Escolar Documentos

Profissional Documentos

Cultura Documentos

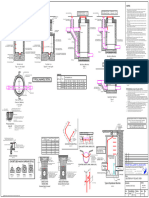

Typical Drainage Details

Enviado por

suhailTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Typical Drainage Details

Enviado por

suhailDireitos autorais:

Formatos disponíveis

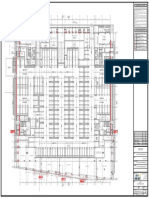

DESIGN REVIEW

YW Ref:- H-3-263-560 Do Not Scale Design review by: Checked by:

Residual hazards:

Mortar bedding and haunching to 1. For general notes refer to drawing 002.

cover and frame to clause 5.6.7 Manhole Covers and frames D400 Manhole covers and frames D400 to BS

to BS EN 124 having a EN 124 having a 600 x 600mm opening Reinforced concrete cover slab to be

2-4 courses of Class B 600x600mm opening with with 150mm deep frame in the highway kitemarked and to BS EN 1919:2002

engineering bricks, concrete 150mm deep frame in the bedded on mortar, proprietary bitumen or

blocks or precast concrete cover highway Mortar bedding and haunching to resin mastic sealant and to be kite marked.

frame seating rings cover and frame to clause E5.6.7

Kiremarked cover slab with DRAWING NOTES

675mm maximum to first step 600x600mm opening

Yorkshire Water Notes

iron from cover level Benching slope to be 1in10 to

Refer to Manhole Precast concrete manhole 1in30. Finish to be high strength 1. All adoptable sewers to be BSI Kitemark (certified to WIS 4-35-01).

Schedule for diameter chamber sections and cover slab or granolithic concrete

In-situ concrete to be GEN3

to be bedded with mortar , 2. Adoptable sewer pipes to be laid in maximum 3 metre lengths unless

(designed to BRE Special Digest 1 there is a specific operational need to lay longer lengths.

proprietary bitumen or resin Bottom precast concrete

Concrete in Aggressive Ground)

mastic sealant ring to be built into base 3. Plastic channel sections in manholes are not acceptable and

Chamber height not

concrete min. 75mm Yorkshire Water would prefer clayware channel in manholes. We

Lifting eyes in concrete rings to

less than 900mm

have found that plastic channels are difficult to set in concrete

be pointed High strength concrete topping to because they float and a satisfactory finish cannot be obtained on

Concrete surround 150mm thick be brought up to a dense smooth Distance between top of

the benching.

face neatly shaped and finished to pipe and underside of PC

all branch connections. (minimum chamber to be 50mm 4. All adoptable sewer works and material to be in accordance

with “Sewers for Adoption” 6th Edition, The Relevant

High-strength concrete topping thickness 20mm)

The bottom precast section to be British/European and Yorkshire Water's

to be brought up to a dense, Standards/Requirements/Addendum to the Mechanical and

built into base concrete minimum

smooth face, neatly shaped and 75mm All insitu concrete to be GEN 3 with 225mm to barrel of pipe Electrical Specification and Kitemarked.

finished to all branch connections sulphate resisting cement unless

5. Manhole covers shall/must have a clear opening of 600mm and shall

(minimum thickness 20mm) Benching slope to be 1:10 to 1:30 otherwise agreed be Class D400 to BS EN 124 with 150mm deep frames in highways.

Self-cleaning toe holes to be Construction joint Inverts formed using channel pipes 6. Filled ground must be filled and consolidated under the supervision

provided where channel exceeds Note: and to the satisfaction of Yorkshire Water before any sewer works

Manholes less than 1.5m to soffit with are carried out.

600mm wide Distance between top of pipe and

1500Ø chamber size or larger should 7. Yorkshire Water is not obliged to accept new filter drain/land

underside of precast section to

Inverts to be formed using have a 1200x675mm opening (central drainage run-off into the public sewer network or adoptable

be minimum 50mm to maximum

channel pieces 300mm or eccentric) sited over channel with drainage system (directly or in-directly). An alternative method of

double twin 600x600mm covers disposal of the land drainage run-off will therefore be required and

you will have to liaise with the Local Authority, Land Drainage

225

Section with regard to the disposal of the filter drain/land drainage

run-off.

