Escolar Documentos

Profissional Documentos

Cultura Documentos

Flow-Assurance Challenges in Gas-Storage Schemes in Depleted Reservoirs

Enviado por

bibiDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Flow-Assurance Challenges in Gas-Storage Schemes in Depleted Reservoirs

Enviado por

bibiDireitos autorais:

Formatos disponíveis

GAS PRODUCTION TECHNOLOGY

Flow-Assurance Challenges in Gas-Storage

Schemes in Depleted Reservoirs

Injection or production of dry gas into or surface facilities, resulting in corro- rium. Generally, producing this amount

or from a depleted gas reservoir could sion, hydrate, and/or ice formation. of water from the reservoir results in

result in serious flow-assurance chal- an increase in the salt concentration

lenges. Parameters involved in water Background (hence, a reduction in water-vapor pres-

evaporation/production and in salt pre- The study model was a 3D, Cartesian- sure and in water evaporation/produc-

cipitation for a gas-production/-injec- grid-type block containing one well. tion). However, it is challenging to

tion well are described quantitatively. The model was intended to represent model this salt-deposition phenomenon

The terms of formation damage (skin) a portion of a gas field (i.e., drainage with commercial simulators.

were evaluated, and some recommen- area) with its corresponding producer/ During injection/production cycles, a

dations for prediction and mitigation injector. A seasonal natural-gas storage/ constant water-production-rate increase

are proposed. Water in the produced production scheme was modeled. First, was observed that corresponded to

gas is a major flow-assurance threat production from the reservoir lasted the constant-rate-vaporization period.

because of the possibility of gas-hydrate 30 months with a maximum daily gas- During this period, it is assumed that

formation in the production system. production rate of 45×106 m3/d. Then, gas is in contact with connate water

Mitigation methods are presented. injection was modeled for 3 months at and that the rock surface is saturated;

10×106 m3/d, followed by 4 months of therefore, vaporization continued until

Introduction soaking (i.e., shut-in). Then, for 5 years the falling-rate period occurred. During

Gas injected into the depleted reser- the following injection/production cycle the falling-rate period, the rock surface

voir normally is a processed/dried gas. was used: 2 months of production, 3 was no longer saturated; therefore, the

However, after injection, the gas is in months of soaking, 3 months of injec- evaporation rate and water-production

contact with hydrocarbon and aqueous tion, 4 months of soaking, and 2 months rate decreased.

phases in the reservoir. Therefore, the of production, for each calendar year.

composition of the produced gas may The following properties were Salinity. Constant salinity was con-

differ from that of the injected gas. More assumed: Reservoir temperature= sidered throughout the entire produc-

importantly, the produced gas will have 104°C, initial reservoir pressure= tion period to predict the maximum

some water (mainly in the form of vapor 250 bar, average porosity=10%, hori- water production for hydrates preven-

at reservoir conditions) because of the zontal permeability in x- and y-direc- tion and to determine inhibitor dosage.

contact with water in the formation. tion=100 md, vertical permeability= During gas injection/production, a por-

During production, the water is produced 10 md, reservoir thickness=110 m, and tion of connate water is evaporated for

with the gas. The net result is evaporation reservoir dimensions of 900×900 m. thermodynamics equilibrium, which

of water from formation brines, result- Connate-water saturation was increases with increasing gas rate and

ing in an increased formation-water salt assumed to be 10%, with a gas/water with pressure decline. Higher forma-

concentration in the reservoir and salt contact at 1005-m depth. The reservoir tion-water salt concentration tends to

formation/deposition. Also, the produced gas was assumed to comprise four slow the rate of evaporation; therefore,

water may condense in the wellbore and/ main components: methane (highest less water is produced.

concentration), ethane, carbon diox-

This article, written by Senior Technology ide, and water. The injected dry gas Capillary Pressure. Assuming a water-

Editor Dennis Denney, contains highlights was assumed to have no water (i.e., 0% wet system, if an aquifer is in contact

of paper SPE 146239, “Flow-Assurance humidity). A modified Peng-Robinson with the reservoir, the capillary pres-

Challenges in Gas-Storage Schemes equation of state was used in the simu- sure effect will increase the amount

in Depleted Reservoirs,” by Alireza lation calculations. of liquid water produced because the

Kazemi, SPE, and Bahman Tohidi, water moves through small pores hav-

SPE, Hydrafact Ltd., and Emile Bakala Water Production. As pressure declines ing the highest capillary pressure. The

Nyounary, Heriot-Watt University, pre- during initial field production, gas higher the capillary pressure, the high-

pared for the 2011 SPE Offshore Europe expands, rock is compacted, and water er the produced-water rate.

