Escolar Documentos

Profissional Documentos

Cultura Documentos

Cleaning Validation Rinsing Tes

Enviado por

Ursula HilleDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cleaning Validation Rinsing Tes

Enviado por

Ursula HilleDireitos autorais:

Formatos disponíveis

TEM-010

Issue date

Cleaning Validation – Rinsing Test

(Ref.VAL-010)

Project number:

Protocol Number:

Product/Active:

Process Line:

RINSING RECOVERY STUDIES

1. Test Description

This test is to be conducted to document the validation of Total Organic Carbon (TOC)

analysis method for use in measuring samples for cleaning validation. A parallel analysis

of rinse samples will be carried out and compared using TOC and High Performance

Liquid Chromatography (HPLC) analysis. Standard solutions will be applied to stainless

steel plates, dried and the residue removed by rinsing using an appropriate solvent

(usually water). Assessment of Linearity, Accuracy (recovery), LOQ, LOD and precision

of the rinsing method will be determined.

2. Test Objective

1. Determine the linearity and precision of a series of standards rinsed from a stainless

steel plate or container and measured by TOC and HPLC over a known concentration

range.

2. Determine the accuracy (recovery) of a series of standards rinsed from a stainless

steel plate or container and measured by TOC and HPLC over a known concentration

range.

3. Determine the Limit of quantitation and limit of detection of a series of standards

measured by TOC and HPLC over a known concentration range.

4. Determine correlation between HPLC and TOC analysis.

5. Determine the final HPLC and TOC rinsing limits based on recovery studies.

3. Acceptance Criteria

Test Objective Measured Response Acceptance Criteria

2

Linearity The correlation coefficient (r ) HPLC: equal to or greater than 0.997

for the linear concentration

TOC: equal to or greater than 0.980

range.

Precision % RSD HPLC: The recovery %RSD less than or equal to

10.0%.

TOC: The recovery %RSD less than or equal to

15.0%.

File Location: Date Printed: Page 1 of 9

TEM-010

Issue date

Cleaning Validation – Rinsing Test

(Ref.VAL-010)

(ii) Carefully pour the required volume of rinse solvent into the container making certain that all

the surface area is contacted by the solvent (the rinse solvent should be at the same temperature

as used in the manufacturing environment). The volume of rinse solution used in the recovery

experiments should be proportional to the rinse volume used in the manufacturing area. Analyze

the resultant rinsate samples by HPLC and TOC.

Residue recovery will be calculated as follows:

result found

% Recovery = × 100%

result expected

(iii) Tabulate results as detailed in results section and plot linear regression and document results

of linear regression analysis for both HPLC and TOC analysis.

5. Results

Linearity - Rinsing Active Residue

1. HPLC Analysis

Active Concentration Peak Area of Active

(ug/mL)

(50%)

(100%)

(400%)

Plot Concentration v’s Peak Area (calculate linear regression)

2

Coefficient of Determination (R ) =

File Location: Date Printed: Page 3 of 9

TEM-010

Issue date

Cleaning Validation – Rinsing Test

(Ref.VAL-010)

Accuracy - Rinsing active residue

For each measured response over the concentration range examined in the Linearity test

calculate % recovery and % RSD for each of the triplicate samples.

where % recovery = result found x 100

result expected

Actual Active Measured responses Average Mean % %

Concentration result recovery RSD

1 2 3 4

(50%)

(100%)

(400%)

1. HPLC Analysis

Compare and summarise results according to acceptance criteria

2. TOC Analysis

Actual Total Measured TOC (ppm) Average Mean % % RSD

Organic TOC (ppm) recovery

Carbon

Concentration

(ppm)

1 2 3 4

(50%)

(100%)

(400%)

Compare and summarise results according to acceptance criteria

Limit of Quantitation

File Location: Date Printed: Page 5 of 9

TEM-010

Issue date

Cleaning Validation – Rinsing Test

(Ref.VAL-010)

Plot Average Recovery (Active) ppm HPLC V’s Average recovery (Total Product

Carbon) ppm TOC

Linear regression line =

Correlation coefficient (R) =

2

Coefficient of determination (R ) =

Determining Final HPLC and TOC Rinsing Limits Based on Recovery Studies

HPLC Rinsing Limits

Determine the lowest and most conservative active rinse recovery value obtained during the

method validation study for HPLC analysis.

