Escolar Documentos

Profissional Documentos

Cultura Documentos

Work Instruction For Pressure Testing Pressure Testing Instruction For Test Pressure Upto 5000 Psi

Enviado por

jamil voraTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Work Instruction For Pressure Testing Pressure Testing Instruction For Test Pressure Upto 5000 Psi

Enviado por

jamil voraDireitos autorais:

Formatos disponíveis

Doc.

#: Annx-SOP-

15

WORK INSTRUCTION FOR PRESSURE TESTING Page # :1 of 3

PRESSURE TESTING INSTRUCTION FOR TEST PRESSURE UPTO 5000 PSI

KEEP AIR PRESSURE OF 6 TO 9 kg/mm2 AT AIR DRIVE SUPPLY INPUT POINT

Step 1: Keep open the release valve

Step 2: Keep control pressure for pump 1 and pump 2 at zero and keep pump 1 and

pump 2 at off position

Step 3: Start pump 1

Step 4 : Slightly increase control pressure of pump 1 so that pump 1 starts, Keep

pump 1 on at this position for two minutes [ This is to release any air in the

system] and then close release valve.

Step 5: Now slowly increase “Control Pressure” of pump 1 to achieve designed test

pressure as per Test Pressure Chart “Up to 5000 PSI”. [Note: If the pressure

increases beyond 5000 PSI, Relief valve will automatically open to release

extra pressure].

Step 6: Hold the test pressure till 3 minutes & check for leakage.

Step 7: Release the pressure and record the result.

Step 8: Repeat from step 1 to step 7, and at step 6 hold the pressure for 15 minutes.

Step 8: Turn pump 1 off and release the pressure by opening release valve.

Step 9: If more job to be tested at the same pressure then change job on testing bed.

Step 10: Close release valve.

Step 11: Start pump 1 and last test pressure will be achieved or you can achieve test

pressure using control pressure for pump 1. Test the job and record the

results. Repeat step 7 to step 10 to test more jobs of same test pressure.

Step 12: To terminate testing, Keep release valve open and turn off pump 1. And turn

control pressure of pump 1 at zero position.

Prepared By: Approved By:

Doc.#: Annx-SOP-

15

WORK INSTRUCTION FOR PRESSURE TESTING Page # :2 of 3

PRESSURE TESTING INSTRUCTION FOR TEST PRESSURE 5000 PSI to 30000

PSI

KEEP AIR PRESSURE OF 6 TO 9 kg/mm2 AT AIR DRIVE SUPPLY INPUT POINT

Step 1: Keep open the release valve

Step 2: Keep control pressure for pump 1 and pump 2 at zero and keep pump 1 and

pump 2 at off position

Step 3: Start pump 1

Step 4 : Slightly increase control pressure of pump 1 so that pump 1 starts, Keep

pump 1 on at this position for two minutes [ This is to release any air in the

system] and then close release valve.

Step 5 : Now slowly increase “Control Pressure” of pump 1 to achieve pressure “ Up to

5000 PSI”.[Note : If the pressure increases beyond 5000 PSI ,relief valve will

automatically open to release extra pressure].

Step 6: Start pump 2.

Step 7: Increase control pressure for pump 2 to achieve designed test pressure as

per test pressure chart “Up to 30,000 PSI”.

Step 8: Hold the test pressure till 3 minutes & check for leakage.

Step 9: Release the pressure and record the result.

Step 10: Repeat from step 1 to step 7, and at step 6 hold the pressure for 15 minutes.

Step 11: Turn pump 1 off and pump 2 and release the pressure by opening release

valve.

Step 12: If more job is to be tested at the same pressure then change job on the testing

bed.

Step 13: Close release valve.

Step 14: Start pump 1 and last pressure of 5000 PSI will be achieved. Then start pump

2 and you will achieve last test pressure. Pressure can be adjusted by control

pressure of pump 2.Test the job and record the results. Repeat steps 9 to

step 12 to test more jobs of same test pressure.

Step 15: To terminate testing, Keep release valve open and turn off pump 1 and pump

2.Also turn control pressure of pump 1 And pump 2 at zero position.

