Escolar Documentos

Profissional Documentos

Cultura Documentos

Technical Instructions 1: Printers OEM Info Tools

Enviado por

Didi WilliamsDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Technical Instructions 1: Printers OEM Info Tools

Enviado por

Didi WilliamsDireitos autorais:

Formatos disponíveis

HP2100TECH

Technical Instructions Printers OEM Info Tools 1

CANON PC-1060/1080f Part Number: C4096A Phillips Screwdriver

CORPORATE HP2100 Gram Load: 230 gms Small Flat Blade Screwdriver

LOS ANGELES, USA Yield @ 5%: 5,000 pgs

HP2100TN Needlenose Pliers

US 1 800 394.9900 Pages/Min.: 10

Int’l +1 818 837.8100 HP2100M (Mac) Soft Lint-Free Cloth

FAX 1 800 394.9910 Resolution: 1200dpi Cotton Swabs

Int’l +1 818 838.7047 OEM Cart: $89.00 Anhydrous Isopropyl Alcohol

ATLANTA, USA

US 1 877 676.4223

Int’l +1 770 516.9488 The HP2100 has a lot of similarities to the HP4000, and a few parts are

FAX 1 877 337.7976 interchangeable. It is based on the same development, toner and drum

Int’l +1 770 516.7794

technology but the engines are different and should be treated as totally

DALLAS, USA separate cartridges.

US 1 877 499.4989

Int’l +1 972 840.4989

FAX 1 877 774.1750 Photo 1

Int’l +1 972 840.1750

Step 1

MIAMI, USA

US 1 800 595.429 Place the cartridge top down, drum side

Int’l +1 305 594.3396 up, on the table with the plastic drum side

FAX 1 800 522.8640

Int’l +1 305 594.3309 plate facing you. With a #1 Phillips screw-

driver, remove two screws. Pull the plastic

NEW YORK, USA

US 1 800 431.7884

drum side plate away.

Int’l +1 631 345.0121 (See Photo 1)

FAX 1 800 431.8812

Int’l +1 631345.0690

SANFORD,USA

US 1 800 786.9049

Int’l +1 919 775.4584

FAX 1 800 786.9049 Photo 2

Int’l +1 919 775.4584 Step 2

TORONTO, CAN Rotate the cartridge and remove the

CAN 1 877 848.0818 drum axle pin from the small gear end

Int’l +1 905 712.9501

FAX 1 877 772.6773 using needlenose pliers.

Int’l +1 905 712.9502

(See Photo 2)

BUENOS AIRES, ARG

ARG 0810 444.2656

Int’l +011 4583.5900

FAX +011 4584.3100

MELBOURNE, AUS

AUS 1 800 003. 100

Int’l +62 03 9561.8102

FAX 1 800 004.302

Int’l +62 03 9561-7751

Step 3 Gray 5%

SYDNEY, AUS

Place the axle pin aside. Pull the drum bend or tear the blade, causing future

AUS 1 800 003.100

Int’l +62 02 9648.2630 shutter back and tape it or hold it with toner leaks. If you plan to use the drum

FAX 1800 004.302 your thumb and grab the drum by the again, wrap it in paper and place it to the

Int’l +62 02 9548.2635

small gear end. side.

MONTEVIDEO,URY

URY 02 902.7206

Lift and pull the drum out, being careful

Int’l +5982 900.8358 not to catch the large drum gear on the

FAX +5982 908.3816 corner of the recovery blade, it may

JOHANNESBURG, S.A.

S.A. +27 11 974.6155

FAX +27 11 974.3593

E-mail: info@futuregraphicsllc.com Website: www.futuregraphicsllc.com

2 HP2100 Technical Instructions

Photo 4

Step 5

You can now remove the two pins that

hold the cartridge together. These are

Step 4

tapered pins pushed in from the outside,

Next, using a pair of needlenose so they must be removed from the inside

pliers, grasp the PCR by the metal of the cartridge. With the drum shutter

shaft, remove it, and place it off to held back, use a long punch or thin flat

the side as well. (See Photo 3) blade screw driver, press the tapered pins

out as far as possible, from the inside on

both ends of the cartridge.

