Escolar Documentos

Profissional Documentos

Cultura Documentos

Chemical Engineering & Design Division: Indian Institute of Integrative Medicine, Jammu

Enviado por

Horus Slughorn0 notas0% acharam este documento útil (0 voto)

16 visualizações4 páginasNumerical solutions of design.

Título original

Design engineering

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoNumerical solutions of design.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

16 visualizações4 páginasChemical Engineering & Design Division: Indian Institute of Integrative Medicine, Jammu

Enviado por

Horus SlughornNumerical solutions of design.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

Indian Institute of Integrative Medicine, Jammu

Chemical Engineering & Design Division

Overview Generate authentic and accurate,

clinically acceptable data, which can

potentially lead to new IPR’s.

Chemical Engineering and Design Division of

IIIM, Jammu is engaged in process development Objectives

and scale-up of laboratory processes on pilot

plant. Generally extraction processes are carried To obtain “New process data”

out on various herbal/medicinal plants. These

extraction processes are scaled-up from 100/500 Improve Yields and

g laboratory-scale to 15-20 kg pilot plant scale Conversions

processes. Thereafter their various process

parameters are optimized, in order to maximize Evaluation of Products & By-products

the yield of these extractions. Preliminary cost estimation

Missions and goals In order to Maximize yield,

Optimisation of following process

To Scale-up and optimize laboratory parameters is carried out: Plant Mat./

scale processes, in order to develop Solvent Ratio; Temperature of

cGMP compliant and commercially viable Extraction Number of Extractions;

technologies transferable to user Time of each extraction.

industry.

Competencies

Develop standardized & quality traditional

medicines which are affordable to Process Development and scale up of

community chemical processes from laboratory

to pilot scale. For this purpose, a

Develop new rational formulation of

multipurpose batch extraction pilot

traditional drugs.

plant, developed, designed and

Generate sufficient data for effective fabricated in IIIM Jammu is presently

regularization and control of herbal / being used. A new computer

traditional medicines moving into controlled cGMP extraction plant has

international markets. been installed and commissioned in

chemical engineering (IIIM Jammu)

Chemical Engineering & Design Division, CSIR-IIIM, Jammu Page 1

for this purpose. compliant Herbal drugs extraction pilot

plant for M/S Tropical Botanics , Malaysia

Plant Capacity: To process around

15-20 kg of material per batch. Facilities

Up scaling carried out from 100 g to One old solvent extraction plant along with

15/20 kg scale solvent recovery system, concentration unit and

drying unit

Purpose to reduce STEPS, reduce Second complete cGMP Herbal Drugs Extraction

SOLVENTS and increase SAFETY of unit was designed, fabricated, installed and

lab. commissioned in March 2009 at IIIM, Jammu.

The major equipments of the plant are as

Processes during their scale up on

follows:-

pilot scale.

Plant material air dryer.

Area of research

Plant material Grinder and

screening system.

Scaled up and optimized process on pilot

plant for the extraction of Tinospora R.O. plant for process water.

cordifolia. The technology was

Extraction system with

transferred to M/S Nicholas Piramal,

condensers breathers and

Mumbai.

automatic material handling

Scaled up and optimized process on pilot system

plant for the extraction of Calcitriol from

Batch solvent storage tanks

Cestrum diurnum. The technology was

transferred to M/S Genova Biotech Ltd. Solvent recovery unit with

Hyderabad.. condenser, breather and storage

tanks.

Scaled up and optimized process on pilot

plant for the extraction of Acteoside from Wiped film evaporator with

Colebrookia opp. The technology was accessories.

transferred to M/S Ochoa Pharma, New

Delhi. Vacuum pan drier.

Scaled up and optimized process on pilot Vacuum tray drier

plant for the extraction of Hyperforin and

Spray drier

Hypericin from Hypericum perforatum.

The technology was transferred to M/S Dry Extract sealing unit.

Nicholas Piramal, Mumbai.

