Escolar Documentos

Profissional Documentos

Cultura Documentos

Diagrama Electrico QSK19 MCRI

Enviado por

eduardomunadacaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Diagrama Electrico QSK19 MCRI

Enviado por

eduardomunadacaDireitos autorais:

Formatos disponíveis

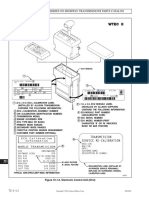

CUMMINS CONFIDENTIAL 16 PIN

This document (and the information shown thereon) is CONFIDENTIAL AND PROPRIETARY OEM POWER CONNECTOR

and shall not be disclosed to others in hard copy or electronic form, reproduced by any means, <N<

or used for any purpose without written consent of Cummins Inc. <P< 10 AMP

<F< UNSWITCHED BATTERY SUPPLY (SERVICE)

<E< 60 PIN ECM

<G< 10AMP 4 PIN ECM POWER CONNECTOR CONNECTOR

<A< UNSWITCHED BATTERY SUPPLY <04 >1> CRANK SPEED +5 VDC SUPPLY VSEN001 <16

<B< <03 >3> CRANK SPEED SIGNAL <27

<J< <02 >2> CRANK SPEED RETURN VSEN001 RET <48

<K< BATTERY RETURN <01

<L< BATTERY RETURN

<S< ETHER INJECTION <31

<C< CHANGES:

<R< >1> CAM SPEED +5VDC SUPPLY 1. Added unused pin numbers 28, 29 on 31 PIN OEM Connector

<D< >3> CAM SPEED SIGNAL <26 2. Changed the two OEM and Power connector type from two 31 pins and 8pin to 23 pin, 31pin and 16pin respectively.

<H< KEYSWITCH INPUT >2> CAM SPEED RETURN 3. Added the Real Time Clock Battery pins to 60 pin Engine Connector

<M< 4. Changed the Coolent Level Sensor pin from the switch input to resistive input

23 PIN OEM CONNECTOR A <39 5. Indicated the connections for spare pins

CORS connector >A> CORS BURN VALVE (PWM)/ SPARE PWM DRIVER <40 50 PIN ECM SPARE RATIOMETRIC INPUT 1 <19 6. Moved the Keyswitch Input to the Power Connector

>F> Not in harness >B> CORS BURN VALVE/ SPARE PWM RETURN <42 CONNECTOR 7. Changed the number of fuses to two for the power connector and one for the service disconnect

>C> ETHER INJECTION >1> INTAKE MANIFOLD PRESSURE +5VDC SUPPLY 8. Changed the Power Connector Pinout

>D> FAN CLUTCH PWM <48 >3> INTAKE MANIFOLD PRESSURE SIGNAL <44 9. Added unused pins to all connectors

>A> DUAL OUTPUT A >2> INTAKE MANIFOLD PRESSURE RETURN 10. Fixed IMV, Lift Pump and Ether Injection pinouts

>E> DUAL OUTPUT B <49 >4> 11. New IMV Pins J1:02 and Lift Pump J1:01

>B> OEM ACTUATOR PWM OUTPUT DEDICATED <38 Rev 1.4

>G> CORS BURN VALVE (PWM)/ SPARE PWM DRIVER >1> AMBIENT AIR PRESSURE +5VDC SUPPLY 12. Added new pinouts for the Turbo Speed Sensor ( Shield pin is not connected)

>K> CORS REMOTE OIL LEVEL /SPARE SWITCH INPUT <14 >3> AMBIENT AIR PRESSURE SIGNAL <03 13. Removed the second fuse in the power connector

<A< >J> COOLANT LEVEL SUPPLY >2> AMBIENT AIR PRESSURE RETURN Rev 1.5

<B< >W> COOLANT LEVEL SIGNAL (49.9k Pullup) <28 14. Changed the Fan Clutch pinout from J1:21 to J2:48, added a connector on the engine side and take it to the OEM side

<C< >X> COOLANT LEVEL RETURN VSEN004 RET <47 15. Changed Dual output A from J2:48 to J1:22. All the PWM output pins have been checked

>P> >3> ACCUMULATOR PRESSURE +5VDC SUPPLY VSEN004 <37 16. J1:21 is kept vacant for the IMV driver output when the new zexel valve is used

>Q> SPARE RATIOMETRIC INPUT 1 >2> ACCUMULATOR PRESSURE SIGNAL <25 Rev 1.6

>O> REMOTE THROTTLE SWITCH SIGNAL <03 >1> ACCUMULATOR PRESSURE RETURN 17. Removed the splice in the power connector thereby using only pins 1 and 4.

