Escolar Documentos

Profissional Documentos

Cultura Documentos

Instructions: 'No' Answers Are To Be Resolved Immediately and Documented

Enviado por

rgrao85Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Instructions: 'No' Answers Are To Be Resolved Immediately and Documented

Enviado por

rgrao85Direitos autorais:

Formatos disponíveis

LAYERED PROCESS AUDIT F8.

06

TURRET DEPARTMENT - DAYS Week of: OPERATOR AREA LEADER TOP MANAGEMENT

W W

THESE ITEMS ARE TO BE CHECKED: M T W T F S RESOLUTION OR RESOLUTION OR RESOLUTION OR

E E

DAILY BY THE OPERATOR O U E H R A CORRECTIVE ACTION (IF CORRECTIVE ACTION (IF CORRECTIVE ACTION (IF

REQUIRED) E REQUIRED) E REQUIRED)

WEEKLY BY AREA LEADER N E D U I T

K K

WEEKLY BY TOP MANAGEMENT

PART # AUDITED PART # AUDITED PART # AUDITED

Instructions: 'No' answers are to be resolved immediately and documented.

I Corrective Action Form F8.08 (found in this folder) should be issued to the responsible

T party as necessary. Auditor is to follow up and return completed C.A. to this folder for

E collection.

M

Operations:

1 Is the first piece off tagged and accessible at the work area?

2 Is the traveler, print, and if applicable process plan, available at the work area?

3 Have all inspections performed been properly documented in the process plan? (i.e.

employee #'s, date, status, results) Missing or incorrect data could result in bad parts

being shipped to the customer.

4 Has the Previous operation been completed (i.e. all inspections performed,

documented and conforming)?

5 Are the correct containers being used if they are specified in the process plan or

traveler?

6 Are parts being packed properly if specified in the process plan or traveler? (i.e.

Quantity/Stacked)

7 Are containers dry and free of dirt, foreign materials and old labels?

8 Are all containers in the area properly tagged with the part #, quantity and status of

the parts they contain?

9 Are any Poka-yoke (mistake proofing) techniques being used on this part during this

process? If yes, are they working properly?

Work Environment:

1 Is the department cleanliness and organization at an optimal level? If no, what can be

done? (Resolve and document on the backside of this paper)

2 Is the proper safety equipment being used? (i.e. safety goggles, hearing protection,

gloves & proper shoes)

3 Are all chemical containers in the area properly labeled?

4 Have employees been trained or are they working under direct supervision? (Ask)

Gages:

Do all gages that are used to make a pass/fail decision contain a sticker for

1 identification and a current due date? (i.e. calipers, micrometers, height gages,

elcometer, digital protractor, ring gages, thread gages)

Is there a check fixture or tooling aide being used on this part? If yes, ask the

2

operator to demonstrate how to use it to ensure it is being used properly.

Compliance:

1 Have the required Layered Process Audits been completed so far this week?

2 Does the operator understand what to check dimensionally? (Ask the question)

3 If this is the last available LPA sheet?

Auditor Initial

Complies = Y Does Not Comply = N Not Applicable = N/A

file:///conversion/tmp/scratch/442674820.xls 7/28/08

Você também pode gostar

- 01 - Layered Process Audit Example B 2011Documento7 páginas01 - Layered Process Audit Example B 2011RN XaverAinda não há avaliações

- Operations: Group Leader: Daily Department Manager: Weekly Plant Manager: MonthlyDocumento4 páginasOperations: Group Leader: Daily Department Manager: Weekly Plant Manager: MonthlyR JAinda não há avaliações

- Example LPADocumento1 páginaExample LPAmedi380% (1)

- Fmea Chart 70kb PDFDocumento1 páginaFmea Chart 70kb PDFmike gamerAinda não há avaliações

- Production Part Approval Process (Ppap) Tracker - ChecklistDocumento4 páginasProduction Part Approval Process (Ppap) Tracker - Checklistkrds chidAinda não há avaliações

- Shainin Vs Six SigmaDocumento4 páginasShainin Vs Six Sigmabaro4518Ainda não há avaliações

- One Point LessonsDocumento27 páginasOne Point LessonsgcldesignAinda não há avaliações

- FMEA Facilitator Thought-Starter QuestionsDocumento5 páginasFMEA Facilitator Thought-Starter QuestionsvikeshmAinda não há avaliações

- Quality ManagementDocumento47 páginasQuality ManagementDora LimAinda não há avaliações

- Gemba Overview - Sheena Butts - IIESHS - WEBINAR v1Documento35 páginasGemba Overview - Sheena Butts - IIESHS - WEBINAR v1Bryan OrdialesAinda não há avaliações

- CPK & PPK CalculatorDocumento6 páginasCPK & PPK CalculatorAhmed TeranAinda não há avaliações

