Escolar Documentos

Profissional Documentos

Cultura Documentos

Module5.IonImplantation - Ee143 F14.ctnguyen

Enviado por

stansilawTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Module5.IonImplantation - Ee143 F14.ctnguyen

Enviado por

stansilawDireitos autorais:

Formatos disponíveis

EE 143: Microfabrication Technology CTN 10/21/14

Lecture Module 5: Ion Implantation

EE 143

Microfabrication Technology

Fall 2014

Prof. Clark T.-C. Nguyen

Dept. of Electrical Engineering & Computer Sciences

University of California at Berkeley

Berkeley, CA 94720

Lecture Module 5: Ion Implantation

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 1

Semiconductor Doping

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 2

Copyright @ 2014 Regents of the University of California at Berkeley

EE 143: Microfabrication Technology CTN 10/21/14

Lecture Module 5: Ion Implantation

Doping of Semiconductors

• Semiconductors are not intrinsically conductive

• To make them conductive, replace silicon atoms in the lattice

with dopant atoms that have valence bands with fewer or

more e-’s than the 4 of Si

• If more e-’s, then the dopant is a donor: P, As

The extra e- is effectively released from the bonded

atoms to join a cloud of free e-’s, free to move like e-’s

in a metal Extra free e-

:

:

:

:

Si

:

Si

:

Si

: . P . : Si : P : Si :

.

:

:

:

:

Si Si Si Dope : Si : Si : Si :

: : : :

:

:

The larger the # of donor atoms, the larger the # of

free e-’s the higher the conductivity

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 3

Doping of Semiconductors (cont.)

• Conductivity Equation: charge magnitude

on an electron

q n n q p p

conductivity hole

electron electron hole density

mobility density mobility

• If fewer e-’s, then the dopant is an acceptor: B

.

:

:

:

Si

:

Si

:

Si

: . B . : Si : B : Si :

.

:

:

:

:

Si Si Si Dope : Si : Si : Si :

: : : :

hole

:

:

:

Lack of an e- = hole = h+

When e-’s move into h+’s, the h+’s effectively move in the

opposite direction a h+ is a mobile (+) charge carrier

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 4

Copyright @ 2014 Regents of the University of California at Berkeley

EE 143: Microfabrication Technology CTN 10/21/14

Lecture Module 5: Ion Implantation

Ion Implantation

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 5

Ion Implantation

• Method by which dopants can be introduced in silicon to

make the silicon conductive, and for transistor devices, to

form, e.g., pn-junctions, source/drain junctions, …

The basic process: Charged dopant accelerated

to high energy by an E-Field

B+ B+ B+ B+ B+ (e.g., 100 keV)

Control current &

time to control the Masking material

dose. B-B-B-B- (could be PR, could be

oxide, etc.)

x Si Depth determined by

energy & type of dopant

Result of I/I

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 6

Copyright @ 2014 Regents of the University of California at Berkeley

EE 143: Microfabrication Technology CTN 10/21/14

Lecture Module 5: Ion Implantation

Ion Implantation (cont.)

Result of I/I

Damage Si layer at

top becomes amorphous

Si Si Si

B not in the lattice,

B so it‘s not electrically

active.

Si Si Si

Ion collides with atoms and

interacts with e-’s in the High Temperature Anneal

lattice all of which slow (also, usually do a drive-in

it down and eventually stop diffusion) (800-1200°C)

it. Si Si Si

Now B in the lattice

& electrically active!

Si Si (serves as dopant)

B

This is a statistical process implanted impurity profile can be

approximated by a Gaussian distribution.

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 7

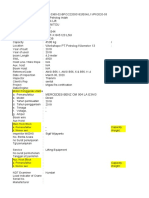

Statistical Modeling of I/I

N(x)

Impurity Unlucky ions

concentration Np

Avg. ions

One std. dev. Lucky ions

away 0.61Np

Rp Rp

2 std. dev.

away 0,14Np Rp Rp

3 std. dev.

away 0.11Np Rp

Distance into Si material, x

R p Projected range = avg. distance on ion trends before stopping

R p Straggle = std. deviation characterizing the spread of the

distribution.

