Escolar Documentos

Profissional Documentos

Cultura Documentos

(Ebook Woodworking) Wood Shop Plans

Enviado por

cliff_wolfeDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

(Ebook Woodworking) Wood Shop Plans

Enviado por

cliff_wolfeDireitos autorais:

Formatos disponíveis

Plans N O W

SECTIONAL

ENTERTAINMENT CENTER

This contemporary project was built with pocket hole joinery —

a “new” technique that required some clever cover-ups.

I t’s easy to see how practical this

project is. The top is a large, solid

wood panel that will hold a fairly good-

But it’s what you can’t see that

I’m excited about. That’s because

this project was built almost exclu-

sized TV, and inside there’s plenty of sively with pocket hole screws, refer

storage space for all of your home to the detail on the next page.

entertainment components. Even the This has been my first experience

back has been carefully designed to with pocket hole joinery, and I want-

provide room for organizing cables. ed to see what could be built with it.

Plus, there are also smaller side But since this project is an “open”

cabinets that can be built and set design, I didn’t want to have any

next to the main TV cabinet, as pocket holes showing. This meant { Build a set of matching side cabinets

shown in the inset photo. Or to give coming up with a number of cre- that can be set right next to the main

the components a little more protec- ative solutions for covering them up. TV case or can “stand alone.” To see

tion, you can build a pair of inset, But the final result was worth it — this side cabinet in a different light,

glass-paneled doors (page 8). not a pocket hole in sight. turn to page 9.

Woodsmith.com page 1 © August Home Publishing Co.

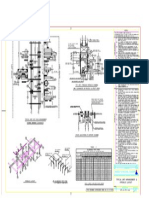

Top panel is #/4"

hardwood

OVERALL DIMENSIONS:

42”W x 24”D x 28”H

!/8"-thick spacers

create shadow

line between

top and case

Pocket !/4" plywood

NOTE: holes

Optional side cabinet CASE back

shown on page 9, TOP

Optional doors for

main case on page 8 BACK

SUPPORT

SHELF

STANDARD CENTER

DIVIDER

Backs have slots

UPPER for cable access

FRONT and air circulation

RAIL

END

PANEL

CASE

BOTTOM

SHELF & Adjustable shelf

has recess in back for END

EDGING STILE

cable access Vertical divider

and air circulation creates two

identical case Shelf standards

openings support shelves !/8"x !/16" rabbet

and cover cut in end panel

pocket holes to create small

shadow line

Face frame

covers plywood

edges of case top POCKET HOLE JOINERY DETAIL

and bottom NOTE:

Pocket hole joint Pocket hole

LOWER created with jig

FRONT and special

To see how this RAIL "stepped"drill

entertainment bit.

center would

look in cherry or walnut, go to 1!/4" fine-threaded

www.woodsmith.com. FRONT pocket hole screw

STILE

MATERIALS & SUPPLIES

A End Panels (2) #/4 ply. - 20!/2 x 21!/8 L Lower Back Rail (1) #/4 x 6 - 38!/2 • (1 pkg.) #8 x 1!/4" Pocket Hole Screws

B Upr. End Rails (2) #/4 x 1!/2 - 20!/2 M Shelf Standards (8) #/8 x 2!/2 - 21&/8 • (6) #8 x 2" Fh Woodscrews

C Lwr. End Rails (2) #/4 x 3 - 20!/2 N Back Supports (4) #/8 x 1!/2 - 19!/8 • (16) Spoon-Style Shelf Supports

D End Stiles (4) #/4 x 1 - 27!/8 O Back Panels (2) !/4 ply. - 20!/4 x 21&/8 • (9) #8 x 1!/4" Rh Woodscrews

E Case Top/Btm. (2) #/4 ply. - 22!/2 x 40!/2 P Shelves (4) #/4 ply. - 19 x 19 • (9) #8 Flat Washers

F Center Divider (1) #/4 ply. - 19!/4 x 21&/8 Q Shelf Edging (4) #/4 x !/4 -19 • (2) !/8" Glass (15&/8" x 17!!/16")*

G Divider Edging (1) #/4 x !/4 - 21&/8 R Top Spacers !/8 x 1!/2 - 180 rgh. • (1 pkg.) !/2"-long Brads*

H Front/Back Stiles (4) #/4 x 1#/4 - 27!/8 S Top Panel (1) #/4 x 24 - 42 • (2 pr.) 2" x 1(/16" Nickel Hinges*

I Upper Front Rail (1) #/4 x 1!/2 - 38!/2 T Door Stiles (4)* #/4 x 2 - 21 • (2) 96mm Stainless-Steel Pulls*

J Lower Front Rail (1) #/4 x 3 - 38!/2 U Door Rails (4)* #/4 x 2 - 15!%/16 • (2) Magnetic Catches & Strikes*

K Upper Back Rail (1) #/4 x #/4 - 38!/2 V Glass Stop* !/4 x !/4 - 140 rgh. * Required for the optional doors

Woodsmith.com page 2 © August Home Publishing Co.

holes

UPPER 1"

1 END RAIL

b.

B END STILE END VIEW

(Backside)

D

1!/2" 1#/4"

NOTE: Panels

are #/4" plywood.