(See Photo 4)

Photo 3 Photo 5

Grasp the pins from the outside and

remove.

(See Photo 5)

Step 6 Step 7 Step 8

Set the toner hopper aside for Lift the wiper blade out and away. Dump Clean or replace the wiper blade and rein-

now. Hold the waste hopper out all waste toner from the hopper, stall it at this time. Clean the PCR with a soft

with the wiper blade facing you, being careful not to damage the recov- clean cloth (do not use water or solvents on

and remove the two Phillips ery blade or foam seal (on the upper this PCR, it reacts differently than those of

head screws holding the wiper back of the waste hopper). Clean the previous PCR technology). Reinstall the PCR,

blade. (See Photo 6) PCR saddles with a cotton swab and place the drum in position and reinstall the

alcohol. axle pin and the plastic side plate. The waste

hopper is now finished and can be set aside.

Photo 6 Photo 7

Step 9

Take the toner hopper and place it on the table

with the mag roller side facing you. The drum

cover is easily broken and attached on the left

side by a wire only. On the right side it is

attached by both a wire and the curved,spring-

loaded plastic “drum cover arm”. To remover it,

lift the drum cover spring arm and latch it on

the cutout of the arm. (See Photo 8)

Photo 8

Step 10

Next, take a flat blade screwdriver and pry

the drum arm outward until it comes

completely off the shaft.

(See Photo 8)

Need trust-worthy, detailed Technical

Instructions for another engine?

Visit: www.futuregraphicsllc.com

HP2100 Technical Instructions 3

Photo 9

Step 11

At this point, pull the wire and arm out on

this side until it is completely released Notes

from the toner hopper.

(See Photo 9)

Step 12

Turn the wire back and upward until the

keyed flat piece of the wire on the other

Photo 10 side is vertical and aligned with the vertical

slot on the plastic side plate, then slide it

out. Do NOT force it, as it will come out

easily when aligned correctly.

(See Photo 10)

You have now completely removed the

drum cover (it is very easy to re-install in

reverse order). Set it aside until the end.

Photo 11 Step 13

Next, use a Phillips screwdriver to remove

the two screws on the left (gear) side of

the toner hopper (See Photo 11)

Step 14

Pressing backward on the latch with a

small, flat blade screwdriver remover the

side plate. All the gears will stay attached to

the side cover and can easily be air cleaned.

Photo 12

Step 15

Rotate the cartridge and remove the two

screws on the other end.

(See Photo 12)

Photo 13

Press backward on the latch with a small,

flat blade screwdriver and remove the side

plate.

(See Photo 13)

Need help with a particular remanu-

facturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

4 HP2100 Technical Instructions

Photo 15

Step 17

The mag roller can now be removed.

(See Photo 15)

Step 16

NOTE: Be careful no to lose the small c-

Using a cotton swab and

shaped inner-bearing guide attached to

alcohol, remove all conductive

the stabilizer arm.

grease from the mag roller

contact and replace with fresh

conductive grease. If you

remove the white plastic mag

roller guide, carefully put it Photo 16

back in the correct position. Step 18

NOTE: This mag roller guide will Remove the two Phillips head screws hold-

cause binding if put back on ing on the doctor blade.

wrong.

(See Photo 16)

(See Photo 14)

NOTE: Be careful not to lose the two clear

mylar shims behind the doctor blade.

clear mylar shims

Photo 14 Photo 17

Step 19

Dump the remaining toner from the toner

hopper and vacuum or clean with com-

pressed air. Clean the toner sensor bar with

a cotton swab and alcohol. (See Photo 17)

Step 20

Use a vacuum or compressed air to clean

the mag roller “magnetic seals”.

Step 21 Step 23 Step 24

The hopper may now be filled through the After splitting the hopper and installing Complete re-assembling the toner hop-

magnetic roller opening and reassembled a gasket seal, add the toner through the per, including reinstallation of the drum

in reverse order, if a seal is not to be used. fill plug hole and re-install the plug. cover assembly. Check for toner leak-

Use rail clips or hopper clips to reattach age.