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 8

Copyright @ 2014 Regents of the University of California at Berkeley

EE 143: Microfabrication Technology CTN 10/21/14

Lecture Module 5: Ion Implantation

Analytical Modeling for I/I

Mathematically:

x Rp

N ( x) N p exp

2

2 R p 2

Area under the

impurity Implanted Dose = Q N ( x ) dx ions / cm 2

distribution curve 0

For an implant completely contained within the Si:

Q 2 N p R p

Assuming the peak is in the silicon: (putting it in one-sided

diffusion form) So we can track the dopant front during a

DI Q subsequent diffusion step.

DI 2 x R p 2 R 2

N ( x) exp 2

, where Dt p

Dt eff 2R p

eff

2

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 9

I/I Range Graphs

• Rp is a function of the

energy of the ion and atomic

•Roughly proportional to ion

energy Rp ion energy number of the ion and target

(some nonlinearties) material

• Lindhand, Scharff and

, Rp

Schiott (LSS) Theory:

• Assumes implantation into

amorphous material, i.e,

atoms of the target material

are randomly positioned

• Yields the curves of Fig. 6.1

and 6.2

• For a given energy, lighter

elements strike Si with

Figure 6.1 higher velocity and penetrate

more deeply

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 10

Copyright @ 2014 Regents of the University of California at Berkeley

EE 143: Microfabrication Technology CTN 10/21/14

Lecture Module 5: Ion Implantation

I/I Straggle Graphs

• Results for Si and SiO2

surfaces are virtually

identical so we can use

these curves for both

Figure 6.2

EE 143: Microfabrication Technology LecM 5 C. Nguyen 2/14/10 11

Copyright @ 2014 Regents of the University of California at Berkeley

Você também pode gostar

- Departure Departure: Info Wind Visib Info Wind VisibDocumento2 páginasDeparture Departure: Info Wind Visib Info Wind VisibTeoria Eldorado do SulAinda não há avaliações

- Vogel v. Sink Suit - Mecklenburg County Superior CourtDocumento32 páginasVogel v. Sink Suit - Mecklenburg County Superior CourtBen SchachtmanAinda não há avaliações

- Ifè Chukwu Musescore FinalDocumento6 páginasIfè Chukwu Musescore FinalChigbo ChiemezieAinda não há avaliações

- ListChoixOrientation 20210421Documento1 páginaListChoixOrientation 20210421MouRad MàfTahAinda não há avaliações

- 19-Sep-18 22-Sep-18 19-Sep-18 22-Sep-18 19-Sep-18 22-Sep-18 19-Sep-18 22-Sep-18Documento1 página19-Sep-18 22-Sep-18 19-Sep-18 22-Sep-18 19-Sep-18 22-Sep-18 19-Sep-18 22-Sep-18Hamrah SiddiquiAinda não há avaliações

- Hayagreeva StotramDocumento3 páginasHayagreeva StotramValli IbAinda não há avaliações

- Étincelle 2bac PCDocumento2 páginasÉtincelle 2bac PCSouhail El AsferAinda não há avaliações

- ListChoixOrientation_20230722Documento1 páginaListChoixOrientation_20230722yasminefassel032Ainda não há avaliações

- Chemical Bonding and Molecular Structure PDFDocumento109 páginasChemical Bonding and Molecular Structure PDFArnav PantAinda não há avaliações

- ListChoixOrientation - 20230411 2Documento1 páginaListChoixOrientation - 20230411 2fayrouzzouitineAinda não há avaliações

- ListChoixOrientation_20240411Documento1 páginaListChoixOrientation_20240411elidrissiilyass913Ainda não há avaliações

- ListChoixOrientation 20220414Documento1 páginaListChoixOrientation 20220414MarouaneAinda não há avaliações

- MassarFile 1649974617Documento1 páginaMassarFile 1649974617MarouaneAinda não há avaliações

- 345 Cau Khau Ngu Tieng Han 3Documento350 páginas345 Cau Khau Ngu Tieng Han 3heaven smileAinda não há avaliações