Rails and stiles

are #/4"-thick

hardwood #/4"

21!/8" B

D

END PANEL 20!/2"

27!/8" END PANEL

A

A

Pocket

22!/2" holes

3"

C

{ A small rabbet is a. END PANEL

all it takes to add A

NOTE: LOWER

an interesting Case assembled END RAIL !/8"

shadow line to with fine-thread, C

1!/4" pocket hole 3!/2"

a frame and #/4" 1!/2"

screws

panel assembly. 1" !/16" Outside

face

Case Construction

The parts of this entertainment cen- this lack of traditional joinery meant flush all the way around the panel. I

ter are fairly typical for case con- that I needed a few “helpers” when sidestepped the problem by creat-

struction. At each end there are frame it was time to assemble the case. ing a shadow line that accents the

and panel assemblies, and these are But more on that later. panel and hides the joint lines, as

connected with top and bottom pan- END PANELS . As with many cases, shown in the margin photo at left.

els. Then to create the two openings, the first thing to work on are the end This is easy to do — just cut a tiny

a vertical center divider will be added. assemblies (Fig. 1). But with pocket rabbet around each panel (Fig. 1a).

What’s unique here is that almost screws the sequence is a bit differ- RAILS & STILES. With the rabbets cut

the entire case is built using a pock- ent. Instead of starting with the on the panels, the rails and stiles can

et hole jig and screws. The nice frames, I cut the 3/4" plywood end be added to create the frame around

thing is that all the pieces are butt panels (A) to size first. the panel (Fig. 1). I started with the

jointed together, so there aren’t any When frame and panel pieces are upper (B) and lower end rails (C)

dadoes, grooves, or other joints to the same thickness (as they will be since they’re cut to length to match

cut. On the other hand, I found that here), it’s pretty tough to get them the width of this panel.

When attaching the rails to the

2 NOTE: Stiles flush

NOTE: Set stiles

next to assembly

panels, the pocket holes could have

with top edge only when laying out been drilled in either the panels or

pocket holes the rails. As you can see in Fig. 1, I

drilled them in the rails. This meant

END D

STILE that the holes in the upper rails were

drilled partially into their edges, but

End panel this method is better because these

and rail

assembly a. holes will end up neatly hidden by

Face clamp the top and bottom panels later on.

Face

clamp I should also note two things here

D

before going on. One is that while in

most situations the locations of the

pocket holes aren’t critical, I’ve

included them here because there

#8 x 1!/4" are so many screws used to build

self-tapping

pocket hole screw this project (Fig. 1b). This way,

you’ll be sure to avoid drilling into a

neighboring pocket hole (or screw).

Woodsmith.com page 3 © August Home Publishing Co.

The other thing to note has to do 3 Brace

with the use of glue. Technically, the End a.

SECTION

screws should provide plenty of 1!/2" assembly VIEW

End

holding power. But to play it safe, it assembly

would be a good idea to apply glue holes E

too. However, you’ll want to use the drilled 8" TOP

in top

glue sparingly so you don’t have a face

lot of excess to clean up. CASE TOP

To complete the frames, the two (22!/2" x 40!/2") #8 x 1!/4"

E pocket

end stiles (D) are ready to be added NOTE: Case top hole screw

(Fig. 2). These pieces are sized to and bottom panels

are #/4" plywood

extend below the lower rail to create

short legs. It sounds simple enough,

Pocket holes

but with the stiles offset, they’re not 4 drilled in

identical — the pieces are actually E bottom face a.

mirrored images of each other. So CASE BOTTOM #8 x 1!/4"

(22!/2" x 40!/2") SECTION pocket

to drill the pocket holes in the right VIEW hole screw

8"

place, it’s best to lay the stiles next

Top edge BOTTOM

to the assembly and mark the edges 1!/2" of lower E

rail

that you’ll be drilling into.

TOP & BOTTOM . Now that the end Scrap cleat

assemblies are complete, they can supports bottom

NOTE: Assembly and aligns

is upside down Scrap

be connected with the case top and edge of bottom cleat

with top of rail

bottom (E), as shown Figs. 3 and 4.

These 3/4" plywood panels are identi-

cal, and once they’ve been cut to

size, they’re ready to be screwed to together, as shown in Fig. 3. (Here, scrap cleat across each end and let

the end assemblies. it’s okay to screw into the top face of the cleat support the panel while

I started with the case top. After the panel — it’ll get covered with a you screw it in place.

drilling the pocket holes in each end hardwood top panel later.) DIVIDER . To divide the case into

of the panel, it’s screwed flush with When attaching the case bottom, two equal openings, the next piece

the top edges of the end assemblies. you’ll need to flip the assembly over, to make is the center divider (F).

But holding this long panel square as shown in Fig. 4. The idea here is When cutting this panel to size, note

to the ends while you’re driving in to position the upper face of this that it won’t end up as deep (wide)

the screws takes more than two panel even with the top edge of the as the top and bottom panels. As

hands. So I made a couple L-shaped lower end rail, as indicated in Fig. you can see in Fig. 5a, it is flush with

braces to help hold the assembly 4a. There’s nothing tricky about the front of the case and stops a few

square while it was being screwed this. All you need to do is clamp a inches short in back. (This space

will be used to create a little trough

5 #8 x 2"

CL

or pocket for the cables.)

