Escolar Documentos

Profissional Documentos

Cultura Documentos

Access Because The Ramps Are So Much Faster, This Screen Will Be Much Shorter, Saving Time and Money!!

Enviado por

tasleemaeroDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Access Because The Ramps Are So Much Faster, This Screen Will Be Much Shorter, Saving Time and Money!!

Enviado por

tasleemaeroDireitos autorais:

Formatos disponíveis

Consider five different failure mode types, each accelerated by a particular stress:

F(t) = failures accelerated by High Temperature Dwells (chemical type failures)

F(r) = Failures accelerated by rapid thermal change rates (some solder issues and mechanical issues)

F(d) = Failures accelerated by hot and cold dwells (particularly solder creep)

F(v) = Failures accelerated by vibration (solder joint issues, mechanical issues, many others)

F(c) = failures only accelerated by a combined thermal and vibration stress environment

All of these failure types contribute to the infant mortality failures in a product. An environmental screen that is just burn-

in only catches F(t). It also takes a relatively long time. Thermal ramps will catch F(r) and some F(d), depending on the

dwell times. Also, some F(t) will be found, simply due to the hot dwells between ramps. It is well known that F(t) type

failures do not represent a large percentage of the failure mode population. The failure rates in burn-in are often very low,

but the failure rates in the field stay high, clearly indicating that accelerating F(t) type failures is not achieving the goal of

reduced infant mortality. All of these failure modes are accelerated by the stresses from a ESPEC Qualmark system

(although true chemical type stuff not so much, but that percentage is so low anyway, it doesn’t matter.)

If you are doing an ESS that includes thermal ramps, the precipitation efficiency of that screen can be calculated with mil

std 344A. Then, a screen using the higher ramp rates that the ESPEC chamber is capable of can be calculated that meets

the same efficiency... we call this AccESS (Accelerated

ESS). Because the ramps are so much faster,

this screen will be much shorter, saving time and money!!

Because the new screen is shorter, you can afford to take the time to extend the hot and cold dwells. This will increase the

efficiency of the screen because of the detection of solder creep issues. These issues were not known or accounted for

when 344A was written, but they are a well documented source of infant mortality now.

If you have done a test on the product to determine the actual thermal limits of the product, and expanded those limits if

possible by eliminating design issues, then the ramps in the ESS can be extended beyond the product specification, based

on the results of the limit test. This increased range will increase the efficiency even further, reducing the test time even

more.

A wide range of latent failure modes can be effectively accelerated by vibration, some only by vibration. If a vibration

limit test is done on the product, so the vibration tolerance is known, and any exposed design issues are eliminated, then

the manufacturer can safely introduce vibration into the ESS for the product. This will greatly expand the overall

efficiency of the screen, because now many of the failure mode types will be accelerated, including those accelerated by a

combined environment (surface mount solder joints) and those that need vibration. The likelihood of capturing any latent

defect, regardless of the stress that accelerates it, is greatly increased. This achieves the goal of reduced infant mortality.

ESPEC offers high thermal ramp rate stresses that can significantly accelerate Reliability Demonstration Testing and ESS.

And ESPEC delivers a mutlitude of testing systems and Accelerated ESS to you!! Contact Us TODAY to get started!

Você também pode gostar

- Advanced Temperature Measurement and Control, Second EditionNo EverandAdvanced Temperature Measurement and Control, Second EditionAinda não há avaliações

- Automotive Sensor Testing and Waveform AnalysisNo EverandAutomotive Sensor Testing and Waveform AnalysisNota: 4.5 de 5 estrelas4.5/5 (13)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionNo EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionNota: 4.5 de 5 estrelas4.5/5 (3)

- Rubber Life Time PredictionDocumento2 páginasRubber Life Time Predictionmans2014Ainda não há avaliações

- Different Environment Tests For ReliabilityDocumento11 páginasDifferent Environment Tests For ReliabilityParthDesaiAinda não há avaliações

- ReliabilityDocumento24 páginasReliabilityDominicAinda não há avaliações

- Shapa Venting Paper 10Documento10 páginasShapa Venting Paper 10nshsharma7475Ainda não há avaliações

- Technical Support FerretechDocumento7 páginasTechnical Support FerretechpraveenAinda não há avaliações

- Environmental Stress Screening TutorialDocumento30 páginasEnvironmental Stress Screening TutorialMariut Elena LarisaAinda não há avaliações