Executed the turnkey project of cGMP

Chemical Engineering & Design Division, CSIR-IIIM, Jammu Page 2

The plant has been installed on proper steel Extraction step optimized on pilot scale.

structure and following utilities were also installed

with appropriate header lines for inlet and outlet Color absorption/adsorption and final

of water, chilled water, air, vacuum and steam concentration and drying in development

etc. stage.

Boiler – Cap- 600kg/h (Thermax Aim to obtain white crystalline powder

make) extract.

Cooling tower SIMAP Project for Steam distillation &

Fractionation of Mint oil at KanyaKumari.

Chilling plant

Projects

Air compressor

National facility project “ cGMP

Vacuum pumps pilot plant for Extraction,

Formulation and Packaging of

The entire plant is controlled by PLC/computer

Traditional (ISM) herbal

with by pass lines for manual operation.

Medicinal formulation” financed

by IIIM Jammu, DST New Delhi,

and Ayush.

Current research

Process development for extraction of

Stevioside/Rebaudioside rich extract from

Stevia (Industry Linkage- Sahara India)

People

Name Expertise E-mail

Er. Anil Kumar Katare Chemical process development, scale-up akkatare@iiim.ac.in

and optimization. Designing of multipurpose

herbal drugs extraction plants, Steam

distillation units, dryers and other process

equipment like distillation columns,

evaporators, heat exchangers and pressure

vessels.

Chemical Engineering & Design Division, CSIR-IIIM, Jammu Page 3

Mrs. Suman Koul Experience in chemical process sumankoul@iiim.ac.in

development, scale-up and optimization.

Operation of herbal drugs extraction plants

and other pilot plants

Sat Pal Operation and maintenance of extraction

and other chemical Engg. pilot plants

Chemical Engineering & Design Division, CSIR-IIIM, Jammu Page 4

Você também pode gostar

- A Guide To Cannabis Extraction Equipment and Machines - Articles - Analytical CannabisDocumento25 páginasA Guide To Cannabis Extraction Equipment and Machines - Articles - Analytical CannabisCamilo Serna Restrepo100% (1)

- SteckDocumento354 páginasStecknaruto100% (1)

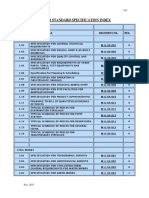

- Water Standard Specification Index As On Dec 2015Documento10 páginasWater Standard Specification Index As On Dec 2015afp15060% (1)

- Wet Steam Washing SystemDocumento7 páginasWet Steam Washing SystemPrudhvi Raj100% (1)

- Evaporation Falling Film Forced Circulation Vapor Recompression Gea 170546Documento20 páginasEvaporation Falling Film Forced Circulation Vapor Recompression Gea 170546Johan van der MenerAinda não há avaliações

- Pilot Plant Scale-Up TechniqueDocumento27 páginasPilot Plant Scale-Up TechniqueVidvendu GuptaAinda não há avaliações

- #Chapter 1 - Pilot Plant Scale Up Techniques-UnlockedDocumento91 páginas#Chapter 1 - Pilot Plant Scale Up Techniques-UnlockedRitika Gupta100% (1)

- Pilot plant design and scale up processDocumento7 páginasPilot plant design and scale up processDrx Rinku KunduAinda não há avaliações

- 2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesDocumento8 páginas2006 01 02 - Pharmaceutical Facilitiy Upgrades - The Containment IssuesHubert BonamisAinda não há avaliações

- Comprehensive Elevator ManualDocumento23 páginasComprehensive Elevator ManualIlham fitriansyahAinda não há avaliações

- Long Life Paneer New PDFDocumento1 páginaLong Life Paneer New PDFsrikumarAinda não há avaliações

- Wiped Film Evaporator For The Distillation of Cardanol From Cashew Nut Shell LiquidDocumento5 páginasWiped Film Evaporator For The Distillation of Cardanol From Cashew Nut Shell Liquidalibaber78Ainda não há avaliações

- Sustainable initiatives towards co-processing of waste in cement kiln - Successes, trends and support for improved utilizationDocumento16 páginasSustainable initiatives towards co-processing of waste in cement kiln - Successes, trends and support for improved utilizationamara gopiAinda não há avaliações