Fh woodscrew a. Before the plywood divider can

8!/4"

8!/4" be screwed into the case, it needs a

TOP

1!/2" SECTION piece of edging (G) to cover the

VIEW plies in the front. I made this thin

strip quickly and safely by ripping a

NOTE: Scrap DIVIDER 1/ "-wide strip from an oversized

spacers can be 4

F

used to position piece of 3/4"-thick hardwood.

center divider

The center divider is the only

CENTER F

21&/8" 21&/8"

case piece that isn’t attached with

DIVIDER

(#/4" plywood) pocket hole screws. Instead, it’s sim-

EDGING

G ply screwed to the top and bottom

panels, flush with the front edges

!/4"

NOTE: Divider (Fig. 5a). But this panel isn’t much

stops short of

back of case easier to hold in place than the top

19!/4" Divider is and bottom panels were, so you may

DIVIDER G flush with

front of case want to clamp some cleats to the

EDGING

(!/4"-thick hardwood) case for support — similar to what

you did with the bottom panel.

Woodsmith.com page 4 © August Home Publishing Co.

UPPER H

K BACK

RAIL

38!/2" a.

42"

1!/2" I

H

Front

face frame

(back view)

H 38!/2"

27!/8"

BACK I 1#/4"

STILE J

UPPER #/4"

L FRONT

L 27!/8"

RAIL 3"

LOWER

BACK

RAIL

1!/2" H b.

#/4"

1#/4" K

NOTE: H

Face frames joined with

pocket screws, as shown in LOWER Back

details 'a' and 'b' J FRONT face frame

RAIL (front view)

#/4"

FRONT H NOTE: Position NOTE:

STILE lower front rail flush Face frames are

with case bottom panel #/4" hardwood 6" L

6

Face Frames, Shelf Standards, & Backs

Now that the main case has been These two face frames aren’t iden- top face of the case bottom. So I set

assembled, it’s time to add a pair of tical though. While the stiles (H) each stile against the case and

face frames, some shelf standards, are the same, the lower back rail marked the position of the bottom

and a couple of back panels. (L) is wider than the lower front panel. These marks can then be

FACE FRAMES. I started with the face rail (J). And to allow the back pan- used to position the lower front rail.

frames that cover the plywood edges els to fit through the opening later When the face frames are assem-

of the case at the front and back on, the upper back rail (K) is nar- bled, they’re ready to be screwed to

(Fig. 6). Typically, I’d just add a face rower than the upper front rail (I). the case (Fig. 7). Don’t worry if the

frame to the front of a case. But the Once the face frame pieces are frames and case don’t end up per-

back frame here will create a shal- cut to size, they’re simply screwed fectly flush all the way around. You

low trough or pocket for the cables. together. This is where pocket hole can always do a little trimming later,

joinery really shines. These frames as shown in the box at left.

are quick and easy to assemble. The SHELF STANDARDS . With the face

FLUSH FACE FRAMES only thing to give extra attention to frames in place, you can make the

is the position of the lower front rail. shelf standards (M) next (Fig. 8).

When gluing a face frame to a large You want it to end up flush with the These 3/8"-thick pieces have a series

case, it’s nearly impossible to get the

edges completely flush. So I usually 7 NOTE: Glue

face frames to

plan to do a little “touch-up.” Most case separately

Back a.

face

times, I’ll use my block plane, setting frame 2"

it to take very fine shavings, see draw- 14!/2"

ing. Or if there’s a only slight shoul- 3!/2" 9"

SIDE

der, I’ll sand it flush, using a sanding SECTION

VIEW

block to prevent rounding the edges.

Front

face Front

Face frames can frame face

be trimmed or frame

planed flush if

necessary, see

box at left

1!/4" 8!/4"

Woodsmith.com page 5 © August Home Publishing Co.

1!/2" N

BACK a. M

SUPPORT SHELF STANDARD

of holes for holding spoon-style 8 19!/8" (#/8" thick) (eight needed)

shelf pins. But they do more than

just support the shelves. These stan-

dards also cover the most visible 2!/2"

pocket holes inside the case.

!/4"-dia.

The shelf standards at the front of holes for

shelf

the case can simply be glued and support

clamped to the sides and center pins

divider. The standards glued flush

with the back of the center divider 21&/8"

are also easy enough to install. 1"

The trick is the back standards at

M

the ends — they also need to align SHELF

with the back of the divider. This is STANDARD

(#/8" thick) !/4"-dia.

easy to do with a couple of scrap through

spacers. But then they’re inset too NOTE: All back supports holes

and back standards

far for clamps to reach them. So to align with center divider, 5"

hold them, I cut some thin, flexible see Fig. 9 below

strips and wedged them between

the standards while the glue dried,

as you can see in Fig. 9. 9

BACK SUPPORTS . While the glue on M a.

the standards was drying, I cut four TOP

SECTION

3/ "-thick back supports (N) to fit VIEW

8 N

Standards Scrap spacer

between the standards at the top in back flush aligns standard BACK SHELF

with center SUPPORT STANDARD

and bottom of the case (Fig. 8). And with back

divider of center M

since they’re flush with the back Thin strips divider

edges of the standards, I used the provide clamping

pressure Scrap

same spacers and flexible strips M N spacer

when gluing them in place.