>L> REMOTE THROTTLE PEDAL/LEVER POS +5VDC SUPPLY Rev 1.7

>M> REMOTE THROTTLE PEDAL/LEVER POSITION SIGNAL <26 >1> FUEL SUPPLY PRESSURE +5VDC SUPPLY 18. Removed the Fan Clutch Breakout Connector

>N> REMOTE THROTTLE PEDAL/LEVER POSITION RETURN >3> FUEL SUPPLY PRESSURE SIGNAL <18 Rev 1.8

>2> FUEL SUPPLY PRESSURE RETURN 19. Added a new connector for the Lift pump , spliced from the existing Lift Pump

>4> Rev 1.9

>V> MULTI UNIT SYNC ON/OFF SWITCH <05 20. Added Fuel Supply Pressure Sensor in J1:18

>T> MULTIPLE UNIT SYNC ID PIN #1 <07 >1> OIL PRESSURE +5VDC SUPPLY VSEN003 <33 Rev 1.10

>S> MULTIPLE UNIT SYNC ID PIN #2 <08 >3> OIL PRESSURE SIGNAL <13 21. Changed pinouts for Droop select ( from J1:43 to J1:29) and Torque Select (from J2:31 to J1:12)

>R> MULTIPLE UNIT SYNC ID PIN #3 <12 >2> OIL PRESSURE RETURN 22. Change Fuel Inlet Temp from J1:14 to J2:31

>U> MULTI UNIT SYNC COMP SWITCH >4> Rev 1.11

23. Changed pinouts for sensors

24. Changed Name for Fuel Inlet Temp Sensor to Fuel Supply Temp

>A> FUEL SUPPLY TEMP SIGNAL <31 DUAL OUTPUT A <22 25. Removed J1587

31 PIN OEM CONNECTOR B >B> FUEL SUPPLY TEMP RET 26. Changed OEM connections for Droop and Torque select to reflect ratiometric inputs.

>1> TURBO SPEED SENSOR SIGNAL <34 Rev 1.12

>2> TURBO SPEED SENSOR RETURN <24 27. Added back pins at top of OEM power connector that were accidently deleted.

< 20 < ACCELERATOR PEDAL / LEVER POSITION / FREQ THROTTLE SUPPLY +5VDC VSEN002 <22 >3> Shield Not Connected 28. Removed second lift pump connector, not needed for production.

< 21 < ACCELERATOR PEDAL / LEVER POSITION SIGNAL <09 Rev 1.13

< 22 < ACCELERATOR PEDAL / LEVER POSITION RETURN VSEN002RET <23 >A> COOLANT TEMPERATURE SIGNAL <15 29. Added CORS driver and Remote Oil level switch input.

< 09 < IDLE VALIDATION SWITCH OFF IDLE SIGNAL <01 >B> COOLANT TEMPERATURE RETURN Rev 1.14

< 10 < IDLE VALIDATION SWITCH ON IDLE SIGNAL <11 30. Added WIF Sensor on J1:14

< 11 < IDLE VALIDATION SWITCH RETURN SWRET <34 >A> WATER IN FUEL SENSOR SIGNAL <14 Rev 2.0

>B> WATER IN FUEL SENSOR RETURN 31. Added CORS/Spare PWM signal to the OEM connector pin G.

< 04 < OEM SWITCH <06 CORS connector not in harness currently but planned for future use.

>A> INTAKE MANIFOLD TEMPERATURE SIGNAL <23 Added note at CORS connector that not in harness.

>B> INTAKE MANIFOLD TEMPERATURE RETURN VSEN003 RET <38 Rev 2.1

RED LAMP < 16 < RED LAMP/ SEVERITY 1 <43 32. Added Coolant Level Sensor Supply

AMBER LAMP < 17 < AMBER LAMP/ SEVERITY 2 <44 33. Added twisted pairs and triplets.