- Question and Answers From Web Seminar: Heatsink 201: Even More About Heatsink DesignDocumento10 páginasQuestion and Answers From Web Seminar: Heatsink 201: Even More About Heatsink DesignooqqAinda não há avaliações

- Keys To Successful Designed Experiments: Mark J. Anderson and Shari L. KraberDocumento10 páginasKeys To Successful Designed Experiments: Mark J. Anderson and Shari L. KraberMiguel ChAinda não há avaliações

- The Guide To Selecting A Test Chamber: 31 Willow RD Ayer, MA 01432 (978) 772-0022Documento14 páginasThe Guide To Selecting A Test Chamber: 31 Willow RD Ayer, MA 01432 (978) 772-0022Sheriff M. SammyAinda não há avaliações

- Zetex HandbookDocumento8 páginasZetex HandbookbolermAinda não há avaliações

- SteamlocDocumento8 páginasSteamlocstuntmanzAinda não há avaliações

- Detecting Premature Bearing FailureDocumento4 páginasDetecting Premature Bearing FailureMuhd Fadzlee ZAinda não há avaliações

- CorrosionboxDocumento4 páginasCorrosionboxmankari.kamal.18022963Ainda não há avaliações

- 20110013317Documento11 páginas20110013317Gautam GadgilAinda não há avaliações

- 11609EN WHY ThermographyDocumento2 páginas11609EN WHY Thermographyg_periwal_pune9635Ainda não há avaliações

- Investigation Into Hand-Arm Vibration Report of FindingsDocumento7 páginasInvestigation Into Hand-Arm Vibration Report of FindingsColin904Ainda não há avaliações

- Chemical Engineering Interview QuestionsDocumento52 páginasChemical Engineering Interview QuestionsAman SrivastavaAinda não há avaliações

- RTD Tolerance Classes TBRTDTOL-0614Documento4 páginasRTD Tolerance Classes TBRTDTOL-0614Anonymous zdCUbW8HfAinda não há avaliações

- Innovations in Fire Fighting EquipmentDocumento6 páginasInnovations in Fire Fighting EquipmentIklil AjaoAinda não há avaliações

- GE Gas Turbine Accessory and Load Gear Compartments Temperature Running HighDocumento20 páginasGE Gas Turbine Accessory and Load Gear Compartments Temperature Running HighShahzad JamesAinda não há avaliações

- Cooling Tower Thermal CapabilityDocumento8 páginasCooling Tower Thermal CapabilityforuzzAinda não há avaliações

- Insulation CalDocumento24 páginasInsulation CalsenaAinda não há avaliações

- Loctite 542: Product Description Technology Cure Speed vs. Bond GapDocumento4 páginasLoctite 542: Product Description Technology Cure Speed vs. Bond GapbabshuagAinda não há avaliações

- Press Release 2019 As Schneider Understanding Shells DVT Tat 072019Documento5 páginasPress Release 2019 As Schneider Understanding Shells DVT Tat 072019aleeimeranAinda não há avaliações

- Webinar FAQ - Shell and Tube Heat ExchangersDocumento8 páginasWebinar FAQ - Shell and Tube Heat Exchangersrameshkarthik810Ainda não há avaliações

- Pruevas Electricas y de Aislamiento de TransformadoresDocumento3 páginasPruevas Electricas y de Aislamiento de TransformadoresDenisse GarciaAinda não há avaliações

- SwiftyCalc Therm Ow Ell Design - ASME PTC 19.3 TW (2010) FlyerDocumento2 páginasSwiftyCalc Therm Ow Ell Design - ASME PTC 19.3 TW (2010) Flyermpj28677Ainda não há avaliações

- Final Technical Report1 Traxdata LogoDocumento9 páginasFinal Technical Report1 Traxdata LogoCS AMDAinda não há avaliações

- Se40 4bDocumento5 páginasSe40 4bnknfiveAinda não há avaliações

- Temperature Control at 19MW On MS5001Documento4 páginasTemperature Control at 19MW On MS5001chdi100% (1)

- My First Journal PDFDocumento7 páginasMy First Journal PDFrangasamy raajAinda não há avaliações

- Heatsink Design OptimizeDocumento17 páginasHeatsink Design Optimizeaakashjazz5Ainda não há avaliações

