Escolar Documentos

Profissional Documentos

Cultura Documentos

Hydraulic Comparison Test Pump Model CPP1200-X: Applications

Enviado por

Toy HeartTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hydraulic Comparison Test Pump Model CPP1200-X: Applications

Enviado por

Toy HeartDireitos autorais:

Formatos disponíveis

Calibration technology

Hydraulic comparison test pump

Model CPP1200-X

WIKA data sheet CT 91.08

Applications

■■ Simple hydraulic test pressure generation on-site, in the

laboratory or in the workshop

■■ For the testing, adjustment and calibration of all types of

pressure measuring instruments

■■ Hydraulic pressure generation up to 1,200 bar

Special features

■■ Precisely adjustable dual-area spindle pump for filling,

pressure generation and fine adjustment of pressure

■■ Freely rotating test connections (i.e. measuring

instruments can be orientated)

■■ Proven technology of the model CPB3800 pressure Comparison test pump CPP1200-X

balance

■■ Compact dimensions

■■ Low weight

Description

Application areas

Test pumps serve as pressure generators for the testing, pump with switching valves enables rapid filling of the test

adjustment and calibration of mechanical and electronic system and smooth pressure generation.

pressure measuring instruments through comparative At the same time, the precisely adjustable spindle pump also

measurements. These units can be used in the laboratory or serves for pressure fine adjustment. A control schematic for

workshop, or on site at the measuring point. pressure generation on the instrument base facilitates quick

and easy operation.

Easy operation

By connecting the test item and a sufficiently accurate The two test connections are equipped with G ½ female

reference pressure measuring instrument to the test pump, loose union connections. Corresponding thread adapters

the same pressure will act on both measuring instruments. By are available for the calibration of instruments with different

comparison of the two measured values at any given pressure connection threads.

value, a check of the accuracy and/or adjustment of the

pressure measuring instrument under test can be carried out. Compact instrument design

The CPP1200-X is also particularly notable for its compact

Easy handling dimensions, which are not altered during operation, since the

The model CPP1200-X comparison test pump is a hydraulic spindle runs within the pump body.

comparison test pump for generating pressure up to 1,200 bar. With those dimensions, the exceptionally robust ABS plastic

It is technically identical to the instrument base of the model housing and the low weight associated with these, the

CPB3800 pressure balance. The integrated dual-area spindle CPP1200-X is also particularly suited for on-site applications.

WIKA data sheet CT 91.08 ∙ 06/2014 Page 1 of 5

Data sheets showing similar products:

Pneumatic hand test pump; model CPP7; see data sheet CT 91.04

Pneumatic hand test pump; model CPP30; see data sheet CT 91.06

Hydraulic hand test pump; models CPP700-H and CPP1000-H; see data sheet CT 91.07

Hydraulic test pumps; models CPP1000-X to CPP7000-X; see data sheet CT 91.05

Specifications Model CPP1200-X

Pressure range 0 ... 1,200 bar

Pressure transmission medium Hydraulic fluid from mineral oil/clean water, free of calcium-carbonate 1)

Reservoir 170 cm³

Pressure connections

Test item connection 2 x G ½ female thread, loose union connection

Distance between test item connections 290 mm

Piston of spindle pump

Piston diameter, low-pressure piston 31.2 mm

Piston diameter, high-pressure piston 12.7 mm

Displacement approx. 10 cm³

Material

Wetted parts Austenitic stainless steel, high tensile brass, nitrile rubber

Permissible ambient conditions

Operating temperature 0 ... 40 °C

Instrument base

Dimensions 401 x 397 x 155 mm (W x D x H), for details, see technical drawings

Weight 13.5 kg

1) Other pressure transmission media available on request.

