Escolar Documentos

Profissional Documentos

Cultura Documentos

Chiller

Enviado por

Mara RecaldeDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Chiller

Enviado por

Mara RecaldeDireitos autorais:

Formatos disponíveis

RECIRCULATING LOOP CHILLER

LOW PROFILE / WEATHER-RESISTANT

MODEL....................... PCP-750G-96-A-WP-LP

HERMETIC SCROLL MODEL

DESCRIPTION

A closed loop, packaged chiller designed specifically to recirculate a clean

coolant at a constant temperature, pressure and flow. Ideal for all installations

where a dependable source of clean cooling water is not available.

Filtrine PCP chillers use a storage-type cooling tank, with immersion coil

evaporator, to provide close temperature control of recirculating coolants.

The tank is sealed to prevent coolant evaporation or fouling, and supplied

with a liquid level gauge, fill port and clean out. The pump recirculates the

coolant at a constant temperature, pressure and flow.

SPECIFICATIONS

COOLING CAPACITY: Btu/hr [min / max].....................................................96,000

Watts [min / max]...........................................................................................28,128

TYPICAL LOW PROFILE CHILLER Rating Conditions:

Coolant Discharge Temperature..................................................... 68OF [20OC]

Ambient Air Temperature.................................................................. 90OF [32OC]

APPLICATIONS COMPRESSOR: HP....................................................................................................7 1/2

Jacket Cooling Computers Description: Lifetime lubricated, hermetic scroll type supplied with

Lasers Power Supplies high/low pressure stat, freeze control, head and suction gauges, pump

Induction Heaters Vacuum Ovens

down solenoid valve, thermostatic expansion valve, refrigerant sight

Machine Tools Injection Molding

Welders Plasma Spraying glass and dehydrator.

MRI Equipment Linear Accelerators STANDARD CONDENSER (Designated by suffix)

CAT Scans Electron Microscopes A-WP Weather-resistant for outdoor installation

COOLING TANK & EVAPORATOR: Capacity................................ 95 Gals. [360 L]

FEATURES Construction: Welded stainless steel shell with stainless steel immersion

Low Profile Design coil evaporator. Tank tested at 250# for 125# working pressure, supplied

Designed for rooftop mounting. Easily concealed by parapet, with drain connection and insulated with closed cell thermo-elastomer

50” overall height for low visibility. Outdoor chiller location with an R factor of 3.7.

removes heat and operating noise from inside building. PUMP: HP...................................................................................................................1-1/2

Energy Saving Design Capacity ..................................................30 GPM @ 40 PSI [114 lpm @ 4 bar]

Unlike most process chillers, compressor runs only as need- Description: Bronze fitted turbine pump mounted on a rubber pad over

ed. Storage design provides close temperature control and a stainless steel condensation tray and supplied with unions and service

safety from freeze-up without constant operation. valves and a pressure relief bypass valve. All piping and fittings brass,

Complete Temperature Control copper or bronze, and insulated with closed cell thermo-elastomer with

Ambient operating temps from -30OF to 120OF an R factor of 3.7.

Welded Stainless Steel Cooling Tank THERMOSTAT: Adjustable Range.................................. 40O to 90OF [4O to 32OC]

Recirculates clean coolant sealed from the atmosphere, Temperature Stability........................................................................ ±2OF [1.4OC]

eliminates bacterial build-up and internal corrosion. CABINET: Anodized aluminum panels with stainless steel corner legs and

Uses HFO Refrigerant top on a welded angle iron frame. Panels removable without tools for

Eliminates use of ozone-depleting and high GWP (Global access to all components.

Warming Potential) refrigerant as per Montreal Protocol. Supply Power:..........................................208-230/60/3 or 460/60/3 or 380/50/3

Full Load Amps.............................................................................................42 or 21

NOTE: FLA may vary depending on options. See MCA and MOP ratings

on nameplate of as-built unit.

PLUMBING CONNECTIONS IN & OUT................................. 1-1/4” [31mm] MPT

SHIPPING WEIGHT........................................................................................... 2,200 lbs

START-UP and FIRST YEAR SERVICE

FILTRINE Mfg. Co. provides start-up and first year service on all parts and

labor. Regular maintenance on a yearly contract basis is a wise investment

and will prevent costly downtime.