See clause 5.6.6.2 for rocker pipe 8. Cover slabs must carry the BSI Kitemark or will be rejected by

details Yorkshire Water Inspector. Sulphate resistant cement (C20-DC2) and

precast concrete products must be used or a laboratory report

provided proving that such precautions are not necessary.

Joint to be as close as possible to

face of manhole to permit 9. The adoptable sewers should be a minimum of 1m and manholes

0.5m from kerb faces and service margins.

satisfactory joint and subsequent

movement 10.“Sewers must have 5 metres clearance from trees and

hedges (please also refer to Figure 2.3 on page 33 in “Sewers for

Adoption” 6th Edition for restrictions on tree planting adjacent to

See clause 5.6.6.2 for rocker pipe sewers)”.

details

Minimum width of benching for 11.Sewers to be laid in Class “S” Bedding (150mm granular bed and

landing area to be 500mm from surround). Where depth of cover to top of the sewer is less than

Joint to be as close as possible to edge of the ladder to the edge of 1.2m in highways and verges (or less than 900mm in none vehicular

face of manhole to permit the channel access then a concrete slab should be provide above granular bed

and surround.

satisfactory joint and subsequent Minimum width of benching to

movement be 225mm 12.Bedding and backfill material to conform to the requirement of

Water Industry Specification 4-08-02 (Table A2).

13.The chamber size of manholes with more than one connection in

them may need to be increased an increment to accommodate the

Minimum width of benching for Pipe joint with channel to be connections and bends.

landing area to be 500mm from located minimum 100mm inside

edge of the double steps to the 14.Yorkshire Water policy is not to accept Type “C” brick manholes

face of manhole and 1050mm dia manhole rings. Instead it is preferred that you use a

edge of the channel

type “B” manhole with 1200mm dia or 1500mm dia rings, with

Minimum width of benching to the opening sited over the channel where depth of cover to pipe

Double step irons in accordance be 225mm soffit is 1 - 1.5m.

with BS EN 13101

15.Design done in accordance with SFA 6

16.Plastic channel sections in manholes are not acceptable and

Pipe joint with channel to be Yorkshire Water would prefer clayware channel in manholes. We

located minimum 100mm inside have found that plastic channels are difficult to set in concrete

face of manhole because they float and a satisfactory finish cannot be obtained on

the benching.

17.Cover slabs must carry the BSI Kitemark or will be rejected by

Yorkshire Water Inspector. Where the clear opening of the

Kitemarked product is different to that of the cover and frame, a

loading bearing slab should be fitted above the cover slab to

bring the size down to 600mm x 600mm for the Yorkshire Water

specified cover size. Please refer to Concrete Pipe Systems

Association (CPSA), 'Technical Bulletin' issued Autumn 2004 for

Kitemarked cover slab opening sizes.

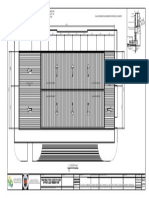

TYPICAL MANHOLE DETAIL TYPE B1/E 18.Sulphate resistant cement (C20-DC2) and precast concrete

products must be used or a laboratory report provided proving

Depth from cover level to soffit of pipe 1.0m to 1.5m that such precautions are not necessary.

Plastic chambers and rings shall comply with BS EN 13598-1 and

BS EN 13598-2 or have equivalent independent approval

TYPICAL MANHOLE DETAIL TYPE B Mortar bedding and haunching to

cover and frame to clause E6.7

Manhole to suit BS EN 124

loading Highways Class D400

L:\adept_projects\00_clients\2015\00.15021 - Hill End Road, Mapplewell\4 - Drawings\00.15021 101 P3 Proposed Drainage Layout.dwg, 10/6/2017 3:48 PM,