Storage case (option)

Material Wood

Dimensions 664 x 614 x 380 mm (W x D x H)

Weight 8.5 kg

CE conformity

Pressure equipment directive 97/23/EC (PS > 1,000 bar; Module A, pressure accessory)

Approvals and certificates, see website

Page 2 of 5 WIKA data sheet CT 91.08 ∙ 06/2014

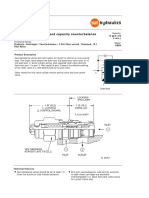

Dimensions in mm

1 1

(1) Test item connections

2 (2) High-pressure shut-off valve

(3) Low-pressure shut-off valve

6 (4) Dual-area spindel pump with star handle

(5) Rotatable feet

(6) Reservoir with sealing plug

3

(7) Pressure generation control schematic

Test item connection

Adapter, see scope

of delivery

Sealing ring

USIT 10.7 x 18 x 1.5

Oil collecting tray

Control schematic on the CPP1200-X instrument base

WIKA data sheet CT 91.08 ∙ 06/2014 Page 3 of 5

Accessories

Designation/Variant Order no.

Storage case for CPP1200-X instrument base 14031237

“BSP” adapter set for G ½ B male test item connector to G ⅛, G ¼, G ⅜ and G ½ female 14031238

“NPT” adapter set for G ½ B male test item connector to ⅛ NPT, ¼ NPT, ⅜ NPT and ½ NPT female 14031239

“Metric” adapter set for G ½ B male test item connector to M12 x 1.5 and M20 x 1.5 female 14031242

Adapter for test item connection, G ½ B male on M16 x 1.5 male with sealing cone, material: stainless steel hardened 11580454

Test item connection piece, G ¾ female to G ½ female, loose union connection 14031251

90° angle connection, for test items with back mounting connection 1564838

Sealing and maintenance set for instrument base, standard version 14031255

Hydraulic fluid based on VG22 mineral oil in plastic bottle, content 0.5 litre 2099954

Tool set consisting of open-ended spanner, BSP adapter, replacement seals, pointer remover and pointer punch 14031263

Recommended reference pressure measuring instruments:

Precision digital pressure gauge model CPG1000

Measuring ranges: up to 700 bar

Accuracy: 0.05 % of span

For further specifications see data sheet CT 10.01

Hand-held pressure indicator model CPH6300

Measuring ranges: up to 1,000 bar

Accuracy: 0.2 % of span

For further specifications see data sheet CT 12.01

Precision hand-held pressure indicator model CPH6400

Measuring ranges: up to 6,000 bar

Accuracy: up to 0.025 % of span

For further specifications see data sheet CT 14.01

ProcessCalibrator model CPH6000

Measuring ranges: up to 6,000 bar

Accuracy: up to 0.025 % of span

For further specifications see data sheet CT 15.01

Page 4 of 5 WIKA data sheet CT 91.08 ∙ 06/2014

Scope of delivery

■■ Instrument base

■■ Dual-area spindle pump for filling, pressure generation

and pressure fine adjustment

■■ 2 test item connections with G ½ female thread, loose

union connection

■■ Adapter set for test item selectable from 3 different sets:

- Set of adapters “BSP” G ½ male on G ⅛, G ¼, G ⅜ and

G ½ female

- Set of adapters “NPT” G ½ male on ⅛ NPT, ¼ NPT,

⅜ NPT and ½ NPT female

- Set of adapters “metric” G ½ male on M12 x 1.5 and

M20 x 1.5 female

■■ VG22 mineral oil (0.5 litre)

■■ Tool and maintenance set

■■ Operating instructions in German and English language

Options

■■ Versions for medium water or Skydrol Calibration assembly CPP1200-X with test gauge as

■■ Storage case for instrument base reference instrument and test item

Ordering information

Model / Package / Medium / Standard set of adapters / Additional adapter set / Angle connection / Storage case / Accessories /

Additional order information

© 2013 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet CT 91.08 ∙ 06/2014 Page 5 of 5

06/2014 GB

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

Você também pode gostar

- Hydraulic Hand Test PumpModels CPP700-HDocumento5 páginasHydraulic Hand Test PumpModels CPP700-Hcaptain essamAinda não há avaliações

- Wika-10000 Psi PDFDocumento6 páginasWika-10000 Psi PDFMEBERUAinda não há avaliações

- Ds ct9110 en CoDocumento6 páginasDs ct9110 en CoJoby JacobAinda não há avaliações

- Hydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test PumpDocumento10 páginasHydraulic Test Pumps Models CPP1000-M, CPP1000-L, Hand Spindle Pump Models CPP1000-X, CPP1600-X, CPP7000-X, Comparison Test Pumppablo bazaesAinda não há avaliações

- PresionCalibracion PDFDocumento24 páginasPresionCalibracion PDFDimas Irman AnugrahAinda não há avaliações

- DS CT9107 GB 10172Documento4 páginasDS CT9107 GB 10172Sameer UsmaniAinda não há avaliações

- Sysmex CA-1500 - PMI - ProDocumento2 páginasSysmex CA-1500 - PMI - ProBakhrom KasimovAinda não há avaliações

- Product Specification CT800 T4 38B 1Documento4 páginasProduct Specification CT800 T4 38B 1PeterAinda não há avaliações

- InstrumentationDocumento15 páginasInstrumentationLenis Ceron0% (1)

- Filter Pressure Drop - Quantum Neo BDE - 20Documento2 páginasFilter Pressure Drop - Quantum Neo BDE - 20leonel rinconesAinda não há avaliações

- Nitrogen Gas Charging & Testing Kit PC280/70: Discover More at WWW - Hydrotechnik.co - UkDocumento3 páginasNitrogen Gas Charging & Testing Kit PC280/70: Discover More at WWW - Hydrotechnik.co - UkYoaquin AAinda não há avaliações

- cpc030 Datasheet PDFDocumento4 páginascpc030 Datasheet PDFChen CYAinda não há avaliações

- Two Three Way Ball ValvesDocumento6 páginasTwo Three Way Ball ValvesUzair AnsariAinda não há avaliações

- Dead Weight Testers: Industrial Pressure CalibratorDocumento8 páginasDead Weight Testers: Industrial Pressure CalibratorKhezzari MerwenAinda não há avaliações

- CO2 Fire Suppression SystemsDocumento18 páginasCO2 Fire Suppression Systemsmarpaung saberindoAinda não há avaliações

- User - Manual 16 2080Documento18 páginasUser - Manual 16 2080Daniel RiveraAinda não há avaliações

- C6MKII - Fluid Friction MeasurementsDocumento6 páginasC6MKII - Fluid Friction MeasurementsRaja Doubts0% (1)

- Adittel 912Documento1 páginaAdittel 912RimmerAinda não há avaliações

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Documento2 páginasCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloAinda não há avaliações

- Catalog Hydraulic Pressure Balance Cpb5800Documento11 páginasCatalog Hydraulic Pressure Balance Cpb5800Fulbert SuriatmadjaAinda não há avaliações

- 0023 EN 202008 BitumenDocumento16 páginas0023 EN 202008 BitumenOmar SaaedAinda não há avaliações

- Ds Pressure CalibratorsDocumento27 páginasDs Pressure CalibratorsDennis masihAinda não há avaliações

- Product Data Sheet Micro Motion cng050 Compressed Natural Gas Flow Meters en 64042Documento16 páginasProduct Data Sheet Micro Motion cng050 Compressed Natural Gas Flow Meters en 64042ElcioAinda não há avaliações

- M0627Documento24 páginasM0627subhransubaral1Ainda não há avaliações

- QuestionnaireDocumento2 páginasQuestionnairenmapeshawarAinda não há avaliações

- Low Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureDocumento1 páginaLow Pressure Test Pump Additel 912: Generate 95% Vacuum To 60 Psi (4 Bar) PressureSiéJustinDembeleAinda não há avaliações

- G77x - 77xK Valve - CatalogueDocumento8 páginasG77x - 77xK Valve - CatalogueEzgi PelitAinda não há avaliações

- Catalog Refrigeration PDFDocumento138 páginasCatalog Refrigeration PDFJavier AffifAinda não há avaliações

- Sampling ProbeDocumento5 páginasSampling Probetriminhdang_phar6701Ainda não há avaliações

- Nantai CatalogDocumento39 páginasNantai Catalognilton cesar marcavillaca quispeAinda não há avaliações

- D 631 Series ValvesDocumento12 páginasD 631 Series ValvesNo PromisesAinda não há avaliações