WHITE LAMP < 18 < WHITE LAMP/ SEVERITY 3 <45 34. Added table indicating mapping for Sensor Names between ECM names and Service Names.

DIAGNOSTIC SWITCH < 01 < DIAGNOSTIC SWITCH <02 Rev 2.2

TORQUE CURVE SELECT <12 35. Removed connector spare pin callouts.

47K NC TORQUE CURVE SELECT < 12 < TORQUE CURVE SELECT 36. Fixed 23 OEM connector pin arrow directions

>A> LIFT PUMP DRIVER PWM SUPPLY <01 37. Added pin for Freq throttle return on the OEM connector

47K NC DROOP SELECT SIGNAL < 13 < DROOP SELECT SIGNAL >B> LIFT PUMP DRIVER RETURN RET 08 <11

ALTERNATE IDLE < 14 < ALTERNATE IDLE / AUXILIARY GOVERNOR SELECT <13

ISC / IDLE INCREMENT < 23 < INTERMEDIATE SPEED CONTROL / IDLE INCREMENT <24 Sensor Voltage Mapping

ISC / IDLE DECREMENT < 24 < INTERMEDIATE SPEED CONTROL / IDLE DECREMENT <25 DROOP SELECT SIGNAL <29

ISC 1 < 25 < INTERMEDIATE SPEED CONTROL 1 / REMOTE PTO <04 Connect Pin ECM Name Service Name

< 26 < INTERMEDIATE SPEED CONTROL 3/ VALIDATE SWITCH <18 >A> IMV DRIVER PWM SUPPLY <02 60 pin 16 Sensor Supply 1 Sensor Supply 3

< 27 < INTERMEDIATE SPEED CONTROL 2 <16 >B> IMV DRIVER RETURN RET 013 <42 60 pin 48 Sensor Supply Return 1 Sensor Supply Return 3

FAN CLUTCH SWITCH < 02 < FAN CLUTCH SWITCH <17 50 pin 22 Sensor Supply 2 Sensor Supply 4

GROUND < 31 < TACHOMETER OUTPUT SIGNAL <41 50 pin 23 Sensor Supply Return 2 Sensor Supply Return 4

>1> INJECTOR DRIVER 1 <45 50 pin 21 Sensor Supply 3 Sensor Supply 1

KEYSWITCH < 08 < OEM SENSOR SUPPLY +5VDC VSEN 003 <21 Cylinder 1 >2> INJECTOR RETURN 1 <53 50 pin 32 Sensor Supply Return 3 Sensor Supply Return 1

< 05 < OEM PRESSURE SIGNAL <35 60 pin 33 Sensor Supply 3 Sensor Supply 1

UNSWITCHED BATTERY + < 06 < OEM TEMPERATURE SIGNAL <19 >1> INJECTOR DRIVER 2 <54 60 pin 38 Sensor Supply Return 3 Sensor Supply Return 1

KEYSWITCH < 07 < OEM TEMPERATURE RETURN VSEN003RET <32 Cylinder 2 >2> INJECTOR RETURN 2 <51 60 pin 37 Sensor Supply 4 Sensor Supply 2

< 30 < FREQUENCY INPUT SIGNAL (VSS) / AUX GOVERNOR <27 60 pin 47 Sensor Supply Return 4 Sensor Supply Return 2

< 19 < FREQUENCY INPUT RETURN (VSS) / AUX GOVERNOR <36 >1> INJECTOR DRIVER 3 <55

< 15 < FREQUENCY THROTTLE <30 Cylinder 3 >2> INJECTOR RETURN 3 <52

< 28 < FREQUENCY THROTTLE RETURN

< 03 < ENGINE PROTECTION OVERRIDE <15 >1> INJECTOR DRIVER 4 <56

< 28 < Cylinder 4 >2> INJECTOR RETURN 4 <58

< 29 <

>1> INJECTOR DRIVER 5 <46

Cylinder 5 >2> INJECTOR RETURN 5 <60

>1> INJECTOR DRIVER 6 <57

Cylinder 6 >2> INJECTOR RETURN 6 <59

9 PIN SERVICE DISCONNECT

DEUTSCH RTC >1> RTC BATTERY BACKUP SUPPLY <35

<F< BATT >2> RTC BATTERY BACKUP RETURN <32

SERVICE <G<

DISCONNECT <H<

<C< J1939 DATALINK SUPPLY > STUB STUB < J1939 ENGINE DATALINK SUPPLY <46

<D< J1939 DATALINK RETURN > A B < J1939 ENGINE DATALINK RETURN <47

<E< J1939 DATALINK SHIELD > < J1939 ENGINE DATALINK SHIELD <37

<J<

<A< BATTERY RETURN

<B< UNSWITCHED BATTERY (+)

