Escolar Documentos

Profissional Documentos

Cultura Documentos

Sop Zetasizer

Enviado por

P SWETHADescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sop Zetasizer

Enviado por

P SWETHADireitos autorais:

Formatos disponíveis

Page 1 of 3

QUALITY CONTROL DEPARTMENT

SOP no. PUN/SOP/Q/2.441 Preparation Date 14/09/2019

Supersedes PUN/SOP/Q/2.440 Effective Date 17/09/2019

No. of Revisions 2 Next Revision 16/09/2020

Product Zetasizer Brand Name Malvern

Model no. Nano-ZS-ZEN3600

TITLE: STANDARD OPERATING PROCEDURE FOR MALVERN ZETASIZER

(Nano-ZS-ZEN3600) PARTICLE SIZE ANALYZER

1. OBJECTIVE: To provide standard instructions for operation of Malvern Zetasizer (Nano-ZS-

ZEN3600)

2. SCOPE: The operation of particle size analyzer is to measure Particle size, Molecular weight and

Zeta potential.

3. RESPONSIBILITY:

3.1. QC analysts and related personnel are responsible for the implication of this procedure.

3.2. QA head is responsible for regular and required amendments in Standard operating procedure.

4. DISTRIBUTION LIST:

4.1. Srushti, Quality Control Head

4.2. Swetha, Production Head

4.3. Sakshi, Formulation and Development Head

4.4. Mitesh, Quality Assurance Head

5. REVISION HISTORY:

`

Version Date Person responsible Description of change

1.0 14/09/2018 Mitesh- QA Head -

2.0 14/09/2019 Mitesh- QA Head Revised cleaning procedure: clean the

instrument with a clean de-dusting cloth only.

6. ABBREVIATIONS:

6.1. QC Quality Control

Prepared by: Reviewed by: Approved by:

Signature

Name Prashanth Ankita Mitesh

Designation QA Executive QA Manager QA Head

Page 2 of 3

QUALITY CONTROL DEPARTMENT

SOP no. PUN/SOP/Q/2.441 Preparation Date 14/09/2019

Supersedes PUN/SOP/Q/2.440 Effective Date 17/09/2019

No. of Revisions 2 Next Revision 16/09/2020

Product Zetasizer Brand Name Malvern

Model no. Nano-ZS-ZEN3600

TITLE: STANDARD OPERATING PROCEDURE FOR MALVERN ZETASIZER

(Nano-ZS-ZEN3600) PARTICLE SIZE ANALYZER

6.2. QA Quality Assurance

6.3. SOP Standard Operating Procedure

6.4. IPA Isopropyl Alcohol

7. PRECAUTIONS:

7.1.1. Make sure to switch off the instrument when not in use.

7.1.2. Cells should be cleaned prior to use. All size and Zeta potential cells should be rinsed/

cleaned with filtered dispersant before use.

7.1.3. The cell should be filled slowly to avoid air bubbles. Ultrasonication can be used to remove

air bubbles, but only if the sample is suitable for use with ultrasonics.

7.1.4. When using syringe for the dispersant, never use the first few drops from the syringe to avoid

contamination of dispersant by residual dust particles.

7.1.5. Hold the cuvette from the top to prevent tampering with the measurements and wipe the sides

with clean tissue.

8. PROCEDURE

8.1.1. Turn ON the instrument and wait for 1 hour for the laser to stabilize.

8.1.2. Start the Zetasizer software.

8.1.3. Choose the appropriate for the measurement. Organic solutions can only be measured in

glass cuvette.