Lowest HPLC rinse recovery value = ____________

The final limits for the active residue for rinse solutions are:

Equipment Equipment Acceptable Rinse Volume Final HPLC Limits for

Surface Residue used to rinse Active incorporating

2

Area (cm ) Level of equipment recovery results

Active (mg) Surface

Mixing Vessel eg. 26,664 eg. 11.1325 eg.2500 mL eg. 11.1325mg/2500mL x

2

cm 0.8966 x 1000ug/mg

= 3.993 ug/mL or ppm

Holding Vessel

File Location: Date Printed: Page 7 of 9

TEM-010

Issue date

Cleaning Validation – Rinsing Test

(Ref.VAL-010)

6. Comments

7. Conclusion

8. Attachments

Validation Discrepancy Forms - nil

Completed Operational Qualification Test protocol:

Position Signature Date

Documented by:

Checked by:

Approved by:

DOCUMENT REVISION HISTORY

Revision Date Reason for Revision Author Initial for Retrieval

# of Outdated Documents

File Location: Date Printed: Page 9 of 9

Você também pode gostar

- Cleaning Validation ProtocolDocumento22 páginasCleaning Validation ProtocolBejoy Karim100% (4)

- Cleaning Validation ProtocolDocumento3 páginasCleaning Validation Protocolpuneetogupta100% (1)

- 02 Cleaning Validation of Double Cone Blender CLV 02Documento2 páginas02 Cleaning Validation of Double Cone Blender CLV 02Ravi Yadav100% (2)

- Validation VialWasher OQ NIHDocumento30 páginasValidation VialWasher OQ NIHcongacon3aAinda não há avaliações

- Dirty-Hold Time Effect On The CleaningDocumento6 páginasDirty-Hold Time Effect On The CleaningOmar FaruqAinda não há avaliações

- Cleaning Validation ProtocolDocumento9 páginasCleaning Validation Protocolyash143565100% (2)

- Cleaning Validation Protocol TEMPLATEDocumento9 páginasCleaning Validation Protocol TEMPLATEnatavceAinda não há avaliações

- Validation Protocol for Oral LiquidDocumento24 páginasValidation Protocol for Oral LiquidAshutosh Shukla100% (2)

- 9 C Validation Protocol TABLETDocumento20 páginas9 C Validation Protocol TABLETMohammed ZubairAinda não há avaliações

- Micro ManualDocumento55 páginasMicro ManualNiranjan PradhanAinda não há avaliações

- Pegasus Farmaco India Raw Material Requisition SlipDocumento1 páginaPegasus Farmaco India Raw Material Requisition Slipasit_mAinda não há avaliações

- Validation of Coating Equipment (Ketik Ulang)Documento6 páginasValidation of Coating Equipment (Ketik Ulang)Dedhieaja0% (1)

- Ointment Process ValidationDocumento25 páginasOintment Process ValidationTrinh Huy CongAinda não há avaliações

- Modi sugar Mills retrospective validation reportDocumento7 páginasModi sugar Mills retrospective validation report9889187549100% (2)

- IQOQ ProtocolDocumento4 páginasIQOQ ProtocolVijay RajaindranAinda não há avaliações

- Procedurefor Cleaning ValidationDocumento21 páginasProcedurefor Cleaning ValidationQ CAinda não há avaliações

- User Requirement Specification For Moisture Analyser: Company NameDocumento6 páginasUser Requirement Specification For Moisture Analyser: Company Namevamshi krishnaAinda não há avaliações

- Master Cleaning Validation PlanDocumento25 páginasMaster Cleaning Validation PlanWidya Lukitasari100% (1)

- PQ FBDDocumento6 páginasPQ FBDScott Adkins100% (1)

- Procedure For Environmental Monitoring by Settle Plate MethodDocumento2 páginasProcedure For Environmental Monitoring by Settle Plate Methodejazmaqsood100% (1)

- Sterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao FinalDocumento54 páginasSterile Drug Insp CPGM 7356-002a - Ora - Lao-Nm 9-10-15 - Emc Lao Finaltito1628100% (1)

- Process Validation of Ointment Creams 2Documento40 páginasProcess Validation of Ointment Creams 2Farhana Shermeen0% (1)