CUMMINS CONFIDENTIAL OEM EXTENSION END

(locate near other OEM connectors)

Wiring Diagram for Tier II/III INDUSTRIAL QSK19 Production J1939 TERMINATOR J1939 TERMINATOR

RESISTOR CONNECTOR J1939 BACKBONE HARNESS RESISTOR CONNECTOR

Rev. 2.2 120Ω <C< J1939 DATALINK SHIELD >C>

<B< J1939 DATALINK RETURN >B> 120Ω

OEM RESPONSIBILITY CUMMINS RESPONSIBILITY <A< J1939 DATALINK SUPPLY >A>

RED DC VOLTAGE

BLUE INPUT SIGNALS

BLACK GROUNDS, SHEILDS AND RETURNS

J1939 ENGINE DATALINK SUPP

J1939 ENGINE DATALINK RETU

J1939 ENGINE DATALINK SUPP

PURPLE OUTPUT SIGNALS

J1939 DATALINK SHIELD

J1939 DATALINK RETURN

GREEN DATALINKS

J1939 DATALINK SUPPLY

STUB B STUB A

Você também pode gostar

- 4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFDocumento201 páginas4Hk1 6HK1 Engine Diagnostic and Drivability Student PDFAnonymous aufoLkcwhZ86% (7)

- QSX15 CM2250 ECF Wiring Diagram: InputDocumento1 páginaQSX15 CM2250 ECF Wiring Diagram: InputAddis Shoe100% (1)

- C15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocumento2 páginasC15 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic Symbolsminh le huu100% (2)

- QST30 CM850 Power Generation Interface Wiring Diagram: Oem Responsibility Cummins ResponsibilityDocumento1 páginaQST30 CM850 Power Generation Interface Wiring Diagram: Oem Responsibility Cummins ResponsibilityTTIBCCA67% (3)

- Cummins - QSB4.5 CM2350Documento18 páginasCummins - QSB4.5 CM2350bedoo54100% (2)

- c15 CaterpillarDocumento20 páginasc15 CaterpillarEddie Kelvin Isidro Laura100% (2)

- Fault Code 559Documento10 páginasFault Code 559lift100% (1)

- Mitsubishi l200 1996 Mitsubishi enDocumento1.723 páginasMitsubishi l200 1996 Mitsubishi enMaksym Shevchenko100% (4)

- Ddec IV Oem Wiring DiagramDocumento1 páginaDdec IV Oem Wiring DiagramEdgar MartínAinda não há avaliações

- Fault Code 115 Engine Magnetic Crankshaft Speed/Position Lost Both of Two Signals - Data Erratic, Intemittent, or IncorrectDocumento4 páginasFault Code 115 Engine Magnetic Crankshaft Speed/Position Lost Both of Two Signals - Data Erratic, Intemittent, or IncorrectAhmedmah100% (1)

- Incal Cals ReleasedDocumento7 páginasIncal Cals Releasedhandoko poca100% (1)

- Bendix WiringDocumento4 páginasBendix Wiringfragman0682550% (2)

- FAULT CODE 259 - Fuel Shutoff Valve - Stuck Open: File: 88-t05-259 Page 1 of 6Documento6 páginasFAULT CODE 259 - Fuel Shutoff Valve - Stuck Open: File: 88-t05-259 Page 1 of 6LuisDelaHozAinda não há avaliações

- Gliderlink PinoutDocumento1 páginaGliderlink PinoutRobertoGomezAinda não há avaliações

- Diagrama de 3406b PDFDocumento2 páginasDiagrama de 3406b PDFIgnacio Cano100% (1)

