Escolar Documentos

Profissional Documentos

Cultura Documentos

Kukdo Epoxy R 46 Yd 013k55 Tds

Enviado por

RAZA MEHDITítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Kukdo Epoxy R 46 Yd 013k55 Tds

Enviado por

RAZA MEHDIDireitos autorais:

Formatos disponíveis

ISO-9001

ISO-14001

KUKDO

December 1,

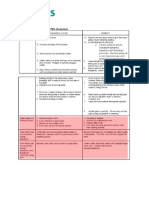

YD-013K55 Powder Coating Epoxy Resin 2004

General Description Film Properties

EPOKUKDO YD-013K55 is a standard solid Epoxy Item YD-013K55 Test Method

Resin derived from ECH(epichlorohydrin) and Gloss(60°) > 90 ASTM D523

Bisphenol-A. The resin is recommended for the hybrid Adhesion 100/100 ASTM D3002

system in combination with polyester resin or straight Impact (Direct) > 500g/50cm ASTM D2794

epoxy system to obtain good gloss, flow, mechanical (Reverse) > 500g/50cm

properties and chemical resistance.

Erichsen > 7mm ISO 1520

Resin Properties

Storage

Item YD-013K55 Test Method

Keep dry and cool condition (under 25°C)

EEW(g/eq) 800-900 KD-AS-001 Keep away from heat sources and direct sunlight

*1

Melt Viscosity (cps) 2,000-5,000 KD-AS-008

*2

Softening Point (°C) 90-100 KD-AS-020 Packaging

Color(G) 0.5 max. KD-AS-025 PE bag of 25kg net weight

*1 I.C.I Viscosity at 150°C Super-sack(bag) of 500kg net weight

*2 Ball & Ring Method

Starting Formulation

Components Part by Weight

YD-013K55 300

CC-314*1 (UCB) 300

Benzoin 4

MFP-VP 6

TiO2 R902 (Dupont) 300

BaSO4 90

*1 Acid Value : 65-75mgKOH/g

Application Condition

Spraying gun Corona charging

Spraying tension 60-80 KV

Film thickness 60-80 µm

Substrates 0.6mm cold-roll steel

Baking condition 180°C×15min

For literature and technical assistance, visit our website at www.kukdo.com

Você também pode gostar

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNo EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsNota: 5 de 5 estrelas5/5 (1)

- KH-819_TDS_Documento1 páginaKH-819_TDS_NganAinda não há avaliações

- Polyamide Resin: General Description PackagingDocumento1 páginaPolyamide Resin: General Description PackagingManuel ChireAinda não há avaliações

- Yd-011x75 TdsDocumento1 páginaYd-011x75 Tdsjoe.sabeh.ysAinda não há avaliações

- Yd-114e TDSDocumento1 páginaYd-114e TDSGİZEM DEMİRAinda não há avaliações

- YDPN 641 S PDFDocumento2 páginasYDPN 641 S PDFsriatul2006Ainda não há avaliações

- YDPN-641: Phenol Novolac EpoxyDocumento2 páginasYDPN-641: Phenol Novolac Epoxysriatul2006Ainda não há avaliações

- YD-114EF: Low Viscosity Epoxy ResinDocumento1 páginaYD-114EF: Low Viscosity Epoxy ResinRICHBRAVO8Ainda não há avaliações

- Sabic® Ldpe 2201H0Documento2 páginasSabic® Ldpe 2201H0Berkosan BalkansAinda não há avaliações

- KD-213 TDSDocumento3 páginasKD-213 TDSalpesh.samruddhigroupAinda não há avaliações

- Polyamide Resin Solution: General Description PackagingDocumento1 páginaPolyamide Resin Solution: General Description PackagingGİZEM D.Ainda não há avaliações

