Escolar Documentos

Profissional Documentos

Cultura Documentos

Speed Control System Steam Turbines

Enviado por

bagastcTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Speed Control System Steam Turbines

Enviado por

bagastcDireitos autorais:

Formatos disponíveis

Modernization of Speed Control

Steam turbines DG/DK

In order to retrofit obsolete steam turbine control systems MAN

PrimeServ provides comprehensive modernization concepts inclu-

ding a contemporary PLC based digital speed controller.

Challenge

Steam turbines are operated in different applications as mechanical drives for compressor

trains or as generator drives for power generation. Furthermore, steam turbines are used

for the supply of constant pressure process steam using the surplus energy to drive ge-

nerators or compressors. As the operating mode strongly depends on the application, the

steam turbine speed control has to fulfill multiple requirements as power control, frequency

control or extraction pressure control. Since control systems have gone through a fast

technical development, the functionality and the control concept of older control systems

may often not meet current standards any more. Furthermore, years of operation may have

increased the risk of malfunctions and component failures whilst spare parts supply and

technical support are often not immediately available any more.

Modernization Solution

In order to retrofit obsolete steam turbine control systems, and therefore to meet current

standards and requirements, MAN PrimeServ provides comprehensive modernization con-

cepts including a contemporary PLC based digital speed control. As standard the speed

control is realized on the SIMATIC PCS7 series or the newly designed Turbolog platform.

In addition, also other platforms as Woodward applications can be provided on request.

The consistent use of industrial standard components as well for the programmable logic

controller as for the independent monitoring systems supports the long-term availability of

spare parts and technical support.

PS_Leaflet_4c_Master.indd 1 02.09.2013 11:58:08

Modernization of Speed Control

Steam turbines DG/DK

The term „highly available“ shall refer to the special, e. g. redundant, design of the respective component intended to support its availability in the wake of a failure · Copyright © MAN Diesel & Turbo · PLM.062013.3 · Printed in Germany

sessed and determined individually for each project. This will depend on the particular characteristics of each individual project, especially specific site and operational conditions · The herein used term „fail-safe“ shall have the meaning as defined in IEC 61508-7.

All data provided in this document is non-binding. This data serves informational purposes only and is especially not warrented or guaranteed in any way. Depending on the specific individual projects, the relevant data may be subject to changes and will be as-

The central module consists of a highly available programmable logic controller as stan-

dard, with the open-loop and closed-loop control functions of the steam turbine train grou-

ped together in a common system. The I/O modules are either realized as standard, highly

available or fail-safe modules according to their intended use and can be further extended

to include additional functions. By updating the control parameters and algorithms as

well as modernizing also the related systems, e. g. the overspeed detection system, MAN

PrimeServ provides for the entire unit being in accordance with current technical standards

and meeting requirements up to IEC 61508 SIL 3 and API 670.

Advantages

Being the OEM of your steam turbine MAN PrimeServ provides you a comprehensive

modernization solution - including the complete loop as well as the necessary mechanical

modifications - for a successful and sustainable upgrade:

n Advanced retrofit solution with modern control and safety concept

n Comprehensive modernization concept tailored to specific train and application

n Industrial standard components for long-term spare parts supply and technical support

n Process control system with clear and intuitive visualization of machine parameters for

user-friendly operation

n Analysis and recording functions for all information as measured values or alarm

messages

n Connection to MAN PrimeServ irds® system for provision of remote service support

MAN Diesel & Turbo

86224 Augsburg, Germany

Comprehensive Modernization

Phone +49 821 322-0

MAN PrimeServ provides comprehensive modernization concepts to modernize your

Fax +49 821 322-3382

equipment – no matter if you want to optimize reliability, operating costs, environmental mtprimeserv@man.eu

sustainability or any other characteristic. Please contact us for further information. www.mandieselturbo.com

PS_Leaflet_4c_Master.indd 2 02.09.2013 11:58:08

Você também pode gostar

- Turbine Governing SystemDocumento77 páginasTurbine Governing SystemGrishma WarkeAinda não há avaliações

- Governing - General PDFDocumento49 páginasGoverning - General PDFManoj Upadhyay100% (1)