WARRANTY

All parts are covered FOB jobsite for (12) months from the start date or (15)

months from date of shipment or whichever comes first. ENERGY SAVING OPTIONS AVAILABLE

SERVICE MAKES THE DIFFERENCE

Recognizing that downtime on critical medical equipment is unacceptable, CONSULT FACTORY

Filtrine has established a national network of qualified service technicians,

selected because of their extensive experience working on medical

equipment chillers and their location within the “Emergency Response Zone”

(approximately 40 miles). This expert and quick service is available on an 8/5

or 24/7 basis for all Filtrine medical chillers and heat exchangers.

Filtrine Mfg. Co. • 15 Kit St. Keene, NH 03431 USA 608-7.5G-WP-LP

800-930-3367 • 603-352-5500 • FAX 603-352-0330 FILTRINE IS ISO 9001:2015 CERTIFIED [PCP-750G-WP-LP]

WEB www.filtrine.com • EMAIL cool@filtrine.com MADE IN USA

PRODUCT LINE APPROVED MARK AVAILABLE

REV. 06.11.18

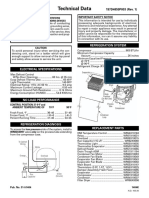

TYPICAL WEATHER-RESISTANT, LOW PROFILE CHILLER SCHEMATIC

AIR

8 DISCHARGE 9 1 2

AIR INTAKE TOP

REAR

LEGEND

1.........Fill Port

2.........Sight Glass H

3.........Return

4.........Discharge

6.........Electrical Connection FRONT

7.........Indicator Lamps

8.........Head Pressure

9.........Suction Pressure

W

D

6 4 3

CHILLER DIMENSIONS and WEIGHTS

FILTRINE W D H SHIP WT

MODEL NUMBER in cm in cm in cm lb kg

PCP-750G-96-A-WP-LP 94 239 87 221 44 112 2200 950

Dimensions & weights may vary depending on options installed-consult factory.

STANDARD OPERATING CONDITIONS VENTILATION PANELS

OUTDOOR AMBIENT: Standard model: air intake at rear, air discharge at top.

-20OF to 90OF (10O to 32OC) Manufacturer recommends 24" minimum clear space

OPTIONAL OPERATING CONDITIONS opposite all ventilation panels.

OUTDOOR AMBIENT: REMOVABLE SERVICE PANELS

Down to -30OF (-34OC) Located on front and left end.

Up to 100OF (38OC) Manufacturer recommends 36" clearance at front for service

Up to 110OF (43OC) and 36" clearance at left end for access to controls.

Up to 120OF (49OC)

CHANNEL SKIDS

NOTE: Higher ambient options may affect unit dimensions. Allow an additional 4" (10cm) to depth and 2" (5cm) to

All information given on this bulletin is for general use only. height for channel skids. Center of 5/8" (16mm) mounting

Confirm specifications with factory for your specific require- holes located 6" (15cm) from chiller end and 1" (2.5cm) from

ment. chiller edge front and rear.

Filtrine Mfg. Co. • 15 Kit St. Keene, NH 03431 USA 608-7.5G-WP-LP

800-930-3367 • 603-352-5500 • FAX 603-352-0330 FILTRINE IS ISO 9001:2015 CERTIFIED [PCP-750G-WP-LP]

WEB www.filtrine.com • EMAIL cool@filtrine.com MADE IN USA

PRODUCT LINE APPROVED MARK AVAILABLE

REV. 06.11.18

Você também pode gostar

- RAC Qualifying ExamDocumento9 páginasRAC Qualifying ExamVirg Sci-hiAinda não há avaliações

- Atlas Copco: U.S. UnitsDocumento12 páginasAtlas Copco: U.S. Unitsousmane doukara100% (1)

- APCD Series Air Cooled Packaged ChillersDocumento49 páginasAPCD Series Air Cooled Packaged Chillersthiroshann60% (5)

- Manual - Carrier (Reparado)Documento156 páginasManual - Carrier (Reparado)Juan Carlos Chapoñan SilvaAinda não há avaliações

- Compressor InfoDocumento180 páginasCompressor Inforadityo_14Ainda não há avaliações

- R-410A Air-Cooled ChillersDocumento84 páginasR-410A Air-Cooled ChillersThe Ka1serAinda não há avaliações