- Class Schedule Planner: Time Monday Tuesday Wednesday Thursday FridayDocumento1 páginaClass Schedule Planner: Time Monday Tuesday Wednesday Thursday FridayAnonymous Ms8nYcbxY2Ainda não há avaliações

- ListChoixOrientation - 20230411 2Documento1 páginaListChoixOrientation - 20230411 2Mohamde BouiddaAinda não há avaliações

- Shot LogDocumento1 páginaShot LogShobha GadhireAinda não há avaliações

- ListChoixOrientation 20220413Documento1 páginaListChoixOrientation 20220413mouadoutga001Ainda não há avaliações

- Analyzing patterns in financial dataDocumento601 páginasAnalyzing patterns in financial dataLAUNCH check engineAinda não há avaliações

- Policy Information 1Documento1 páginaPolicy Information 1Teddie B. YapAinda não há avaliações

- Subarctic SurvivalDocumento3 páginasSubarctic SurvivalTyraAinda não há avaliações

- 52 Pecasfaceis PDFDocumento29 páginas52 Pecasfaceis PDFGeorge FelixAinda não há avaliações

- Henry Jackson Society Accounts 2008Documento14 páginasHenry Jackson Society Accounts 2008Spin WatchAinda não há avaliações

- 1st Sec AlgebraDocumento43 páginas1st Sec AlgebraAmer MomenAinda não há avaliações

- Metals and How To Weld ThemDocumento1 páginaMetals and How To Weld ThemJack JohnsonAinda não há avaliações

- Govt Bond Yields Quarterly DataDocumento29 páginasGovt Bond Yields Quarterly DataemilstaykovAinda não há avaliações

- الضرائب المباشرة و الضرائب غير المباشرةDocumento2 páginasالضرائب المباشرة و الضرائب غير المباشرةAnonymous eY2RY80TBAinda não há avaliações

- La ViolenceDocumento1 páginaLa ViolenceVortex FFAinda não há avaliações

- EDC-I Easy Solution SEM3-1 PDFDocumento112 páginasEDC-I Easy Solution SEM3-1 PDFSumedh SatamAinda não há avaliações

- Heat Transfer Operation 1118062019092802 PDFDocumento7 páginasHeat Transfer Operation 1118062019092802 PDFChemical EngineeringAinda não há avaliações

- Technical & Journey Log CrescentDocumento1 páginaTechnical & Journey Log CrescentAmit KumarAinda não há avaliações

- Lewis Structures, Shapes, and PolarityDocumento3 páginasLewis Structures, Shapes, and PolarityJohn BartolomeAinda não há avaliações

- w319 Lewis Structures Shapes and PolarityDocumento3 páginasw319 Lewis Structures Shapes and PolarityDkaye GorospeAinda não há avaliações

- w319 Lewis Structures Shapes and Polarity PDFDocumento3 páginasw319 Lewis Structures Shapes and Polarity PDFJohn BartolomeAinda não há avaliações

- Centrul de Invatamant la Distanta si Formare ContinuaDocumento5 páginasCentrul de Invatamant la Distanta si Formare ContinuaGeorge OlteanuAinda não há avaliações

- RapportChoixReOrientation 20230913Documento1 páginaRapportChoixReOrientation 20230913Mohamed DahbiAinda não há avaliações

- Do 040 S2014 PDFDocumento3 páginasDo 040 S2014 PDFgarhgelhAinda não há avaliações

- Loan Amortization Template 14Documento2 páginasLoan Amortization Template 14Metiku DigieAinda não há avaliações

- ExcavatorDocumento1 páginaExcavatorHudson PasaribuAinda não há avaliações

- Daily Time Record Daily Time RecordDocumento4 páginasDaily Time Record Daily Time RecordNorwin BulosanAinda não há avaliações

- Fork Lift 39Documento1.273 páginasFork Lift 39pediAinda não há avaliações

- Feasibility Study, ESIA (Environmental and Social Luuq Doolow Beled Hawo)Documento332 páginasFeasibility Study, ESIA (Environmental and Social Luuq Doolow Beled Hawo)mustafurade1Ainda não há avaliações