- Praj Matrix The Innovation Center Sept 2021Documento8 páginasPraj Matrix The Innovation Center Sept 2021sagnikniyogiAinda não há avaliações

- Teplotni Technika enDocumento9 páginasTeplotni Technika enunconfusiusAinda não há avaliações

- Pharmaceutical Pilot Scale UpDocumento51 páginasPharmaceutical Pilot Scale UpDerejeAinda não há avaliações

- Debottlenecking of A Batch Pharmaceutical Cream ProductionDocumento9 páginasDebottlenecking of A Batch Pharmaceutical Cream Productionmailtorubal2573Ainda não há avaliações

- FAM AggXtream Presentation Rev8Documento11 páginasFAM AggXtream Presentation Rev8cdkueaAinda não há avaliações

- INDMAX Technology: Produce Light Olefins & Gasoline from PetroleumDocumento3 páginasINDMAX Technology: Produce Light Olefins & Gasoline from PetroleumMinhquang NgoAinda não há avaliações

- The Role of the Laboratory in the Dyehouse ProcessDocumento2 páginasThe Role of the Laboratory in the Dyehouse ProcessIbrahim EtmanAinda não há avaliações

- Hidrodestilación Asistida MatrixDocumento4 páginasHidrodestilación Asistida MatrixDaniel BaqueroAinda não há avaliações

- Chemical ManagementDocumento9 páginasChemical Managementalialharbi021Ainda não há avaliações

- 10+ years Petrochemical EngineerDocumento4 páginas10+ years Petrochemical EngineerFahad RockingAinda não há avaliações

- Surrogate TestingDocumento7 páginasSurrogate TestingOmkarAinda não há avaliações

- Scigenics PresentationDocumento33 páginasScigenics PresentationMuthuswamy Shanmugasundaram0% (1)

- Group 1_POM_pptDocumento14 páginasGroup 1_POM_pptayushyaAinda não há avaliações

- Evaluating Capacity of Palm Oil Mill Using Simulation Towards Effective Supply Chain 3f A Case StudyDocumento10 páginasEvaluating Capacity of Palm Oil Mill Using Simulation Towards Effective Supply Chain 3f A Case StudyWAN NOURUL AINNA A.Ainda não há avaliações

- 2017-06 Advance HSE Products and ServicesDocumento4 páginas2017-06 Advance HSE Products and ServicesAyatAinda não há avaliações

- 1.2. Textile - SaffronDocumento2 páginas1.2. Textile - Saffroneric tanudjaja100% (1)

- yoghurt Manufacturing Task 1[1] (1) - final1Documento4 páginasyoghurt Manufacturing Task 1[1] (1) - final1hansaja3711Ainda não há avaliações

- SAFC Pharma - St. Louis - Biologic APIs and ConjugationDocumento2 páginasSAFC Pharma - St. Louis - Biologic APIs and ConjugationSAFC-GlobalAinda não há avaliações

- Katalog V36 ENDocumento35 páginasKatalog V36 ENDominik_LjubicicAinda não há avaliações

- Khairul Hafidzi Bin Sidek: Education FieldDocumento2 páginasKhairul Hafidzi Bin Sidek: Education Fieldhafiezy77Ainda não há avaliações

- SAFC Pharma - Gillingham Facility - Experienced CGMP Manufacturing ProviderDocumento2 páginasSAFC Pharma - Gillingham Facility - Experienced CGMP Manufacturing ProviderSAFC-GlobalAinda não há avaliações

- Teplotni Technika - ENDocumento9 páginasTeplotni Technika - ENNaveenbala25Ainda não há avaliações

- Pilot Plant Plan To Reduce Toxic WasteDocumento2 páginasPilot Plant Plan To Reduce Toxic WasteSam MurrayAinda não há avaliações

- Merck Process DevelopmentDocumento12 páginasMerck Process DevelopmentrkponrajAinda não há avaliações

- Team Members: Faculty: Prof. Srinivas SeethamrajuDocumento5 páginasTeam Members: Faculty: Prof. Srinivas SeethamrajuSatyamSahuAinda não há avaliações