- 125 V DC Fault AlarmDocumento7 páginas125 V DC Fault AlarmThetTinAungAinda não há avaliações

- Seal Oil PresentationDocumento10 páginasSeal Oil PresentationjeromejoeAinda não há avaliações

- GT 6B Gas Fuel Inlet Pressure 96FG-2ABC False Indication - Automation & Control Engineering Forum PDFDocumento1 páginaGT 6B Gas Fuel Inlet Pressure 96FG-2ABC False Indication - Automation & Control Engineering Forum PDFnboulegrouneAinda não há avaliações

- Governingsystem 131127063004 Phpapp01 PDFDocumento38 páginasGoverningsystem 131127063004 Phpapp01 PDFhari setiawan100% (1)

- Turbine Governing System-An OverviewDocumento22 páginasTurbine Governing System-An Overview94gauravAinda não há avaliações

- GE Digital Relays 2010Documento76 páginasGE Digital Relays 2010rajap2737Ainda não há avaliações

- Universal Relay Family: GE Consumer & IndustrialDocumento22 páginasUniversal Relay Family: GE Consumer & IndustrialJulio Antonio Bastías VargasAinda não há avaliações

- MK6e Control System ChecksDocumento4 páginasMK6e Control System ChecksAugustine Owo Ukpong100% (1)

- Gas Turbine ConstructionDocumento7 páginasGas Turbine ConstructionLeelananda100% (1)

- Isochronous and DroopDocumento15 páginasIsochronous and DroopNadeem Khan100% (1)

- HP Feed WaterDocumento13 páginasHP Feed WaterAxlejunz Dublin RondinaAinda não há avaliações

- Steam TurbinesDocumento45 páginasSteam TurbinesHaseeb Bokhari100% (1)

- Speed & Load Control of TurbineDocumento12 páginasSpeed & Load Control of Turbinekalaivani sAinda não há avaliações

- Better Understanding of Gas Turbine ControlDocumento117 páginasBetter Understanding of Gas Turbine ControlShahzad James100% (1)

- M624 MBATech Electrical Subrat Sharma Final ReportDocumento64 páginasM624 MBATech Electrical Subrat Sharma Final ReportJosef MorganAinda não há avaliações

- Sagar Pandey AtpDocumento44 páginasSagar Pandey AtpIshankAinda não há avaliações

- GPS DCS Time SyhchronisationDocumento6 páginasGPS DCS Time Syhchronisationkoushik42000Ainda não há avaliações

- Docslide - Us Servo Valve CalibrationDocumento19 páginasDocslide - Us Servo Valve CalibrationnboulegrouneAinda não há avaliações

- Lube Oil SystemDocumento4 páginasLube Oil SystempawangwlAinda não há avaliações

- Speed (%) Vs Time (Min) : Gas Turbine Starting CurveDocumento2 páginasSpeed (%) Vs Time (Min) : Gas Turbine Starting CurveAdy FardyAinda não há avaliações

- Hydrastep & Hydratect: Water/steam Monitoring SystemsDocumento8 páginasHydrastep & Hydratect: Water/steam Monitoring Systemsगुंजन सिन्हाAinda não há avaliações

- Turbine Start UpDocumento15 páginasTurbine Start UprobiansahAinda não há avaliações

- Deh Governing-LancoDocumento35 páginasDeh Governing-LancoPRAMOD KUMAR NANDAAinda não há avaliações

- Leveltrol MasoneilanDocumento34 páginasLeveltrol MasoneilanChristopher GeorgeAinda não há avaliações

- STGDocumento12 páginasSTGLiji Brijesh100% (1)

- Generator TheoryDocumento48 páginasGenerator TheorysulemankhalidAinda não há avaliações

- Controls & Instrumentation FOR 660 MW Supercritical Unit at TirodaDocumento23 páginasControls & Instrumentation FOR 660 MW Supercritical Unit at TirodaAakash kumar ShrivastavaAinda não há avaliações

- Steam Turbine GoverningDocumento10 páginasSteam Turbine Governingsimhhhh100% (1)

- Ex2100e and Ex2100 Comparison Fact Sheet EnglishDocumento1 páginaEx2100e and Ex2100 Comparison Fact Sheet EnglishOrissa KonsbahalAinda não há avaliações

