Escolar Documentos

Profissional Documentos

Cultura Documentos

Economiser Coil - Drawing PDF

Enviado por

Anjaneya ReddyTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Economiser Coil - Drawing PDF

Enviado por

Anjaneya ReddyDireitos autorais:

Formatos disponíveis

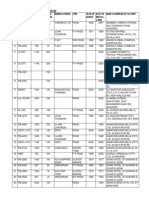

8 7 6 5 4 3 2 1

Sheet. 1 of 1

SEPL-J1008-01-001 IBR FIG : 28 (ix) (a) OD 50.8

DRG NR. 1635 240 20 Nrs AT 90 P = 1710

70°-80° 4.5

ALL DIMENSIONS ARE IN MM UNLESS OTHERWISE SPECIFIED. IF IN DOUBT ASK. DO NOT SCALE.

H 2100 3 H

5

t

1050 1050

448.5

°

TYPE.II TYPE.I

OD

1to2.5

° ±1

525

30

C C 2.5to4

- 40

100 3399 76.5

35°

150

DETAIL-A 1to2

TYP. DETAIL OF BUTT WELDING OF

HTA

25

1°

TUBE TO TUBE 6

45°±

SCALE 1:1

6

1to2

ENGINEERING NOTES

8

2 7 8

TYP 1. ADDITIONAL JOINT IN COIL IS PERMITTED, HOWEVER

G G

D D JOINT SHOULD CLEAR THE BEND PORTION OF THE COIL. Ø70

6

2. THE THINNING OF TUBE SHALL NOT BE GRATER THAN

DETAIL : B

20% OF THE NOMINAL THICKNESS, i.e., THE THICKNESS

OF THE TUBE AFTER BENDING SHALL NEVER BE LESS THAN SCALE 2:1

3.6mm.

HTA - HYDRO TEST ALLOWANCE,

HTA SHALL BE CUTOFF AFTER HYDROTEST

DESIGN DATA

17 Nrs. AT 153 P = 2601

17 S x 153P = 2601

DESCRIPTION UNITS

DESIGN CODE - IBR 1950 WITH LATEST AMENDMENTS UP TO 2017

3780 DESIGN PRESSURE(MAWP) kg/cm2 .g 76

TYP kg/cm2 .g

TEST PRESSURE (HYDRO) 114

F DESIGN METAL TEMPERATURE °C 228 (217+11) F

P.W.H.T (STRESS RELIEVING) - NIL

JOINT FACTOR - 1

INSPECTION - CIB, TELANGANA

CORROSION ALLOWANCE mm As Per IBR FOR CS

TYP EMPTY WEIGHT Kg 8191

R76.5

TYP

863

3880

TYP

E TYPE.I TYPE.II E

4 1

TYPE.II

TYPE.II

TYPE.II

TYPE.II

TYPE.II

TYPE.II

TYPE.II

TYPE.II

TYPE.II

TYPE.II

130

TYPE.I

TYPE.I

TYPE.I

TYPE.I

TYPE.I

TYPE.I

TYPE.I

TYPE.I

TYPE.I

TYPE.I

4033 249

4282 300 TOTAL WEIGHT ( Kg) 8190.43

4582

SECTION : CC 8 CLAMP PLATE 40W x 5 THK x 3337 Lg. IS 2062 Gr. A / B 40 209.56 --

C C

80 ELEVATION END VIEW TYP. COIL CLAMP DETAIL

7 CLAMP PLATE 50W x 5 THK x 3337 Lg. IS 2062 Gr. A / B 40 261.95 --

83.83 TYP

TYP DESIGN CALCULATION IS 2062 GR.