29.09.17 PPIC Detail added JR CB P3

Depth from cover level to soffit of pipe 1.5m to 3m 600mm clear opening

10.06.16 Brick work note amended JR CB P2

Access opening restricted to 18.05.16 Initial Issue JR CB P1

Surface course 350mm diameter or 300mm x

Binder course 300mm if depth of chamber to Date Revision By Chkd Rev

Under all hardstanding areas backfill with 40mm down Base course invert is greater than 1m

graded stone , hard- core. elsewhere (ie soft landscaped Civil and Structural

areas) backfill with approved selected material. Precast concrete slab or in -situ DOT Type 1 sub base minimum Consulting Engineers

concrete slab to support cover 150mm bellow precast concrete Engineering Better Solutions Together

and frame slab

Flexible seal Class B engineering brickwork or

precast concrete cover frame Tel 0113 239 4518 14 Festoon Rooms, Sunny Bank Mill

a

Granular bed & surround Web www.adeptcsce.com Farsley, Leeds LS28 5UJ

Temporarily cap shaft during seating rings

(see table B below) construction

email inbox@adeptcsce.com

85 Tottenham Court Road

London, W1T 4TQ - Tel: 020 3287 6677

Minimum internal dimensions

a

450mm diameter or 450mm x Project

450mm

Hill End Road, Mapplewell

DIMENSION a :- in rock or material containing hard DOT Type 1 sub base or concrete

spots sleeved jointed pipes - 150mm min. socketed surround

pipes - 200mm min. elsewhere sleeved jointed

pipes - 150mm min socketed pipes - 150mm min. Joints between base and shaft Base unit to have all connections Title

and between shaft components with soffit levels set no lower

PIPE NOMINAL

BORE (DN)

MAX. PARTICLE

SIZE (mm)

CLASS OF

BEDDING

SUITABLE IMPORTED GRANULAR MATERIALS to be fitted with water tight seals then that of the main pipe Typical Drainage Details -

10 S 10mm NOMINAL SINGLE-SIZED OR 10mm TO 5mm

Sheet 1 of 2

100 dia Granular bedding material

GRADED. Client

OVER 100 15 S max 14mm NOMINAL SINGLE-SIZED OR 14mm TO Joint to be as close as possible to Invert of connecting pipe at least

TO 150 dia 5mm GRADED. face of chamber to permit Polypipe Non man entry deep

OVER 150 20 S max 20mm NOMINAL SINGLE -SIZED OR 20mm TO satisfactory joint and subsequent inspection chamber (ICDB1)

50mm above that of the main

pipe

ESH Property Services

TO 600dia 5mm GRADED. movement or similar approved

OVER 600 40 S max 40mm NOMINAL SINGLE-SIZED OR 40mm TO Scale @ A1 Drawn Checked

5mm GRADED. TYPICAL INSPECTION CHAMBER DETAIL TYPE 3 1:20 JR CB

TABLE B. Maximum depth from cover level to soffit of pipe Date

May 2016

Status

Preliminary

CLASS `S` PIPE BEDDING DETAIL in areas subject to vehicle loading 3m, non-entry Drg. No.

00.15021/102

Rev.

P3

Você também pode gostar

- DTF Structural DrawingsDocumento35 páginasDTF Structural Drawings宋海波Ainda não há avaliações

- 2104-20 Manhole DetailsDocumento1 página2104-20 Manhole DetailsJULIEN GEORGES NGUELE BALLAAinda não há avaliações

- ADM - Estidama Temp Program Simplified Submittal - Form 2 - (3) 22.01.14Documento1 páginaADM - Estidama Temp Program Simplified Submittal - Form 2 - (3) 22.01.14Chawki Al AsmarAinda não há avaliações

- Fpa101249 BR (A) 001-003Documento3 páginasFpa101249 BR (A) 001-003chriscundyAinda não há avaliações

- Fpa101249 BR (D) 001-003Documento3 páginasFpa101249 BR (D) 001-003chriscundyAinda não há avaliações

- Thatch Roof Guard HouseDocumento2 páginasThatch Roof Guard HouseTrisha van der Merwe100% (2)

- Off R1Documento1 páginaOff R1Josphat benzAinda não há avaliações

- 06 Ground Floor PlanDocumento1 página06 Ground Floor PlanCiobanu BogdanAinda não há avaliações

- 9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)Documento1 página9946Z - 0657-SP-SL-DE-C-G77-451-P3 - Private Construction Details (Sheet 2 of 2)jmdavies.isAinda não há avaliações

