Operating ManualNorrelle Joy MagbanuaAinda não há avaliações

- Micro ScannerDocumento2 páginasMicro ScannerArun KumarAinda não há avaliações

- Descaling SOPDocumento2 páginasDescaling SOPTauqir Shaukat100% (1)

- SIDE STREAM FILTRATION HIGH CAPACITY AND LOW FLUSH WATER LOSSDocumento1 páginaSIDE STREAM FILTRATION HIGH CAPACITY AND LOW FLUSH WATER LOSSAmit ChaudharyAinda não há avaliações

- Durgapur Steel Plant 11kV Switchboard Replacement Tender SpecificationDocumento180 páginasDurgapur Steel Plant 11kV Switchboard Replacement Tender SpecificationKanupriya AgarwalAinda não há avaliações

- Acid Rinsing FRP TankDocumento2 páginasAcid Rinsing FRP Tankkasvikraj0% (1)

- Equip SCH Rev 3.0Documento26 páginasEquip SCH Rev 3.0Weain DionAinda não há avaliações

- AGZ026BDocumento106 páginasAGZ026Bciperu55Ainda não há avaliações

- Esm ManualDocumento4 páginasEsm ManualAkhil BhadouriaAinda não há avaliações

- Deluge Valve - SD-DVA PDFDocumento15 páginasDeluge Valve - SD-DVA PDFboxyfunAinda não há avaliações

- Equal-Friction-Method (From Engineering Toolbox)Documento2 páginasEqual-Friction-Method (From Engineering Toolbox)Naw AzAinda não há avaliações

- Distribution Substations For Electrical Engineers - BeginnersDocumento14 páginasDistribution Substations For Electrical Engineers - BeginnersPrashant RajputAinda não há avaliações

- Operations ManualDocumento19 páginasOperations ManuallogesniceAinda não há avaliações

- POWER PLANT RAW WATER SYSTEMDocumento21 páginasPOWER PLANT RAW WATER SYSTEMAniesh MahajanAinda não há avaliações

- JSW Cement FZE Annex 11 List of Spare PartsDocumento16 páginasJSW Cement FZE Annex 11 List of Spare Partsabdullah amanullahAinda não há avaliações

- AHU Design GuidelinesDocumento3 páginasAHU Design GuidelinesAsad ansariAinda não há avaliações

- Functional Change of Sac Into Iac: Standard Field Operating ProcedureDocumento7 páginasFunctional Change of Sac Into Iac: Standard Field Operating ProcedureMithun Singh RajputAinda não há avaliações

- VFD Price List 28 Nov 2014Documento12 páginasVFD Price List 28 Nov 2014jsrplc7952Ainda não há avaliações

- Itp: Acidification Vessel: Tag: A-325-02-01-C3Documento8 páginasItp: Acidification Vessel: Tag: A-325-02-01-C3Jeroan AyamAinda não há avaliações

- Motor Selection FoliosDocumento26 páginasMotor Selection Folios8085roAinda não há avaliações

- Instrument Air Dryer and Instrument Air ReceiverDocumento4 páginasInstrument Air Dryer and Instrument Air ReceiverAzizul HakimAinda não há avaliações

- Solving Engine Loss Issues with Root Cause AnalysisDocumento13 páginasSolving Engine Loss Issues with Root Cause AnalysisashishsinglaAinda não há avaliações

- HJDocumento4 páginasHJShajil VazhakkalilAinda não há avaliações

- Configure and operate TT412, TT12A-TT12C timersDocumento1 páginaConfigure and operate TT412, TT12A-TT12C timersPasindu PriyankaraAinda não há avaliações

- General Specification For Electric Actuators - Integral Motor ControlDocumento4 páginasGeneral Specification For Electric Actuators - Integral Motor ControlschgirlAinda não há avaliações

- Environmental Control System A Complete Guide - 2020 EditionNo EverandEnvironmental Control System A Complete Guide - 2020 EditionAinda não há avaliações

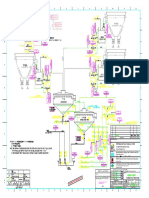

- Bah Side ViewDocumento1 páginaBah Side ViewSonratAinda não há avaliações

- Part List - BEL0800 PDFDocumento1 páginaPart List - BEL0800 PDFSonratAinda não há avaliações

- Bah ElevationDocumento1 páginaBah ElevationSonratAinda não há avaliações

- SMP For Dry Ash UnloaderDocumento8 páginasSMP For Dry Ash UnloaderSonratAinda não há avaliações

- HCSD PDFDocumento1 páginaHCSD PDFSonratAinda não há avaliações

- PM For Fly Ash Dry SystemDocumento31 páginasPM For Fly Ash Dry SystemSonratAinda não há avaliações

- ESP-FLD. BLOWER-Model PDFDocumento1 páginaESP-FLD. BLOWER-Model PDFSonratAinda não há avaliações