5 6 TEST COVER Ø70 x 8 THK 40 9.67 --

R26

E250 BR

7

TYP

3 SIZE OF TUBE : OD 50.8 x 4.5 WT

R5 5 BEND TUBE OD 50.8 x 4.5 THK - 3967 + 50 HTA Lg. SA 210 GR A1 10 204.70 IBR

D THICKNESS OF TUBE (T) : 4.5 mm D

30 150 TYP 17 S x 153 P = 2601 100 30

MATERIAL : SA 210 Gr.A1

DETAIL OF CLAMP 4 BEND TUBE OD 50.8 x 4.5 THK - 4545 + 50 HTA Lg. SA 210 GR A1 10 234.52 IBR

40

50

ALLOWABLE STRESS AT DESIGN TEMPERATURE (f) : 1202 kg/cm 2

28 7 8

AS PER ASME SEC. II, PART.D , TABLE.1A 3 BEND TUBE OD 50.8 x 4.5 THK - 4207 + 50 HTA Lg. SA 210 GR A1 10 217.08 IBR

PD

MIN REQ. THK OF THE TUBE AS PER REG. 338(a) (EQ. Nr. 87) (t) : +c+c1 - Eqn. - 87

=

2f + P

50

18

5 3 2 BEND TUBE OD 50.8 x 4.5 THK - 8240 + 50 HTA Lg. SA 210 GR A1 160 6802.95 IBR

P1 = DESIGN PRESSURE : 76 kg/cm2 (g)

=

D = OUTSIDE DIAMETER : 50.8 mm

SECTION : DD c = ADDITIVE THICKNESS : 0.75 mm 1 BEND TUBE OD 50.8 x 4.5 THK - 4845 + 50 HTA Lg. SA 210 GR A1 10 250.00 IBR

Ø18 10 30

DEVELOPED LENGTH : 3337 SCALE 1:3 c1 = THINNING ALLOWANCE DUE TO BENDING AS PER 338(b) : 100 100

= = 12.46 % = 20% CONSIDERED PART WEIGHT INSPECTION/

QTY : 40 Nrs. 4R 4x76.5 DESCRIPTION SIZE MATL.SPEC. QTY. REMARKS

SCALE 1:3

28 8 D

+2

50.8

+2 Nr. (Kgs) CERTIFICATE

B

THINNING ALLOWANCE DUE TO BENDING AT 20% OF NOM. THK. : = 0.90 mm

BILL OF MATERIAL

= =

= =

40

18

76 x 50.8

3 REQ. WALL THICKNESS (t) : + 0.75 + 0.90 = 3.21 mm

448.5

C 2 x 1202 +76 C

Ø18 10 30

DEVELOPED LENGTH : 3337 B

MIN. THICKNESS TO BE PROVIDED AS PER REQ. 338 (b) : 3.25 mm

PROVIDED THICKNESS (T) : 4.5 mm

QTY : 40 Nrs.

SCALE 1:3 : 4.5 mm > 3.25 mm HENCE SATISFACTORY.

R76.5 5 2f (T-c1-c ) 2 x 1202 (4.5-0.75-0.90)

MAXIMUM ALLOWANCE WORKING PRESSURE : =

448.5

D-(T-c1-c ) 50.8-(4.5-0.75-0.90)

90 20

TYP

3638.5

1

°

: 142.886 kg/cm > 18 kg/cm 2

2

HENCE OKAY.

DEVELOPED LENGTH : 4207

HYDRO TEST CONDITION:

QTY : 10 Nrs. PD

MIN REQ. THK OF THE TUBE AS PER REG. 338(a) (EQ. Nr. 87) (t) : +c+c1 - Eqn. - 87

R76.5 2f + P

TYP P = HYDRO TEST PRESSURE : 114 kg/cm 2(g)

90 20

1

°

3398.5 ~ ISSUED FOR COMMENTS / APPROVAL AND CONSTRUCTION

100 ALLOWABLE STRESS AT HYDRO TEST TEMPERATURE, 40°C (f) : 1202 kg/cm 2 A RK AHAMAD RS 12.12.18

DEVELOPED LENGTH : 3967 114 x 50.8 REV.Nr. ZONE DESCRIPTION DRAWN CHKD. APPD. DATE B

B 2 QTY : 10 Nrs. REQ. WALL THICKNESS (t) : + 0.75 + 0.90 = 3.95 mm

2 x 1202 +114

180°

PROJECT :

240

GGM Energy Ventures Pvt. Ltd.

: 4.5 mm > 3.95 mm HENCE OKAY.