- SABIC® SUPEER™ - VM006 PROVISIONAL DATA SHEET - Global - Technical - Data - SheetDocumento2 páginasSABIC® SUPEER™ - VM006 PROVISIONAL DATA SHEET - Global - Technical - Data - SheetAna Maria MuresanAinda não há avaliações

- Bpxe B6ctalDocumento2 páginasBpxe B6ctalVusal HasanovAinda não há avaliações

- PE LL6201 Series DatasheetDocumento1 páginaPE LL6201 Series DatasheetmaheshgupteAinda não há avaliações

- Riblene FC 30Documento2 páginasRiblene FC 30Josevi Jiménez MerinoAinda não há avaliações

- Araldite - GT7074Documento2 páginasAraldite - GT7074maz234Ainda não há avaliações

- Lldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalDocumento2 páginasLldpe Ll0209Aa Linear Low Density Polyethylene: 3) Typical Data Test Method Typical Value Unit Property PhysicalĐỗ Ngọc TúAinda não há avaliações

- Repsol Alcudia PE046Documento1 páginaRepsol Alcudia PE046armandoestavanquitoAinda não há avaliações

- SABIC® LLDPE - 118NJA - Americas - Technical - Data - SheetDocumento2 páginasSABIC® LLDPE - 118NJA - Americas - Technical - Data - Sheetdiana sarmientoAinda não há avaliações

- Standard Liquid Epoxy Resin Yd 128Documento6 páginasStandard Liquid Epoxy Resin Yd 128Ronald MarcanoAinda não há avaliações

- Epofine 184-Finehard 907 - Acc 062Documento4 páginasEpofine 184-Finehard 907 - Acc 062Karishma PrabhuAinda não há avaliações

- Epofine 221 - Finehard 964 - Accelerator 070Documento4 páginasEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuAinda não há avaliações

- ISO TITLEDocumento4 páginasISO TITLEOswaldo Manuel Ramirez Marin100% (2)

- Tasnee LD 1925as: Low Density PolyethyleneDocumento2 páginasTasnee LD 1925as: Low Density PolyethyleneMootaz Nagy El SabaaAinda não há avaliações

- Exceed™ S 9272ML: Performance PolymerDocumento2 páginasExceed™ S 9272ML: Performance PolymerMaram YasserAinda não há avaliações

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocumento2 páginasSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDiana SarmientoAinda não há avaliações

- Hfi5110 300516Documento2 páginasHfi5110 300516李万福Ainda não há avaliações

- Technical Data Sheet ADFLEX F 500Documento2 páginasTechnical Data Sheet ADFLEX F 500leftpowtaAinda não há avaliações

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregDocumento5 páginasEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuAinda não há avaliações

- Exceed S 9243MLDocumento2 páginasExceed S 9243MLzhen liuAinda não há avaliações

- TDS-PE-102-UB5502H (Provisional) 2019Documento2 páginasTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraAinda não há avaliações

- Ravalene CR LS 5241Documento1 páginaRavalene CR LS 5241ThamimAinda não há avaliações

- Utek PYJ9114 SMC SHEETDocumento2 páginasUtek PYJ9114 SMC SHEETFrederik TjonnelandAinda não há avaliações

- Exceed™ XP 8358 Series: Performance PolymerDocumento2 páginasExceed™ XP 8358 Series: Performance PolymerMaram YasserAinda não há avaliações

- 118 WJDocumento3 páginas118 WJAmin HunzaiAinda não há avaliações

- Rodenburg Biopolymers-Solanyl® C8001Documento4 páginasRodenburg Biopolymers-Solanyl® C8001Xuân Giang NguyễnAinda não há avaliações

- Exceed XP 8784 SeriesDocumento2 páginasExceed XP 8784 SeriesAli RazuAinda não há avaliações

- Perfecto TR UN BPXE-9Z8VBQDocumento2 páginasPerfecto TR UN BPXE-9Z8VBQRAinda não há avaliações