BACK PANELS . At this point, the 1/4"

plywood back panels (O) can be cut

to finished size to fit inside the case,

as shown in Fig. 10. But before glu- these slots, I first drilled a 1"-dia. frame (which is why there are two

ing these panels in place, I cut three hole at each end. Then the waste back panels in the first place). And

access slots across the back of each between the holes can be removed the back face frame also prevents

(Fig. 10a). This will make it easier to with a sabre saw, and the slots can you from being able to nail the pan-

feed the cables through when con- be sanded smooth. els in place. But a few scrap spacers

necting the components, as well as The back panels have to be angled will apply enough pressure to hold

let the air circulate freely. To make to be slid in front of the back face them while the glue dries (Fig. 10b).

10 5!/8"

a. BACK Access

O slot

5"

Waste 1"

10"

BACK PANEL

(!/4" plywood) Access NOTE: Tall

O slots lower rail

and inset

21&/8" backs create b.

shallow BACK SHELF

BACK O pocket for STANDARD

PANEL SUPPORT

excess cable

5" BACK O O

PANEL

Scrap spacer holds back

20!/4" while glue dries

NOTE: Small

spacers used while NOTE: Slots in

gluing backs in place back allow for easy TOP SECTION VIEW

(similar to Fig. 9) cable management

and better air flow

Woodsmith.com page 6 © August Home Publishing Co.

S

24" TOP PANEL

42"

(#/4" thick) SIDE SECTION

11 !/8"

VIEW

a.

1!/2" S

20#/4"

R

TOP !/8"

SPACER R

(!/8" thick) 1!/2"

41#/4"

23#/4" %/16"-dia.

#8 x 1!/4" shank

Rh screw hole

10" & washer

1"

SHELF

P

4!/2"

19"

19"

1"rad. b. EDGING Q

{ The decorative

Front

shadow line on the Q SHELF stile

P

end assemblies is SHELF

EDGING

repeated under the NOTE: Shelves are #/4" (#/4" x !/4") Spoon- !/4"

top panel. This NOTE: Make plywood and style pin

four shelves rest on !/4" spoon- SIDE SECTION

time, it’s created style shelf pins VIEW

with thin spacers.

Shelves & Top

The main case of the entertainment TOP PANEL & SPACERS . Now that the The spacers are mitered to length

center is just about complete. All that’s shelves are in place, the last area to so they set 1/8" back from the edges

left is to add some adjustable shelves work on is the top of the case. As of the case, as shown in Fig. 11a.

and a hardwood top with some thin you can see in Fig. 11, there are two This creates a thin shadow line simi-

spacers, as in Fig. 11 above. layers here: A large panel that rests lar to the one on the end panels of

SHELVES . The shelves (P) are 3/4" on a layer of thin spacers. the case. (See margin photo at left.)

plywood panels with hardwood edg- The actual top panel (S) is glued Also to help support the top panel, I

ing (Q) added to the front of each. up from 3/4"-thick hardwood. And added a spacer at the center.

(For the edging, I ripped a 1/4"-wide while the glue is drying on this When the glue is dry, the case top

strip from 3/4"-thick hardwood.) panel, you can begin working on the can be cut to match the case and

Then to make it easier to organize second layer that’s sandwiched then screwed in place. I made the

the cables (and let the air circulate), between the top and the case (Fig. shank holes oversized so the top

I used my sabre saw to create a 11). It’s a thin “frame” of top spacers can expand and contract freely. (To

cutout on the back of each shelf and (R) cut from stock that’s been find out how I finished the entertain-

sanded this profile smooth. resawn or planed down to 1/8" thick. ment center, turn to page 12.) W

CUTTING DIAGRAM

#/4" x 7!/4" - 96" Hard Maple (4.8 Bd. Ft.) #/4" - 48" x 96" Maple Plywood

B C C

D D N

E A F

R

#/4" x 7!/4" - 96" Hard Maple (4.8 Bd. Ft.) I K

H H

J U U A

E

V

#/4" x 7!/4" - 96" Hard Maple (4.8 Bd. Ft.)

T T #/4" - 48" x 48" !/4" - 48" x 24"

L Maple Plywood Maple Plywood

U U

Q G

P P O

#/4" x 7!/4" - 96" Hard Maple (Two Boards @ 4.8 Bd. Ft. Each)

S S

P P O

#/4" x 5!/2" - 96" Hard Maple (3.7 Bd. Ft.)

M M M M

NOTE: Top spacers (R) and glass stop (V) must be resawn to get blanks needed.

Woodsmith.com page 7 © August Home Publishing Co.

OPTIONAL DOORS

SAFETY NOTE:

Cut glass stop from

1 oversized blank

If you’d like to build a pair of inset V

doors for this entertainment center, GLASS

you’ll find they’re just simple frames STOP

with glass panels, as shown in Fig. 1.

2" U

Like the face frames on the case,

these doors could’ve been built

quickly with pocket hole joinery.