Prepared By: Approved By:

Doc.#: Annx-SOP-

15

WORK INSTRUCTION FOR PRESSURE TESTING Page # :3 of 3

The minimum TEST PRESSURE for API SPEC 6A

RATED WORKING PRESSURE HYDROSTATIC TEST PRESSURE

2000 PSI 4000 PSI

3000 PSI 6000 PSI

5000 PSI 10000 PSI

10000 PSI 15000 PSI

15000 PSI 22500 PSI

20000 PSI 30000 PSI

The minimum TEST DURATION for API SPEC 6A

PSL NO. 1st Cycle 2st Cycle

1 3 Minutes 15 Minutes

2 3 Minutes 15 Minutes

3 3 Minutes 15 Minutes

4 3 Minutes 15 Minutes

Prepared By: Approved By:

Você também pode gostar

- (Equip (Accumulator)Documento34 páginas(Equip (Accumulator)Nagendra Singh Ranawat100% (4)

- Friction Loss in PipeDocumento12 páginasFriction Loss in Pipenextdarklord50% (2)

- Project Plan Template: Project Conception and InitiationDocumento5 páginasProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZAinda não há avaliações

- Project Plan Template: Project Conception and InitiationDocumento5 páginasProject Plan Template: Project Conception and InitiationAnonymous 4eQB3WZAinda não há avaliações

- Double Stage CompresserDocumento5 páginasDouble Stage Compressernishugupta3hAinda não há avaliações

- Procurement progress tracking sheetDocumento10 páginasProcurement progress tracking sheetRoland NicolasAinda não há avaliações

- BOP Test Procedure PDFDocumento2 páginasBOP Test Procedure PDFAhmed100% (2)

- Sop For Boiler Hydro TestDocumento4 páginasSop For Boiler Hydro TestHardik ThumarAinda não há avaliações

- Weekly Fire Pump InspectionDocumento6 páginasWeekly Fire Pump InspectionShabaaz Mohammed AbdulAinda não há avaliações

- Accumulator Draw Down TestDocumento8 páginasAccumulator Draw Down Testadeelsn100% (4)

- Thick Walled Cylinders (Corrected)Documento17 páginasThick Walled Cylinders (Corrected)John Larry CorpuzAinda não há avaliações

- Astm D1894-14Documento7 páginasAstm D1894-14Huỳnh Phúc NguyễnAinda não há avaliações

- Well Test ProcedureDocumento6 páginasWell Test Procedureinyene ekereAinda não há avaliações

- Air Conditioning Maintenance ProceduresDocumento10 páginasAir Conditioning Maintenance ProceduresSuryo Eka FAinda não há avaliações

- Food Safety Culture ExcellenceDocumento5 páginasFood Safety Culture Excellencejamil voraAinda não há avaliações

- BOP Test ProcedureDocumento2 páginasBOP Test ProcedureAhmedAinda não há avaliações

- Design of Slow Sand Filter FinalDocumento11 páginasDesign of Slow Sand Filter FinalHemant SonawadekarAinda não há avaliações

- Product Launch Marketing PlanDocumento17 páginasProduct Launch Marketing Planjamil voraAinda não há avaliações

- Series and Parallel PumpsDocumento8 páginasSeries and Parallel PumpsLanyoong67% (3)

- En 12874-2001 Flame Arresters - Performance Requirements, Test Methods and Limits For UseDocumento46 páginasEn 12874-2001 Flame Arresters - Performance Requirements, Test Methods and Limits For Usecicciox123Ainda não há avaliações

- BSEE Test ProcedureDocumento35 páginasBSEE Test ProcedureNatraji100% (2)

- Intermediate Well Control Equipment InspectionDocumento4 páginasIntermediate Well Control Equipment InspectionEdwin MP0% (1)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNo EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNota: 1 de 5 estrelas1/5 (2)

- Unit Start Up ProcedureDocumento14 páginasUnit Start Up ProceduredineshmehtaAinda não há avaliações

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsAinda não há avaliações

- B - PVG - Hands On - v4 PDFDocumento57 páginasB - PVG - Hands On - v4 PDFJose Manuel Barroso PantojaAinda não há avaliações

- Mokveld Test Unit VTU-1Documento1 páginaMokveld Test Unit VTU-1eng_moh04Ainda não há avaliações

- Guide to competent bodies for material quality certificationDocumento13 páginasGuide to competent bodies for material quality certificationJAFFERAinda não há avaliações

- M.S. and high tensile nuts bolts productionDocumento5 páginasM.S. and high tensile nuts bolts productionscribddaduAinda não há avaliações

- Lab Manual For Drilling SimulatorDocumento8 páginasLab Manual For Drilling SimulatorLemony Snickit50% (2)

