Escolar Documentos

Profissional Documentos

Cultura Documentos

Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGV

Enviado por

sadiqTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGV

Enviado por

sadiqDireitos autorais:

Formatos disponíveis

UTP A 2133 Mn

TIG rod

Classifications

EN ISO 14343 Material-No.

WZ 21 33 Mn Nb ~ 1.4850

Characteristics and field of use

UTP A 2133 Mn is suitable for joining and surfacing heat resistant base materials of identical and

of similar nature, such as

1.4859 G X 10 NiCrNb 32 20

1.4876 X 10 NiCrAlTi 32 21 UNS N08800

1.4958 X 5 NiCrAlTi 31 20 UNS N08810

1.4959 X 8 NiCrAlTI 31 21 UNS N08811

A typical application is the root welding of centrifugally cast pipes in the petrochemical industry for

operation temperatures up to 1050° C in dependence with the atmosphere.

Scale resistant up to 1050° C. Good resistance to carburising atmosphere.

Typical analysis in %

C Si Mn Cr Ni Nb Fe

0,12 0,3 4,5 21,0 33,0 1,2 balance

Mechanical properties of the weld metal

Yield strength RP0,2 Tensile strength Rm Elongation A Impact strength KV

MPa MPa % J [RT]

400 600 20 70

Welding instruction

Clean the weld area thoroughly. Low heat input. Max. interpass temperature 150° C.

Approvals

TÜV (No. 10451)

Rod diameter x length [mm] Current type Shielding gas (EN ISO 14175)

2,0 x 1000 DC (-) I1

2,4 x 1000 DC (-) I1

3,2 x 1000 DC (-) I1

All information provided is based upon careful investigation and intensive research. 03/2014 Rev. 0

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

Você também pode gostar

- UTP A 6222 MoDocumento1 páginaUTP A 6222 MoKara WhiteAinda não há avaliações

- 11062016000000utp A 068 HHDocumento1 página11062016000000utp A 068 HHtqtatqawAinda não há avaliações

- ER316L Ss en 1Documento1 páginaER316L Ss en 1brayanAinda não há avaliações

- L1 34428 en B Boehler-AWS-ER309L Ss en 1Documento1 páginaL1 34428 en B Boehler-AWS-ER309L Ss en 1Edgar HornusAinda não há avaliações

- A389 CuNiDocumento1 páginaA389 CuNiPrathamesh OmtechAinda não há avaliações

- Utp A 3444Documento1 páginaUtp A 3444Sun SunAinda não há avaliações

- Bohler AWS ER308LDocumento1 páginaBohler AWS ER308LbrayanAinda não há avaliações

- Bohler Aws Er308lDocumento1 páginaBohler Aws Er308lJuan ShunaAinda não há avaliações

- Thermanit GE-316L PDFDocumento1 páginaThermanit GE-316L PDFsmpoe017Ainda não há avaliações

- Utp A 068 HH: ClassificationsDocumento1 páginaUtp A 068 HH: ClassificationsErickAinda não há avaliações

- Utp A 80 M: ClassificationsDocumento1 páginaUtp A 80 M: ClassificationsInaamAinda não há avaliações

- UTP A 8051 Ti: ClassificationsDocumento1 páginaUTP A 8051 Ti: ClassificationsGustavo OrozcoAinda não há avaliações

- T - Thermanit ATS 4 - Ss - en - 5Documento1 páginaT - Thermanit ATS 4 - Ss - en - 5rusf123Ainda não há avaliações

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocumento1 página11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczAinda não há avaliações

- BOEHLER Q T 309L TIG RodDocumento1 páginaBOEHLER Q T 309L TIG RodbrayanAinda não há avaliações

- T - Thermanit 22 - 09 - de - en - 5Documento1 páginaT - Thermanit 22 - 09 - de - en - 5brayanAinda não há avaliações

- T - Thermanit 25 - 09 CuT - de - en - 5Documento1 páginaT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANIAinda não há avaliações

- Boehler EAS 4 M-IG - Tig RodDocumento1 páginaBoehler EAS 4 M-IG - Tig RodbrayanAinda não há avaliações

- Utp 068 HHDocumento1 páginaUtp 068 HHRoberto_PrrAinda não há avaliações

- Thermanit 25-35 R-Tigrod High Alloyed-W Z 25 35 - 21072020030650Documento1 páginaThermanit 25-35 R-Tigrod High Alloyed-W Z 25 35 - 21072020030650Nima SharifiAinda não há avaliações

- Utp 630Documento1 páginaUtp 630brayanAinda não há avaliações

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocumento2 páginasThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezAinda não há avaliações

- Utp A 3444 - 2Documento1 páginaUtp A 3444 - 2Sun SunAinda não há avaliações

- 03 Bushing-Cedaspa Type FDocumento7 páginas03 Bushing-Cedaspa Type FKatherine SmithAinda não há avaliações

- Bushings For PT MY2014Documento36 páginasBushings For PT MY2014Shung Tak ChanAinda não há avaliações