- Apcd 5050 ADocumento64 páginasApcd 5050 Aavinash rathodAinda não há avaliações

- Eg en YlcsDocumento52 páginasEg en YlcsItalo LeivaAinda não há avaliações

- Ahri Standard 550Documento123 páginasAhri Standard 550CARLOSAinda não há avaliações

- Variable Speed Pumping: A Guide to Successful ApplicationsNo EverandVariable Speed Pumping: A Guide to Successful ApplicationsNota: 3 de 5 estrelas3/5 (2)

- Yk Style FDocumento80 páginasYk Style Fmohd irshadAinda não há avaliações

- R134a Water-cooled Screw Chillers User's Manual 100-190 TonsDocumento116 páginasR134a Water-cooled Screw Chillers User's Manual 100-190 TonsSumit DasAinda não há avaliações

- Air Cooled Scroll Chiller Service Manual T1/R407C/50Hz : Gree Electric Appliances Inc. of ZhuhaiDocumento58 páginasAir Cooled Scroll Chiller Service Manual T1/R407C/50Hz : Gree Electric Appliances Inc. of ZhuhaiOng MatAinda não há avaliações

- Optimising Chillers and TowersDocumento7 páginasOptimising Chillers and TowersAbhishek SauntokheeAinda não há avaliações

- How to Save Energy and Money in RefrigerationDocumento67 páginasHow to Save Energy and Money in Refrigerationcyclon2010100% (1)

- Dunham-Bush ACHDX-55 - 245TR-50Hz-ScrewDocumento16 páginasDunham-Bush ACHDX-55 - 245TR-50Hz-ScrewEdgar José Silva Rincón0% (1)

- Anti Condensation Heaters March 2011Documento52 páginasAnti Condensation Heaters March 2011SandeepAinda não há avaliações

- APCN Series Screw Chillers: Range 45 TR To 470 TR (158 KW To 1600 KW)Documento43 páginasAPCN Series Screw Chillers: Range 45 TR To 470 TR (158 KW To 1600 KW)Ahmad Salah100% (1)

- Secop Compressors CatalogueDocumento180 páginasSecop Compressors CatalogueBraian Cabañas Visca BarçaAinda não há avaliações

- Cubigel Compressors & Condensing Units General Catalogue PDFDocumento84 páginasCubigel Compressors & Condensing Units General Catalogue PDFSilvaAinda não há avaliações

- Fans and BlowersDocumento57 páginasFans and BlowersmaylynXiXAinda não há avaliações

- RECIRCULATING LOOP CHILLER LOW PROFILE WEATHER-RESISTANTDocumento2 páginasRECIRCULATING LOOP CHILLER LOW PROFILE WEATHER-RESISTANTbioarquitecturaAinda não há avaliações

- Hercules Water Cooled Centrifugal ChillersDocumento32 páginasHercules Water Cooled Centrifugal ChillersWaltinegojiya CadondonAinda não há avaliações

- Tech Data ZIS42D (31-51404) 197D4859P003-1Documento2 páginasTech Data ZIS42D (31-51404) 197D4859P003-1Cesar Calderon GrAinda não há avaliações

- APCN-S Series Air Cooled Packaged Chillers: Range 50 TR To 435 TR (176 KW To 1529 KW)Documento47 páginasAPCN-S Series Air Cooled Packaged Chillers: Range 50 TR To 435 TR (176 KW To 1529 KW)Ahmad SalahAinda não há avaliações

- YorkDocumento48 páginasYorkNoushad P HamsaAinda não há avaliações

- HitecsaDocumento28 páginasHitecsaleonelAinda não há avaliações

- Xyl A50Documento44 páginasXyl A50Ixtlan007Ainda não há avaliações

- Model YK Centrifugal Liquid Chillers Design Level F: FORM 160.73-EG1Documento78 páginasModel YK Centrifugal Liquid Chillers Design Level F: FORM 160.73-EG1Zainul Abedin SayedAinda não há avaliações

- APCYDocumento64 páginasAPCYChachou MohamedAinda não há avaliações

- Thermostatic Expansion Valves: Technical BrochureDocumento12 páginasThermostatic Expansion Valves: Technical BrochuresenAinda não há avaliações

- Gree LSQWRFDocumento20 páginasGree LSQWRFMiroslav LuladžićAinda não há avaliações

- ACMR Range 8 TR To 280 TRDocumento48 páginasACMR Range 8 TR To 280 TRmegas13 manAinda não há avaliações