- Exceed™ XP 8318MJ: Performance PolymerDocumento2 páginasExceed™ XP 8318MJ: Performance PolymerMaram YasserAinda não há avaliações

- CASTROL PERFECTO XDocumento3 páginasCASTROL PERFECTO XHector Martin BarajasAinda não há avaliações

- Ficha Tecnica Castrol Perfecto X RangeDocumento3 páginasFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezAinda não há avaliações

- Exceed™ XP 8656ML: Performance PolymerDocumento2 páginasExceed™ XP 8656ML: Performance PolymerCristian RodriguezAinda não há avaliações

- Sikasil Ig 25Documento2 páginasSikasil Ig 25Amjad AlQasrawiAinda não há avaliações

- Vitralit 1650 English Tds Panacol AdhesiveDocumento4 páginasVitralit 1650 English Tds Panacol Adhesivetito3007Ainda não há avaliações

- Product Data Sheet: Molylube Ultra Open Gear LubricantDocumento2 páginasProduct Data Sheet: Molylube Ultra Open Gear LubricantDiegoAinda não há avaliações

- Epoxy System LR620 Laminating: DescriptionDocumento3 páginasEpoxy System LR620 Laminating: DescriptionFarzad LotfalipourAinda não há avaliações

- Resin Epox Mec8243Documento6 páginasResin Epox Mec8243Safety AdvisorsAinda não há avaliações

- Epoxy SpecDocumento2 páginasEpoxy SpecBinod SharmaAinda não há avaliações

- Exceed™ S 9333 Series: Performance PolymerDocumento2 páginasExceed™ S 9333 Series: Performance PolymerMaram YasserAinda não há avaliações

- Sikasil SG-500: High Performance Structural Silicone AdhesiveDocumento2 páginasSikasil SG-500: High Performance Structural Silicone Adhesivethe enverAinda não há avaliações

- EP 520 EPC 520 Rev. 3Documento2 páginasEP 520 EPC 520 Rev. 3yoniAinda não há avaliações

- SABICs P6006NDocumento2 páginasSABICs P6006NroybharggavAinda não há avaliações

- SABIC® LLDPE - MG500026 - Global - Technical - Data - SheetDocumento2 páginasSABIC® LLDPE - MG500026 - Global - Technical - Data - Sheetabhimanyu.xplastAinda não há avaliações

- Data SheetDocumento2 páginasData SheetDridi BadreddineAinda não há avaliações

- Shell Omala 220 Gear OilDocumento2 páginasShell Omala 220 Gear OilGeviena Pinky Sy SarmientoAinda não há avaliações

- Iso-Superior Glycols-Plain: Product Features & ApplicationsDocumento1 páginaIso-Superior Glycols-Plain: Product Features & ApplicationsEldiyar AzamatovAinda não há avaliações

- Epofine 179-1: Finehard 906-1Documento4 páginasEpofine 179-1: Finehard 906-1Karishma PrabhuAinda não há avaliações

- Glass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesDocumento2 páginasGlass Fiber Reinforced PBT Material Injection Molding Grade Pellets / GranulesmuthuAinda não há avaliações

- Arakril Ak 840Documento2 páginasArakril Ak 840decopinturas rdAinda não há avaliações

- Alzamil Chiller - SeriesDocumento13 páginasAlzamil Chiller - SeriesRAZA MEHDIAinda não há avaliações

- Alzamil Water Cooled - SeriesDocumento45 páginasAlzamil Water Cooled - SeriesRAZA MEHDIAinda não há avaliações

- TDS EpicureCuring Agent 3055Documento4 páginasTDS EpicureCuring Agent 3055RAZA MEHDIAinda não há avaliações

- The Corian Book PDFDocumento80 páginasThe Corian Book PDFRAZA MEHDIAinda não há avaliações

- Driers Basics - PpsDocumento20 páginasDriers Basics - PpsRAZA MEHDIAinda não há avaliações