Oil and Gas Conference and Exhibition, solubility in the gas increases, resulting

Aberdeen, 6–8 September. The paper has in more connate water being evapo- Gas Velocity (Gas Rate). An increase

not been peer reviewed. rated to satisfy thermodynamic equilib- in gas injection/production from

For a limited time, the full-length paper is available free to SPE members at www.jptonline.org.

JPT • NOVEMBER 2011 95

10×106 to 15×106 std m3/d results in tion damage. However, if a large aquifer 200 m, the effect on gas production and

a 10% increase in the total water pro- support does exist, then the produced water production was negligible.

duced at the end of 91 months of the water will be water from evaporation

injection/production cycle (2550 m3 vs. plus liquid water from water influx. Dynamic Flow

2315 m3). This observation indicates When considering capillary pressure Natural-Depletion Phase. As the pres-

that a higher evaporation rate will occur in the model, with or without existence sure decreases while gas is produced

in the vicinity of the well and near per- of an aquifer, water is produced along by natural depletion, the molar fraction

forations, where the highest gas velocity with gas at each gas-production period of water in the gas phase increases.

will be encountered (resulting in higher during the five injection/production Also, the increase in evaporation will

pressure drops). Nevertheless, a higher cycles. The total amount of water evap- cause salt deposition in the formation,

gas velocity leaves less time for equi- orated and produced, resulting in salt and the salt precipitation will partially

librium; thus, there will be less water transport in the near wellbore region, reduce the pore-throat cross-section-

evaporation. Further, this higher evapo- will depend strongly on the magnitude al flow area, increasing the local gas

ration rate is likely to occur locally, in of capillary pressure. velocity and, consequently, the evapo-

the pore throats, where some reduction ration rate. In radial flow toward the

in permeability has happened because Near-Wellbore Effects wellbore, these phenomena combine,

of salt precipitation. A realistic option is to assume that leading to a more-severe halite deposi-

most of the water evaporation is likely tion near the wellbore and perforations.

Salt-Induced Skin to occur in the near-wellbore region,

By examining the total-water-produc- which will experience maximum for- Dry-Gas-Injection Phase. As dry gas is

tion graphs from previous studies, if no mation damage. As water is produced injected into the formation, it contacts

or a weak aquifer exists, then most of (evaporated) the deposited salt reduces connate water. The result is evapora-

the produced water could be assumed the permeability in the evaporation tion of some of the connate water. This

to be from evaporation. This situation area. It was observed that because the process is driven mainly by the velocity

could be similar to a well completed far zone of evaporation is close to the of the gas and its relative humidity.

from the aquifer or in a large gas res- wellbore (e.g., 150 m from wellbore),

ervoir during the early gas-production the effect on gas productivity was more Soak Phase (Shut-In). When the well

stage during which no water influx severe (i.e., 25% less gas production is shut in for a prolonged period of time

occurs in the reservoir. These situations for the 150-m zone). However, when after gas injection, some of the gas will

could lead to salt deposition and forma- considering a radius of approximately dissolve in the water, and the molar water

West Virginia University

College of Engineering and Mineral Resources - Department of Petroleum and Natural Gas Engineering

The Department of Petroleum and Natural Gas Engineering (PNGE) at West Virginia University invites applications and nominations for two tenure-

track faculty positions at the level of Assistant or Associate Professor. Applicants must have an earned Ph.D. in petroleum engineering and or

natural gas engineering or a closely related field, and the ability to provide teaching excellence in a variety of petroleum engineering courses, both

at the graduate and undergraduate levels. The department values intellectual diversity and demonstrated ability to work with diverse students and

colleagues. Both positions are expected to be filled on or after January 1st 2012.

Drilling and Completion

The successful candidate for this position is expected to develop an active, externally sponsored research program in the area of Natural Gas

Recovery from Unconventional Reservoirs, with an emphasis on drilling and completion in Marcellus shale.

Enhanced Oil Recovery

The successful candidate for this position is expected to develop an active, externally sponsored research program in the area of Enhanced Oil

Recovery.