- Cummins ISM CM875: Electrical Circuit DiagramDocumento11 páginasCummins ISM CM875: Electrical Circuit Diagramroberto martir100% (3)

- FAULT CODE 121 - Engine Speed/Position Sensor Circuit - Lost One of Two Signals From The Magnetic Pickup SensorDocumento1 páginaFAULT CODE 121 - Engine Speed/Position Sensor Circuit - Lost One of Two Signals From The Magnetic Pickup SensorDonald Santana100% (1)

- QSK60 2-0 Industrial With CENSE Wiring DiagramDocumento1 páginaQSK60 2-0 Industrial With CENSE Wiring DiagramManfred Toro100% (1)

- Diagram - Cummins ISC/ISL Electrical Schematic P94-6015 C 01Documento6 páginasDiagram - Cummins ISC/ISL Electrical Schematic P94-6015 C 01eng_hamada_4u100% (1)

- Cummins Confidential: 146797638.xls - Ms - Office, Tab: Wiring Diagram Page 1 of 2Documento2 páginasCummins Confidential: 146797638.xls - Ms - Office, Tab: Wiring Diagram Page 1 of 2Nova kurniawan 34100% (2)

- QSB5.9 Troubleshooting and Repair Manual Electronic Control System Vol2 4021416 810pages CONTENTSDocumento6 páginasQSB5.9 Troubleshooting and Repair Manual Electronic Control System Vol2 4021416 810pages CONTENTSDmitry54% (13)

- Diagrama Ele C18 CatDocumento8 páginasDiagrama Ele C18 Catdantespeak100% (1)

- Cummins: Fault Code: 433 PID: P102 FMI: 2Documento5 páginasCummins: Fault Code: 433 PID: P102 FMI: 2Enrrique Lara100% (1)

- Code Qst30Documento13 páginasCode Qst30carlosmansilla86% (7)

- Detail "B": 90 DEG 180 DEGDocumento3 páginasDetail "B": 90 DEG 180 DEGcarlos ramos100% (1)

- Cummins: Fault Code: 364 PID: P1689, S233 SPN: 1077 FMI: 9Documento6 páginasCummins: Fault Code: 364 PID: P1689, S233 SPN: 1077 FMI: 9Enrrique Lara100% (2)

- Aux101 Service ManualDocumento98 páginasAux101 Service ManualKaiser lqbalAinda não há avaliações

- Diagraama QuantumDocumento6 páginasDiagraama QuantumClaudio Rene Silva Hernandez100% (1)

- Cummins QST 30 SchematicDocumento1 páginaCummins QST 30 SchematicJacques Van Niekerk87% (23)

- C11 Engine: Electrical Circuit DiagramDocumento12 páginasC11 Engine: Electrical Circuit DiagramDiego LiraAinda não há avaliações

- Fault Code 254Documento2 páginasFault Code 254Hamzeh M AbuRub50% (2)

- Fault Code 154 Intake Manifold Air Pressure/Temperature Sensor Circuit - Voltage Below Normal or Shorted To Low SourceDocumento12 páginasFault Code 154 Intake Manifold Air Pressure/Temperature Sensor Circuit - Voltage Below Normal or Shorted To Low SourceAhmedmahAinda não há avaliações

- C32 Industrial Wiring DiagramDocumento4 páginasC32 Industrial Wiring DiagramHữu Linh100% (2)

- SAAB 900 1993 (Opt)Documento38 páginasSAAB 900 1993 (Opt)mnbvqwertAinda não há avaliações

- Cummins Diesel QSB QSC QSL Cm850 4021524 Rev 2 Wiring DiagramDocumento124 páginasCummins Diesel QSB QSC QSL Cm850 4021524 Rev 2 Wiring Diagramjulianmata100% (2)

- Wiring Schematic: Detroit Diesel Series 60 EnginesDocumento1 páginaWiring Schematic: Detroit Diesel Series 60 EnginesMario PattyAinda não há avaliações

- Fault Code: 559 - SPN: 157 - FMI: 18: ISX15 CM2350 X101Documento14 páginasFault Code: 559 - SPN: 157 - FMI: 18: ISX15 CM2350 X101Jose100% (1)