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDocumento1 páginaECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratAinda não há avaliações

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDocumento1 páginaBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratAinda não há avaliações

- ASH WATER PUMP HOUSE-Model PDFDocumento1 páginaASH WATER PUMP HOUSE-Model PDFSonratAinda não há avaliações

- Pdi EspDocumento1 páginaPdi EspSonratAinda não há avaliações

- Silo Unloading ModelDocumento1 páginaSilo Unloading ModelSonratAinda não há avaliações

- StructureDocumento1 páginaStructureSonratAinda não há avaliações

- Over Flow Pump Concentrator Buffer Tank ModelDocumento1 páginaOver Flow Pump Concentrator Buffer Tank ModelSonratAinda não há avaliações

- Compressor House ModelDocumento1 páginaCompressor House ModelSonratAinda não há avaliações

- Water & Slurry BalanceDocumento1 páginaWater & Slurry BalanceSonratAinda não há avaliações

- Silo Blower Compressor ModelDocumento1 páginaSilo Blower Compressor ModelSonratAinda não há avaliações

- SEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingDocumento1 páginaSEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingSonratAinda não há avaliações

- VP To Buffr Hopper-ModelDocumento1 páginaVP To Buffr Hopper-ModelSonratAinda não há avaliações

- Innovating To Create IT-Based New Business Opportunities at UPSDocumento17 páginasInnovating To Create IT-Based New Business Opportunities at UPSjieminaAinda não há avaliações

- MPMCDocumento47 páginasMPMCvaseem_ahmedAinda não há avaliações

- PC Software EddyAssist EDocumento14 páginasPC Software EddyAssist EizmitlimonAinda não há avaliações

- 6av6 640 0ca11 0ax0 Touchpanel TP177 Micro Siemens ManualDocumento32 páginas6av6 640 0ca11 0ax0 Touchpanel TP177 Micro Siemens Manualyassine ELMHAinda não há avaliações

- GS-KB55S Operating InstuctionsDocumento8 páginasGS-KB55S Operating InstuctionsPiero CaprettiAinda não há avaliações

- ElecEng4FJ4 Module03 PDFDocumento22 páginasElecEng4FJ4 Module03 PDFFrew FrewAinda não há avaliações

- Curriculum VitaeDocumento1 páginaCurriculum VitaeImamMukhriAinda não há avaliações

- 3D Network Blu-Ray / Disc Player With Media Library: Service ManualDocumento147 páginas3D Network Blu-Ray / Disc Player With Media Library: Service ManualPaul KupasAinda não há avaliações

- Aashto 1972 CarolDocumento30 páginasAashto 1972 CarolIjeal KuAinda não há avaliações

- DVCon Europe 2015 TA1 5 PaperDocumento7 páginasDVCon Europe 2015 TA1 5 PaperJon DCAinda não há avaliações

- Ab Ansys Hfss 3d Data SheetDocumento3 páginasAb Ansys Hfss 3d Data SheetmikeAinda não há avaliações

- Chapter 3 PCM and TDMDocumento49 páginasChapter 3 PCM and TDMjudgelightAinda não há avaliações

- TE FusionDocumento8 páginasTE Fusionculeros1Ainda não há avaliações

- Marine Elevators (200902)Documento6 páginasMarine Elevators (200902)Arky HarkyanAinda não há avaliações

- IHM Board ControlsDocumento1 páginaIHM Board ControlsjoseAinda não há avaliações

- NSFAS Laptop FormDocumento2 páginasNSFAS Laptop FormKagiso China'män NtsaneAinda não há avaliações

- SQL IndexDocumento20 páginasSQL IndexKeerthana PAinda não há avaliações

- IT518 - Game Design and Development Syllabus With Learning OutcomesDocumento4 páginasIT518 - Game Design and Development Syllabus With Learning OutcomesJagan LankaAinda não há avaliações

- ZXWN EIR Technical SpecificationDocumento35 páginasZXWN EIR Technical SpecificationCoachArun MishraAinda não há avaliações

- UniversalDocumento8 páginasUniversalMateus LoufaresAinda não há avaliações

- IISP 2020 - B K RoyDocumento37 páginasIISP 2020 - B K RoyHimangshu DekaAinda não há avaliações

- DEMOLITION WORKS CONCRETE PLATFORMSDocumento7 páginasDEMOLITION WORKS CONCRETE PLATFORMSRazvanBucurAinda não há avaliações

- HUAWEI WATCH GT3 42mm User Guide - (MIL-B19,01, EN-GB)Documento39 páginasHUAWEI WATCH GT3 42mm User Guide - (MIL-B19,01, EN-GB)wijayanataAinda não há avaliações

- 55W Constant Current LED Driver DIP Switch SeriesDocumento5 páginas55W Constant Current LED Driver DIP Switch SeriesE ShAinda não há avaliações