- FSSSDocumento8 páginasFSSSVijay PorwalAinda não há avaliações

- Governing System, RSE & TG ExpansionsDocumento40 páginasGoverning System, RSE & TG Expansionssaravan1891100% (2)

- Hydraulic Valves AnalyticsDocumento8 páginasHydraulic Valves Analyticspartha6789Ainda não há avaliações

- Steam Turbine ControlDocumento13 páginasSteam Turbine Controlnirbhay111100% (4)

- Tsi FinalDocumento41 páginasTsi FinalAnand KumarAinda não há avaliações

- Boiler Control6.3.7Documento58 páginasBoiler Control6.3.7Nandkumar KhachaneAinda não há avaliações

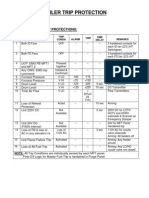

- Boiler Trip Protection: Master Fuel Trip ProtectionsDocumento2 páginasBoiler Trip Protection: Master Fuel Trip ProtectionsKuntal Satpathi100% (3)

- NEW 505view Operator Interface MANUALDocumento60 páginasNEW 505view Operator Interface MANUALWilliam Will Controle WoodwardAinda não há avaliações

- Installation and Operation Manual: 505E Digital Governor For Extraction Steam TurbinesDocumento218 páginasInstallation and Operation Manual: 505E Digital Governor For Extraction Steam Turbinesagus triprasetyoAinda não há avaliações

- TSIDocumento55 páginasTSISamAinda não há avaliações

- Product Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Documento12 páginasProduct Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Sakthi Sekar CbiAinda não há avaliações

- VariStroke-I Actuator Power Up Reset Issue - Service Bulletin - 1596 - NEWDocumento2 páginasVariStroke-I Actuator Power Up Reset Issue - Service Bulletin - 1596 - NEWAshraf AbdelrahmanAinda não há avaliações

- Integrated Turbine-Compressor ControlDocumento8 páginasIntegrated Turbine-Compressor ControlAbdul RohmanAinda não há avaliações

- GTG - Know How Training 27 Feb 2013 - 2Documento25 páginasGTG - Know How Training 27 Feb 2013 - 2aden mngAinda não há avaliações

- Speed TronicDocumento3 páginasSpeed Tronicscribdkhatn0% (1)

- Fisher ProdOvervueDocumento88 páginasFisher ProdOvervueduongleanhAinda não há avaliações

- Boiler OverviewDocumento35 páginasBoiler Overviewshashank dasAinda não há avaliações

- Detail Writeup of MarkvieDocumento128 páginasDetail Writeup of MarkvieramkrishnaAinda não há avaliações

- Generator Operation PMIDocumento30 páginasGenerator Operation PMIrohit_0123100% (2)

- Presentation On Presentation On Plant Controls & Inst. Overview OF GGSR - Bathinda (CPP) GGS (C) Owner: M/S Hmel PMC: M/S EILDocumento34 páginasPresentation On Presentation On Plant Controls & Inst. Overview OF GGSR - Bathinda (CPP) GGS (C) Owner: M/S Hmel PMC: M/S EILGunadevan ChandrasekaranAinda não há avaliações

- Draft (1) RevDocumento2 páginasDraft (1) RevLeelanandaAinda não há avaliações

- Main Steam Turbine Controls Retrofit ISA FinalDocumento13 páginasMain Steam Turbine Controls Retrofit ISA Finalvankayalasurya100% (1)

- CEA Plant Performance Report 2011-12Documento251 páginasCEA Plant Performance Report 2011-12lovelyshreeAinda não há avaliações

- Low Pressure Governing SystemDocumento113 páginasLow Pressure Governing SystemBalgopal Raju75% (4)

- Null BiasDocumento33 páginasNull BiasGoh Seng TakAinda não há avaliações

- GE Frame 6 - Change The Start EngineDocumento9 páginasGE Frame 6 - Change The Start EngineShahzad JamesAinda não há avaliações

- Governing System of Gas TurbineDocumento128 páginasGoverning System of Gas Turbinesaptarshi roy100% (3)

- Power Plant Operation and Maintenance ServicesDocumento4 páginasPower Plant Operation and Maintenance ServicesAhmed El Tayeb0% (1)