- 1034 PDFDocumento80 páginas1034 PDFMohammad IsmailAinda não há avaliações

- WPS250S in H S e PDocumento6 páginasWPS250S in H S e PMuntasir MunirAinda não há avaliações

- WPS30S in D S e PDocumento8 páginasWPS30S in D S e PMesfin MamoAinda não há avaliações

- APCN-S Series: Air Cooled Packaged ChillersDocumento52 páginasAPCN-S Series: Air Cooled Packaged ChillersMohamed ROUBIOAinda não há avaliações

- APCN-S Series: Air Cooled Packaged ChillersDocumento52 páginasAPCN-S Series: Air Cooled Packaged Chillersahmed abdohAinda não há avaliações

- YCAL0317CDocumento114 páginasYCAL0317CDaniel Pinto GodoyAinda não há avaliações

- Plumbing and HVAC PDFDocumento131 páginasPlumbing and HVAC PDFalbaAinda não há avaliações

- Vet Tipo T2 - TE2 - Danfoss PDFDocumento12 páginasVet Tipo T2 - TE2 - Danfoss PDFceluis vargasAinda não há avaliações

- GE_gtr_gts_gtt_htr_hts_httDocumento26 páginasGE_gtr_gts_gtt_htr_hts_httMarcelo CordónAinda não há avaliações

- Planta Panaven Modelo GMS22PX6SDocumento6 páginasPlanta Panaven Modelo GMS22PX6Sfranklin velasco100% (1)

- 50 Metric Tonne 55 Short Ton Payload - 28 M 36.6 Yd CapacityDocumento2 páginas50 Metric Tonne 55 Short Ton Payload - 28 M 36.6 Yd CapacitynambiiasAinda não há avaliações

- PL Cooling System 7 - 1Documento0 páginaPL Cooling System 7 - 1Luis Alberto OrtegaAinda não há avaliações

- APCN S ChillerDocumento72 páginasAPCN S ChillerMamdooh AbdallahAinda não há avaliações

- 160.73-Eg1 YorkDocumento72 páginas160.73-Eg1 Yorkmauricio.vidalyork6735Ainda não há avaliações

- CarrierDocumento108 páginasCarrierRAMAEL82Ainda não há avaliações

- DB - Air Cooled Flooded Chiller PDFDocumento32 páginasDB - Air Cooled Flooded Chiller PDFJason LimAinda não há avaliações

- AOSCA80000Documento62 páginasAOSCA80000arunAinda não há avaliações

- DADS..W Liquidcooled EngDocumento40 páginasDADS..W Liquidcooled EngtorbaAinda não há avaliações

- Vortex AC 115 V Manual (English)Documento20 páginasVortex AC 115 V Manual (English)kujawat11Ainda não há avaliações

- Apcy-P Series: Screw ChillersDocumento48 páginasApcy-P Series: Screw ChillersThe Ka1serAinda não há avaliações

- Coil SelectionDocumento40 páginasCoil Selectionbudi budihardjoAinda não há avaliações

- Im-7 Unit CoolerDocumento108 páginasIm-7 Unit CoolerstefanAinda não há avaliações

- Technical Data: Refrigeration SystemDocumento2 páginasTechnical Data: Refrigeration SystemMiguel RamirezAinda não há avaliações

- 608 750GDocumento2 páginas608 750GbioarquitecturaAinda não há avaliações

- Catalogo Unidad Condensadora Bomba de Calor PC090-180 y PD180-240 Americana AHRI PDFDocumento126 páginasCatalogo Unidad Condensadora Bomba de Calor PC090-180 y PD180-240 Americana AHRI PDFBladimir Patino - TRS BUCARAMANGAAinda não há avaliações

- Ge Desalination PlantDocumento2 páginasGe Desalination PlantMugesh100% (1)

- SKM Fan Coil Series: Chilled WaterDocumento33 páginasSKM Fan Coil Series: Chilled WaterHewa AkreyAinda não há avaliações

- DCLC Centrifugal Chillers for Cooling and EfficiencyDocumento6 páginasDCLC Centrifugal Chillers for Cooling and Efficiencygerald077Ainda não há avaliações

- Hussmann Super Plus Manuales de ServicioDocumento147 páginasHussmann Super Plus Manuales de Serviciofanny a. rugerioAinda não há avaliações