8.1.4. Fill the cuvette to the depth of approximately 1cm.

8.1.5. Make a new Measurement File, then select Measure Manual.

8.1.6. Click to Measurement type to choose the experiment type.

8.1.7. Click on sample and choose the name and write any notes as needed.

8.1.8. Click on Sample Material and choose your sample material from the list.

8.1.9. You may add a new material if the Refractive index is known.

8.1.10. Choose a dispersant or add new as needed.

Prepared by: Reviewed by: Approved by:

Signature

Name Prashanth Ankita Mitesh

Designation QA Executive QA Manager QA Head

Page 3 of 3

QUALITY CONTROL DEPARTMENT

SOP no. PUN/SOP/Q/2.441 Preparation Date 14/09/2019

Supersedes PUN/SOP/Q/2.440 Effective Date 17/09/2019

No. of Revisions 2 Next Revision 16/09/2020

Product Zetasizer Brand Name Malvern

Model no. Nano-ZS-ZEN3600

TITLE: STANDARD OPERATING PROCEDURE FOR MALVERN ZETASIZER

(Nano-ZS-ZEN3600) PARTICLE SIZE ANALYZER

8.1.11. Temperature: at least 120s equilibrium time should be allowed since the room is very cold.

8.1.12. Cell type: choose a category and model.

8.1.13. Measurement: duration and repetitions may be adjusted.

8.1.14. Press OK to accept the Measurement settings.

8.1.15. Load the sample and press Start.

8.1.16. To view the data, select a measurement and look through the tabs (e.g. intensity or volume

PSD).

8.1.17. On a particular tab select Edit Copy Size Values/ Graph.

8.1.18. Then data can be transferred to excel spreadsheet.

8.1.19. Turn off the instrument.

9. CLEANING AND MAINTENANCE

9.1. Switch OFF the instrument.

9.2. Switch OFF the mains for power supply.

9.3. Clean the instrument with a soft de-dusting cloth.

9.4. Care must be taken that samples are not split on the instrument or in the cuvette chamber.

10. REFERENCE:

10.1. Rawi, F. M. (2016). SOP for Malvern Zetasizer (Basic). (January 2014).

https://doi.org/10.13140/RG.2.1.3285.1440

Maintain log book as per the prescribed format

NOTE: In case of any difficulty or malfunctioning, inform the reviewer or approver.

Prepared by: Reviewed by: Approved by:

Signature

Name Prashanth Ankita Mitesh

Designation QA Executive QA Manager QA Head

Você também pode gostar

- Cleaning and disinfection of food factories: a practical guideNo EverandCleaning and disinfection of food factories: a practical guideAinda não há avaliações

- XYZ Tablet 20mg FCTDocumento123 páginasXYZ Tablet 20mg FCTAnonymous jzlKNORAinda não há avaliações

- Format Ahu ValDocumento3 páginasFormat Ahu ValKrishna RajAinda não há avaliações

- Unilab Research Compound: Ravs Equipment Preventive Maintenance (PM) SummaryDocumento92 páginasUnilab Research Compound: Ravs Equipment Preventive Maintenance (PM) SummaryMhike EcoAinda não há avaliações

- Validation TableDocumento11 páginasValidation TableAlison LewisAinda não há avaliações

- Inspection QueriesDocumento3 páginasInspection Queriesmuhammad qasimAinda não há avaliações

- Index of QA WorkingDocumento2 páginasIndex of QA WorkingsajidAinda não há avaliações

- Calibration of ExperimentsDocumento48 páginasCalibration of ExperimentsNgocThuc LeAinda não há avaliações

- Concentration (MG/ML) Avg. Peak Area (Standard) : Linearity Graph of Amikacin SulfateDocumento6 páginasConcentration (MG/ML) Avg. Peak Area (Standard) : Linearity Graph of Amikacin SulfatesajidAinda não há avaliações

- Equipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreDocumento1 páginaEquipment List For Proposed Project of Herbion Pakistan (PVT) Limited, LahoreMuhammad Rizwan KhanAinda não há avaliações

- Calibration Curve: Tartaric Acid: Peak AreaDocumento10 páginasCalibration Curve: Tartaric Acid: Peak Areajanesalazar3369Ainda não há avaliações

- Product Spect - VPODocumento2 páginasProduct Spect - VPOKomathi BalasupramaniamAinda não há avaliações

- Summary Caldece 112.8 KG NewDocumento23 páginasSummary Caldece 112.8 KG NewfajarRS69Ainda não há avaliações

- Purified Water User PointDocumento1 páginaPurified Water User PointMuhammadAmdadulHoqueAinda não há avaliações