- Cleaning Validation To Be Developed From This Article On Metformin TabletsDocumento9 páginasCleaning Validation To Be Developed From This Article On Metformin TabletsPramba Kumar AhujaAinda não há avaliações

- Temperature Mapping Study and QualificationDocumento19 páginasTemperature Mapping Study and QualificationJewel Hernandez100% (2)

- Validation Protocall For AutoclaveDocumento7 páginasValidation Protocall For AutoclaveBalakrishnan S NadarAinda não há avaliações

- Cross Contamination Prevention in HVACDocumento8 páginasCross Contamination Prevention in HVAChuynhhaichauchauAinda não há avaliações

- Tablet Process Validation ProtocolDocumento37 páginasTablet Process Validation ProtocolOsama Mahmoud75% (4)

- Environmental Monitoring Performance QualificationDocumento8 páginasEnvironmental Monitoring Performance Qualificationmehdi bahramiAinda não há avaliações

- DHS ValidationDocumento7 páginasDHS Validationmuna82dasAinda não há avaliações

- Title: Cleaning Validation Report For - ToDocumento41 páginasTitle: Cleaning Validation Report For - TocpkakopeAinda não há avaliações

- Blend UniformityDocumento10 páginasBlend Uniformityitung23Ainda não há avaliações

- How To Validate An AutoclaveDocumento3 páginasHow To Validate An AutoclaveqhpuongAinda não há avaliações

- HVAC QualificationDocumento41 páginasHVAC QualificationramajayamAinda não há avaliações

- Validation of Lab Incubators & OvensDocumento4 páginasValidation of Lab Incubators & Ovensltrevino100Ainda não há avaliações

- Annex4-TRS992 Hold Time Study GuidelineDocumento8 páginasAnnex4-TRS992 Hold Time Study Guidelinensk79in@gmail.com100% (1)

- 8.3 Operation Qualification Protocol For Dispensing BoothDocumento4 páginas8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- Hold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For UseDocumento11 páginasHold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For Usegopusankar100% (5)

- Hold Time Study of 70% IpaDocumento5 páginasHold Time Study of 70% IpaAshok Lenka100% (4)

- Disinfectant Validation ProtocolDocumento12 páginasDisinfectant Validation Protocolhbhatt8890% (10)

- Validation Protocol For Efficacy of Chemical DisinfectantsDocumento8 páginasValidation Protocol For Efficacy of Chemical DisinfectantsMohamed KamalAinda não há avaliações

- Bulk Holding Time Study ReportDocumento8 páginasBulk Holding Time Study ReportFaress RabiAinda não há avaliações

- Cleaning Validation ProtocolDocumento17 páginasCleaning Validation Protocolswathikotla92% (36)

- Prosses Validation Protocol For Ivermectin InjectionDocumento25 páginasProsses Validation Protocol For Ivermectin Injectionمحمد عطاAinda não há avaliações

- Cleaning Validation MACO v2.0Documento2 páginasCleaning Validation MACO v2.0Ovais08100% (2)

- Cleaning Validation of Liquid Filling LineDocumento9 páginasCleaning Validation of Liquid Filling LineOryza SativaAinda não há avaliações

- Performance Qualification Protocol and Report For AutoclaveDocumento19 páginasPerformance Qualification Protocol and Report For AutoclaveMubarak PatelAinda não há avaliações

- Validation-An Important Tool of GMP: About Authors: Karmveer TomarDocumento4 páginasValidation-An Important Tool of GMP: About Authors: Karmveer TomarShiv KumarAinda não há avaliações

- Autoclave Validation PresentationDocumento17 páginasAutoclave Validation PresentationAnkur Bhatia100% (1)

- CLEANING VALIDATION PROTOCOLDocumento7 páginasCLEANING VALIDATION PROTOCOLArieTamaAinda não há avaliações

- Disinfectant ValidationDocumento7 páginasDisinfectant Validationrose itaAinda não há avaliações

- JAGSONPAL HOLD TIME STUDYDocumento3 páginasJAGSONPAL HOLD TIME STUDYAshok Lenka100% (2)

- Validation master plan Complete Self-Assessment GuideNo EverandValidation master plan Complete Self-Assessment GuideAinda não há avaliações