- 2014 68 Eu PDFDocumento96 páginas2014 68 Eu PDFAlienshow100% (1)

- Starting Up and Stopping of The GasplantDocumento5 páginasStarting Up and Stopping of The GasplantHendra TambunanAinda não há avaliações

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideNo EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideNota: 5 de 5 estrelas5/5 (1)

- Food Safety Culture Module BrochureDocumento8 páginasFood Safety Culture Module Brochurejamil voraAinda não há avaliações

- One Page Opps ProcecedureDocumento2 páginasOne Page Opps ProcecedureAaron Jrz RamseyAinda não há avaliações

- Alex Test Protocol 070921Documento6 páginasAlex Test Protocol 070921NeelixAinda não há avaliações

- Regulator Performance Test Procedure Operation ManualDocumento2 páginasRegulator Performance Test Procedure Operation ManualCavid MAMMADOVAinda não há avaliações

- Proper operation of PV411A hand pumpDocumento2 páginasProper operation of PV411A hand pumpChristian AlvarezAinda não há avaliações

- Water Plant SOP 2-13-17Documento8 páginasWater Plant SOP 2-13-17Mauro Domingo'sAinda não há avaliações

- Lab Manual Sem1 2015 2016-11092015Documento26 páginasLab Manual Sem1 2015 2016-11092015Putri SaidatinaAinda não há avaliações

- TK-99D Installation InstructionsDocumento4 páginasTK-99D Installation InstructionsWattsAinda não há avaliações

- RecommendationDocumento6 páginasRecommendationIskandar IslahudinAinda não há avaliações

- Steam Test ProcedureDocumento1 páginaSteam Test ProcedureKecik KmAinda não há avaliações

- 5000 PSI Gas Gun Operating Manual SupplementDocumento6 páginas5000 PSI Gas Gun Operating Manual SupplementVahidAinda não há avaliações

- LPR-N Tester Valve Funcionamiento 1Documento33 páginasLPR-N Tester Valve Funcionamiento 1Александр КинтероAinda não há avaliações

- AGRINOZE Quality Control Plan (Final)Documento8 páginasAGRINOZE Quality Control Plan (Final)Juleha PermatasariAinda não há avaliações

- 2.0 Pressure TestingDocumento11 páginas2.0 Pressure TestingHATEMAinda não há avaliações

- Aeration Commisioning - STPDocumento7 páginasAeration Commisioning - STPdexterAinda não há avaliações

- Manual - Medister - Vertical - Automatic D.D AutocalveDocumento10 páginasManual - Medister - Vertical - Automatic D.D Autocalvemaruti jadhavAinda não há avaliações

- HP BypassDocumento15 páginasHP Bypass150819850Ainda não há avaliações

- Series & Parallel PumpDocumento14 páginasSeries & Parallel PumpDivaan Raj Karunakaran100% (3)

- Ammonia Plant SopsDocumento31 páginasAmmonia Plant SopsKarthik Manjunath100% (1)

- Guidance For Lab: Part A. Beginning of The ExperimentDocumento4 páginasGuidance For Lab: Part A. Beginning of The ExperimentlemizeAinda não há avaliações

- BOPE Pressure Test Procedures: A. Choke Manifold PT ProceduresDocumento4 páginasBOPE Pressure Test Procedures: A. Choke Manifold PT ProceduressfsfAinda não há avaliações

- Lab Procedure Water Flow LossesDocumento2 páginasLab Procedure Water Flow LossesChanel AnnAinda não há avaliações

- GSS-SWI-002-0005 Reserval Gas Analyser Function Test V2!2!6476903 - 01Documento5 páginasGSS-SWI-002-0005 Reserval Gas Analyser Function Test V2!2!6476903 - 01alfonzitoAinda não há avaliações

- Series TK-1 Installation InstructionsDocumento4 páginasSeries TK-1 Installation InstructionsFEBCOAinda não há avaliações

- Level Measurement & Calibration ExperimentDocumento12 páginasLevel Measurement & Calibration ExperimentNUR QURRATUAINIAinda não há avaliações

- CHE504 Membrane Test UnitDocumento2 páginasCHE504 Membrane Test UnitSyazwina AziziAinda não há avaliações

- Teknisi InstrumentDocumento17 páginasTeknisi InstrumentHelmy RosadiAinda não há avaliações

- Experiment DescriptionDocumento3 páginasExperiment DescriptionsydneyAinda não há avaliações