West Virginia University is a comprehensive land grant institution with medical, law, and business schools, over 29,000 students, and has Carnegie

Doctoral Research Extensive standing. The PNGE Department has 5 faculty members, approximately 200 undergraduates, and 45 graduate

students. The Department offers B.S. (PNGE), M.S. (PNGE), and doctoral degrees. The College has seven departments, over 3,000 students, 120

faculty, and approximately $25 million in research expenditures per annum. The University is located within a growing high technology corridor that

includes several federal research facilities as well as the West Virginia High Technology Consortium. Morgantown and the vicinity have a diverse

population of about 62,000, and is ranked as one of the most livable cities in the country. The city is readily accessible and is within driving distance

from Pittsburgh, PA and Washington, D.C.

Candidates should submit current curriculum vitae, names and addresses of three references, a one page summary statement describing

qualifications for the position, and plans for teaching and research. Review of applications for both positions will start on September 16th, 2011.

These positions will remain open and applications will continue to be reviewed until appointments are made.

Send inquiries and applications to:

Dr. Aminian

Chair, Faculty Search Committee

Department of Petroleum and Natural Gas Engineering West Virginia University is the recipient of an NSF ADVANCE Award

West Virginia University for gender equity.

P.O. Box 6070 WEST VIRGINIA UNIVERSITY IS AN AFFIRMATIVE ACTION/EQUAL

Morgantown, WV 26506-6070 OPPORTUNITY EMPLOYER

96 JPT • NOVEMBER 2011

content in the gaseous phase will be at a Economic Implications. Assuming an a significant role with respect to water

maximum. After pressure/temperature arbitrary hydrate-inhibitor dosage of 1% production and amount of inhibitor

stabilization, some of the water in the of the produced-water volume, hydrate- required to prevent hydrate formation.

gas phase may recondense, increasing control-cost comparisons were carried out • Salt precipitation will reduce pore-

the water saturation in the near-wellbore for different water-production scenarios. throat size, resulting in less gas and

region. This recondensation could redis- • An increase of formation salinity water being produced.

solve some of the deposited salt. When from fresh water to brine resulted in Comparing systems with and with-

production is resumed after the soak- 7.5% reduction in hydrate-control cost. out salt precipitation showed a 19%

ing period, salt precipitation will occur • The inhibitor cost when consider- reduction in water production in the

because of pressure drop and water evap- ing moderate capillary pressure was case with salt precipitation and, conse-

oration in the near-wellbore region. 10 times that for the zero-capillary- quently, a hydrate-inhibitor-cost reduc-

pressure case. Capillary pressure plays tion of 19%. JPT

Production-After-Soaking Phase.

Generally, the same production phe-

nomenon occurs in this stage. But

the produced water is a combination

of water in gaseous phase from previ-

ous evaporation (dry-gas injection) and

water evaporated because of pressure

drop. However, as gas is produced, the

salt saturation increases in the near-well-

bore region because of evaporation. This

process could result in water migration

to the near-wellbore region because of

the concentration difference. This ten-

dency is greater when a communicating

aquifer exists.

Reducing Halite Deposition. To reduce

salt precipitation during dry-gas injec-

tion/production, freshwater stimulation

on regular basis is recommended because

salt is highly soluble in water. Regular

water washing will help dissolve salt pre-

cipitates in the near-wellbore region and

perforations. Also, the use of long perfo-

ration intervals rather than deep perfora-

tions is recommended. This method will

increase the interface between formation

and wellbore and, therefore, lessen the

flow restriction. Reducing the pressure

drop in the near-wellbore region by any

means is the main objective.

Formation fracturing could be used to

bypass the damaged zone. The fracture

would provide wider flow paths that

would reduce the gas velocity to the well-

bore and provide a larger well/formation

interface. Consequently, the water-evap-

oration rate and salt precipitation could

be reduced in the near-wellbore region.

Whatever abrasive, high-pressure, high-

Natural-Gas Hydrates volume operation you have planned

for your completion, you’re going to

Water produced during gas withdrawal want packing that’s up to the task.

may condense in the wellbore, tubing, Our well service packing solutions are

and surface facilities and may cause cor- engineered to keep you up and running

through it all. Count on us.

rosion or formation of hydrates and/ www.TuffBreed.com

or ice. The amount of hydrates formed

and/or inhibitor required is a function

of the amount of water in the system.