- Biocontamination Control for Pharmaceuticals and HealthcareNo EverandBiocontamination Control for Pharmaceuticals and HealthcareNota: 5 de 5 estrelas5/5 (1)

- Validation Master Plan A Complete Guide - 2020 EditionNo EverandValidation Master Plan A Complete Guide - 2020 EditionAinda não há avaliações

- cGMP Current Good Manufacturing Practices for PharmaceuticalsNo EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsNota: 1 de 5 estrelas1/5 (2)

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersAinda não há avaliações

- Regulatory Aspects of Pharmaceutical Quality System: Brief IntroductionNo EverandRegulatory Aspects of Pharmaceutical Quality System: Brief IntroductionAinda não há avaliações

- Software Verification And Validation A Complete Guide - 2020 EditionNo EverandSoftware Verification And Validation A Complete Guide - 2020 EditionAinda não há avaliações

- Comissionamento FarmaceuticoDocumento4 páginasComissionamento FarmaceuticoUrsula HilleAinda não há avaliações

- kARL FISCHER 870 TITRIN PDFDocumento100 páginaskARL FISCHER 870 TITRIN PDFUrsula HilleAinda não há avaliações

- Food Chemical Codex 1996Documento917 páginasFood Chemical Codex 1996Ursula HilleAinda não há avaliações

- Hypoglycemic Effect of Oregano (Origanum Vulgare)Documento17 páginasHypoglycemic Effect of Oregano (Origanum Vulgare)Ursula HilleAinda não há avaliações

- Ich Q1F PDFDocumento1 páginaIch Q1F PDFSailaja ChirravuriAinda não há avaliações

- Disinfectant Validation ProtocolDocumento12 páginasDisinfectant Validation Protocolhbhatt8890% (10)

- Method Validation POPDocumento3 páginasMethod Validation POPUrsula HilleAinda não há avaliações

- 70 8310 Simultaneous Analysis of Glycerides (Mono Di and Triglycerides) and Free Fatty Acids in Palm OilDocumento3 páginas70 8310 Simultaneous Analysis of Glycerides (Mono Di and Triglycerides) and Free Fatty Acids in Palm OilUrsula HilleAinda não há avaliações

- Tartarugas Cuidados MedicaçõesDocumento7 páginasTartarugas Cuidados MedicaçõesUrsula HilleAinda não há avaliações

- Sulfonamides: (Veterinary-Systemic)Documento17 páginasSulfonamides: (Veterinary-Systemic)Ursula HilleAinda não há avaliações

- Apostila de Formulações CosméticasDocumento15 páginasApostila de Formulações CosméticasUrsula HilleAinda não há avaliações

- Botanica Nos CosmeticosDocumento27 páginasBotanica Nos CosmeticosUrsula HilleAinda não há avaliações

- Oregano Cravo e Pimpinela Promotor de Crescimento FrangosDocumento6 páginasOregano Cravo e Pimpinela Promotor de Crescimento FrangosUrsula HilleAinda não há avaliações

- Cleaning and Cleaning Validation For Formulated Products Manual 040 SampleDocumento7 páginasCleaning and Cleaning Validation For Formulated Products Manual 040 SampleUrsula Hille0% (1)

- Rapid Mixer Granulator Design SpecificationsDocumento10 páginasRapid Mixer Granulator Design SpecificationsUrsula HilleAinda não há avaliações

- GIT Dr. Jahangir Kaboutari Assistant Professor of Pharmacology Faulty of Veterinary Medicine, University of Shahrekord. Shahrekord. IranDocumento110 páginasGIT Dr. Jahangir Kaboutari Assistant Professor of Pharmacology Faulty of Veterinary Medicine, University of Shahrekord. Shahrekord. IranUrsula HilleAinda não há avaliações

- Validation of Swab Sampling Method for Cleaning ValidationDocumento4 páginasValidation of Swab Sampling Method for Cleaning Validationjaanhoney100% (1)

- Blend Uniformity AnalysisDocumento16 páginasBlend Uniformity AnalysisUrsula Hille100% (1)

- Formulas FarmaceuticasDocumento544 páginasFormulas FarmaceuticasUrsula Hille75% (4)

- Formulas FarmaceuticasDocumento544 páginasFormulas FarmaceuticasUrsula Hille75% (4)

- Track roller repairDocumento2 páginasTrack roller repairKhincho ayeAinda não há avaliações