- Monthly Record Process Validation: Note: Red Font Is WPS/ACTUAL Date For Previous MonthDocumento31 páginasMonthly Record Process Validation: Note: Red Font Is WPS/ACTUAL Date For Previous MonthFajarRachmadiAinda não há avaliações

- Flow Chart Neozep F Exp TabletDocumento4 páginasFlow Chart Neozep F Exp TabletRio FebriansyahAinda não há avaliações

- Cefepime For Injection USP (Dossier) PDFDocumento66 páginasCefepime For Injection USP (Dossier) PDFsofiaAinda não há avaliações

- B-Block B Iii Area Clean Room Entry & Exit Pictorial DisplayDocumento24 páginasB-Block B Iii Area Clean Room Entry & Exit Pictorial DisplaySanathAinda não há avaliações

- Related Substances of Cefipime IPDocumento4 páginasRelated Substances of Cefipime IPBhawani singhAinda não há avaliações

- Microbiology Available Equipments Data As Per NABL FormatDocumento8 páginasMicrobiology Available Equipments Data As Per NABL FormatKrishna ChaitanyaAinda não há avaliações

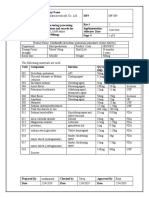

- Siddhi Vinayak Industries.: Batch Manufacturing RecordDocumento11 páginasSiddhi Vinayak Industries.: Batch Manufacturing RecordPANKAJAinda não há avaliações

- IQ Risk AnalysisDocumento1 páginaIQ Risk AnalysisNadine LilleAinda não há avaliações

- Annexure - VIDocumento19 páginasAnnexure - VIKiran KumarAinda não há avaliações

- Bag Filter: NO Client Site Location Application Capacity Q'Ty Completion RemarksDocumento6 páginasBag Filter: NO Client Site Location Application Capacity Q'Ty Completion Remarksbasavaraju535Ainda não há avaliações

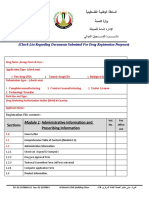

- Check List Regarding Documents Submitted For Drug Registration PurposesDocumento8 páginasCheck List Regarding Documents Submitted For Drug Registration PurposesMayson Bali100% (1)

- Premix Jordan (VAPCO®)Documento2 páginasPremix Jordan (VAPCO®)Tayyab TahirAinda não há avaliações

- Docs h06 FM 018Documento2 páginasDocs h06 FM 018ArchanAinda não há avaliações

- Lab Ledger PhyDocumento287 páginasLab Ledger PhyMumtazAhmadAinda não há avaliações

- Product Cost-Pharma (1.2.16)Documento406 páginasProduct Cost-Pharma (1.2.16)EmranAinda não há avaliações

- Chemical Analysis of Soft WaterDocumento4 páginasChemical Analysis of Soft WaterBhawani singhAinda não há avaliações

- Siphar Bod-03-06-2011Documento4 páginasSiphar Bod-03-06-2011Indra NeelAinda não há avaliações

- TENTATIVE BOM - Amitriptyline 12.5 MG and Chlordiazepoxide 5 MG TabletDocumento2 páginasTENTATIVE BOM - Amitriptyline 12.5 MG and Chlordiazepoxide 5 MG TabletGaFf ArAinda não há avaliações

- List of Licenses / Certificates: As Per List Attached Here WithDocumento2 páginasList of Licenses / Certificates: As Per List Attached Here Withkanji63Ainda não há avaliações

- Raw Data Report of TabletDocumento11 páginasRaw Data Report of TabletShubam SharmaAinda não há avaliações

- 161 ListDocumento8 páginas161 ListAnnie KhanAinda não há avaliações

- Propose Modification For Change Room (BLS) First Change (Officer For Primary Area) : Sl. No Modification Responsible Dept Timeline RemarksDocumento4 páginasPropose Modification For Change Room (BLS) First Change (Officer For Primary Area) : Sl. No Modification Responsible Dept Timeline RemarksshdphAinda não há avaliações

- QC TestsDocumento12 páginasQC Testsembermich100% (1)