- Vlsi TestingDocumento79 páginasVlsi Testingkarnika143Ainda não há avaliações

- SPE-169195-MS Development, Test and Offshore Use of A Fouling Repellent Coating For Plate Heat ExchangersDocumento6 páginasSPE-169195-MS Development, Test and Offshore Use of A Fouling Repellent Coating For Plate Heat ExchangersTangtang Guo100% (1)

- SwiftyCalc - Wake Frequency Calculation Using The ASME PTC 19.3 TW (2010) StandardDocumento2 páginasSwiftyCalc - Wake Frequency Calculation Using The ASME PTC 19.3 TW (2010) StandardtemperaturelaneAinda não há avaliações

- Literature Review On Temperature Data LoggerDocumento4 páginasLiterature Review On Temperature Data Loggerjolowomykit2100% (1)

- The Hot Topic of Motor TemperatureDocumento6 páginasThe Hot Topic of Motor Temperaturezionees01Ainda não há avaliações

- FEA On ThermowellDocumento4 páginasFEA On Thermowellvaisakp777Ainda não há avaliações

- Chilworth Chemical Reaction Hazards GuideDocumento36 páginasChilworth Chemical Reaction Hazards GuidechemsguyAinda não há avaliações

- Temperature Cycling Testing - Coffin-Manson Equation - Delserro Engineering SolutionsDocumento11 páginasTemperature Cycling Testing - Coffin-Manson Equation - Delserro Engineering SolutionsmrbustaAinda não há avaliações

- Fryquel EHC PlusDocumento4 páginasFryquel EHC PlusZuli Nur CahyoAinda não há avaliações

- The Longford Gas Plant ExplosionDocumento6 páginasThe Longford Gas Plant ExplosionselereakAinda não há avaliações

- O-Engineers Jan 2018Documento39 páginasO-Engineers Jan 2018Enpak ArsalanAinda não há avaliações

- W W W W W: by Glenn Friedman, P.E., Member ASHRAEDocumento7 páginasW W W W W: by Glenn Friedman, P.E., Member ASHRAEavinmjAinda não há avaliações

- General Phased Array Questions PDFDocumento7 páginasGeneral Phased Array Questions PDFMarcus AntoniusAinda não há avaliações

- Q A Fike Webinar Explosion Risk Assessment and Explosion Protection DoDocumento3 páginasQ A Fike Webinar Explosion Risk Assessment and Explosion Protection DoAda-MAinda não há avaliações

- DSC Beginners GuideDocumento9 páginasDSC Beginners GuidelumineurAinda não há avaliações

- Fan Diagnosis in The FieldDocumento10 páginasFan Diagnosis in The FieldDavide LanzoniAinda não há avaliações

- CapaciSense Tip Clearance and Vibration Monitoring Systems BrochureDocumento16 páginasCapaciSense Tip Clearance and Vibration Monitoring Systems Brochurevladgor858Ainda não há avaliações

- HW4 Transient1DSlab 01-2czx5uuDocumento19 páginasHW4 Transient1DSlab 01-2czx5uuGonKil0% (1)

- Translating The Economic Benefits of Parallel Memory Test To Non-Memory DevicesDocumento4 páginasTranslating The Economic Benefits of Parallel Memory Test To Non-Memory DevicesKhoo Voon ChingAinda não há avaliações

- Balancing Production Reliability ReformersDocumento6 páginasBalancing Production Reliability ReformersejremediosAinda não há avaliações

- Fouling FactorsDocumento3 páginasFouling FactorshurrikenAinda não há avaliações

- Vibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingNo EverandVibrations of Power Plant Machines: A Guide for Recognition of Problems and TroubleshootingAinda não há avaliações

- Automotive Equipment Usage and Repair StrategiesNo EverandAutomotive Equipment Usage and Repair StrategiesNota: 5 de 5 estrelas5/5 (1)

- Operational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseNo EverandOperational Amplifier Noise: Techniques and Tips for Analyzing and Reducing NoiseNota: 5 de 5 estrelas5/5 (1)

- Prismic R10: Product SpecificationDocumento2 páginasPrismic R10: Product SpecificationParag HemkeAinda não há avaliações

- XRF Theory PDFDocumento258 páginasXRF Theory PDFXONΔΡΑΚΗΣ ΓΙΩΡΓΟΣ100% (1)

- Fesc 115Documento8 páginasFesc 115Sundeep GargAinda não há avaliações

- Report TextDocumento2 páginasReport Textsusila10Ainda não há avaliações

- Op Protection KIDocumento5 páginasOp Protection KIDragan IlicAinda não há avaliações