- Internal Audit Check List MRDocumento3 páginasInternal Audit Check List MRGanesh Iyer100% (1)

- Rolled Throughput Yield (Training)Documento7 páginasRolled Throughput Yield (Training)Madhavan RamAinda não há avaliações

- A3 Toyota 8 Step TemplatesDocumento11 páginasA3 Toyota 8 Step TemplatesBharathAinda não há avaliações

- Rca - 5w2h - Is-Is Not WorksheetDocumento6 páginasRca - 5w2h - Is-Is Not WorksheetmfritzAinda não há avaliações

- Overall Equipment Effectiveness (O.E.E.) Monitoring Sheet: Shift 1Documento28 páginasOverall Equipment Effectiveness (O.E.E.) Monitoring Sheet: Shift 1Sukhjot SinghAinda não há avaliações

- Room With A View - Boeing ObeyaDocumento2 páginasRoom With A View - Boeing ObeyaJohn TopperAinda não há avaliações

- Shanin Techniques Jo MoorenDocumento3 páginasShanin Techniques Jo MoorenAnonymous X0iytQQYJ6Ainda não há avaliações

- QC Tool - Control Chart Sieve Agg. 0.150mm 200diaDocumento3 páginasQC Tool - Control Chart Sieve Agg. 0.150mm 200diachinhon0% (1)

- Standard Work Sheets - v04Documento3 páginasStandard Work Sheets - v04Balaji SAinda não há avaliações

- DK Qap QHS 12-FR 03-R6 - CarDocumento1 páginaDK Qap QHS 12-FR 03-R6 - CarErlan Gus HermawanAinda não há avaliações

- 5y AnalysisDocumento2 páginas5y AnalysispsathishthevanAinda não há avaliações

- Six Sigma Case StudyDocumento13 páginasSix Sigma Case StudyvishalbhtAinda não há avaliações

- Lean / Flow Manufacturing: - Everyone Has A Role!Documento36 páginasLean / Flow Manufacturing: - Everyone Has A Role!Antonio PargaAinda não há avaliações

- 1.QAD.P10.F01 - 4M Change Tracking SheetDocumento1 página1.QAD.P10.F01 - 4M Change Tracking SheetPOOJA KUMARIAinda não há avaliações

- Problem Solving - PdcaDocumento61 páginasProblem Solving - PdcaNurul HidayahAinda não há avaliações

- Sample Downtime ReportDocumento37 páginasSample Downtime ReportRidwanAinda não há avaliações

- DFMEA Sample For A PenDocumento3 páginasDFMEA Sample For A PenVinay GowdaAinda não há avaliações

- Current State of Quality in The Automotive Industry: Scott Gray Director, Quality Products and Services, AIAGDocumento26 páginasCurrent State of Quality in The Automotive Industry: Scott Gray Director, Quality Products and Services, AIAGSelvaraj SAinda não há avaliações

- Lean Six Sigma CrosswordDocumento1 páginaLean Six Sigma CrosswordexamplecgAinda não há avaliações

- GR&R Training DraftDocumento53 páginasGR&R Training DraftLOGANATHAN VAinda não há avaliações

- Lean EN 2018Documento48 páginasLean EN 2018Karan KarnikAinda não há avaliações

- First Time Quality: SAP Course #: 62006505Documento65 páginasFirst Time Quality: SAP Course #: 62006505MickloSoberanAinda não há avaliações

- 5S Routine Audit Form: Quit Created by Javier RubioDocumento7 páginas5S Routine Audit Form: Quit Created by Javier RubioLa MetalurgicaAinda não há avaliações

- HA CEDAC Workshop INDO Kaizen PartDocumento16 páginasHA CEDAC Workshop INDO Kaizen PartHardi BanuareaAinda não há avaliações

- Master Black Belt Statistician in USA Resume John DubucDocumento2 páginasMaster Black Belt Statistician in USA Resume John DubucJohnDubucAinda não há avaliações

- Layered Audit ChecklistDocumento4 páginasLayered Audit ChecklistNavnath TamhaneAinda não há avaliações

- 5S & TPMDocumento19 páginas5S & TPMJesus Chi GorosicaAinda não há avaliações

- WCM ChecklistDocumento13 páginasWCM ChecklistYurdun OrbakAinda não há avaliações

- 1.4.quality GateDocumento15 páginas1.4.quality GateMOHAN SAinda não há avaliações

- VSM ExerciseDocumento1 páginaVSM ExerciseJacob EdwardsAinda não há avaliações

- 3L and 5 Why Presentation - MKGDocumento70 páginas3L and 5 Why Presentation - MKGMukesh GuptaAinda não há avaliações