R76.5 PROJECT Nr.: J1008 EQUIPMENT Nr. -

180°

3880

240

TYP 2f (T-c1-c ) 2 x 1202 (4.5-0.75-0.90)

MAXIMUM ALLOWANCE WORKING PRESSURE : =

D-(T-c1-c ) 50.8-(4.5-0.75-0.90)

3780 R76.5 : 142.886 kg/cm 2 > 27 kg/cm 2 CLIENT / OWNER GGM Energy Ventures Pvt. Ltd.

TYP HENCE OKAY.

R76.5 100

TYP DEVELOPED LENGTH : 8240

QTY : 160 Nrs. 4 PK DESIGNED AND SUPPLIED SAMANTHULA ENGINEERING PVT. LTD.

180°

MIN REQ. THK OF THE TEST COVER AS PER REG. 342(b) (EQ. Nr. 89A) (t) = d x + C - Eqn. - 89A

240

B f HYDERABAD - 500 018, INDIA.

d = ID OF TUBE = 41.8 mm

114 x 0.28

4205 P = HYDRO TEST PRESSURE = 114 kg/cm2 = 41.8 x + 1 - Eqn. - 89A Warmex Engineering Pvt Ltd,

100 1192 MANUFACTURED BY

C = ID OF TUBE = 1 mm HYDERABAD - 500 055, INDIA.

DEVELOPED LENGTH : 4545 K = FOR DIRECTLY STRENGTH WELDED END = 0.28 = 6.84 mm ~ 7 mm

QTY : 10 Nrs. 1 : 1192 kg/cm 2 NAME SIGN DATE

180°

A ALLOWABLE STRESS AT HYDRO TEST TEMPERATURE, 40°C (f) TITLE A

240

B DRAWN RK RK 11.12.18 ECONOMISER COILS for BANK .1

PROVIDED THICKNESS OF TEST COVER = 8 mm > 6 mm , HENCE OKAY.

R76.5 4505 CHECKED AHAMAD AHAMAD 12.12.18

TYP

DEVELOPED LENGTH : 4845 APPROVED RS RS 12.12.18 SCALE DRG.Nr. REV.NR.

PROJECTION

SEPL-J1008-01-001

QTY : 10 Nrs. 1:12.5 A

REF.DRG.Nr. Sheet. 1 of 1

8 7 6 5 4 3 2 1

Você também pode gostar

- Longitudinal Section B-B Transverse Section A-A: Welding Details Not To ScaleDocumento1 páginaLongitudinal Section B-B Transverse Section A-A: Welding Details Not To ScalebunkeringAinda não há avaliações

- Ygnis Ingl+ S Multiflam 170.1-200.1Documento24 páginasYgnis Ingl+ S Multiflam 170.1-200.1DihorulAinda não há avaliações

- DZL 4-1.25-AiiDocumento10 páginasDZL 4-1.25-AiiSamulaAinda não há avaliações

- PRO 810354 02 Poster-SteamBoilerEquipment enDocumento1 páginaPRO 810354 02 Poster-SteamBoilerEquipment enbertan dağıstanlıAinda não há avaliações

- Steam Network - Spirax Sarco - Submittal PDFDocumento388 páginasSteam Network - Spirax Sarco - Submittal PDFRamy MahmoudAinda não há avaliações

- EPRF Report Com Fulton Steam BoilersDocumento13 páginasEPRF Report Com Fulton Steam BoilersBlackzero68Ainda não há avaliações

- Research Study Diesel To BiomassDocumento9 páginasResearch Study Diesel To BiomassDarrel MagnoAinda não há avaliações

- 750 204 OM Profire D LND Apr08Documento120 páginas750 204 OM Profire D LND Apr08Rosanny Borges ChirinosAinda não há avaliações

- Miura Boilers Steam GeneratorsDocumento2 páginasMiura Boilers Steam GeneratorsDhonyAhmedPradjoegoAinda não há avaliações

- SSGC New ConnectionDocumento19 páginasSSGC New ConnectionmimranislamAinda não há avaliações