- CycloalkanesDocumento60 páginasCycloalkanesmeri hardina zd100% (1)

- SM Haddci 1-A.2 GBDocumento171 páginasSM Haddci 1-A.2 GBheorgyAinda não há avaliações

- Design of Offshore StructuresDocumento29 páginasDesign of Offshore StructuresJOSE PRASOBH..JAinda não há avaliações

- Scope TC 9124Documento1 páginaScope TC 9124Esscon Engineering Services Pvt. Ltd.Ainda não há avaliações

- Attachment PDFDocumento2 páginasAttachment PDFYunita RamadhantiAinda não há avaliações

- Datasheet BSS66Documento1 páginaDatasheet BSS66Diego DiazAinda não há avaliações

- Activity Grade 9Documento4 páginasActivity Grade 9Rosemarie ItumAinda não há avaliações

- View Interpolation For Image Synthesis: Shenchang Eric Chen, Lance Williams Apple Computer, IncDocumento10 páginasView Interpolation For Image Synthesis: Shenchang Eric Chen, Lance Williams Apple Computer, IncPiyush JainAinda não há avaliações

- Tutorial On Structural Analysis Using BEAM Elements of CAEPIPEDocumento5 páginasTutorial On Structural Analysis Using BEAM Elements of CAEPIPEFRANCISCOAinda não há avaliações

- Pengaruh Kandungan Frekuensi Gempa Terhadap Simpangan Dan Drift Ratio 2 Arah Struktur Bangunan Set-Back Bertingkat BanyakDocumento9 páginasPengaruh Kandungan Frekuensi Gempa Terhadap Simpangan Dan Drift Ratio 2 Arah Struktur Bangunan Set-Back Bertingkat BanyakIvan MuhammadAinda não há avaliações

- 2021 Physicsbowl Exam Equations: Continued On Next PageDocumento3 páginas2021 Physicsbowl Exam Equations: Continued On Next PageThe Entangled Story Of Our WorldAinda não há avaliações

- Pollen and Spore Morphology, Plant Taxonomy - ErdtmanDocumento178 páginasPollen and Spore Morphology, Plant Taxonomy - ErdtmanAndres Elgorriaga100% (1)

- Role of Physics in Daily LifeDocumento2 páginasRole of Physics in Daily LifeSadam MaharAinda não há avaliações

- Various Types of Surfaces: Made By:-Nilesh Bhojani Guided By: - Prof. B.K. PatelDocumento15 páginasVarious Types of Surfaces: Made By:-Nilesh Bhojani Guided By: - Prof. B.K. Patelnilesh bhojaniAinda não há avaliações

- RDM-chapter 1Documento35 páginasRDM-chapter 1Mat MatttAinda não há avaliações

- Physics of Artificial GravityDocumento15 páginasPhysics of Artificial GravityWilliam RiveraAinda não há avaliações

- Iwnicki 01 06Documento37 páginasIwnicki 01 06VICTOR HUGO ORTIZ MOSCOSOAinda não há avaliações

- Unit 3 Moulding Processes: StructureDocumento18 páginasUnit 3 Moulding Processes: StructureChethan Madappady75% (4)

- 03 Combustor Dynamics Monitoring (CDM)Documento9 páginas03 Combustor Dynamics Monitoring (CDM)Luis Alonso Dipaz ZeaAinda não há avaliações

- ReiewDocumento19 páginasReiewcullen bohannonAinda não há avaliações

- Finite Element Analysis of Steel CordDocumento6 páginasFinite Element Analysis of Steel CordSanjiv Kumar SinghAinda não há avaliações

- Asadur RahmanDocumento48 páginasAsadur Rahmanah waAinda não há avaliações

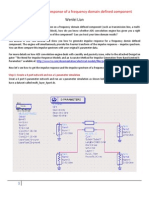

- Impulse Response of Frequency Domain ComponentDocumento17 páginasImpulse Response of Frequency Domain Componentbubo28Ainda não há avaliações

- KISSsoft Calculation Programs For Machine DesignDocumento22 páginasKISSsoft Calculation Programs For Machine DesignAbhijeet DeshmukhAinda não há avaliações

- Arta211 MidtermsDocumento2 páginasArta211 MidtermsWallen LagradaAinda não há avaliações