- Dropping-Softening Point SystemsDocumento9 páginasDropping-Softening Point SystemsRAZA MEHDIAinda não há avaliações

- Driers Basics - PpsDocumento20 páginasDriers Basics - PpsRAZA MEHDIAinda não há avaliações

- Filter TroubleshootingDocumento9 páginasFilter TroubleshootingRAZA MEHDIAinda não há avaliações

- MSDS 8420 - PMMDocumento7 páginasMSDS 8420 - PMMRAZA MEHDIAinda não há avaliações

- MSDS PolyliteDocumento16 páginasMSDS PolyliteRAZA MEHDIAinda não há avaliações

- Automatic Apparatus For Softening PointDocumento2 páginasAutomatic Apparatus For Softening PointRAZA MEHDIAinda não há avaliações

- Polylite TDSDocumento3 páginasPolylite TDSRAZA MEHDIAinda não há avaliações

- Premier 50 50Documento1 páginaPremier 50 50RAZA MEHDIAinda não há avaliações

- Color B ValueDocumento2 páginasColor B ValueRAZA MEHDIAinda não há avaliações

- ASTM D 1475-98 (2003) - Density PDFDocumento5 páginasASTM D 1475-98 (2003) - Density PDFRAZA MEHDIAinda não há avaliações

- Astm D-1652-04 - EewDocumento4 páginasAstm D-1652-04 - EewRAZA MEHDI100% (1)

- ASTM D2071 Amine Value Fatty AminesDocumento4 páginasASTM D2071 Amine Value Fatty Aminesrazamehdi3Ainda não há avaliações

- ICI Viscosity Cap Series BrookfieldDocumento2 páginasICI Viscosity Cap Series BrookfieldRAZA MEHDIAinda não há avaliações

- N-282D Powder Coating Resin PC-17-5Nwith PUDocumento4 páginasN-282D Powder Coating Resin PC-17-5Nwith PURAZA MEHDIAinda não há avaliações

- InTech-Unsaturated Polyester Resin For Specialty ApplicationsDocumento2 páginasInTech-Unsaturated Polyester Resin For Specialty ApplicationsRAZA MEHDIAinda não há avaliações

- D2073 Total Primary Secondary and Tertiary Amine Values ofDocumento3 páginasD2073 Total Primary Secondary and Tertiary Amine Values ofRAZA MEHDIAinda não há avaliações

- N-281E Powder Coating Resin PC-17-4NDocumento4 páginasN-281E Powder Coating Resin PC-17-4NRAZA MEHDIAinda não há avaliações

- Epoxy Curing Agents and Modifiers Technical DatasheetDocumento1 páginaEpoxy Curing Agents and Modifiers Technical DatasheetRAZA MEHDIAinda não há avaliações

- Astman NPG Glycol: Powder Coating Resin PC-17-4N Based OnDocumento4 páginasAstman NPG Glycol: Powder Coating Resin PC-17-4N Based OnRAZA MEHDIAinda não há avaliações

- Aamer Ali Shah, Fariha Hasan, Abdul Hameed, Safia Ahmed - Biological Degradation of Plastics: A Comprehensive ReviewDocumento21 páginasAamer Ali Shah, Fariha Hasan, Abdul Hameed, Safia Ahmed - Biological Degradation of Plastics: A Comprehensive ReviewNatalí PalaiAinda não há avaliações

- Steam Distillation ExplainedDocumento2 páginasSteam Distillation ExplainedLouie Shaolin LungaoAinda não há avaliações

- Calculation For CO2 Released During CalcinationDocumento4 páginasCalculation For CO2 Released During CalcinationD N SHARMAAinda não há avaliações

- Bulacan Loft: Product SpecificationsDocumento22 páginasBulacan Loft: Product SpecificationsLang AwAinda não há avaliações

- Sigma Vyrobni Program enDocumento12 páginasSigma Vyrobni Program enEntropay UserAinda não há avaliações