- Portable Pneumatic Calibrator Series 65-120: Special FeaturesDocumento4 páginasPortable Pneumatic Calibrator Series 65-120: Special FeaturesOmar RockeAinda não há avaliações

- Bomba Presion Neumatica Hidraulica King NutrionicsDocumento5 páginasBomba Presion Neumatica Hidraulica King NutrionicsMariela ValenciaAinda não há avaliações

- Catalogue Nantai-Sophia YeDocumento40 páginasCatalogue Nantai-Sophia YeKassia FolegoAinda não há avaliações

- DownloadDocumento11 páginasDownloadMaria Celina Machado de MedeirosAinda não há avaliações

- Compact Prover 8in-40in 166KBDocumento4 páginasCompact Prover 8in-40in 166KBLuis BobadillaAinda não há avaliações

- 2:1 Pilot Ratio, Vented Counterbalance ValveDocumento3 páginas2:1 Pilot Ratio, Vented Counterbalance Valvefrancis_15inAinda não há avaliações

- SC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHDocumento60 páginasSC-600 - Electro-Pneumatic - Devices - Pressure Control Valves REXROTHadrianahoukiAinda não há avaliações

- Standard Procedure For Calibration of GaugesDocumento12 páginasStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyAinda não há avaliações

- 01intro Baxter 1550Documento12 páginas01intro Baxter 1550Victor ManuelAinda não há avaliações

- Procedures Manual Volume FourDocumento10 páginasProcedures Manual Volume FourMuhammad saadAinda não há avaliações

- Pressure CalibratorsDocumento10 páginasPressure CalibratorsClaudio SantellanesAinda não há avaliações

- 181 Darley254Documento1 página181 Darley254Jose MelloAinda não há avaliações

- BR Valves Test Benches en Co 61985 PDFDocumento12 páginasBR Valves Test Benches en Co 61985 PDFcafe negroAinda não há avaliações

- Nantai Automotive Technology Co., LTD Taian Nantai Experimental Equipment Co. LTDDocumento35 páginasNantai Automotive Technology Co., LTD Taian Nantai Experimental Equipment Co. LTDမင္းထက္အာကာAinda não há avaliações

- Pavetest DivisionDocumento46 páginasPavetest DivisionjohanAinda não há avaliações

- C16601 Proinert®2 Selector ValveDocumento2 páginasC16601 Proinert®2 Selector Valvevld20082Ainda não há avaliações

- Pneumatic Pressure Balance Model CPB5000: ApplicationsDocumento12 páginasPneumatic Pressure Balance Model CPB5000: ApplicationsEliseo PardoAinda não há avaliações

- CF Hydraulic Sampling Products.01Documento18 páginasCF Hydraulic Sampling Products.01Patrick FoAinda não há avaliações

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocumento4 páginas5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevAinda não há avaliações

- STERIS - Finn Aqua T Series Pure Steam Generator - TDS - SD791Documento8 páginasSTERIS - Finn Aqua T Series Pure Steam Generator - TDS - SD791Anderson BaziaAinda não há avaliações

- 916 - Pneumatic Pressure Test Pump PDFDocumento1 página916 - Pneumatic Pressure Test Pump PDFJokoSusiloAinda não há avaliações

- Axial Piston Variable Pump A2VKDocumento12 páginasAxial Piston Variable Pump A2VKAkbarmoradiAinda não há avaliações

- Chemcad Sizing ToolsDocumento48 páginasChemcad Sizing Toolsparedanil100% (1)

- 299HDocumento20 páginas299HJulian Esteban Arnaiz VargasAinda não há avaliações

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNo EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNota: 5 de 5 estrelas5/5 (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideNo EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideNota: 4 de 5 estrelas4/5 (8)

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsNo Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsNota: 1 de 5 estrelas1/5 (1)

- Lexus JTJBT20X740057503 AllSystemDTC 20230702045631Documento2 páginasLexus JTJBT20X740057503 AllSystemDTC 20230702045631Venerable DezzyAinda não há avaliações

- Watercolor SecretsDocumento60 páginasWatercolor Secretsmissdoisneau98% (47)

- 1 s2.0 S0956713515002546 Main PDFDocumento9 páginas1 s2.0 S0956713515002546 Main PDFIfwat ThaqifAinda não há avaliações