- Metals and AlloysDocumento3 páginasMetals and AlloysPatrycja WesołowskaAinda não há avaliações

- Anchor Bolt Dia CheckDocumento2 páginasAnchor Bolt Dia CheckSaravanan SAinda não há avaliações

- JK F?J :JJ. J J JT ?J'?: L?î? I I Ltî, I L?îil IYA I, J!T L I ItpîtfaDocumento1 páginaJK F?J :JJ. J J JT ?J'?: L?î? I I Ltî, I L?îil IYA I, J!T L I ItpîtfattAinda não há avaliações

- راس المال الفكري ودوره في تحقيق الميزة التنافسيةDocumento18 páginasراس المال الفكري ودوره في تحقيق الميزة التنافسيةSabreena BenarbiaAinda não há avaliações

- KVJTP - Fire - Safety Certi - 2021Documento2 páginasKVJTP - Fire - Safety Certi - 2021Distribuidora Y Comercializadora Dore's S.A.SAinda não há avaliações

- FAB-FR-75-01-5-B Daily Work Production RecordDocumento1 páginaFAB-FR-75-01-5-B Daily Work Production RecordRonnel LeanoAinda não há avaliações

- Bach - BWV 4 - Viola 2.pdf Másolata PDFDocumento3 páginasBach - BWV 4 - Viola 2.pdf Másolata PDFElemér AlbertAinda não há avaliações

- Bendravimo Psichologijos Žinių Patikrinimo Ir Savarankiškų Darbų UžduotysDocumento43 páginasBendravimo Psichologijos Žinių Patikrinimo Ir Savarankiškų Darbų UžduotysDaiva ValienėAinda não há avaliações

- Script de SonidoDocumento1 páginaScript de SonidoIsabella Lopez MesaAinda não há avaliações

- Magonia - No 39 - 1991 04Documento7 páginasMagonia - No 39 - 1991 04nevilleAinda não há avaliações

- The Stony Brook Press - Volume 20, Issue 15Documento24 páginasThe Stony Brook Press - Volume 20, Issue 15The Stony Brook PressAinda não há avaliações

- The Stony Brook Press - Volume 17, Issue 15Documento8 páginasThe Stony Brook Press - Volume 17, Issue 15The Stony Brook PressAinda não há avaliações

- Production line 1 جاتنلا ا طخ: Kenzy Quality SystemDocumento2 páginasProduction line 1 جاتنلا ا طخ: Kenzy Quality SystemHADEER ELSAYEDAinda não há avaliações

- Their: Icat:ionsDocumento9 páginasTheir: Icat:ionsMare NostrumAinda não há avaliações

- Short title for document on 1990s housing policyDocumento26 páginasShort title for document on 1990s housing policyMimzAinda não há avaliações

- Rate Analysis Norms - DOIDocumento118 páginasRate Analysis Norms - DOIMWIDD 01100% (1)

- 2022학년도 수능- 영어 정답,해설Documento30 páginas2022학년도 수능- 영어 정답,해설임가은Ainda não há avaliações

- Micro/Nano Processing Tech Course OverviewDocumento14 páginasMicro/Nano Processing Tech Course OverviewstansilawAinda não há avaliações

- Lec3w MaterialsI Ee143 f14 PDFDocumento3 páginasLec3w MaterialsI Ee143 f14 PDFstansilawAinda não há avaliações

- Module7 Interconnects Ee143 s10 Ctnguyen PDFDocumento16 páginasModule7 Interconnects Ee143 s10 Ctnguyen PDFstansilawAinda não há avaliações

- SP 2005 Lecture23Documento22 páginasSP 2005 Lecture23stansilawAinda não há avaliações

- SP 2005 Lecture19Documento36 páginasSP 2005 Lecture19stansilawAinda não há avaliações

- Lec3w MaterialsI Ee143 f14 PDFDocumento3 páginasLec3w MaterialsI Ee143 f14 PDFstansilawAinda não há avaliações

- Lecture38 PDFDocumento2 páginasLecture38 PDFstansilawAinda não há avaliações

- Micro/Nano Processing Tech Course OverviewDocumento14 páginasMicro/Nano Processing Tech Course OverviewstansilawAinda não há avaliações