- The 717Documento2 páginasThe 717An LeAinda não há avaliações

- Cleaning Krisbow 2013 (Low Res) 2Documento12 páginasCleaning Krisbow 2013 (Low Res) 2Andres Agung PerdanaAinda não há avaliações

- Host 1Documento6 páginasHost 1Lukman FafaAinda não há avaliações

- 66 67wvh8m8dall BLL-2936104Documento50 páginas66 67wvh8m8dall BLL-2936104ManunoghiAinda não há avaliações

- MS Gree Aircon Midwall Service Manual PDFDocumento55 páginasMS Gree Aircon Midwall Service Manual PDFMacSparesAinda não há avaliações

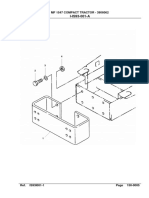

- MF1547Front Linkage - Seat PDFDocumento18 páginasMF1547Front Linkage - Seat PDFAhmad Ali NursahidinAinda não há avaliações

- 32961part Genie Z-45-22Documento138 páginas32961part Genie Z-45-22johanaAinda não há avaliações

- Syabas Water ApplicationDocumento7 páginasSyabas Water ApplicationKen Chia0% (1)

- How to ping NodeB and RNC using RTN transmission IPDocumento14 páginasHow to ping NodeB and RNC using RTN transmission IPPaulo DembiAinda não há avaliações

- Dome AbcsDocumento1 páginaDome AbcsRiddhi BhutadaAinda não há avaliações

- AST Waveguide Switch 1 1 PDFDocumento5 páginasAST Waveguide Switch 1 1 PDFANTONIO MARMOLAinda não há avaliações

- ATI Axially Compliant Compact Orbital Sander: (Model 9150 AOV 10) Product ManualDocumento34 páginasATI Axially Compliant Compact Orbital Sander: (Model 9150 AOV 10) Product ManualRobert KissAinda não há avaliações

- Datasheet Modevapac v2.1 PDFDocumento4 páginasDatasheet Modevapac v2.1 PDFParvezAinda não há avaliações

- Request Documents or InfoDocumento6 páginasRequest Documents or InfoRashika RampalAinda não há avaliações

- Microstation GuideDocumento158 páginasMicrostation GuideMishra KirtiwardhanAinda não há avaliações

- Manual de Teatro en Casa Nuevo PanasonicDocumento56 páginasManual de Teatro en Casa Nuevo PanasonicMiguel Angel Aguilar BarahonaAinda não há avaliações

- IEEEtran HOWTO PDFDocumento28 páginasIEEEtran HOWTO PDFMario CruzAinda não há avaliações

- Elite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21Documento40 páginasElite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21aayush raghav (RA1811003020302)Ainda não há avaliações

- ZQYM Diesel Cummins Series Injector 2023.07Documento13 páginasZQYM Diesel Cummins Series Injector 2023.07harbh9355Ainda não há avaliações

- LRP I Approved ProjectsDocumento1 páginaLRP I Approved ProjectsTheReviewAinda não há avaliações

- Plan for Inspection and Testing of LV Power CablesDocumento1 páginaPlan for Inspection and Testing of LV Power CablesRami KsidaAinda não há avaliações

- 1st Term Exam Part 2 - QSDocumento10 páginas1st Term Exam Part 2 - QSMark Anthony TajonAinda não há avaliações

- HazMat DOTDocumento48 páginasHazMat DOTRenalyn TorioAinda não há avaliações

- 515 TSG PorosityDocumento60 páginas515 TSG Porosityripecue100% (3)

- Section 3.3.4 Neutral Earthing Resistors R1Documento7 páginasSection 3.3.4 Neutral Earthing Resistors R1waelabouelelaAinda não há avaliações

- Ladybug5 DatasheetDocumento2 páginasLadybug5 DatasheetEloy Ricardo Franco FigueiraAinda não há avaliações

- Usb Modem 2Documento4 páginasUsb Modem 2emadAinda não há avaliações

- IWWA Directory-2020-2021Documento72 páginasIWWA Directory-2020-2021venkatesh19701Ainda não há avaliações

- Automated Car Parking System DocumentationDocumento5 páginasAutomated Car Parking System DocumentationVamsiVaddadiAinda não há avaliações