2" x 1(/16"

Plus, you can buy hardwood plugs nickel hinge

for making the pocket holes less vis- 21"

ible. Stainless

FRAME . But I didn’t want the join- T steel pull

STILE

ery to be visible at all, so I built the

door frames with stub tenons and

grooves (Figs. 1 and 1a). And when 15!%/16"

sizing the door stiles (T) and rails RAIL U Glass NOTE: Initially, door

T sized for !/16" gap on

(U), I allowed for a 1/16" gap around (!/8"x 15&/8"- 17!!/16") outside edges but no

15#/16" gap between doors

the two doors, but no gap between

them. (This makes the math a bit

easier, and the edges of the center a. Trim door b. c. STOP

to create V

stiles will be trimmed later to quickly STILE

!/16" gap

T !/4"

create an even 1/16" gap.) !/8"

With the stiles and rails cut to #/8" glass

2" RAIL

U !/4"

size, 3/8"-deep grooves need to be cut !/4" 2" T U

on the inside edges of the pieces !/2"-

TOP long

(Fig. 1a). Then you can cut the stub #/8" CROSS brad

SECTION

#/4" Pull SECTION

tenons to fit into these grooves.

After the frames have been assem-

bled, they’re ready for the rabbet that make installation easier, I cut the Quarter-round glass stop (V) will

will hold the glass (Fig. 1c). With the mortises in the door frames only, as hold the glass in place. (When mak-

grooves already cut, there’s not indicated in Fig. 3a. (The hinges will ing these tiny strips, it’s best to start

much material left to be removed, so be surface mounted to the case.) To with oversized pieces to be safe.)

the rabbet can be routed in a single do this, I used my table saw, attach- Then they’re mitered to length and

pass (Fig. 2). But you’ll still need to ing a tall auxiliary fence to the miter nailed to the frame (Fig. 1c).

square up the corners with a chisel. gauge to support the frame (Fig. 3). MOUNT DOORS . Now the doors are

HINGE MORTISES. I planned to mount GLASS. At this point, the doors are ready to be mounted to the case.

the doors on butt hinges. And to ready for the 1/8" glass panels. With inset doors, the goal is to get

an even gap around and between the

2 NOTE:

Square corners

3 doors. I like to concentrate on the

with chisel

gaps around the doors first. Then

Rout creating the gap between the doors

clockwise Tall aux.

fence is a simple matter of planing or sand-

ing a little off each center stile.

HARDWARE. When the doors fit well,

Mortise

the last step is to add pulls to the

for 2 x 1(/16" doors and magnetic catches to the

butt hinge

inside of the case (Figs. 1b and 4). W

a.

FRONT

2"

VIEW 4

Rabbet U

bit 2 x 1(/16"

butt T

hinge

2"

!/2" CROSS

SECTION Strike

#/8" !/16" Magnetic

a. Bench catch

Woodsmith.com page 8 © August Home Publishing Co.

SIDE CABINET

This side cabinet is the perfect “side-

kick” to the entertainment center on

page 1. Since its top panel is flush

with the sides, the cabinet will nestle

up tight on either side of the TV cab-

inet. And the small drawer and

adjustable shelf offer quite a bit of

additional space for storage.

But don’t limit this cabinet to

being just a component of the enter-

tainment center. When set next to a

bed or arm chair, as shown in the

photos below, it also makes a great

little nightstand or end table.

CONSTRUCTION NOTES . As you might

expect, building this cabinet is simi-

lar to building the TV cabinet — only

this one is even easier because the

workpieces are smaller. However,

there are some important differ-

ences to note. Instead of a vertical

center divider, the side cabinet has a

horizontal divider that creates a

small drawer opening. Plus, the

back is quite a bit different. It still

has a face frame, but there’s no ply-

wood back to the cabinet and no panel with pocket hole screws. CONNECTING PANELS . With the stiles

pocket for excess cables. Again, I drilled the stepped holes for in place, the two end assemblies are

END ASSEMBLIES . This small cabinet the screws in the rails (instead of complete and can be connected with

starts out just like the larger TV unit: the panel) so they’d end up being the 3/4" plywood top (E) and bottom

by building two end assemblies, as hidden later. Then the two stiles (D) (E) panels (Fig. 1). Here’s where

shown in Fig. 1. First, the end panel can be cut to size and attached to the big difference between the two

(A) is cut to size, and the small rab- the assembly. And as on the larger cabinets begins. Instead of a vertical

bet that creates the shadow line is case before, you want to get these center divider, these side cabinets

cut, refer to Figs. 1 and 1a on page 3. pocket holes in the right places, so have a horizontal divider (E) that

Next, the upper (B) and lower when laying them out, it’s best to set will support the drawer.

end rails (C) are attached to the the stiles next to the assembly. The divider is identical to the top

and bottom panels except for one

thing. I drilled 3/4"-dia. access holes

in each corner so I’d be able to

screw the hardwood top panel to the

case later on (Figs. 1b and 4a). And

while I was at it, I drilled the over-

sized shank holes (5/16") in the top

(E). (They’re oversized so the hard-

wood top will be able to expand and

contract with changes in humidity.)

When connecting the end assem-

blies with the plywood panels, I start-

ed with the top and bottom pieces.