- Autoclave_Sterivap double door 160 LDocumento9 páginasAutoclave_Sterivap double door 160 Lsantirat.phoAinda não há avaliações

- Anthem Biosciences - OverviewDocumento29 páginasAnthem Biosciences - OverviewNitish JondhaleAinda não há avaliações

- 32 (1) (1) .00 YrsDocumento4 páginas32 (1) (1) .00 YrsmeenuAinda não há avaliações

- Engineer's SEO-Optimized ResumeDocumento4 páginasEngineer's SEO-Optimized ResumeFahad RockingAinda não há avaliações

- PharmaDocumento14 páginasPharmauhdisuhdisAinda não há avaliações

- Revamping Concepts For Urea Plants by Hans Van Den TillaartDocumento31 páginasRevamping Concepts For Urea Plants by Hans Van Den TillaartMarc NijsseAinda não há avaliações

- Stok PreparationDocumento5 páginasStok PreparationtisaAinda não há avaliações

- Pulp Plant SchedulingDocumento5 páginasPulp Plant SchedulingsauravAinda não há avaliações

- Designing Effective Drug Formulations - PA - Q416 - 34Documento4 páginasDesigning Effective Drug Formulations - PA - Q416 - 34Sateesh KumarAinda não há avaliações

- Successful Control System Cutover at The World'S Largest Oil Processing PlantDocumento2 páginasSuccessful Control System Cutover at The World'S Largest Oil Processing Plantyusuf alamerAinda não há avaliações

- Industrial Water Treatment Plant for Umm Wu'al Phosphate Fertilizer ProjectDocumento2 páginasIndustrial Water Treatment Plant for Umm Wu'al Phosphate Fertilizer Projectadalcayde2514Ainda não há avaliações

- Freeze Dryer Equipment Performance Qualification 1706216082Documento21 páginasFreeze Dryer Equipment Performance Qualification 1706216082Jozef HedjesiAinda não há avaliações

- Selection Process at The ACME Laboratories LTDDocumento11 páginasSelection Process at The ACME Laboratories LTDAshiq MirzaAinda não há avaliações

- Herculano - Brasil - 3 5MTPA Beneficiation Plant - Iron Ore - Project ProfileDocumento1 páginaHerculano - Brasil - 3 5MTPA Beneficiation Plant - Iron Ore - Project ProfileCarlos Hurtado GarcíaAinda não há avaliações

- Development of The Irradiation Facility SIBO INRATDocumento7 páginasDevelopment of The Irradiation Facility SIBO INRATValerie GoldyAinda não há avaliações

- Hiren - Resure For DhirajDocumento4 páginasHiren - Resure For Dhirajsinha_ravikant11Ainda não há avaliações

- Articulo DestilaciónDocumento6 páginasArticulo DestilaciónMarbel VldAinda não há avaliações

- Automatic Control System For Spray Drier Pilot Plant: Supriya Pote, Sneha SuditDocumento5 páginasAutomatic Control System For Spray Drier Pilot Plant: Supriya Pote, Sneha SuditerpublicationAinda não há avaliações

- ESIMFAQDocumento5 páginasESIMFAQBharath KumarAinda não há avaliações

- Utility Operator CVDocumento5 páginasUtility Operator CVLogan EthanAinda não há avaliações

- HOT Engineering & Construction CoDocumento28 páginasHOT Engineering & Construction CoDKHILLALI YAAKOUBAinda não há avaliações

- Introto AKWandtheie Petroleum Analytics Learning MachineDocumento21 páginasIntroto AKWandtheie Petroleum Analytics Learning Machinerodrigo belloAinda não há avaliações

- S SBRDocumento7 páginasS SBRGwee YongkuanAinda não há avaliações

- Process Validation Protocol of Granules For Oral AdministrationDocumento6 páginasProcess Validation Protocol of Granules For Oral AdministrationRezaul haque himelAinda não há avaliações

- Sapien VRT PublicationDocumento4 páginasSapien VRT PublicationhalessteveAinda não há avaliações

- Ptmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportDocumento23 páginasPtmail - m1021 - Ss - Ev Ultimate Market Intelligence ReportPIYUSH GOPALAinda não há avaliações

- Sub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)Documento2 páginasSub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)estelauAinda não há avaliações

- 2013 Midterm 3Documento16 páginas2013 Midterm 3billbyoag123Ainda não há avaliações

- Quantum Mechanics 1Documento88 páginasQuantum Mechanics 1Mehul GuptaAinda não há avaliações

- Zseise 40 ADocumento23 páginasZseise 40 ANini FarribasAinda não há avaliações

- Syllabus of Diploma in Electrical EngineeringDocumento17 páginasSyllabus of Diploma in Electrical EngineeringJoson Chan100% (1)

- Seller'S Disclosure and Condition of Property Addendum (Residential)Documento8 páginasSeller'S Disclosure and Condition of Property Addendum (Residential)Barbara BishopAinda não há avaliações

- Total Rewinding and Reconditioning of 3KW MotorDocumento5 páginasTotal Rewinding and Reconditioning of 3KW MotorCBD COLLEGE INCAinda não há avaliações

- Ufc 3 430 09Documento106 páginasUfc 3 430 09carlcrowAinda não há avaliações

- TMX53DC 1607 121 (Drawings Electric)Documento13 páginasTMX53DC 1607 121 (Drawings Electric)ChristianAinda não há avaliações

- AMX AC Power Source ManualDocumento114 páginasAMX AC Power Source ManualjassadAinda não há avaliações

- Dna60 PDFDocumento15 páginasDna60 PDFAc IdAinda não há avaliações

- RECYCLED ASPHALTDocumento27 páginasRECYCLED ASPHALTwillypraviantoAinda não há avaliações

- DC Machine Theory and Transformer PrinciplesDocumento32 páginasDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaAinda não há avaliações

- Technical Assistance Consultant's Report: Energy Storage Option For Accelerating Renewable Energy PenetrationDocumento364 páginasTechnical Assistance Consultant's Report: Energy Storage Option For Accelerating Renewable Energy PenetrationAlezsander RguezArAinda não há avaliações

- Gas Chromatograph OptimizationDocumento18 páginasGas Chromatograph OptimizationUmair KazmiAinda não há avaliações

- Orient Price List NewDocumento3 páginasOrient Price List Newrohan12345670% (1)

- KPSC/ KSEB/ SSC Electrical Score Academy: Questions: 75Documento9 páginasKPSC/ KSEB/ SSC Electrical Score Academy: Questions: 75sreevasanthAinda não há avaliações

- Thermal Shock Resistant Neoceram Glass-CeramicDocumento2 páginasThermal Shock Resistant Neoceram Glass-CeramicAmândio PintoAinda não há avaliações

- TERAO Presentation August 2022Documento48 páginasTERAO Presentation August 2022LuatNguyenAinda não há avaliações

- Enatel's microCOMPACT Power SystemDocumento2 páginasEnatel's microCOMPACT Power SystemomarpatAinda não há avaliações

- Impulse Valve Operator Kit IV.1.09.01Documento2 páginasImpulse Valve Operator Kit IV.1.09.01eduardo gonzalezav0% (1)

- Multidisciplinary Nature of Environmental StudiesDocumento6 páginasMultidisciplinary Nature of Environmental StudiesWiz Calvin ManutdAinda não há avaliações

- DC Components Co., LTD.: Rectifier SpecialistsDocumento3 páginasDC Components Co., LTD.: Rectifier SpecialistsPICVIOAinda não há avaliações

- Xref 2010Documento1 páginaXref 2010Axel Mahya AvichenaAinda não há avaliações

- Fabric Expansion JointsDocumento28 páginasFabric Expansion Jointswarmachine269889Ainda não há avaliações

![yoghurt Manufacturing Task 1[1] (1) - final1](https://imgv2-2-f.scribdassets.com/img/document/720269247/149x198/4b28dd416f/1712309903?v=1)