- OSOS OMBLIGO AmigurumiDocumento12 páginasOSOS OMBLIGO AmigurumiANDREA ULTENGOAinda não há avaliações

- Saic M 1043Documento1 páginaSaic M 1043Hussain Nasser Al- NowiesserAinda não há avaliações

- TCET FE Applied Chemistry - I Resource Book (2018-19)Documento261 páginasTCET FE Applied Chemistry - I Resource Book (2018-19)KevinAinda não há avaliações

- API 570 - 01 API 570 and B31.3 PracticeDocumento5 páginasAPI 570 - 01 API 570 and B31.3 PracticeMegan KirbyAinda não há avaliações

- ASTM C892 High Temperature Fiber Blanket InsulationDocumento4 páginasASTM C892 High Temperature Fiber Blanket InsulationMike DukasAinda não há avaliações

- 607 Mixers - CAT - 991402 - 08-07-2021-WebDocumento72 páginas607 Mixers - CAT - 991402 - 08-07-2021-WebJyothi JyothiAinda não há avaliações

- Lcy 6733Documento1 páginaLcy 6733quangga10091986Ainda não há avaliações

- User's Guide: BondekDocumento8 páginasUser's Guide: BondekMing ChongAinda não há avaliações

- Carbonization of Coal for Metallurgical Coke Production GuideDocumento7 páginasCarbonization of Coal for Metallurgical Coke Production GuideKadiripuram ArjunAinda não há avaliações

- Chemguard C306-MS-C 3% AFFF Concentrate: DescriptionDocumento2 páginasChemguard C306-MS-C 3% AFFF Concentrate: DescriptionChyeAmshariYumanAinda não há avaliações

- TLE-FoodProcessing8 Q2M5Week8 OKDocumento15 páginasTLE-FoodProcessing8 Q2M5Week8 OKAmelita Benignos OsorioAinda não há avaliações

- Building SSR 2007 08Documento239 páginasBuilding SSR 2007 08VenkataLakshmiKorrapatiAinda não há avaliações

- Unsur Transisi Deret 1Documento62 páginasUnsur Transisi Deret 1Miniatur IniAinda não há avaliações

- US Small Business Administration Table of Small Business Size StandardsDocumento44 páginasUS Small Business Administration Table of Small Business Size StandardsMilton RechtAinda não há avaliações

- A Review of Natural Fiber Composites PropertiesDocumento65 páginasA Review of Natural Fiber Composites Propertieschatgpt51023Ainda não há avaliações

- MoRTH 1000 Materials For StructureDocumento18 páginasMoRTH 1000 Materials For StructureApurv PatelAinda não há avaliações

- Crockmaster 680Documento2 páginasCrockmaster 680dyetex100% (1)

- Cold Water Plumbing DesignDocumento17 páginasCold Water Plumbing DesignKHA120096 StudentAinda não há avaliações

- DEP Shell Table of ContentsDocumento14 páginasDEP Shell Table of ContentsMomchil Pekov100% (2)

- Intermetallics: Volker Güther, Melissa Allen, Joachim Klose, Helmut Clemens TDocumento11 páginasIntermetallics: Volker Güther, Melissa Allen, Joachim Klose, Helmut Clemens TSofiane TaaneAinda não há avaliações

- Abrasion Resistance of High-Strength Concrete in Hydraulic StructuresDocumento8 páginasAbrasion Resistance of High-Strength Concrete in Hydraulic StructuresEjaz RahimiAinda não há avaliações

- Colored Gold - WikipediaDocumento30 páginasColored Gold - Wikipediashehalan nilumindaAinda não há avaliações

- Rugged AC Magnetic Particle Inspection ProbeDocumento2 páginasRugged AC Magnetic Particle Inspection ProbeNubia BarreraAinda não há avaliações

- Brochure Poliver March 2014Documento2 páginasBrochure Poliver March 2014NayBonitaAinda não há avaliações