- SEC - TE - 01A - Sections 1 and 2Documento1 páginaSEC - TE - 01A - Sections 1 and 2erniE抖音 AI Mobile Phone Based MovieAinda não há avaliações

- Wa0000.Documento3 páginasWa0000.nmarozhe_225151671Ainda não há avaliações

- RW Tew 22Documento1 páginaRW Tew 22Yong TonghannAinda não há avaliações

- S-241 - ARCH - 04.05.2022-ModelDocumento1 páginaS-241 - ARCH - 04.05.2022-ModelSuhail AhamedAinda não há avaliações

- Basement Parking: Muindi Mbingu Street AboveDocumento1 páginaBasement Parking: Muindi Mbingu Street AboveNehemiah KoechAinda não há avaliações

- A.Typical Roadway Section: Pavement Design ParametersDocumento1 páginaA.Typical Roadway Section: Pavement Design ParametersrickAinda não há avaliações

- Abdul Majeed Taban 2Documento1 páginaAbdul Majeed Taban 2Muhangi ChristopherAinda não há avaliações

- C.H. - 0+465.5 Section No5Documento1 páginaC.H. - 0+465.5 Section No5Fran LuqueAinda não há avaliações

- Sloping Side Elevation: Base Slab PlanDocumento1 páginaSloping Side Elevation: Base Slab PlanMwesigwa DaniAinda não há avaliações

- Chi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsDocumento1 páginaChi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsPhanLạcKhanhAinda não há avaliações

- ElevationsDocumento1 páginaElevationsRotich KiplangatAinda não há avaliações

- Construction Notes: D. Notes On Foundation Design CriteriaDocumento9 páginasConstruction Notes: D. Notes On Foundation Design CriteriaIrene Ionie Rarangol - TengcoAinda não há avaliações

- B1 - (04) - R3 - Third Floor LayoutDocumento1 páginaB1 - (04) - R3 - Third Floor LayoutBernardo Cuamba JuniorAinda não há avaliações

- Khuthi Munarini-A2Documento1 páginaKhuthi Munarini-A2anzaniAinda não há avaliações

- Weld SymbolDocumento1 páginaWeld SymbolblithevincentAinda não há avaliações

- Benja PlanDocumento1 páginaBenja Planmasumba patrickAinda não há avaliações

- 202 Sections EE & FFDocumento1 página202 Sections EE & FFD HOLAinda não há avaliações

- FootingDocumento1 páginaFootingSanjeev VermaAinda não há avaliações

- JP305821Documento7 páginasJP305821alexanderAinda não há avaliações

- Val2 Art HLS SHD SST 40 2 Cov 002 ADocumento24 páginasVal2 Art HLS SHD SST 40 2 Cov 002 AAnh KyAinda não há avaliações

- Type 1 Structural DrawingDocumento23 páginasType 1 Structural Drawingmyoaung.clickAinda não há avaliações

- Block 3 - Courtyard North: H.MclarnonDocumento1 páginaBlock 3 - Courtyard North: H.MclarnonCosmin CosminAinda não há avaliações

- Ewan Engineering Consultancy: Engineered/Contractor To Verify and Submit Calculation For The Approval of EngineersDocumento1 páginaEwan Engineering Consultancy: Engineered/Contractor To Verify and Submit Calculation For The Approval of EngineersAbid AyubAinda não há avaliações

- Civil - Drawing - Type 5 QuartersDocumento1 páginaCivil - Drawing - Type 5 QuartersDhilip KumarAinda não há avaliações

- FLOOR 2AACAsdcfdfefwaswe2dcdcedDocumento1 páginaFLOOR 2AACAsdcfdfefwaswe2dcdcedKanak YadavAinda não há avaliações

- Single - Storey House Masonry Finishes RoofDocumento8 páginasSingle - Storey House Masonry Finishes Roofmingkun2Ainda não há avaliações

- Wall Chart RoutingDocumento2 páginasWall Chart RoutingscribdeerAinda não há avaliações

- Construction Details FFDocumento6 páginasConstruction Details FFantonAinda não há avaliações