- Man 48 60cr Imo Tier II Marine PDFDocumento428 páginasMan 48 60cr Imo Tier II Marine PDFDavidenko IlyaAinda não há avaliações

- Pumping Control CcnterDocumento2 páginasPumping Control CcnterbagastcAinda não há avaliações

- New 4 PackDocumento2 páginasNew 4 PackbagastcAinda não há avaliações

- 1522 PDFDocumento2 páginas1522 PDFbagastcAinda não há avaliações

- 1522 PDFDocumento2 páginas1522 PDFbagastcAinda não há avaliações

- CorrelatorDocumento2 páginasCorrelatorbagastcAinda não há avaliações

- H High Pressure Wheel WashDocumento2 páginasH High Pressure Wheel WashbagastcAinda não há avaliações

- 1522 PDFDocumento2 páginas1522 PDFbagastcAinda não há avaliações

- (Ebook - Free Energy) - Free - Energy - Projects - 1Documento152 páginas(Ebook - Free Energy) - Free - Energy - Projects - 1Lsor76100% (1)

- Green ArrowDocumento51 páginasGreen ArrowbagastcAinda não há avaliações

- 3E Plus V4 Users ManualDocumento60 páginas3E Plus V4 Users ManualManikanda PrabhuAinda não há avaliações

- Alstom Hydro Pelton Power Plant PDFDocumento12 páginasAlstom Hydro Pelton Power Plant PDFbagastcAinda não há avaliações

- Industrial Insulation ManualDocumento191 páginasIndustrial Insulation ManualHaris PrawotoAinda não há avaliações

- 218 HO Dual Battery System (ACB) 11-28-02Documento29 páginas218 HO Dual Battery System (ACB) 11-28-02arkhom1Ainda não há avaliações

- RS485 Quick Guide: TIA/EIA-485-A StandardDocumento2 páginasRS485 Quick Guide: TIA/EIA-485-A StandardHanumantha Reddy BevinalAinda não há avaliações

- BOMAFA Steam Conditioning ValvesDocumento8 páginasBOMAFA Steam Conditioning ValvesbagastcAinda não há avaliações

- MD-Blue-Pipe Fitting and Flange ToolsDocumento12 páginasMD-Blue-Pipe Fitting and Flange Toolssandii123Ainda não há avaliações

- BOMAFA Corporate Profile EnglishDocumento6 páginasBOMAFA Corporate Profile Englishshan07011984Ainda não há avaliações

- Dump Tube - R01Documento3 páginasDump Tube - R01bagastcAinda não há avaliações

- UPS SRT8 - 10K 1027822864 - HardwireDocumento1 páginaUPS SRT8 - 10K 1027822864 - HardwirebagastcAinda não há avaliações

- CMI Energy HRSG Brochure PDFDocumento8 páginasCMI Energy HRSG Brochure PDFbagastcAinda não há avaliações

- Desuperheater PDFDocumento7 páginasDesuperheater PDFbagastcAinda não há avaliações

- Produktkatalog 2019 WebDocumento280 páginasProduktkatalog 2019 WebbagastcAinda não há avaliações

- Desuperheater PDFDocumento7 páginasDesuperheater PDFbagastcAinda não há avaliações

- Catalogue Studer en 2018 08.18Documento44 páginasCatalogue Studer en 2018 08.18bagastc100% (1)

- Penstock ManualDocumento159 páginasPenstock Manualstudent_bl95% (21)

- Erection of TurbineDocumento73 páginasErection of TurbineNipun PharliaAinda não há avaliações

- Apc UpsDocumento22 páginasApc UpsbagastcAinda não há avaliações

- Smart-UPS On-Line - Manual OperacionDocumento35 páginasSmart-UPS On-Line - Manual Operaciondiegomustto2Ainda não há avaliações

- 4 HDPE PipeIPS - DIPSDocumento2 páginas4 HDPE PipeIPS - DIPSbagastcAinda não há avaliações

- Part 3 Energy, Head and Bernoulli's EquationDocumento5 páginasPart 3 Energy, Head and Bernoulli's EquationJoren HuernoAinda não há avaliações