- Winters OilandgascatalogueDocumento156 páginasWinters OilandgascatalogueJOSE DEL CARMEN TOLEDOAinda não há avaliações

- 3K111-3K193 3K361-3K393: 3K Series - Single Stage Stainless Steel End-Suction Centrifugal PumpsDocumento8 páginas3K111-3K193 3K361-3K393: 3K Series - Single Stage Stainless Steel End-Suction Centrifugal PumpsJose Cieza r.Ainda não há avaliações

- GAIL UJJAIN BOQ Scope of WorkDocumento8 páginasGAIL UJJAIN BOQ Scope of WorkgloomyworldAinda não há avaliações

- ASHRAE Seminars JEFBOL 2013-10-01 Abridged MSODocumento68 páginasASHRAE Seminars JEFBOL 2013-10-01 Abridged MSOMIGUELAinda não há avaliações

- UltracoolDocumento4 páginasUltracoolYing Kei ChanAinda não há avaliações

- Evaporator and Condensers TypesDocumento4 páginasEvaporator and Condensers TypesOwais SiddiquiAinda não há avaliações

- Air2Air Manual SPXDocumento16 páginasAir2Air Manual SPXGary McKayAinda não há avaliações

- Ps 8DT90A PriruckaDocumento2 páginasPs 8DT90A PriruckaPavol GyuríkAinda não há avaliações

- Racqb 2Documento7 páginasRacqb 2ratchagaraja0% (1)

- DOCWin2.1 EsDocumento135 páginasDOCWin2.1 EsWall OmarAinda não há avaliações

- Suntec Energy System - Heat Pump in IndiaDocumento15 páginasSuntec Energy System - Heat Pump in IndiasuntecAinda não há avaliações

- Duct Air Leakage PDFDocumento3 páginasDuct Air Leakage PDFWilliam GrecoAinda não há avaliações

- MSZ-AP Product Information Sheet 2019Documento2 páginasMSZ-AP Product Information Sheet 2019ervinAinda não há avaliações

- 52c, P-3ae PtacDocumento56 páginas52c, P-3ae Ptackennethfbarnes0% (1)

- Content: R410A Tropical Split Type AC Technical Manual ContentDocumento166 páginasContent: R410A Tropical Split Type AC Technical Manual ContentRizwanAinda não há avaliações

- Chaptr28 MASTERCLASS - AIR CONDITIONING TECHNOLOGYDocumento3 páginasChaptr28 MASTERCLASS - AIR CONDITIONING TECHNOLOGYChuku EbubeAinda não há avaliações

- STULZ Air Conditioning Company ProfileDocumento98 páginasSTULZ Air Conditioning Company ProfileХохоAinda não há avaliações

- COMPANY PROFILE Henrich Airconditioning Service 2020Documento23 páginasCOMPANY PROFILE Henrich Airconditioning Service 2020Henry San PedroAinda não há avaliações

- SPD4121 1617 05-Load PDFDocumento60 páginasSPD4121 1617 05-Load PDFKyaw San OoAinda não há avaliações

- Factory Location and Model Specifications for 2007 Frigidaire Room Air ConditionersDocumento61 páginasFactory Location and Model Specifications for 2007 Frigidaire Room Air ConditionersEnmanuel J AriasAinda não há avaliações

- Heat Loss CalculationDocumento9 páginasHeat Loss CalculationAthanasios AntonopoulosAinda não há avaliações

- Impak 2 - 4tcc - CatalogoDocumento32 páginasImpak 2 - 4tcc - CatalogoyadiraaromAinda não há avaliações

- RN Iom 190402Documento136 páginasRN Iom 190402Michael PasayAinda não há avaliações

- LK Abans Offer Product ListDocumento39 páginasLK Abans Offer Product Listලහිරු විතානාච්චිAinda não há avaliações

- Technical Data & Service Manual: Outdoor Model No. Product Code No. Applicable Indoor Model No. V/ø/HzDocumento242 páginasTechnical Data & Service Manual: Outdoor Model No. Product Code No. Applicable Indoor Model No. V/ø/HzBorja MonDe YorkAinda não há avaliações

- Water Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35Documento28 páginasWater Cooled Water Chillers, Condenserless Water Chillers, Water-to-Water Reverse Cycle Heat Pumps. Models CWP-A, CWP-A/RC & CWP-A/HP 02 To 35jeromeduytscheAinda não há avaliações