- Boundary Wall DrawingDocumento1 páginaBoundary Wall Drawingsandip wankhadeAinda não há avaliações

- MR Shumba A3Documento1 páginaMR Shumba A3MunyaradziAinda não há avaliações

- BA BA' BB BC BD BE BF BG BH BJ BK BL BM BN BP BQ BR: General NotesDocumento1 páginaBA BA' BB BC BD BE BF BG BH BJ BK BL BM BN BP BQ BR: General NotesAditya HegdeAinda não há avaliações

- 17 1197 Column LayoutDocumento1 página17 1197 Column LayoutKeise AliAinda não há avaliações

- Front Elevation 1:100 West Elevation 1:100: E E D D C C B B A ADocumento1 páginaFront Elevation 1:100 West Elevation 1:100: E E D D C C B B A AKamagara Roland AndrewAinda não há avaliações

- 230510-MS-LS-502-9F-T Pergola Details R01Documento1 página230510-MS-LS-502-9F-T Pergola Details R01Mateen JawreAinda não há avaliações

- Govt. of Bihar: Section at B - B: Weir PortionDocumento1 páginaGovt. of Bihar: Section at B - B: Weir Portionविवेक कुमारAinda não há avaliações

- Pixuate SCS Gantry Design v1.2Documento1 páginaPixuate SCS Gantry Design v1.2ashok aAinda não há avaliações

- Castillejos WELL DataDocumento3 páginasCastillejos WELL DataJohn Christopher BaquingAinda não há avaliações

- Ngwebu Zaka RDocumento1 páginaNgwebu Zaka RMunyaradziAinda não há avaliações

- Acuv Stage 5-PlansDocumento1 páginaAcuv Stage 5-PlansMonde Tidimalo Lunathi MbaluAinda não há avaliações

- AR4.1b Corp AdministrativDocumento1 páginaAR4.1b Corp Administrativmoraru_coriolanAinda não há avaliações

- Kiguli STR 1Documento1 páginaKiguli STR 1Seremba SolomonAinda não há avaliações

- Annex - II-A (Ii) - B - HAUNA FOUNDATIONDocumento1 páginaAnnex - II-A (Ii) - B - HAUNA FOUNDATIONDumoluhleAinda não há avaliações

- General Notes:: Type "D" BearingsDocumento1 páginaGeneral Notes:: Type "D" BearingsMiguel Angel Montaña PeñaAinda não há avaliações

- Foundations and Column Pedestals: General NotesDocumento3 páginasFoundations and Column Pedestals: General NotesMaher ElabdAinda não há avaliações

- A B C D E: RevisedDocumento1 páginaA B C D E: RevisedSteven SahaniAinda não há avaliações

- Drawing 3.Documento1 páginaDrawing 3.tiyaniAinda não há avaliações

- Kovilabakkam GADocumento1 páginaKovilabakkam GAsuhailAinda não há avaliações

- Reaffirmed 2004Documento11 páginasReaffirmed 2004krixotAinda não há avaliações

- Gutter Detail: Eva Mae V. Parrenas Romeo Andig Raul N. Banias M.D.,Mpa Atty. Suzette A. Mamon Arthur R. Defensor JRDocumento1 páginaGutter Detail: Eva Mae V. Parrenas Romeo Andig Raul N. Banias M.D.,Mpa Atty. Suzette A. Mamon Arthur R. Defensor JRalezandro del rossiAinda não há avaliações

- Off the Bookshelf Coloring Book: 45+ Weirdly Wonderful Designs to Color for Fun & RelaxationNo EverandOff the Bookshelf Coloring Book: 45+ Weirdly Wonderful Designs to Color for Fun & RelaxationNota: 4.5 de 5 estrelas4.5/5 (12)

- Grouting ManualDocumento36 páginasGrouting ManualJorgeaul100% (1)

- Summer Training Project On ACC CementsDocumento77 páginasSummer Training Project On ACC Cementsabhinav pandey69% (13)

- Ready Mix Concrete: Technical Seminar Report OnDocumento7 páginasReady Mix Concrete: Technical Seminar Report OnadityaAinda não há avaliações