- Bangladesh Datasheets January 2017 Wee ChieftainDocumento1 páginaBangladesh Datasheets January 2017 Wee ChieftainFAVIOAinda não há avaliações

- Project On Conservation of Steam in Electroplating in Hero CyclesDocumento7 páginasProject On Conservation of Steam in Electroplating in Hero Cyclessharanjeet4uAinda não há avaliações

- Fulton ModSync Wiring DiagramDocumento3 páginasFulton ModSync Wiring DiagramjrodAinda não há avaliações

- Boiler Comp. For 250bhpDocumento2 páginasBoiler Comp. For 250bhpNewaz KabirAinda não há avaliações

- Borderer Boiler Complete ManualDocumento228 páginasBorderer Boiler Complete ManualNitrogeno MPDAinda não há avaliações

- Claver Brooks General Boiler InformationDocumento10 páginasClaver Brooks General Boiler Informationnecio77Ainda não há avaliações

- Stainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Documento5 páginasStainless Steel ANSI Pipe Flanges - A Guide: 1. What Type of Flange Is Required?Utada HikaruAinda não há avaliações

- KSR Kuebler Transparent Level Gauge Attc 5Documento56 páginasKSR Kuebler Transparent Level Gauge Attc 5Hassan Sleem100% (1)

- The Power of An Atom.: High Performance, Low Emissions, Real Energy Optimization and Trouble-Free PerformanceDocumento12 páginasThe Power of An Atom.: High Performance, Low Emissions, Real Energy Optimization and Trouble-Free PerformanceCarlos LehmanAinda não há avaliações

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Documento4 páginasBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaAinda não há avaliações

- Result: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationDocumento2 páginasResult: Economizer Heating Surface and Outlet Flue Gas Temperature CalculationjagjitAinda não há avaliações

- Condensate PresentationDocumento1 páginaCondensate PresentationPrudhvi RajAinda não há avaliações

- Ohio Special Operating and Maintenance Guide-Wetback 100-225HP PDFDocumento135 páginasOhio Special Operating and Maintenance Guide-Wetback 100-225HP PDFIrvinSerranoJAinda não há avaliações

- 2ND CLASS Boilers in Lahore CircleDocumento14 páginas2ND CLASS Boilers in Lahore CircleGoldenshakehandAinda não há avaliações

- Groundfos CR 10-10Documento8 páginasGroundfos CR 10-10defriyantoAinda não há avaliações

- Steam Boiler Systems From Bosch: Highly Efficient and Reliable Process HeatDocumento19 páginasSteam Boiler Systems From Bosch: Highly Efficient and Reliable Process Heatnemi90Ainda não há avaliações

- Aalborg XW SuperheaterDocumento2 páginasAalborg XW SuperheaterPanagiotisAinda não há avaliações

- PRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2Documento13 páginasPRICE E1203257Mrev4-20-EST-JON EPPM MARAFIQ STG 5&6 FPS OPTION 2AliZenatiAinda não há avaliações

- 06 - MedupiGx - C2 SC3 Pricing Data - Aux Boiler SparesDocumento33 páginas06 - MedupiGx - C2 SC3 Pricing Data - Aux Boiler SparesTrịnh Đức HạnhAinda não há avaliações

- Steam PlantsDocumento228 páginasSteam PlantsMark Allen San Antonio100% (1)

- Boiler Parts and DefinitionDocumento3 páginasBoiler Parts and DefinitionKarlFrederickNoblezaAinda não há avaliações

- Booster Korean Steam Generator ManualDocumento26 páginasBooster Korean Steam Generator ManualUmar MajeedAinda não há avaliações

- Boiler Log HourlyDocumento2 páginasBoiler Log Hourlymohamed abd el attyAinda não há avaliações

- SERIES 22.2: Heavy Duty Gear ReducersDocumento2 páginasSERIES 22.2: Heavy Duty Gear ReducersAmir KhanAinda não há avaliações

- Fulton RBCDocumento112 páginasFulton RBCYolan Lopez100% (1)

- 400kgs Steam Boiler Oil FiredDocumento5 páginas400kgs Steam Boiler Oil FiredManikandanAinda não há avaliações