- UNDP NP Dhangadhi SWM TOR FinalDocumento4 páginasUNDP NP Dhangadhi SWM TOR FinalNirmal K.c.Ainda não há avaliações

- 4th Six Weeks RecoveryDocumento8 páginas4th Six Weeks RecoveryAshley HighAinda não há avaliações

- Heron's Formula For The Area of A Triangle - Shailesh A ShiraliDocumento9 páginasHeron's Formula For The Area of A Triangle - Shailesh A ShiraliAltananyAinda não há avaliações

- 801 Aeronca PDFDocumento17 páginas801 Aeronca PDFVishveshAinda não há avaliações

- Greyhound Free Patt.Documento14 páginasGreyhound Free Patt.claire_garlandAinda não há avaliações

- Baldor Motor TestDocumento14 páginasBaldor Motor TestChecho BuenaventuraAinda não há avaliações

- Appetizer Summative TestDocumento36 páginasAppetizer Summative TestArgelynPadolinaPedernalAinda não há avaliações

- A Duality Principle For The Entanglement Entropy of Free Fermion SystemsDocumento12 páginasA Duality Principle For The Entanglement Entropy of Free Fermion SystemsCroco AliAinda não há avaliações

- Kia September 2020 Price List: Picanto ProceedDocumento2 páginasKia September 2020 Price List: Picanto ProceedCaminito MallorcaAinda não há avaliações

- NMMT City Bus SystemDocumento3 páginasNMMT City Bus Systemharish guptaAinda não há avaliações

- Ddrive Transmission ReportDocumento43 páginasDdrive Transmission Reportelah150% (2)

- The DSG DQ200 LifespanDocumento1 páginaThe DSG DQ200 Lifespanqt99qzyhrbAinda não há avaliações

- MicrosoftDynamicsNAVAdd OnsDocumento620 páginasMicrosoftDynamicsNAVAdd OnsSadiq QudduseAinda não há avaliações

- Titanvene ll0209sr Product Data SheetpdfDocumento1 páginaTitanvene ll0209sr Product Data SheetpdfHanry WRAinda não há avaliações

- Instant Download Professional Nursing Practice Concepts Perspectives 7th Blais Hayes Test Bank PDF ScribdDocumento32 páginasInstant Download Professional Nursing Practice Concepts Perspectives 7th Blais Hayes Test Bank PDF ScribdDanielle Searfoss100% (10)

- SMA - Core 1 - IEC62109-2 - 0 Test ReportDocumento6 páginasSMA - Core 1 - IEC62109-2 - 0 Test ReportFurqan HamidAinda não há avaliações

- 0707-Passive VoiceDocumento6 páginas0707-Passive VoiceKhôi TrầnAinda não há avaliações

- Rolling Bearings VRMDocumento2 páginasRolling Bearings VRMRollerJonnyAinda não há avaliações

- Presentation On Anther Culture: Submitted To Submitted byDocumento22 páginasPresentation On Anther Culture: Submitted To Submitted byvishnu0751Ainda não há avaliações

- TSBDocumento3 páginasTSBnoe dela vegaAinda não há avaliações

- Sugar Factory InsulationDocumento29 páginasSugar Factory InsulationZerihun Negash100% (1)

- Atlas-Complejidad Económica PDFDocumento362 páginasAtlas-Complejidad Económica PDFRafael QuiñonesAinda não há avaliações

- Concrete ON MALDIVESDocumento55 páginasConcrete ON MALDIVESKãrthìçk JkrAinda não há avaliações

- Aoc f22sDocumento43 páginasAoc f22sJoao Jose Santos NetoAinda não há avaliações

- Photography Techniques (Intermediate)Documento43 páginasPhotography Techniques (Intermediate)Truc Nguyen100% (2)

- Research Report 2011 Asses Water ChambalDocumento41 páginasResearch Report 2011 Asses Water Chambalsamyak sambhareAinda não há avaliações

- Vanilla Farming: The Way Forward: July 2019Documento6 páginasVanilla Farming: The Way Forward: July 2019mituAinda não há avaliações