- Acene CreamDocumento2 páginasAcene CreamJai MurugeshAinda não há avaliações

- Requirements For NABLDocumento1 páginaRequirements For NABLSiva ShankarAinda não há avaliações

- New ProjectDocumento4 páginasNew Projectjpmaurya77Ainda não há avaliações

- Bhaluka Equipment, Utilities and QC Instrument DetailsDocumento15 páginasBhaluka Equipment, Utilities and QC Instrument DetailsRamboAinda não há avaliações

- No. of SOP Pending in All Cross Functional DepartmentDocumento64 páginasNo. of SOP Pending in All Cross Functional DepartmentNishit SuvaAinda não há avaliações

- Attachment For Iq of Heating Ventilation and Air Conditioning For CADILA (AHU No.-01)Documento6 páginasAttachment For Iq of Heating Ventilation and Air Conditioning For CADILA (AHU No.-01)PAWAN KUMARAinda não há avaliações

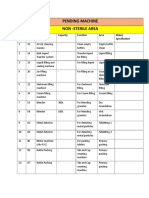

- Pending Machine Non - Sterile Area: S. NO. Room No. Equipment Name Capacity Function Area Make/ SpecificationDocumento3 páginasPending Machine Non - Sterile Area: S. NO. Room No. Equipment Name Capacity Function Area Make/ Specificationjpmaurya77Ainda não há avaliações

- Vidya Bharti College, Seloo Requirement of Chemical and Media For Microbiology PracticalDocumento11 páginasVidya Bharti College, Seloo Requirement of Chemical and Media For Microbiology PracticalYogesh BanginwarAinda não há avaliações

- Master List of DocumentDocumento2 páginasMaster List of Documentmygoo0% (1)

- 01 Disintegration Test For Tablets and CapsulesDocumento30 páginas01 Disintegration Test For Tablets and CapsulesmefroAinda não há avaliações

- Analysis Request Form 2014Documento52 páginasAnalysis Request Form 2014Mohamad ArtaAinda não há avaliações

- Iso Document File ListDocumento13 páginasIso Document File ListABHINAV99Ainda não há avaliações

- DOEH Pesticide FilesDocumento20 páginasDOEH Pesticide FilesMichael_Lee_RobertsAinda não há avaliações

- Raya Pharmaceuticals Co. LTD: Cataflam®Documento8 páginasRaya Pharmaceuticals Co. LTD: Cataflam®Mayson BaliAinda não há avaliações

- Master Listof Watertreatment PlantDocumento2 páginasMaster Listof Watertreatment PlantHarpal SainiAinda não há avaliações

- Print 24.1.18 Sop LlistDocumento11 páginasPrint 24.1.18 Sop Llistkalaiarasi ravichandranAinda não há avaliações

- Chemical TitrationDocumento5 páginasChemical TitrationVikasAinda não há avaliações

- 2nd Floor Ceph Area Hilton PharmaDocumento1 página2nd Floor Ceph Area Hilton PharmamhmaharAinda não há avaliações

- Lovex RegistrDocumento64 páginasLovex RegistrbishopshehadehAinda não há avaliações

- Capsule Shape Weight & Thickness ChartDocumento1 páginaCapsule Shape Weight & Thickness ChartMahesh Patil KahatulAinda não há avaliações

- Internal Calibration Check HPLC System (Agilent Prime LC 1260 Infinity II)Documento6 páginasInternal Calibration Check HPLC System (Agilent Prime LC 1260 Infinity II)Aayushi SanghalAinda não há avaliações

- URS Deviation ListDocumento4 páginasURS Deviation ListjaiminAinda não há avaliações

- SOP FOR STIFFNESS Tester (09.6.17)Documento2 páginasSOP FOR STIFFNESS Tester (09.6.17)Q AAinda não há avaliações

- Application of Extra Over in Bill of QuantitiesDocumento10 páginasApplication of Extra Over in Bill of QuantitiesAsh SimsAinda não há avaliações

- FMEA Procedure K-PosDocumento111 páginasFMEA Procedure K-PosFábio GonçalvesAinda não há avaliações

- Ensocoat en PDFDocumento2 páginasEnsocoat en PDFAndrés HerreraAinda não há avaliações