To do this, I used braces and cleats

Nightstand or end table. This side cabinet doesn’t have to be set next to the just as I did before with TV cabinet,

TV cabinet. It’s the perfect size for a nightstand (left). And since the back looks refer to Figs. 3 and 4 on page 4.

as good as the front, it can be set out away from the wall as an end table (right). Attaching the divider is similar to

the bottom panel. It’s positioned by

Woodsmith.com page 9 © August Home Publishing Co.

UPPER

TOP Pocket END RAIL

E holes 2!/2" B

a couple of cleats, but these scrap 1 %/16"-dia.

pieces can be cut to match the 1!/2" a. B b. shank

height of the opening between the hole

top and divider (41/4"), as shown in E

DIVIDER

Fig. 2. Then with the case flipped END E

END STILE 1!/2" B

upside down, the divider and cleats 16!/2" PANEL D

simply rest on the top panel. 24!/8" A D

FACE FRAMES . Now the front and 18!/8" 1!/2"

NOTE: #/4"-dia.

back face frames ready to be added Panels are

A

access

A

to the case, as shown in Fig. 3. The 16!/2" #/4" plywood. hole to

Rails and SIDE attach

front face frame establishes the stiles are VIEW top

BOTTOM

opening for the drawer, while the #/4"-thick

E #8 x 1!/4"

hardwood

one in back merely cleans up the 3" 3" !/8"x !/16" pocket

rabbet hole screw

back side so you’ll be able to set the E

cabinet out away from a wall. 1"

NOTE: C

When cutting the face frame Case assembled 3!/2" 3!/2" CROSS

pieces to size, the four front and with fine-threaded, 14!/2" C C SECTION

1!/4" pocket hole screws LOWER

back stiles (F) are identical, as well END RAIL

as the lower rails (I). There are two

narrow upper front rails (G) that 2 Access

hole

create the drawer opening. And as a.

NOTE: Drill

for the upper back rail (H), it’s 61/2" #/4"-dia. access 2!/2"

wide and covers the entire back of holes before DIVIDER

attaching E 4!/4" Cleat

the drawer opening. divider

4!/4"

Assembling the face frames here SECTION

VIEW

isn’t much different than those made NOTE:

Assembly is Scrap cleat

for the TV cabinet. Both lower rails upside down supports divider

should end up flush with the bottom

panel, as shown in Fig. 3a. And

1#/4"

there’s the extra upper front rail that 3

should also be flush with the divider. a.

In both cases, you can set the stiles 3!/2" 1!/2" 2!/2" 6!/2"

F

against the case and mark the loca- 2"

tion of the plywood panels. SIDE

TOP PANEL & SPACERS . After the face 1!/2" H SECTION

G UPPER 1#/4" VIEW

frames had been pocket-screwed to UPPER 24!/8" BACK

the front and back of the case, the FRONT RAIL

RAILS 14!/2"

next area I worked on was the top of NOTE:

the cabinet. Like the TV cabinet, Size back rail I

to cover edges

there are two layers here, as you of both top 3"

can see in Fig. 4. and divider

F

First, I glued up an oversized 3/4"- STILE F 7"

thick hardwood top panel (K). 3"

Then while the glue was drying, I NOTE: 2#/4"

worked on the top spacers (J). LOWER All rails positioned

RAIL flush with top

Again, these create the shadow line face of plywood panels

I

under the top panel, so you’ll need

to plane or resaw some stock down

to 1/8" thick for these pieces. Then 4 TOP PANEL K

SECTION VIEW

they’re simply mitered to length so a.

18" 18" 1!/2" K

they set back 1/8" from the outside

edge of the cabinet.

After the top spacers have been

J

glued in place, the top panel can be

17#/4" 17#/4" !/8"

cut to finished size and then #8 x 1!/4"

screwed down to the cabinet. (You’ll Rh screw

JJ & washer

need a long screwdriver to be able TOP SPACER

(!/8" thick)

to tighten the woodscrews.)

Woodsmith.com page 10 © August Home Publishing Co.

Drawer 5 GUIDE SIDE 96mm FRONT

Now that the case for the side cabinet O BACK M stainless- L

is complete, the next thing to work L steel pull

on is the small drawer that fits into 3&/16"

the opening, as shown in Fig. 5.

CUT TO SIZE. When sizing the draw-

SIDE

er pieces, I cut the front and back M !/4"-deep

(L) so there would be a 1/16" gap at groove

16!/4" 14#/8"

the sides and top. The side (M)

pieces are resawn or planed down to 16!/2" N

1/ " thick and are cut to length so the

2 BOTTOM

(!/4" ply. -13&/8"x 15#/4")

drawer ends up 1/2" short of the full O NOTE: Drawer

depth of the cabinet. (Later a stop has !/16" gap at

sides and top

will be added so the drawer ends up

SIDE

flush with the front face.) SECTION TOP SECTION Face

Pull & frame

LOCKING RABBET JOINT . To join the machine L GUIDE

O stile

drawer pieces, I used a fairly simple screw

3&/16" CL

locking rabbet joint, as described in !/4" !/16"

1!/16" 1"

the box below. However, if you own

a router and a dovetail jig, the pieces !/4" !/2" M

are sized so that you could join them N

BOTTOM L

with half-blind dovetails. (!/4" ply.)

a. b. #/4"

BOTTOM . Before assembling the

drawer pieces, you’ll want to cut a

groove near the bottom of each

piece to hold a 1/4" plywood drawer 6 KICKER

bottom (N), as shown in Fig. 5a. P a.