- Anand Kumar ResumeDocumento3 páginasAnand Kumar ResumeArun ShishodiaAinda não há avaliações

- Proplanner PFEP Overview - 092912Documento46 páginasProplanner PFEP Overview - 092912Proplanner AsiaAinda não há avaliações

- Layered Process Audit Checklist (LPA)Documento5 páginasLayered Process Audit Checklist (LPA)ALBERTO ALVARADO CARRILLOAinda não há avaliações

- 6-Panel TemplateDocumento14 páginas6-Panel TemplateKaya Eralp Asab100% (1)

- Leader Standard Work Up 3Documento12 páginasLeader Standard Work Up 3jesusmemAinda não há avaliações

- 5S Audit MudaMastersDocumento1 página5S Audit MudaMastersManoj ShahAinda não há avaliações

- Redesigning Enterprise Process For E-BusinessDocumento211 páginasRedesigning Enterprise Process For E-BusinessMuarif AsdaAinda não há avaliações

- A3 Practical Problem Solving Principle DocumentDocumento10 páginasA3 Practical Problem Solving Principle DocumentNabil Raja DamanikAinda não há avaliações

- 07 Standardized Work QIP V4 Fev 2021 Training MaterialDocumento83 páginas07 Standardized Work QIP V4 Fev 2021 Training Materialawdhut kulkarniAinda não há avaliações

- Homologation and Self-CertificationDocumento10 páginasHomologation and Self-CertificationAli Raza Virk100% (1)

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Documento5 páginasFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123DanistergladwinAinda não há avaliações

- Cobbledick Layered Process Audits PDFDocumento22 páginasCobbledick Layered Process Audits PDFelyesAinda não há avaliações

- Tuv Rheinland Training Schedule 2017Documento19 páginasTuv Rheinland Training Schedule 2017ramnathAinda não há avaliações

- Critical To Customer RequirementsDocumento29 páginasCritical To Customer RequirementsVaibhav SinghAinda não há avaliações

- 8dproblem PDFDocumento64 páginas8dproblem PDFidenbelleAinda não há avaliações

- 8D Problem SolvingDocumento9 páginas8D Problem SolvingManu ElaAinda não há avaliações

- Supplier Capability Self Assessment Form 2015 PROTECTEDDocumento24 páginasSupplier Capability Self Assessment Form 2015 PROTECTEDrgrao85Ainda não há avaliações

- Green Belt Project Storyboard v2.0 TemplateDocumento27 páginasGreen Belt Project Storyboard v2.0 Templatergrao85Ainda não há avaliações

- Company Namebuhler: Deputy Manager - ProjectsDocumento1 páginaCompany Namebuhler: Deputy Manager - Projectsrgrao85Ainda não há avaliações

- Supplier Capability Self Assessment Form 2015 PROTECTEDDocumento24 páginasSupplier Capability Self Assessment Form 2015 PROTECTEDrgrao85Ainda não há avaliações

- Starter Product RevenueDocumento5 páginasStarter Product Revenuergrao85Ainda não há avaliações

- ENG FRM 001 Ve 1Documento535 páginasENG FRM 001 Ve 1rgrao85Ainda não há avaliações

- AVP Performance Head Stud Kit For 6.0L Power Stroke: Parts Included: Tools NeededDocumento2 páginasAVP Performance Head Stud Kit For 6.0L Power Stroke: Parts Included: Tools Neededrgrao85Ainda não há avaliações

- Flexman QuestionDocumento2 páginasFlexman Questionrgrao85Ainda não há avaliações

- Procurement & LogisticDocumento1 páginaProcurement & Logisticrgrao85Ainda não há avaliações

- Auto and Auto Ancillaries Sector in IndiaDocumento13 páginasAuto and Auto Ancillaries Sector in Indiargrao85Ainda não há avaliações

- Elements of Forecasting: LN Yr Logyr Actual Sales Estd - Sales-1 Est - Logsales Est - Lnsales LN Sales Log Sales Time PeriodDocumento10 páginasElements of Forecasting: LN Yr Logyr Actual Sales Estd - Sales-1 Est - Logsales Est - Lnsales LN Sales Log Sales Time Periodrgrao85Ainda não há avaliações

- S20157enDocumento137 páginasS20157enrgrao85Ainda não há avaliações

- Mold Design Fundamental Calculation BATTERY COVERDocumento7 páginasMold Design Fundamental Calculation BATTERY COVERrgrao85Ainda não há avaliações

- Apparel Pattern DesigningDocumento17 páginasApparel Pattern Designingrgrao85Ainda não há avaliações

- Element ListDocumento1 páginaElement Listrgrao85Ainda não há avaliações

- Marketing Research Tactical Plan: Scope Definition PhaseDocumento1 páginaMarketing Research Tactical Plan: Scope Definition Phasergrao85Ainda não há avaliações