- Design and Analysis Report BuildingDocumento40 páginasDesign and Analysis Report Buildingdhakal.binaya07Ainda não há avaliações

- The Concrete Industry Sustainability Performance ReportDocumento24 páginasThe Concrete Industry Sustainability Performance Reportmohamed sabryAinda não há avaliações

- NITSCHEDULEDocumento7 páginasNITSCHEDULEmarcAinda não há avaliações

- Alumanation 301 Za PDFDocumento2 páginasAlumanation 301 Za PDFAntonio MarrufoAinda não há avaliações

- Bituminous Mix Design PDFDocumento62 páginasBituminous Mix Design PDFShaim Rehan100% (1)

- Shera Board Cladding FacadeDocumento1 páginaShera Board Cladding Facadevabegu9Ainda não há avaliações

- Punching Shear Strength of Slabs and Influence of Low Reinforcement RatioDocumento40 páginasPunching Shear Strength of Slabs and Influence of Low Reinforcement RatioThai DamAinda não há avaliações

- JAFZA Construction Regulation - Third Edition 2003Documento73 páginasJAFZA Construction Regulation - Third Edition 2003Abdul JabbarAinda não há avaliações

- Pile Foundation Design: A Student Guide: Ascalew Abebe & DR Ian GN SmithDocumento82 páginasPile Foundation Design: A Student Guide: Ascalew Abebe & DR Ian GN SmithDavid HongAinda não há avaliações

- Tender NoticeDocumento26 páginasTender NoticeEng Abdulahi HajiAinda não há avaliações

- 1.time Shedule Capasitor Bank PetapahanDocumento1 página1.time Shedule Capasitor Bank PetapahanYoga VirgozAinda não há avaliações

- Design of Reinforced Concrete StructuresDocumento628 páginasDesign of Reinforced Concrete StructuresajAinda não há avaliações

- Modul 5 - Shallow and Deep Foundation - KuchingDocumento10 páginasModul 5 - Shallow and Deep Foundation - KuchingEmily Jampong EmilyAinda não há avaliações

- Masonry ConstructionDocumento15 páginasMasonry Constructionsaima BatoolAinda não há avaliações

- Design of Two Way SlabDocumento180 páginasDesign of Two Way SlabGino Paolo ObsiomaAinda não há avaliações

- Department of Agriculture and Food: MARCH 2006Documento29 páginasDepartment of Agriculture and Food: MARCH 2006ThiênSứBanPhúcAinda não há avaliações

- Paver Block Factory Inspection - LOG - Updated As On 07 05 2018Documento5 páginasPaver Block Factory Inspection - LOG - Updated As On 07 05 2018Ritesh kumarAinda não há avaliações

- Prism CementDocumento34 páginasPrism CementLochan JaiswalAinda não há avaliações

- Cal Year IndexDocumento36 páginasCal Year IndexKA25 ConsultantAinda não há avaliações

- Construction and Building MaterialsDocumento21 páginasConstruction and Building MaterialsChirag B ShettyAinda não há avaliações

- Eb204 1Documento337 páginasEb204 1alikaroutAinda não há avaliações

- ASTM C0192 - C0192M - 07 - 15 Preparación y Curado de Especimenes de Concreto en Laboratorio PDFDocumento8 páginasASTM C0192 - C0192M - 07 - 15 Preparación y Curado de Especimenes de Concreto en Laboratorio PDFJohnny Araya VigilAinda não há avaliações

- Design of Canal Distributary With Hydraulic FallDocumento19 páginasDesign of Canal Distributary With Hydraulic FallRajeev Ranjan100% (1)

- (12-21) Water Tank Paper-FormatDocumento10 páginas(12-21) Water Tank Paper-Formatmohammed nafethAinda não há avaliações

- 033000fl Euclid StegoDocumento42 páginas033000fl Euclid StegoabobeedoAinda não há avaliações

- Study of Cracks in Buildings PDFDocumento15 páginasStudy of Cracks in Buildings PDFjacobian18Ainda não há avaliações

- Course Pre Requisite Fkaas 31-7-2017Documento2 páginasCourse Pre Requisite Fkaas 31-7-2017ShueibAinda não há avaliações