- Oxygen Plant Manual SupplementDocumento8 páginasOxygen Plant Manual SupplementInge NecoAinda não há avaliações

- Report about new ATEX centrifugal pump of the open drainDocumento2 páginasReport about new ATEX centrifugal pump of the open drainnapolitana2010Ainda não há avaliações

- Chapt 2 PumpsDocumento6 páginasChapt 2 PumpsManuelAinda não há avaliações

- Commissioning checklist for HP bypass systemDocumento8 páginasCommissioning checklist for HP bypass systemGansehAinda não há avaliações

- Orifice Plate Meter ExperimentDocumento6 páginasOrifice Plate Meter ExperimentAli RazzaqAinda não há avaliações

- 410.5 Valve SettingDocumento5 páginas410.5 Valve SettingHassan GDOURAAinda não há avaliações

- (Continuous or Shoot Mode) ? Certain Value System Is ReadyDocumento4 páginas(Continuous or Shoot Mode) ? Certain Value System Is ReadynemoneoAinda não há avaliações

- Teste A Las Bombas, RevisionesDocumento2 páginasTeste A Las Bombas, RevisionesMario PazAinda não há avaliações

- Measure Force of Water Jet Impacting PlateDocumento23 páginasMeasure Force of Water Jet Impacting PlateALIKHAN CU-40-2019BAinda não há avaliações

- IQF-Operating Manual - VSP-8AEDocumento12 páginasIQF-Operating Manual - VSP-8AEtsg.smart.iot2Ainda não há avaliações

- Level Measurement & Calibration ExperimentDocumento12 páginasLevel Measurement & Calibration Experimentmirza farhanAinda não há avaliações

- Fasteners - Stainless SteelDocumento10 páginasFasteners - Stainless Steeljamil voraAinda não há avaliações

- Readme 1Documento1 páginaReadme 1Jogn DebAinda não há avaliações

- Design Manufacture and Simulation of BalDocumento82 páginasDesign Manufacture and Simulation of BalMEER MUSTAFA ALIAinda não há avaliações

- StdoutDocumento1 páginaStdoutMohammed NourAinda não há avaliações

- New PED - tcm37-17564Documento3 páginasNew PED - tcm37-17564jamil voraAinda não há avaliações

- Nuts and BoltsDocumento42 páginasNuts and Boltsjamil voraAinda não há avaliações

- Full Quality Assurance Certificate: L&T Valves LimitedDocumento5 páginasFull Quality Assurance Certificate: L&T Valves Limitedjamil voraAinda não há avaliações

- Annex Iv Eu Declaration of Conformity (No XXXX)Documento1 páginaAnnex Iv Eu Declaration of Conformity (No XXXX)jamil voraAinda não há avaliações

- StdoutDocumento1 páginaStdoutMohammed NourAinda não há avaliações

- Annex 1 Essential Safety RequirementDocumento12 páginasAnnex 1 Essential Safety Requirementjamil voraAinda não há avaliações

- MOdule H RequirementDocumento8 páginasMOdule H Requirementjamil voraAinda não há avaliações

- Crawley Borough Council: Food ComplaintsDocumento5 páginasCrawley Borough Council: Food Complaintsjamil voraAinda não há avaliações

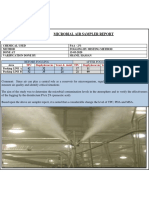

- A Study of Microbial Air Sample by PAA As DisinfectantDocumento1 páginaA Study of Microbial Air Sample by PAA As Disinfectantjamil voraAinda não há avaliações

- Guidelines For Certification of Grower Groups: 5.1 SCOPEDocumento27 páginasGuidelines For Certification of Grower Groups: 5.1 SCOPEjamil voraAinda não há avaliações

- Data - of Best KindDocumento4 páginasData - of Best Kindkt1996Ainda não há avaliações

- Accreditation of Certification Bodies: 4. Accreditation Criteria 4.1 Categories For AccreditationDocumento39 páginasAccreditation of Certification Bodies: 4. Accreditation Criteria 4.1 Categories For AccreditationdemiAinda não há avaliações

- ASME VIII Div 1 Thickness FormulaDocumento2 páginasASME VIII Div 1 Thickness Formulajamil voraAinda não há avaliações

- OCA - 095 Equipment Information Sheet-Handler - 181119Documento1 páginaOCA - 095 Equipment Information Sheet-Handler - 181119jamil voraAinda não há avaliações