- Bywor MXseries MLDocumento8 páginasBywor MXseries MLLEONARDO MOLERO CLEMENTEAinda não há avaliações

- DeZURIK KCG Knife Gate ValvesDocumento12 páginasDeZURIK KCG Knife Gate ValvesKithkarnonAinda não há avaliações

- Steam Boiler ProjectDocumento32 páginasSteam Boiler ProjectSwastik BhokareAinda não há avaliações

- Omv enDocumento50 páginasOmv enMuhamad Saukie100% (1)

- Innovation For Boiler TubeDocumento2 páginasInnovation For Boiler TubemasgrahaAinda não há avaliações

- Tugas BoilerDocumento33 páginasTugas BoilerAgus Dwi Nurcahyo JemberAinda não há avaliações

- Vertical Tubeless Gas Fired IOMDocumento102 páginasVertical Tubeless Gas Fired IOMElvis RivadeneiraAinda não há avaliações

- Nrs 1-50 GestraDocumento28 páginasNrs 1-50 Gestramike tsakirisAinda não há avaliações

- Boiler: Heat Sources Materials Energy Boiler EfficiencyDocumento10 páginasBoiler: Heat Sources Materials Energy Boiler EfficiencyrpercorAinda não há avaliações

- CRS Manual - PPPU PumpDocumento27 páginasCRS Manual - PPPU PumpRishabh VermaAinda não há avaliações

- MODEL: PFTA 1500-4: Ratings & Performance DataDocumento4 páginasMODEL: PFTA 1500-4: Ratings & Performance DataAnonymous izGbhcAinda não há avaliações

- Thermax BoilerDocumento2 páginasThermax Boilerhara-kiri0% (2)

- Greenoxe SeriesDocumento32 páginasGreenoxe SeriesLorenzo MasottiAinda não há avaliações

- Ppe Exp.3 ROLLNO 1Documento9 páginasPpe Exp.3 ROLLNO 1Aniket SinghAinda não há avaliações

- 1 TPH 10.54 KG, Vapi Care PharmaDocumento16 páginas1 TPH 10.54 KG, Vapi Care PharmashastrysnAinda não há avaliações

- RLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelDocumento45 páginasRLP-1000-PM-SP-001 - IFI - Scope of Work For Detailed Engineering & Design For Storage Tanks, In-Plant Piping, Supports & Structural SteelAdewaleAinda não há avaliações

- Boiler OfferDocumento10 páginasBoiler OfferManohar PandianAinda não há avaliações

- 78 - Triumph Stoker BrochureDocumento2 páginas78 - Triumph Stoker BrochureMatias MancillaAinda não há avaliações

- 1 - Transmittal No. R0051734-CTCDocumento7 páginas1 - Transmittal No. R0051734-CTCNanang Cesc UttaAinda não há avaliações

- Boiler Design SoftwareDocumento9 páginasBoiler Design SoftwareRaja T0% (1)

- ss3900 Ept360015c MosfetDocumento1 páginass3900 Ept360015c MosfetANSELMO LIMA0% (1)

- (14-21"color TV Basic Schematic Diagram) : CRT BoardDocumento1 página(14-21"color TV Basic Schematic Diagram) : CRT BoardAndrei Blas Azaña100% (1)

- Vector Brochure PDFDocumento11 páginasVector Brochure PDFDoDuyBacAinda não há avaliações

- Machine FoundationDocumento4 páginasMachine Foundationp kishorAinda não há avaliações

- ASTM A108 TolerancesDocumento9 páginasASTM A108 TolerancesJosh ByronAinda não há avaliações

- Air Gasification of FuelDocumento8 páginasAir Gasification of FuelB DASAinda não há avaliações

- Executive Summary of Unit-4 TG Performance Test On 25.12.2014Documento6 páginasExecutive Summary of Unit-4 TG Performance Test On 25.12.2014Ankur DasAinda não há avaliações

- WTP Manual PDFDocumento248 páginasWTP Manual PDFArunkumar ChandaranAinda não há avaliações