- Bhel Turbine Block 3 PresentationDocumento29 páginasBhel Turbine Block 3 PresentationnischalAinda não há avaliações

- Abdul Wasay C.VDocumento2 páginasAbdul Wasay C.VAhmad TahirAinda não há avaliações

- ABB Manual PDFDocumento264 páginasABB Manual PDFСемён СемёновичAinda não há avaliações

- EC - I MCQ Question Bank On Unit 5 & 6-1Documento12 páginasEC - I MCQ Question Bank On Unit 5 & 6-1Harshad jambhaleAinda não há avaliações

- OMAC B Series Lobe Pump Operation and Maintenance Manual 201 PDFDocumento116 páginasOMAC B Series Lobe Pump Operation and Maintenance Manual 201 PDFEdwin SalazarAinda não há avaliações

- Dresser Rand 2134 RLHADocumento2 páginasDresser Rand 2134 RLHAashumishra007100% (2)

- 1.turbine Efficiency PDFDocumento64 páginas1.turbine Efficiency PDFAnudeep Chittluri100% (2)

- Rotor Evaluation Regarding RunoutDocumento7 páginasRotor Evaluation Regarding Runoutdm mAinda não há avaliações

- Gas Turbine Start-UpDocumento36 páginasGas Turbine Start-UpHeryanto Syam100% (2)

- TurboExpander CalculationsDocumento7 páginasTurboExpander Calculationsvkumaran100% (1)

- Ejercicos Van WylenDocumento11 páginasEjercicos Van WylenJorgeJiménezAinda não há avaliações

- Pressure Screen Fundamentals 2020 2013.1.261Documento43 páginasPressure Screen Fundamentals 2020 2013.1.261RajanbabuAinda não há avaliações

- Asce Epri Guides 1989Documento59 páginasAsce Epri Guides 1989david_rosemberg50% (2)

- Thermofluids Lab IIDocumento32 páginasThermofluids Lab IIZulkeefal DarAinda não há avaliações

- Roto Jet OverviewDocumento2 páginasRoto Jet Overviewgeverett2765Ainda não há avaliações

- Ts Ecet PaperDocumento11 páginasTs Ecet PaperAvala lokeshAinda não há avaliações

- Gas Turbine - Part 1Documento82 páginasGas Turbine - Part 1Manuel L Lombardero100% (2)

- KE52 Jurnal SNTTM2019Documento8 páginasKE52 Jurnal SNTTM2019yadiAinda não há avaliações

- 15AFB Cervenka M The Rolls Royce Trent EngineDocumento40 páginas15AFB Cervenka M The Rolls Royce Trent Enginesaroj2058Ainda não há avaliações

- Performance Evaluation of New and In-Service Turbine Oils: Turbine Oil Stability Test (TOST) ASTM D943Documento2 páginasPerformance Evaluation of New and In-Service Turbine Oils: Turbine Oil Stability Test (TOST) ASTM D943Gautam BandyopadhyayAinda não há avaliações

- Windmill ReportDocumento44 páginasWindmill ReportSavitesh KumarAinda não há avaliações

- R5310302 Hydraulic Machinery & SystemsDocumento1 páginaR5310302 Hydraulic Machinery & SystemssivabharathamurthyAinda não há avaliações

- V150-4.0 - 4.2MW DECS - AppendixCDocumento7 páginasV150-4.0 - 4.2MW DECS - AppendixCLưu SơnAinda não há avaliações

- Energy (H) QPDocumento34 páginasEnergy (H) QPChloe CadoretAinda não há avaliações

- Flying WindmillsDocumento16 páginasFlying WindmillsSHASHIKANT PATEL IET Lucknow StudentAinda não há avaliações

- N6DMComponent Sheet Aug 2012Documento39 páginasN6DMComponent Sheet Aug 2012Huda LestraAinda não há avaliações

- Ttcover Letter Joanita Carla Sek Dos RemediosDocumento11 páginasTtcover Letter Joanita Carla Sek Dos RemediosImaculada XimenesAinda não há avaliações

- Wake Effects - QuestionsDocumento6 páginasWake Effects - QuestionsindrasyifaiAinda não há avaliações

- Principles of TurbomachineryDocumento13 páginasPrinciples of Turbomachineryraj jangidAinda não há avaliações