- Financial StatementDocumento34 páginasFinancial Statementrgrao850% (2)

- New Production Dev TimelineDocumento2 páginasNew Production Dev Timelinergrao85Ainda não há avaliações

- LME Steel Rebar FactsheetDocumento2 páginasLME Steel Rebar Factsheetrgrao85Ainda não há avaliações

- Real Time Color: Based Object Detection and TrackingDocumento15 páginasReal Time Color: Based Object Detection and TrackingRahul RepalaAinda não há avaliações

- KauneDocumento7 páginasKauneEnos Marcos Bastos100% (1)

- Check Point + Siemplify: ChallengeDocumento3 páginasCheck Point + Siemplify: ChallengeriyasathsafranAinda não há avaliações

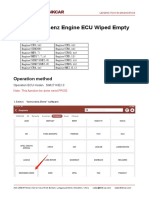

- Mercedes Benz Engine ECU Wiped EmptyDocumento9 páginasMercedes Benz Engine ECU Wiped EmptyP BAinda não há avaliações

- SpeedControl V90 S7-1200 DOC enDocumento23 páginasSpeedControl V90 S7-1200 DOC enDavid LucioAinda não há avaliações

- CH 4 - Footprinting and Social EngineeringDocumento64 páginasCH 4 - Footprinting and Social EngineeringcoderAinda não há avaliações

- Role of Statistics in Artificial IntelligenceDocumento3 páginasRole of Statistics in Artificial IntelligencegyandassenpaiAinda não há avaliações

- OneDrive For BusinessDocumento29 páginasOneDrive For BusinessJohann NeethlingAinda não há avaliações

- Assignment On VOIPDocumento5 páginasAssignment On VOIPRayan KarimAinda não há avaliações

- Altezza Auto Mirror ClosureDocumento7 páginasAltezza Auto Mirror ClosureChard CharlesAinda não há avaliações

- Napolcom MC 2019-007Documento3 páginasNapolcom MC 2019-007Edward MagatAinda não há avaliações

- DICTMDocumento20 páginasDICTMJohn Carlo Leynes BrunoAinda não há avaliações

- Variable DC Power Supply Project ReportDocumento10 páginasVariable DC Power Supply Project ReportEngr. Zeeshan mohsin73% (22)

- Small and Thin 2 G Accelerometer ADXL322: Features General DescriptionDocumento16 páginasSmall and Thin 2 G Accelerometer ADXL322: Features General DescriptionPrateek AgrawalAinda não há avaliações

- Sending Output of Concurrent Programs Via EmailDocumento1 páginaSending Output of Concurrent Programs Via EmailAshish HarbhajankaAinda não há avaliações

- LogcatDocumento2 páginasLogcatBLACK RAKESH YTAinda não há avaliações

- Digital Modulation HandoutDocumento18 páginasDigital Modulation HandoutAyham ALZABEN (AZMiKs)Ainda não há avaliações

- It - Mega - Courses 1Documento13 páginasIt - Mega - Courses 1Telt100% (4)

- Spool ADocumento280 páginasSpool ARadheyaKahatAinda não há avaliações

- CCNP Switching LAB Preparation TestDocumento2 páginasCCNP Switching LAB Preparation TestGiannisDemetriouAinda não há avaliações

- Dell Inspiron 15r 5521 QuoteDocumento4 páginasDell Inspiron 15r 5521 QuoteAnush PremAinda não há avaliações

- The Drying of Granular FertilizersDocumento16 páginasThe Drying of Granular FertilizersnataliamonteiroAinda não há avaliações

- An Illustrated History of ComputersDocumento18 páginasAn Illustrated History of Computersmirarad5052Ainda não há avaliações

- Ulss Ulsm UlslDocumento1 páginaUlss Ulsm UlslHamzaAinda não há avaliações

- KEM DensitometersDocumento8 páginasKEM DensitometersTank Top 2Ainda não há avaliações

- CSE 211: Data Structures Lecture Notes I: Ender Ozcan, Şebnem BaydereDocumento11 páginasCSE 211: Data Structures Lecture Notes I: Ender Ozcan, Şebnem Baydereapi-3705606Ainda não há avaliações

- Test Bank and Soluiton 2018-2019Documento40 páginasTest Bank and Soluiton 2018-2019A plus Test bank and Solution manualAinda não há avaliações

- LP Introduction SolvedDocumento9 páginasLP Introduction SolvedRakesh ChandraAinda não há avaliações

- Ibwave Release NotesDocumento17 páginasIbwave Release Noteshysteria_kAinda não há avaliações

- Why Implements AmDocumento23 páginasWhy Implements Amdayanx2014Ainda não há avaliações