Therefore, it is important to predict the

amount of water in the system for design-

ing prevention techniques/facilities.

JPT • NOVEMBER 2011 97

Você também pode gostar

- Sick Well AnalysisDocumento22 páginasSick Well AnalysisAnonymous sW2KixAinda não há avaliações

- 01 IK IESYS e Communications OverviewDocumento12 páginas01 IK IESYS e Communications OverviewHernando AlborAinda não há avaliações

- Oil and Gas Artificial Fluid Lifting TechniquesNo EverandOil and Gas Artificial Fluid Lifting TechniquesNota: 5 de 5 estrelas5/5 (1)

- Thermal de SalDocumento8 páginasThermal de SalMajid KhanAinda não há avaliações

- The Effect of Flow Parameters On Liquid Loading AnDocumento9 páginasThe Effect of Flow Parameters On Liquid Loading AnJamshed SoomroAinda não há avaliações

- Performance of RO Units at High TemperaturesDocumento10 páginasPerformance of RO Units at High TemperaturesRoy JudeAinda não há avaliações

- Production Optimization of Liquid Loading Gas Condensate Wells: A Case StudyDocumento10 páginasProduction Optimization of Liquid Loading Gas Condensate Wells: A Case StudyHajji Assamo PadilAinda não há avaliações

- Liquid Unloading in A Big Bore Completion - Comparison Gas Lift & Velocity stringSPE-88523-MSDocumento14 páginasLiquid Unloading in A Big Bore Completion - Comparison Gas Lift & Velocity stringSPE-88523-MSQaiser HafeezAinda não há avaliações

- Deep BlowDocumento9 páginasDeep BlowJanimatorAinda não há avaliações

- SPE-2559-PA Shale Control With Balanced Activity ObmDocumento8 páginasSPE-2559-PA Shale Control With Balanced Activity ObmWilliam RocaAinda não há avaliações

- SPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionDocumento13 páginasSPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionsouthliAinda não há avaliações

- EVAPORATIONDocumento13 páginasEVAPORATIONGuevara, Blez M.Ainda não há avaliações

- Controls of Water Cresting in Horizontal WellDocumento11 páginasControls of Water Cresting in Horizontal WellMiguel AlvaradoAinda não há avaliações

- Gas HydrateDocumento54 páginasGas Hydratefatma belkacemiAinda não há avaliações

- Effect of Non-Darcy Flow Coefficient Variation Due To Water Vaporization On Well Productivity of Gas Condensate ReservoirsDocumento9 páginasEffect of Non-Darcy Flow Coefficient Variation Due To Water Vaporization On Well Productivity of Gas Condensate ReservoirskhayalAinda não há avaliações

- Oil DictionaryDocumento129 páginasOil Dictionarybalu10000Ainda não há avaliações

- Articulo JalesDocumento22 páginasArticulo JalesCristian Villa SiordiaAinda não há avaliações

- Ogst 200053Documento10 páginasOgst 200053Carmel UyumbuAinda não há avaliações

- Spe 87307 PaDocumento9 páginasSpe 87307 PaM Raees KhanAinda não há avaliações

- Water Unloading of Gas Wells Using The Concurrent-Water-Collection MethodDocumento12 páginasWater Unloading of Gas Wells Using The Concurrent-Water-Collection MethodMustapha MellalAinda não há avaliações

- SPE 88797 Determination of Recovery and Relative Permeability For Gas Condensate ReservoirsDocumento11 páginasSPE 88797 Determination of Recovery and Relative Permeability For Gas Condensate ReservoirsmsmsoftAinda não há avaliações

- Laboratory Study and Prediction of Calcium Sulphate at High-Salinity Formation WaterDocumento12 páginasLaboratory Study and Prediction of Calcium Sulphate at High-Salinity Formation WaterTunji AminuAinda não há avaliações

- Spe 143777 Ms - Coa Modificado SLBDocumento12 páginasSpe 143777 Ms - Coa Modificado SLBmiguel_jose123Ainda não há avaliações

- 7 - Spe-172364-MsDocumento10 páginas7 - Spe-172364-MsAhmad HassanAinda não há avaliações

- SPE 93000 Seawater As IOR Fluid in Fractured ChalkDocumento10 páginasSPE 93000 Seawater As IOR Fluid in Fractured ChalkKonul AlizadehAinda não há avaliações