Once the bottom is cut to size, the SIDE

STOP SECTION

drawer can be glued together, and Q #/4"

Size to put

the pull can be added to the front. drawer P

16!/2" flush with

GUIDES, KICKER, & STOP. To guide the front

NOTE: Q

drawer in and out of the opening, Size stop so

drawer front #/4"

there are a few more pieces to add.

is flush with 14#/8"

First, I glued drawer guides (O) face frame

along the sides of the cabinet. These

HOW TO MAKE LOCKING RABBETS

To build the drawers on the small cab- With a locking rabbet, a short tongue

inet, I used a locking rabbet joint, see is cut on the front and back pieces,

photo. It’s much stronger than a sim- as in Steps 1 and 2. Then these

ple butt or rabbet joint, and it’s not as tongues simply lock into dadoes cut

difficult as cutting dovetails. in each side piece, see Step 3.

Aux.

L END fence

Aux. !/4" SIDE

fence FRONT/ VIEW END Aux.

!/4" BACK VIEW fence M

END !/4"

VIEW !/4"

!/2" Dado

blade L

!/2"

!/4"

Tongue

1 On the front and back pieces, cut

a !/4"-wide slot on each end. Raise

the blade so the depth matches the

2 Next create a short tongue on

the inside face of each front and

back piece. Sneak up on the fence

3 Finally to hold the tongue on the

front and back pieces, cut !/4” x !/4”

dadoes at the ends of each side piece.

thickness of the drawer sides (!/2"). setting until the tongue is !/4" long. (Check the setup with a test piece.)

Woodsmith.com page 11 © August Home Publishing Co.

are sized to stick past the face frame 7

stiles 1/16", as shown in Fig. 5b. (To a. SIDE

make it easier to “feed” the drawer SECTION

R

into the cabinet, I tapered the front SHELF

STANDARD R

1" of each guide with sandpaper.) (#/8" thick) #/4"

Next, to keep the drawer from tip- S 1"

ply.

2!/2"

ping as it’s pulled out, I glued a kick- 13&/8"

er (P) under the top of the case

(Fig. 6). Then I added a stop (Q) at 15&/8" !/4"-dia.

holes

the back of the case. You’ll want SHELF S 4"

to sneak up on the width of this 15%/8" T

piece so that when the drawer

stops against it, the drawer’s front

T !/4"

face will be flush with the face frame. EDGING

SHELVES & STANDARDS. For this small

cabinet, I saved the shelves for last

(Fig. 7). To support these panels,

four shelf standards (R) will need

FINISHING TOUCH

to be resawn or planed down to 3/8"

thick. They’re basically the same as When deciding on the finish for difficult to stain evenly anyway —

the standards in the TV cabinet (just the entertainment center, I chose it often ends up looking “blotchy.”

shorter), as shown in Fig. 7. not to stain the wood. For one Instead, I sanded the project to

Finally, you can cut the shelf (S) thing, the light color of maple fits 180-grit and then applied several

to size from 3/4" plywood (Fig. 7). well with the project’s contempo- coats of a wipe-on polyurethane.

And since this cabinet is open in the rary style. And besides, the color However, this would also be a

back as well as the front, I glued of the plywood and hardwood was great project for trying your

hardwood edging (T) to both the a good match, and maple can be hand at a water-based topcoat.

front and back edges of the shelf. W

MATERIALS & SUPPLIES CUTTING DIAGRAM

A End Panels (2) #/4 ply. - 14!/2 x 18!/8

B Upper End Rails (2) #/4 x 1!/2 - 14!/2 #/4" x 7!/4" - 96" Hard Maple (4.8 Bd. Ft.) O

C Lower End Rails (2) #/4 x 3 - 14!/2

K K K R R

D End Stiles (4) #/4 x 1 - 24!/8

E Top/Btm./Divider (3) #/4 ply. - 16!/2 x 16!/2

P Q

F Front/Back Stiles (4) #/4 x 1#/4 - 24!/8 #/4" x 7!/4" - 96" Hard Maple (4.8 Bd. Ft.)

G Upper Front Rails (2) #/4 x 1!/2 - 14!/2 H

I I C C

G B F F

H Upper Back Rail (1) #/4 x 6!/2 - 14!/2

I Front/Back Lower Rails (2) #/4 x 3 - 14!/2

#/4" x 5!/2" - 96" Hard Maple (3.7 Bd. Ft.)

J Top Spacers (1) !/8 x 1!/2 - 90 rgh.