- 7TAI029690R0014 rc10 250aDocumento3 páginas7TAI029690R0014 rc10 250aflowAinda não há avaliações

- E7604-1!05!09 Practical Contamination Management enDocumento45 páginasE7604-1!05!09 Practical Contamination Management enAlie Bhin Abhu DhabiAinda não há avaliações

- 20 Sabiana Carisma Coanda Carte Tehnica 10.10.11 CI enDocumento28 páginas20 Sabiana Carisma Coanda Carte Tehnica 10.10.11 CI enccercel9898Ainda não há avaliações

- Effect of Dents in PipelinesDocumento9 páginasEffect of Dents in PipelinesAnonymous avGU1iAinda não há avaliações

- Cookery 9 (Clean, Sanitize and Store Kitchen Tools and Equipment)Documento5 páginasCookery 9 (Clean, Sanitize and Store Kitchen Tools and Equipment)Maureen Madriaga88% (8)

- Engineering Failure Analysis: S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. GijbelsDocumento8 páginasEngineering Failure Analysis: S. Barella, M. Boniardi, S. Cincera, P. Pellin, X. Degive, S. GijbelsGholamreza MahmoodiAinda não há avaliações

- 3 Quick Closing Valve SystemsDocumento13 páginas3 Quick Closing Valve SystemsrsalvasanAinda não há avaliações

- WA500-1 10001-UpDocumento933 páginasWA500-1 10001-UpRavinder Singh100% (5)

- Timing Cover 190EDocumento8 páginasTiming Cover 190ESergio Belmar CrisostoAinda não há avaliações

- Maintenance and Repair of Centrifugal PumpsDocumento4 páginasMaintenance and Repair of Centrifugal Pumpsaserf251Ainda não há avaliações

- Grain Size Effects in Aluminum Processed by Severe Plastic DeformationDocumento6 páginasGrain Size Effects in Aluminum Processed by Severe Plastic DeformationuuseppAinda não há avaliações

- Revised Guidelines For Bio-Medical Waste IncineratorDocumento34 páginasRevised Guidelines For Bio-Medical Waste Incineratorandik_yAinda não há avaliações

- Motor Protection and Control - Catalogue - 2012Documento392 páginasMotor Protection and Control - Catalogue - 2012Jigyesh SharmaAinda não há avaliações

- Biomass Briquette MachineDocumento4 páginasBiomass Briquette Machineramanathan72-1Ainda não há avaliações

- Pamantasan NG CabuyaoDocumento15 páginasPamantasan NG CabuyaoJudithRavelloAinda não há avaliações

- Automation of Boiler Gas Burner Management System Using PLC: P. K. Bhowmik, S.K. DharDocumento5 páginasAutomation of Boiler Gas Burner Management System Using PLC: P. K. Bhowmik, S.K. DharAkoKhalediAinda não há avaliações

- Site Cast Tilt Up Concrete Version 18 1Documento4 páginasSite Cast Tilt Up Concrete Version 18 1Prakash RajAinda não há avaliações

- HLLDocumento40 páginasHLLClinton ThomsonAinda não há avaliações

- Expertip Tips For Reducing Forming Fabric Drive LoadDocumento5 páginasExpertip Tips For Reducing Forming Fabric Drive LoadnotengofffAinda não há avaliações

- How To Make Glass (With Pictures) - WikihowDocumento11 páginasHow To Make Glass (With Pictures) - WikihowAustin JosephAinda não há avaliações

- Pps Seat 163 Seat Ateca EngDocumento71 páginasPps Seat 163 Seat Ateca EngManu Fran0% (2)

- Orifice and Chemical Tracer Flow Test Measurements On Production Geothermal Wells PDFDocumento1 páginaOrifice and Chemical Tracer Flow Test Measurements On Production Geothermal Wells PDFindeskeyAinda não há avaliações

- Nt20703 Lab Report Dietary FiberDocumento2 páginasNt20703 Lab Report Dietary FiberAmne BintangAinda não há avaliações

- Bvsde Paho Toilets CompostDocumento10 páginasBvsde Paho Toilets CompostSean ColonAinda não há avaliações