- Spe 193123-MSDocumento18 páginasSpe 193123-MSbayuAinda não há avaliações

- Edge-Water DriveDocumento25 páginasEdge-Water Driveرجل من زمن اخرAinda não há avaliações

- EvaporationDocumento115 páginasEvaporationGuevara, Blez M.Ainda não há avaliações

- The Graduation Tower of Bad Kösen (Germany) Its History and The Formation of ThornstoneDocumento2 páginasThe Graduation Tower of Bad Kösen (Germany) Its History and The Formation of ThornstoneAnonymous pIpfPMrd3Ainda não há avaliações

- SPE 59773 Investigation of Well Productivity in Gas-Condensate ReservoirsDocumento5 páginasSPE 59773 Investigation of Well Productivity in Gas-Condensate ReservoirsHamed GeramiAinda não há avaliações

- Degassing Water For Fish CultureDocumento9 páginasDegassing Water For Fish CulturePrabir Kumar PatiAinda não há avaliações

- Mechanistic Modeling of Gas-Liquid Two-Phase Flow in PipesDocumento2 páginasMechanistic Modeling of Gas-Liquid Two-Phase Flow in PipesRama Chandra Reddy kuluriAinda não há avaliações

- Eos With The Modified Debye-HuckelDocumento5 páginasEos With The Modified Debye-HuckelnouimehidiAinda não há avaliações

- Well Productivity in Gas/Condensate ReservoirsDocumento2 páginasWell Productivity in Gas/Condensate Reservoirsمصطفى وديع موسى حسونAinda não há avaliações

- SPE 168165 Engineered Approach To Isolate Intervals Invaded by Water or Gas in Naturally Fractured Carbonate FormationsDocumento12 páginasSPE 168165 Engineered Approach To Isolate Intervals Invaded by Water or Gas in Naturally Fractured Carbonate FormationsLeopold Roj DomAinda não há avaliações

- Hydrology 05Documento7 páginasHydrology 05Mica L. SanoAinda não há avaliações

- Leachate GenerationDocumento35 páginasLeachate Generationrvsingh17gmailcomAinda não há avaliações

- Gas Storage in Aquifers and Salt CavernsDocumento58 páginasGas Storage in Aquifers and Salt Cavernssaladinayubi1234100% (2)

- Amphoteric Polymer Improves Hydrocarbon/Water Ratios in Producing Wellsċan Indonesian Case StudyDocumento6 páginasAmphoteric Polymer Improves Hydrocarbon/Water Ratios in Producing Wellsċan Indonesian Case StudySofiaAinda não há avaliações

- Capillary End Effects and Gas Production From Low Permeability FormationsDocumento13 páginasCapillary End Effects and Gas Production From Low Permeability FormationsRosa K Chang HAinda não há avaliações

- Spe 693 GDocumento8 páginasSpe 693 GKacha SmitAinda não há avaliações

- A Novel Ammonia - Carbon Dioxide Forward (Direct) Osmosis Desalination ProcessDocumento11 páginasA Novel Ammonia - Carbon Dioxide Forward (Direct) Osmosis Desalination ProcessmohAinda não há avaliações

- Humphreys.-The Material Balance Equation For A Gas Condensate Reservoir With Significant Water VaporizationDocumento8 páginasHumphreys.-The Material Balance Equation For A Gas Condensate Reservoir With Significant Water VaporizationSergio FloresAinda não há avaliações

- 200 150 Dama-FakirDocumento14 páginas200 150 Dama-Fakirrosnah chaniagoAinda não há avaliações

- ESP Design Changes For High GLR and High Sand ProductionDocumento3 páginasESP Design Changes For High GLR and High Sand ProductionKardusAinda não há avaliações

- Spe 147765 Advanced Chemical Water-Shutoff Treatments in Multilayer Gas Reservoirs: A Case Study Frompeciko Field, East Kalimantan, IndonesiaDocumento12 páginasSpe 147765 Advanced Chemical Water-Shutoff Treatments in Multilayer Gas Reservoirs: A Case Study Frompeciko Field, East Kalimantan, Indonesiahade wantoAinda não há avaliações

- Properties of Oilfield WatersDocumento7 páginasProperties of Oilfield WatersMaisam AbbasAinda não há avaliações