L L M M D

K Top Panel (1) #/4 x 18 - 18

L Drawer Front/Back (2) #/4 x 3&/16 - 14#/8 J T

!/4" - 24" x 24"

M Drawer Sides (2) !/2 x 3&/16 - 16!/4 #/4"- 48" x 48" Maple Plywood Maple Plywood

N Drawer Bottom (1) !/4 ply. - 13&/8 x 15#/4

O Drawer Guides (2) #/4 x 1!/16 - 16!/2 A A N

P Drawer Kicker (1) #/4 x #/4 - 16!/2

Q Drawer Stop (1) #/4 x !/2 - 14#/8

R Shelf Standards (4) #/8 x 2!/2 - 13&/8

S Shelf (1) #/4 ply. - 15&/8 x 15%/8 E E

T Shelf Edging (2) #/4 x !/4 - 15%/8

• (1 pkg.) 1!/4" Pocket Hole Screws NOTE:

• (4) #8 x 1!/4" Rh Woodscrews Top spacers (J) must

E S be resawn to get

• (4) #8 Flat Washers blanks needed.

• (1) 96mm Stainless-Steel Pull

• (4) Spoon-Style Shelf Supports

Woodsmith.com page 12 © August Home Publishing Co.

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Easy Chinese Recipes PDFDocumento151 páginasEasy Chinese Recipes PDFTrafalgar100% (10)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- Digital Booklet - The Addams FamilyDocumento20 páginasDigital Booklet - The Addams FamilyAlejandro Andres Castillo Pino50% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Thieves' World Murder at The Vulgar Unicorn (d20)Documento81 páginasThieves' World Murder at The Vulgar Unicorn (d20)Red Stone100% (4)

- P90X3 FitnessGuideDocumento117 páginasP90X3 FitnessGuideAlfie Roel Gutierrez100% (4)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Past Tenses and Present Perfect 1 - 108801Documento2 páginasPast Tenses and Present Perfect 1 - 108801Eleu TeaAinda não há avaliações

- Foldable Stool Reverse Engineering The Tallon StooDocumento37 páginasFoldable Stool Reverse Engineering The Tallon StooEnrique CoronelAinda não há avaliações

- Minstrels & TroubadoursDocumento7 páginasMinstrels & TroubadoursAdam Russell RobertsonAinda não há avaliações

- Numbers and Words Repeated PatternsDocumento211 páginasNumbers and Words Repeated PatternsVI BĂNG100% (1)

- The NamesakeDocumento3 páginasThe Namesakenilanjan_chatterje_2100% (2)

- MGP7711-Conan Pocket Edition PDFDocumento394 páginasMGP7711-Conan Pocket Edition PDFHans Petersson100% (4)

- Multi-channel formats in electroacoustic compositionDocumento4 páginasMulti-channel formats in electroacoustic compositionNikos StavropoulosAinda não há avaliações

- NullDocumento3 páginasNullapi-26009013Ainda não há avaliações

- Delhi Containment ZonesDocumento40 páginasDelhi Containment ZonesShraddha ChowdhuryAinda não há avaliações

- INVERSIONDocumento2 páginasINVERSIONCarmenAinda não há avaliações

- Chef John's Calabrian Chicken RecipeDocumento2 páginasChef John's Calabrian Chicken RecipearkcaverAinda não há avaliações

- Winter Academic State ChampionsDocumento2 páginasWinter Academic State ChampionsstprepsAinda não há avaliações

- DMS IIT Delhi Dress Code for Corporate EventsDocumento3 páginasDMS IIT Delhi Dress Code for Corporate EventsSantu BiswaaAinda não há avaliações

- Manual de Partes Ricoh MPC2050 PDFDocumento314 páginasManual de Partes Ricoh MPC2050 PDFLuis AlbertoAinda não há avaliações

- Era Weapon IDsDocumento7 páginasEra Weapon IDsArpoo mAinda não há avaliações

- SatFlower I6 User Manual V1.0Documento62 páginasSatFlower I6 User Manual V1.0Nithin Raj KAinda não há avaliações

- Abb Switch Disconnectors 1Documento3 páginasAbb Switch Disconnectors 1Farid GergesAinda não há avaliações

- Fuelfocus™ Programmer User Manual Revision A00 April 2020: All Rights ReservedDocumento40 páginasFuelfocus™ Programmer User Manual Revision A00 April 2020: All Rights ReservedRamonAinda não há avaliações

- Breakfast (Morning) Lunch or Dinner (Noon To Evening) Drinks DessertsDocumento4 páginasBreakfast (Morning) Lunch or Dinner (Noon To Evening) Drinks DessertsJa CkiAinda não há avaliações

- Phil Parker Bye PDFDocumento5 páginasPhil Parker Bye PDFMarc MorehouseAinda não há avaliações

- Application For SLMC Id CardDocumento5 páginasApplication For SLMC Id Cardanapayan.manoranjanAinda não há avaliações

- Animation PresentationDocumento13 páginasAnimation Presentationdin2kxpAinda não há avaliações

- July 2017 TV, Home Theater and DVD Price ListDocumento13 páginasJuly 2017 TV, Home Theater and DVD Price Listanahh ramakAinda não há avaliações

- In The House Crossword Puzzle Crosswords Icebreakers Oneonone Activities Tests W 40439Documento2 páginasIn The House Crossword Puzzle Crosswords Icebreakers Oneonone Activities Tests W 40439Dayani BravoAinda não há avaliações

- Iranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102Documento1 páginaIranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102reza329329Ainda não há avaliações

- Help Children Be Grateful Pray-Ers: NovemberDocumento4 páginasHelp Children Be Grateful Pray-Ers: NovemberStaci InskeepAinda não há avaliações