- Module6.Diffusion - Ee143 F14.ctnguyenDocumento13 páginasModule6.Diffusion - Ee143 F14.ctnguyenstansilawAinda não há avaliações

- Lec 03Documento13 páginasLec 03stansilawAinda não há avaliações

- Oxidation of Si: Why SiO2 is Critical for Semiconductor IndustryDocumento11 páginasOxidation of Si: Why SiO2 is Critical for Semiconductor IndustrystansilawAinda não há avaliações

- Module7 Interconnects Ee143 s10 CtnguyenDocumento16 páginasModule7 Interconnects Ee143 s10 CtnguyenstansilawAinda não há avaliações

- Lec25w.vtimplant - Ee143 f14.CtnDocumento7 páginasLec25w.vtimplant - Ee143 f14.CtnstansilawAinda não há avaliações

- Mercury WavelengthsDocumento4 páginasMercury WavelengthsMainak DuttaAinda não há avaliações

- Lec26w.deviceCharacterization - Ee143 f14.CtnDocumento16 páginasLec26w.deviceCharacterization - Ee143 f14.CtnstansilawAinda não há avaliações

- hw1 Ee143 f14 Web PDFDocumento3 páginashw1 Ee143 f14 Web PDFstansilawAinda não há avaliações

- Module7 Interconnects Ee143 s10 Ctnguyen PDFDocumento16 páginasModule7 Interconnects Ee143 s10 Ctnguyen PDFstansilawAinda não há avaliações

- Module4.Etching - Ee143 f14.CtnDocumento20 páginasModule4.Etching - Ee143 f14.CtnstansilawAinda não há avaliações

- SP 2005 Lecture05 PreviewDocumento1 páginaSP 2005 Lecture05 PreviewstansilawAinda não há avaliações

- Module3.FilmDeposition - Ee143 F14.ctnguyenDocumento24 páginasModule3.FilmDeposition - Ee143 F14.ctnguyenstansilawAinda não há avaliações

- EE 143 Microfabrication Technology Fall 2014: Prof. Clark T.-C. NguyenDocumento9 páginasEE 143 Microfabrication Technology Fall 2014: Prof. Clark T.-C. NguyenstansilawAinda não há avaliações

- SP 2005 Lecture04 PreviewDocumento2 páginasSP 2005 Lecture04 PreviewstansilawAinda não há avaliações

- SP 2005 Lecture08 CIMDocumento13 páginasSP 2005 Lecture08 CIMstansilawAinda não há avaliações

- Lec1p 1stDayAdmin PDFDocumento4 páginasLec1p 1stDayAdmin PDFstansilawAinda não há avaliações

- 3.155J/6.152J Lecture 21: Fluids Lab Testing: Prof. Akintunde I. Akinwande Massachusetts Institute of Technology 5/2/2005Documento13 páginas3.155J/6.152J Lecture 21: Fluids Lab Testing: Prof. Akintunde I. Akinwande Massachusetts Institute of Technology 5/2/2005stansilawAinda não há avaliações

- SP 2005 Lecture09 PDFDocumento17 páginasSP 2005 Lecture09 PDFstansilawAinda não há avaliações

- SP 2005 Lecture06 PreviewDocumento1 páginaSP 2005 Lecture06 PreviewstansilawAinda não há avaliações

- CVD Processes ExplainedDocumento14 páginasCVD Processes ExplainedstansilawAinda não há avaliações

- Oxidation of Si: Why SiO2 is Critical for Semiconductor IndustryDocumento11 páginasOxidation of Si: Why SiO2 is Critical for Semiconductor IndustrystansilawAinda não há avaliações

- Tabla de Colores Winsor & NewtonDocumento8 páginasTabla de Colores Winsor & NewtonArq Copy ChorrillosAinda não há avaliações

- Membrane Technology in Water Treatment ApplicationsDocumento11 páginasMembrane Technology in Water Treatment ApplicationsleechulmiuAinda não há avaliações

- Code All Item RohanDocumento127 páginasCode All Item RohanKapooAinda não há avaliações