- UTP Cladding en 2017Documento12 páginasUTP Cladding en 2017Gourav SharmaAinda não há avaliações

- UTP A 3545 NBDocumento1 páginaUTP A 3545 NBNapol HengbumrungAinda não há avaliações

- UTP A 3545 NB PDFDocumento1 páginaUTP A 3545 NB PDFNAinda não há avaliações

- UTP A 3545 NB PDFDocumento1 páginaUTP A 3545 NB PDFNAinda não há avaliações

- UTP 6222 MoDocumento1 páginaUTP 6222 ModantegimenezAinda não há avaliações

- 19042016000000T - Union I CrMo 910 - Tig RodDocumento1 página19042016000000T - Union I CrMo 910 - Tig RodRushita SolankiAinda não há avaliações

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocumento1 páginaThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavAinda não há avaliações

- Avesta: Welding Wire TIGDocumento1 páginaAvesta: Welding Wire TIGErenBaşaraAinda não há avaliações

- Böhler CN 13/4-Mc Hi: Classifi CationsDocumento1 páginaBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakAinda não há avaliações

- 1 4501 Super Duplex TubesDocumento3 páginas1 4501 Super Duplex TubesAlma JakirovićAinda não há avaliações

- Böhler Cat 409 Cb-Ig: Classifi CationsDocumento1 páginaBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakAinda não há avaliações

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocumento1 páginaB Boehler Aws E316l 17 Se en 5a Mds PDFInaamAinda não há avaliações

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocumento3 páginasConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390Ainda não há avaliações

- Rod - Union I Crmo 910Documento1 páginaRod - Union I Crmo 910Rushita SolankiAinda não há avaliações

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocumento1 páginaThermanit 308 Mo 1SE3A00G 3407112 ENbrayanAinda não há avaliações

- 31102015000000B - Boehler E 308 H PW-FD - CWDocumento1 página31102015000000B - Boehler E 308 H PW-FD - CWKARLAinda não há avaliações

- Bushing For Power TransformersDocumento32 páginasBushing For Power TransformersShung Tak Chan100% (1)

- Consumables For E911 Crmo Steel: En/Din AstmDocumento3 páginasConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelAinda não há avaliações

- EJ Handbook.A5Documento261 páginasEJ Handbook.A5ElMacheteDelHuesoAinda não há avaliações

- CERTILAS EN Edition2023 320Documento1 páginaCERTILAS EN Edition2023 320Alireza KhodabandehAinda não há avaliações

- L1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1Documento1 páginaL1 - 6689 - en - B - Boehler Fox CN 22 9 N - Se - en - v1cristian popescuAinda não há avaliações

- Utp A Dur 250Documento1 páginaUtp A Dur 250rusf123Ainda não há avaliações

- 29102015000000B - Boehler CN 22 9 N-IG - TRDocumento1 página29102015000000B - Boehler CN 22 9 N-IG - TRAnibal QuezadaAinda não há avaliações

- HV Full CatalogueDocumento17 páginasHV Full CataloguemaggamAinda não há avaliações

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocumento1 páginaThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanAinda não há avaliações

- مكونات نقط اللحام شامل بنط اللحامDocumento2 páginasمكونات نقط اللحام شامل بنط اللحامdaha333Ainda não há avaliações

- Utp 34 NDocumento1 páginaUtp 34 NbrayanAinda não há avaliações

- Bushings PDFDocumento32 páginasBushings PDFRacha AmelAinda não há avaliações

- Utp 86 FNDocumento1 páginaUtp 86 FNc131508Ainda não há avaliações

- DC Switches 2015Documento32 páginasDC Switches 2015Rizky NAinda não há avaliações

- b41588 A3478 T - Ae4634ffc6Documento12 páginasb41588 A3478 T - Ae4634ffc6kerusacba_2011Ainda não há avaliações

- 308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsDocumento1 página308H Tig: Category GMAW-GTAW Solid Wires Type ApplicationsFilipe CordeiroAinda não há avaliações

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsAinda não há avaliações

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesNo EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesNota: 4.5 de 5 estrelas4.5/5 (7)

- Inspection Unit Capabilities: Ensuring Mechanical Integrity of Plant EquipmentDocumento1 páginaInspection Unit Capabilities: Ensuring Mechanical Integrity of Plant EquipmentsadiqAinda não há avaliações

- Inspection Unit Capabilities: Ensuring Mechanical Integrity of Plant EquipmentDocumento1 páginaInspection Unit Capabilities: Ensuring Mechanical Integrity of Plant EquipmentsadiqAinda não há avaliações

- Fuel ConsumptionDocumento2 páginasFuel ConsumptionsadiqAinda não há avaliações

- Contact: Artistic Milliners 02 (Denim Division)Documento4 páginasContact: Artistic Milliners 02 (Denim Division)sadiqAinda não há avaliações

- Vibration Analysis: Mobius InstituteDocumento1 páginaVibration Analysis: Mobius InstitutesadiqAinda não há avaliações