- Fault Code 197: Coolant Level - Data Valid But Below Normal Operational Range - Moderately Severe LevelDocumento3 páginasFault Code 197: Coolant Level - Data Valid But Below Normal Operational Range - Moderately Severe LevelHamilton MirandaAinda não há avaliações

- Fault Code 422: Coolant Level - Data Erratic, Intermittent, or IncorrectDocumento3 páginasFault Code 422: Coolant Level - Data Erratic, Intermittent, or IncorrectFABIANLG2486100% (3)

- QSL9-4021586 - 2 - Wiring DiagramDocumento1 páginaQSL9-4021586 - 2 - Wiring Diagramgraduadoesime94% (16)

- C-10, C-12, 3406E, C-15, and C-16 Electrical System On-Highway EngineDocumento2 páginasC-10, C-12, 3406E, C-15, and C-16 Electrical System On-Highway Engineигорь100% (1)

- FAULT CODE 135 (Automotive Application) Oil Pressure Sensor Circuit - Voltage Above Normal, or Shorted To High SourceDocumento14 páginasFAULT CODE 135 (Automotive Application) Oil Pressure Sensor Circuit - Voltage Above Normal, or Shorted To High SourceJose Ruiz100% (2)

- 3PHASE Gas Separator - V2105 - 4.7x16 - For - OriginalDocumento44 páginas3PHASE Gas Separator - V2105 - 4.7x16 - For - Originalvgogulakrishnan100% (1)

- Wtec Ii: Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocumento35 páginasWtec Ii: Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanAinda não há avaliações

- Diagrama qsx15 PDFDocumento7 páginasDiagrama qsx15 PDFSoumya Ranjan NayakAinda não há avaliações

- CorsaDocumento11 páginasCorsaKijo SupicAinda não há avaliações

- AEB15.74 Oct13 PDFDocumento97 páginasAEB15.74 Oct13 PDFPhạm NhấtAinda não há avaliações

- Edoc - Pub Manual de International CF 600Documento119 páginasEdoc - Pub Manual de International CF 600RASMAJONAinda não há avaliações

- QSB33 CM2150 Wiring DiagramDocumento2 páginasQSB33 CM2150 Wiring Diagramibrahem100% (2)

- Wiring Arness QSB 3.3Documento2 páginasWiring Arness QSB 3.3Daniel PáezAinda não há avaliações

- Cummins Wiring Diagrams: Wiring Diagram (Part 2 of 4)Documento2 páginasCummins Wiring Diagrams: Wiring Diagram (Part 2 of 4)Jim Lieb100% (4)

- Qdoc - Tips Ddec IV Oem Wiring DiagramDocumento1 páginaQdoc - Tips Ddec IV Oem Wiring DiagramAlberto Rodríguez0% (1)

- ISX and QSX15 Electronic Control System Troubleshooting and Repair ManualDocumento4 páginasISX and QSX15 Electronic Control System Troubleshooting and Repair ManualLaiq100% (2)

- Submersible and Semi Submersible RigsDocumento4 páginasSubmersible and Semi Submersible RigsanshulAinda não há avaliações

- Fault Code 278-01Documento6 páginasFault Code 278-01Enrrique LaraAinda não há avaliações

- Exxonmobil Olefins Process DescriptionDocumento5 páginasExxonmobil Olefins Process Descriptionamiramirimehr100% (1)

- 06R0862362+6067MK62 Piezas Comunes PDFDocumento2 páginas06R0862362+6067MK62 Piezas Comunes PDFAlexis SanchezAinda não há avaliações

- Asme b31.4 InterpretationDocumento18 páginasAsme b31.4 InterpretationOrlando Rojas100% (1)

- QSB33 CM2150 Wiring Diagram PDFDocumento2 páginasQSB33 CM2150 Wiring Diagram PDFpabloAinda não há avaliações

- CNG An OverviewDocumento5 páginasCNG An OverviewaoleolAinda não há avaliações

- 134 Fault CodeDocumento3 páginas134 Fault CodeHamilton Miranda100% (1)

- P94-1298 Diagrama Electrico CAT C15Documento6 páginasP94-1298 Diagrama Electrico CAT C15pedro luisAinda não há avaliações

- Schematic C4.4Documento8 páginasSchematic C4.4Asep ShaifurrahmanAinda não há avaliações