- Fibrolit® - Fett-Ld: Safety Data SheetDocumento5 páginasFibrolit® - Fett-Ld: Safety Data Sheetks2000n1Ainda não há avaliações

- Folien SFPS 0Documento6 páginasFolien SFPS 0BUDAPESAinda não há avaliações

- Lesson 11 Environmental Crisis and Sustainable DevelopmentDocumento41 páginasLesson 11 Environmental Crisis and Sustainable DevelopmentJoyce GarciaAinda não há avaliações

- Emulsion LectureDocumento30 páginasEmulsion LectureRay YangAinda não há avaliações

- 1 s2.0 S235271021931085X MainDocumento11 páginas1 s2.0 S235271021931085X MainLiu SadikAinda não há avaliações

- Cswip 3.1 Part 2Documento20 páginasCswip 3.1 Part 2Alam MD SazidAinda não há avaliações

- General Methods of Extraction and Isolation of AlkaloidsDocumento11 páginasGeneral Methods of Extraction and Isolation of AlkaloidsMuhdar FarmaAinda não há avaliações

- Zeta Plus S Series Depth Filter Cartridges and CapsulesDocumento4 páginasZeta Plus S Series Depth Filter Cartridges and Capsulesgeorgadam1983Ainda não há avaliações

- 2 SCDocumento31 páginas2 SCsusuAinda não há avaliações

- Equilibrium For VotechDocumento27 páginasEquilibrium For VotechDesy SudirmanAinda não há avaliações

- VMP Manual PDFDocumento106 páginasVMP Manual PDFkikiAinda não há avaliações

- Solvent DeasphaltingDocumento1 páginaSolvent DeasphaltingTheiva GanesAinda não há avaliações

- Supreme Motor Oil MSDSDocumento7 páginasSupreme Motor Oil MSDSsofelsbabaAinda não há avaliações

- PORTFOLIO - BIOLOGICAL CELL Prepared by 1st Year MBBS Student-LEKSHMIDocumento10 páginasPORTFOLIO - BIOLOGICAL CELL Prepared by 1st Year MBBS Student-LEKSHMIspillai11Ainda não há avaliações

- Keeping Cats Safe from PoisonsDocumento2 páginasKeeping Cats Safe from PoisonsLulu MAinda não há avaliações

- Aerodynamics - IIDocumento10 páginasAerodynamics - IIVejay RamAinda não há avaliações

- Sanden PDFDocumento42 páginasSanden PDFLocalmapa Milton Brande100% (1)

- How TiO2 Improves Paint Weather ResistanceDocumento8 páginasHow TiO2 Improves Paint Weather Resistanceuocmogiandi_aAinda não há avaliações

- Csec Chemistry - A5Documento17 páginasCsec Chemistry - A5Mencarty DocentAinda não há avaliações

- Glyconutrients and MannatechDocumento5 páginasGlyconutrients and MannatechJillyStoneyAinda não há avaliações

- CARBOXYLIC ACID Derivatives - Salts and ReactionsDocumento6 páginasCARBOXYLIC ACID Derivatives - Salts and ReactionsmarcelompassosAinda não há avaliações

- D19 2 en Fuel SpecificationDocumento35 páginasD19 2 en Fuel SpecificationPaulo GodinhoAinda não há avaliações

- Sanken News: House of Fashion Shopping MallDocumento10 páginasSanken News: House of Fashion Shopping Mallmalan_ubAinda não há avaliações

- Potatoes: Nutritional Recommendations ForDocumento44 páginasPotatoes: Nutritional Recommendations ForNik NikAinda não há avaliações

- Oxygen/Acetylene Welding and Cutting Works: Safe Operating ProcedureDocumento1 páginaOxygen/Acetylene Welding and Cutting Works: Safe Operating ProcedurejayadushAinda não há avaliações

- MME B.Tech IV-SEM REG MR-21 Model-Question-PapersDocumento10 páginasMME B.Tech IV-SEM REG MR-21 Model-Question-Papersankit pandeyAinda não há avaliações

- Production ManualsDocumento14 páginasProduction ManualsgreatgeniusAinda não há avaliações