- Basic Investigations On Enhanced Gas Recovery by Gas-Gas DisplacementDocumento12 páginasBasic Investigations On Enhanced Gas Recovery by Gas-Gas DisplacementEleonora LetorAinda não há avaliações

- Losses From Precipitation: Module-2Documento40 páginasLosses From Precipitation: Module-2rohitAinda não há avaliações

- Water Shut Off by Rel Perm Modifiers - Lessons From Several FieldsDocumento14 páginasWater Shut Off by Rel Perm Modifiers - Lessons From Several FieldsCarlos SuárezAinda não há avaliações

- Scientific: Condensate Reservoirs Benefits and RisksDocumento9 páginasScientific: Condensate Reservoirs Benefits and RisksHomam MohammadAinda não há avaliações

- SPE CopDocumento17 páginasSPE CopLawrence MbahAinda não há avaliações

- Halite Scale Formation in Gas-Producing WellsDocumento7 páginasHalite Scale Formation in Gas-Producing WellsIsrael Arias GonzálezAinda não há avaliações

- Study On Deposit Formation Model in Sulfde Containing Natural GasDocumento8 páginasStudy On Deposit Formation Model in Sulfde Containing Natural Gasaoudj salaheddineAinda não há avaliações

- EvaporationDocumento4 páginasEvaporationGuevara, Blez M.Ainda não há avaliações

- SPE 166098 Managing Shut-In Time To Enhance Gas Flow Rate in Hydraulic Fractured Shale Reservoirs: A Simulation StudyDocumento13 páginasSPE 166098 Managing Shut-In Time To Enhance Gas Flow Rate in Hydraulic Fractured Shale Reservoirs: A Simulation StudyalizareiforoushAinda não há avaliações

- 21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8Documento14 páginas21 Century Phosphoric Acid Plant Designs (Bigger Is Better) : Page 1 of 8kaldjdsjkaAinda não há avaliações

- Water ConingDocumento2 páginasWater ConingTajEddeenAinda não há avaliações

- Evaporation Group 2Documento26 páginasEvaporation Group 2XaneAinda não há avaliações

- Scientific American Supplement, No. 446, July 19, 1884No EverandScientific American Supplement, No. 446, July 19, 1884Ainda não há avaliações

- Dictionary of Hydrology and Water Resources: 2Nd EditionNo EverandDictionary of Hydrology and Water Resources: 2Nd EditionAinda não há avaliações

- Economics of Underground Gas Storage: Stoizi& D &SDocumento4 páginasEconomics of Underground Gas Storage: Stoizi& D &SbibiAinda não há avaliações

- Spe 17741 PDFDocumento8 páginasSpe 17741 PDFbibiAinda não há avaliações

- Spe 53716Documento13 páginasSpe 53716bibiAinda não há avaliações

- Ashen A 2016Documento13 páginasAshen A 2016bibiAinda não há avaliações

- SPE 109039 Well Construction On Wireline: Ole Eddie Karlsen, Welltec, and Guthorm Lothe and Stig Aasland, StatoilDocumento6 páginasSPE 109039 Well Construction On Wireline: Ole Eddie Karlsen, Welltec, and Guthorm Lothe and Stig Aasland, StatoilbibiAinda não há avaliações

- Geomechanical Effects of Gas Storage in Depleted Gas Fields: ISRM International Symposium 2008Documento8 páginasGeomechanical Effects of Gas Storage in Depleted Gas Fields: ISRM International Symposium 2008bibiAinda não há avaliações

- Flexstone China Cs PDFDocumento2 páginasFlexstone China Cs PDFbibiAinda não há avaliações

- Spe 2367 Pa PDFDocumento8 páginasSpe 2367 Pa PDFbibiAinda não há avaliações

- Design of Gas Storage Fields: SPE I059-GDocumento5 páginasDesign of Gas Storage Fields: SPE I059-GbibiAinda não há avaliações

- Qverview On Underground Storage of Natural Gas: Current StatusDocumento9 páginasQverview On Underground Storage of Natural Gas: Current StatusbibiAinda não há avaliações

- Use and Misuse of Reservoir Simulation Models: The U. of Texas at AustinDocumento8 páginasUse and Misuse of Reservoir Simulation Models: The U. of Texas at AustinbibiAinda não há avaliações