- AsdasdaDocumento1 páginaAsdasdasadiqAinda não há avaliações

- RiskWISE Import Template StorageTank 11-Aug-2018 145718412Documento41 páginasRiskWISE Import Template StorageTank 11-Aug-2018 145718412irfanlarikhotmailcomAinda não há avaliações

- TE's DescriptionDocumento10 páginasTE's DescriptionsadiqAinda não há avaliações

- RiskWISE Import Template StorageTank 11-Aug-2018 145718412Documento41 páginasRiskWISE Import Template StorageTank 11-Aug-2018 145718412irfanlarikhotmailcomAinda não há avaliações

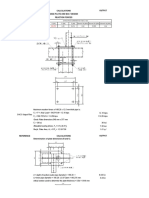

- Base Plate & Bolt DesignDocumento2 páginasBase Plate & Bolt DesigndovermanAinda não há avaliações

- Chemistry in The LaundryDocumento38 páginasChemistry in The LaundryAldayantiAinda não há avaliações

- Waste DisposalDocumento5 páginasWaste DisposalCharan ReddyAinda não há avaliações

- Rubber World HNBR Article - Therban AT PDFDocumento9 páginasRubber World HNBR Article - Therban AT PDFAnusha Rajagopalan100% (1)

- As 3895.1-1991 Methods For The Analysis of Copper Lead Zinc Gold and Silver Ores Determination of Gold (FireDocumento6 páginasAs 3895.1-1991 Methods For The Analysis of Copper Lead Zinc Gold and Silver Ores Determination of Gold (FireSAI Global - APACAinda não há avaliações

- 1 3 DiiminoisoindolineDocumento6 páginas1 3 Diiminoisoindolinekanji63Ainda não há avaliações

- BBS T5a P01 STR 2100Documento31 páginasBBS T5a P01 STR 2100Franklyn GenoveAinda não há avaliações

- Inorganic Chemistry Chem-318 Lec 3Documento24 páginasInorganic Chemistry Chem-318 Lec 3Mahnoor ShakeelAinda não há avaliações

- BF Alkali ProblemDocumento6 páginasBF Alkali ProblemSuresh BabuAinda não há avaliações

- Improvement of Soft Clay With Cement and Bagasse Ash WasteDocumento11 páginasImprovement of Soft Clay With Cement and Bagasse Ash WasteAnonymous NxpnI6jC100% (1)

- Latex CompoundingDocumento3 páginasLatex Compoundingvimalpoly75% (4)

- Aromatic WatersDocumento5 páginasAromatic WatersManjeeta Mandlik90% (10)

- Layer Stack InformationDocumento9 páginasLayer Stack InformationMadhav DimbleAinda não há avaliações

- Module 3 - Lesson 2 ThermodynamicsDocumento98 páginasModule 3 - Lesson 2 ThermodynamicsZarina SalesAinda não há avaliações

- Industrial Waste Management: Engr. Abaid UllahDocumento19 páginasIndustrial Waste Management: Engr. Abaid UllahAsma KhanAinda não há avaliações

- QUIZ 2 Landfill AnswersDocumento4 páginasQUIZ 2 Landfill AnswersSigmund SiyAinda não há avaliações

- API 570 Piping InspectionDocumento35 páginasAPI 570 Piping InspectionIrvansyah Razadin100% (9)

- Wood Mechanical FastenersDocumento4 páginasWood Mechanical FastenersUzoetue Chidera KennedyAinda não há avaliações

- MSDS King Madu BorneoDocumento5 páginasMSDS King Madu BorneoWahyuBangkitAinda não há avaliações

- Cleaning Supplies Tools Chemicals and EquipmentsDocumento97 páginasCleaning Supplies Tools Chemicals and EquipmentsErlyn Alcantara100% (2)

- Som 1Documento1 páginaSom 1Cristina Mauren PajesAinda não há avaliações

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Documento3 páginasQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentAinda não há avaliações

- Chains and Buckets Etc.Documento6 páginasChains and Buckets Etc.dariusiasdasdAinda não há avaliações

- 1993-Schmalzried - Internal Solid State ReactionsDocumento57 páginas1993-Schmalzried - Internal Solid State ReactionsDavid Hernández EscobarAinda não há avaliações

- Unofficial Mock 6Documento3 páginasUnofficial Mock 6Disha MukherjeeAinda não há avaliações

- Chemistry Matters Ch02 Textbk ANSDocumento3 páginasChemistry Matters Ch02 Textbk ANSZeneon71% (14)

- JR Et Al. - 2004 - Liquid Armor Protective Fabrics Utilizing Shear Thickening FluidsDocumento9 páginasJR Et Al. - 2004 - Liquid Armor Protective Fabrics Utilizing Shear Thickening FluidsThiago SantosAinda não há avaliações

- 225-Garbage Management ManualDocumento21 páginas225-Garbage Management ManualAnant Ajithkumar100% (1)

- Is 3589Documento22 páginasIs 3589Otavio123100% (1)

- Monografia EYEC 11th FinalDocumento77 páginasMonografia EYEC 11th FinalGaylordAinda não há avaliações