- OCA - 115c - Initial Application (Processing & Trading) - 181119Documento4 páginasOCA - 115c - Initial Application (Processing & Trading) - 181119jamil voraAinda não há avaliações

- OCA - 097 Product Flowinformation Sheet-Handler - 181119Documento2 páginasOCA - 097 Product Flowinformation Sheet-Handler - 181119jamil voraAinda não há avaliações

- ECO GUARD Brochure (W) PDFDocumento4 páginasECO GUARD Brochure (W) PDFSANTHWANAM MED CAREAinda não há avaliações

- Adiabatic compression of ammonia gas estimates final T, work, and entropy changeDocumento3 páginasAdiabatic compression of ammonia gas estimates final T, work, and entropy changeShyn GysawAinda não há avaliações

- Practical Design Criteria: LoadingsDocumento7 páginasPractical Design Criteria: LoadingsSmrutiAinda não há avaliações

- Wavin PE Pressure Pipes Data SheetDocumento2 páginasWavin PE Pressure Pipes Data SheetConspiracy_PTAinda não há avaliações

- 6.2020-3015 Dolphin Wake StructureDocumento9 páginas6.2020-3015 Dolphin Wake StructureHua Hidari YangAinda não há avaliações

- Gas Hold-Up, Mixing Time and Circulation Time in InternalDocumento9 páginasGas Hold-Up, Mixing Time and Circulation Time in Internalali abdulrahman al-ezziAinda não há avaliações

- Actuated Ball Valve 357 A - BDKDocumento4 páginasActuated Ball Valve 357 A - BDKfarhanakhtar ansariAinda não há avaliações

- Past Final Papers 1Documento21 páginasPast Final Papers 1Luqmanhakim XavAinda não há avaliações

- Natural Convection Manual - 220902 - 120419Documento6 páginasNatural Convection Manual - 220902 - 120419Mail BotAinda não há avaliações

- Introduction On CreepDocumento24 páginasIntroduction On CreepAbdul RahimAinda não há avaliações

- Proportional Relief ValvesDocumento9 páginasProportional Relief ValvesSemeer AliAinda não há avaliações

- Asme B 31.3Documento30 páginasAsme B 31.3Deven SutharAinda não há avaliações

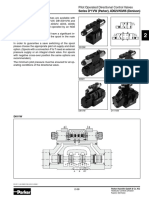

- Válvula Direcional - Série d41Documento16 páginasVálvula Direcional - Série d41Fabricio LucioAinda não há avaliações

- Articulo 1Documento9 páginasArticulo 1DORIS HELENA GUTIÉRREZ LONDOÑOAinda não há avaliações

- Valerio Steven Ce175-5w B2 CW5Documento4 páginasValerio Steven Ce175-5w B2 CW5Steven ValerioAinda não há avaliações

- Everything about steam condensersDocumento17 páginasEverything about steam condensersASHOKAinda não há avaliações

- Continuous-Flow Synthesis of IbuprofenDocumento4 páginasContinuous-Flow Synthesis of IbuprofenCao Thị Vân GiangAinda não há avaliações

- R05422105 Hypersonic AerodynamicsDocumento4 páginasR05422105 Hypersonic AerodynamicsPratap VeerAinda não há avaliações

- Glossary of Water Treatment Terms: Term ExplanationDocumento12 páginasGlossary of Water Treatment Terms: Term ExplanationprakashAinda não há avaliações

- 2019 11 27.11.46.56 Hydrulics and Pneumatics (Syllabus)Documento1 página2019 11 27.11.46.56 Hydrulics and Pneumatics (Syllabus)Harry HarryAinda não há avaliações

- Service & operating manual for Alemite model 8329 air-operated double diaphragm pumpDocumento19 páginasService & operating manual for Alemite model 8329 air-operated double diaphragm pumpCesar Marcello Cordova GuerreroAinda não há avaliações

- Torco ProcessDocumento12 páginasTorco ProcessBengisu Tiryaki100% (1)

- Greetings: HVAC Design of Commercial Buildings With TESDocumento49 páginasGreetings: HVAC Design of Commercial Buildings With TESchitradevipAinda não há avaliações

- DynasetDocumento64 páginasDynasetAlexis Peña0% (1)

- Lecture 3 Sprinkler Irrigation DesignDocumento23 páginasLecture 3 Sprinkler Irrigation DesignThomasAinda não há avaliações

- WJPPS 23519Documento17 páginasWJPPS 23519Sandip PhokeAinda não há avaliações