- Exxonmobil - Serpentina H2S Management Project: Material Requisition For H2S Absorbent Modular SkidDocumento21 páginasExxonmobil - Serpentina H2S Management Project: Material Requisition For H2S Absorbent Modular SkidPrakash RajAinda não há avaliações

- ERP Implementation in PharmaDocumento11 páginasERP Implementation in PharmaSiddharth SiddhuAinda não há avaliações

- HiraDocumento1 páginaHirajanisha11Ainda não há avaliações

- Cost Estimation FundamentalsDocumento15 páginasCost Estimation FundamentalsUsmanAinda não há avaliações

- Key GCC Projects To Be Awarded in The Next 6 MonthsDocumento2 páginasKey GCC Projects To Be Awarded in The Next 6 MonthsDinesh Adwani100% (1)

- t8 b6 Faa HQ Peter Challen FDR - 3-26-04 MFRDocumento4 páginast8 b6 Faa HQ Peter Challen FDR - 3-26-04 MFR9/11 Document ArchiveAinda não há avaliações

- AT ScreeningTechnology 2022 ArchivDocumento36 páginasAT ScreeningTechnology 2022 ArchivAndreasAinda não há avaliações

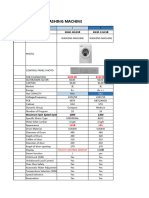

- Front Loading Washing Machine-2023!11!11 AREFDocumento15 páginasFront Loading Washing Machine-2023!11!11 AREFzakirzandan0Ainda não há avaliações

- PDFDocumento415 páginasPDFlamjedAinda não há avaliações

- Mohammad Zainullah Khan: Education SkillsDocumento1 páginaMohammad Zainullah Khan: Education SkillsMohammad Zainullah KhanAinda não há avaliações

- NBN-TE-CTO-211 B2B Technical Specification v0.12Documento32 páginasNBN-TE-CTO-211 B2B Technical Specification v0.12Zhiyi WangAinda não há avaliações

- Sepa Credit Transfer Pain 001 001 03 XML File Structure July 2013Documento28 páginasSepa Credit Transfer Pain 001 001 03 XML File Structure July 2013Francisco XascasAinda não há avaliações

- Delete Entity in FusionDocumento4 páginasDelete Entity in FusionBick KyyAinda não há avaliações

- Where Big Ideas Take A Small ShapeDocumento7 páginasWhere Big Ideas Take A Small Shapera suAinda não há avaliações

- Guidebook IIDocumento188 páginasGuidebook IIAnand AgrawalAinda não há avaliações

- Chubb ExtinguisherDocumento14 páginasChubb Extinguisherprsiva2420034066Ainda não há avaliações

- Manager SelfDocumento32 páginasManager SelfAnonymous iWHqiyAinda não há avaliações

- VAG Valves NRVDocumento3 páginasVAG Valves NRVMAYANKAinda não há avaliações

- BCOMDEG - Project Management 2 - July 23 - S1Documento3 páginasBCOMDEG - Project Management 2 - July 23 - S1ThatoAinda não há avaliações

- 6 SAP PP Level I TrainingDocumento45 páginas6 SAP PP Level I TrainingsowjanyaAinda não há avaliações

- NTT Docomo Case StudyDocumento4 páginasNTT Docomo Case StudyLy Nguyen LeAinda não há avaliações

- Support Frame, Access PlatformDocumento3 páginasSupport Frame, Access PlatformWilliam VillamizarAinda não há avaliações

- VOLTE For DummiesDocumento52 páginasVOLTE For Dummiespmo79Ainda não há avaliações

- Total Quality Management Session by MukherjeeDocumento2 páginasTotal Quality Management Session by Mukherjeearnab.for.ever9439Ainda não há avaliações

- As1170 3Documento8 páginasAs1170 3sriharsha.jalluAinda não há avaliações

- Texas RRC Oil and Gas RulesDocumento225 páginasTexas RRC Oil and Gas RulesjaceAinda não há avaliações

- JD Edwards EnterpriseOne Applications PDFDocumento262 páginasJD Edwards EnterpriseOne Applications PDFailiheng100% (1)