- Ul 142 Aboveground TanksDocumento2 páginasUl 142 Aboveground TanksCarlos Morales PérezAinda não há avaliações

- QDB 15 PowerplantsDocumento54 páginasQDB 15 PowerplantsKueh Chew Chai92% (12)

- Cat c15 DiagrammaDocumento11 páginasCat c15 DiagrammaHarlinton descalziAinda não há avaliações

- Paramax PHDDocumento38 páginasParamax PHDRensa Nitraga Syarif100% (1)

- Diagrama CollageDocumento14 páginasDiagrama CollageJuan del AngelAinda não há avaliações

- Sabp A 056 PDFDocumento36 páginasSabp A 056 PDFWalid MegahedAinda não há avaliações

- Eton Viper 70 ManualDocumento40 páginasEton Viper 70 ManualLou Calabrese100% (1)

- V80838 Murphy PowerView Wiring DiagramsDocumento2 páginasV80838 Murphy PowerView Wiring DiagramsPaulPaucarCampos100% (1)

- Manual de Partes QSK19Documento17 páginasManual de Partes QSK19acere18100% (1)

- VALVES CLEARANCE ADJUSTMENT For MTU 16V2000Documento1 páginaVALVES CLEARANCE ADJUSTMENT For MTU 16V2000JUAN JOSE VESGA RUEDA100% (1)

- Cummins Confidential: This Document (And The Information Shown Thereon) Is CONFIDENTIAL AND PROPRIETARYDocumento1 páginaCummins Confidential: This Document (And The Information Shown Thereon) Is CONFIDENTIAL AND PROPRIETARYibrahem100% (1)

- 4.3L V6 2002 Service Manual PDFDocumento187 páginas4.3L V6 2002 Service Manual PDFAlfredo Guzmán100% (1)

- CBSE Class 10 Geography WorksheetDocumento3 páginasCBSE Class 10 Geography WorksheetSagar NaikAinda não há avaliações

- Fuel Cells On AerospaceDocumento4 páginasFuel Cells On Aerospacevvtarun50% (2)

- Sarnia Lambton Propylene Investment Opportunity Final Report EDocumento38 páginasSarnia Lambton Propylene Investment Opportunity Final Report EPranav Bhat100% (1)

- Ignite Water in Your Car - Robert Kurpas Firestorm Plugs - Dual Anode Coaxial InjectorDocumento13 páginasIgnite Water in Your Car - Robert Kurpas Firestorm Plugs - Dual Anode Coaxial InjectorN4CR0% (1)

- Api 610Documento1 páginaApi 610Angel CipagautaAinda não há avaliações

- Chapter4 ADocumento47 páginasChapter4 AKeely ArmstrongAinda não há avaliações

- LG WTG1030SF 10kg Top Load Washing Machine User ManualDocumento44 páginasLG WTG1030SF 10kg Top Load Washing Machine User ManualMayank BurmanAinda não há avaliações

- A New Class of Green Mineral Scale Inhibitors For Squeeze TreatmentsDocumento12 páginasA New Class of Green Mineral Scale Inhibitors For Squeeze TreatmentsJu BbinAinda não há avaliações

- Overview: Philippine Downstream Oil Industry and Pricing: Hideliza V. LudoviceDocumento26 páginasOverview: Philippine Downstream Oil Industry and Pricing: Hideliza V. LudoviceJhun PaaAinda não há avaliações

- A Six CylinderDocumento1 páginaA Six CylindervasanthavananAinda não há avaliações

- ImmediatelyDocumento17 páginasImmediatelyJomhel CalluengAinda não há avaliações

- Derivados PetroleoDocumento48 páginasDerivados PetroleoCarlos TimanaAinda não há avaliações

- Analysis of Breakdown Voltage and Cost Reduction of Transformer Oil by Using Nomex Paper and Filler PDFDocumento7 páginasAnalysis of Breakdown Voltage and Cost Reduction of Transformer Oil by Using Nomex Paper and Filler PDFvvingtsabtaAinda não há avaliações

- ME MotronicDocumento3 páginasME Motronicdory7dawAinda não há avaliações

- Aceite Roto Z 2935004222Documento2 páginasAceite Roto Z 2935004222jhon jairo arangoAinda não há avaliações