- Datasheet - HK f7313 39760Documento7 páginasDatasheet - HK f7313 39760niko67Ainda não há avaliações

- Netflix - WikipediaDocumento3 páginasNetflix - WikipediaHanako ChinatsuAinda não há avaliações

- Etop Tata DocomoDocumento5 páginasEtop Tata DocomoSrikanth Kumar KonduriAinda não há avaliações

- DeltaBox Catalogue UK 2021Documento37 páginasDeltaBox Catalogue UK 2021Philip G. SantiagoAinda não há avaliações

- Odot Microstation TrainingDocumento498 páginasOdot Microstation TrainingNARAYANAinda não há avaliações

- Performance Considerations Before Upgrading To Oracle 19c DatabaseDocumento48 páginasPerformance Considerations Before Upgrading To Oracle 19c DatabaseJFLAinda não há avaliações

- DM No. 312, S. 2021Documento3 páginasDM No. 312, S. 2021sherileneAinda não há avaliações

- Pakistan Machine Tool Factory Internship ReportDocumento14 páginasPakistan Machine Tool Factory Internship ReportAtif MunirAinda não há avaliações

- 8 PCO Training Invitation Letter December 2018Documento2 páginas8 PCO Training Invitation Letter December 2018sayo goraAinda não há avaliações

- Workshop Manual Automatic Transmission 30 40leDocumento2 páginasWorkshop Manual Automatic Transmission 30 40leDony TedyantoAinda não há avaliações

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Documento20 páginasEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Ion IonutAinda não há avaliações

- 4 Power TransmissionDocumento27 páginas4 Power TransmissionMehmetAinda não há avaliações

- What Is A SAP LockDocumento3 páginasWhat Is A SAP LockKishore KumarAinda não há avaliações

- Project 1 - Nimisha AgrawalDocumento13 páginasProject 1 - Nimisha AgrawalNimisha AgrawalAinda não há avaliações

- Specialty Lubricants Molykote®: 44MA GreaseDocumento2 páginasSpecialty Lubricants Molykote®: 44MA GreasefadhlidzilAinda não há avaliações

- ACI Concrete International Vol 45 No 8 2023Documento76 páginasACI Concrete International Vol 45 No 8 2023Cristopher TenorioAinda não há avaliações

- Sloba Dragovic - ResumeDocumento3 páginasSloba Dragovic - ResumeSloba DragovicAinda não há avaliações

- Jill K. Hatanaka: San Joaquin County Office of Education 2707 Transworld Drive Stockton, CA 95206 209-401-2406Documento3 páginasJill K. Hatanaka: San Joaquin County Office of Education 2707 Transworld Drive Stockton, CA 95206 209-401-2406api-114772135Ainda não há avaliações

- ISRA University FormDocumento4 páginasISRA University Formpure14Ainda não há avaliações

- Checklist of E/OHS Activities For Asbestos Management: Name of Publication DateDocumento20 páginasChecklist of E/OHS Activities For Asbestos Management: Name of Publication DateidahssAinda não há avaliações

- EHB02 Technical Specifications: 1. External DimensionsDocumento5 páginasEHB02 Technical Specifications: 1. External DimensionsArmandoCalderonAinda não há avaliações

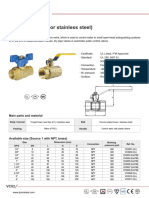

- VC02 Brass Ball Valve Full Port Full BoreDocumento2 páginasVC02 Brass Ball Valve Full Port Full Boremahadeva1Ainda não há avaliações

- Neurophone Ebook EnglDocumento19 páginasNeurophone Ebook EnglViolin_teacher100% (3)

- Residential Construction Schedule: Click Here To Create in SmartsheetDocumento14 páginasResidential Construction Schedule: Click Here To Create in SmartsheetVinayak VagheAinda não há avaliações

- أثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFDocumento146 páginasأثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFNezo Qawasmeh100% (1)

- Cessna 525 LimitationsDocumento16 páginasCessna 525 LimitationsCesar BanchoffAinda não há avaliações

- Powershell Simple and Effective Strategies To Execute Powershell Programming - Daniel JonesDocumento53 páginasPowershell Simple and Effective Strategies To Execute Powershell Programming - Daniel JonesdemisitoAinda não há avaliações

- API 620 Vs API 650Documento5 páginasAPI 620 Vs API 650govimanoAinda não há avaliações