Step 22

both pieces of the hopper back Step 25

If you plan to split and seal the hopper, together, being careful to align them

it must be done so with a splitting properly. With the toner hopper and waste hop-

machine or “dremel” tool along the per units now re-assembled, test each

toner hopper weld as shown by the one for free movement and lack of

arrows in photo 18. (See Photo 18) noise by turning them manually.

Photo 18 Photo 19

Step 26

Finally, join the two hoppers together.

Align them and push the two pins into

place.

(See Photo 19)

The cartridge is now ready for testing.

Future Graphics (FG) is a distributor of compatible replacement parts and products for imagining equipment.

None of FG's products are genuine OEM replacement parts and no affiliation or sponsorship is to be implied between FG and any OEM.

Você também pode gostar

- Technical Instructions 1: Supplies ToolsDocumento7 páginasTechnical Instructions 1: Supplies Toolsapi-3697952100% (2)

- Technical Instructions 1: Printers/Supplies ToolsDocumento6 páginasTechnical Instructions 1: Printers/Supplies ToolsAmaury LoraAinda não há avaliações

- HP1160/1320/P2015 Technical Instructions SummaryDocumento7 páginasHP1160/1320/P2015 Technical Instructions SummaryRicardo LawrenceAinda não há avaliações

- Technical Instructions 1: Printers/OEM Info Tools & SuppliesDocumento5 páginasTechnical Instructions 1: Printers/OEM Info Tools & Suppliesnelutuanv-1Ainda não há avaliações

- Technical Instructions 1: Printers OEM Info ToolsDocumento5 páginasTechnical Instructions 1: Printers OEM Info ToolshusincelejoAinda não há avaliações

- Technical Instructions 1: Cartridge Information Tools & SuppliesDocumento5 páginasTechnical Instructions 1: Cartridge Information Tools & SuppliesWill PughAinda não há avaliações

- Technical Instructions 1: Printers Cartridge Info ToolsDocumento8 páginasTechnical Instructions 1: Printers Cartridge Info Tools202457Ainda não há avaliações

- Technical Instructions 1: Supplies ToolsDocumento8 páginasTechnical Instructions 1: Supplies ToolsRatatam RatatamowiczAinda não há avaliações

- Technical Instructions Printers Cartridge Info Tools 1: CorporateDocumento6 páginasTechnical Instructions Printers Cartridge Info Tools 1: CorporateFilipe FariasAinda não há avaliações

- HP3500/3700 Printer Cartridge Cleaning GuideDocumento8 páginasHP3500/3700 Printer Cartridge Cleaning GuideMomchil IlievAinda não há avaliações

- Technical Instructions 1: Printers OEM Info Tools & SuppliesDocumento11 páginasTechnical Instructions 1: Printers OEM Info Tools & SuppliesMomchil IlievAinda não há avaliações

- Technical Instructions 1: Printers & OEM Info Tools & SuppliesDocumento6 páginasTechnical Instructions 1: Printers & OEM Info Tools & SuppliesMomchil IlievAinda não há avaliações

- XeroxN24,30,42, DC220,332,340 Recycle PDFDocumento10 páginasXeroxN24,30,42, DC220,332,340 Recycle PDFMomchil IlievAinda não há avaliações

- Printers OEM Info Tools: Technical Instructions 1Documento4 páginasPrinters OEM Info Tools: Technical Instructions 1202457Ainda não há avaliações

- Technical Instructions 1: Printers OEM Info ToolsDocumento4 páginasTechnical Instructions 1: Printers OEM Info ToolsservicerAinda não há avaliações

- Step 1: Oem InformationDocumento4 páginasStep 1: Oem Informationlegion4everAinda não há avaliações

- MP 305+SP/SPF (D259) Parts CatalogDocumento159 páginasMP 305+SP/SPF (D259) Parts CatalogRicoh EscanerAinda não há avaliações

- Part List Ricoh 305+ D259 - EXPDocumento168 páginasPart List Ricoh 305+ D259 - EXParnezguidogonzaloAinda não há avaliações

- Technical Instructions 1: Printers OEM Info ToolsDocumento4 páginasTechnical Instructions 1: Printers OEM Info Toolsjt_scribdAinda não há avaliações

- MP305 Part CatalogoDocumento169 páginasMP305 Part CatalogoLeonard FreitasAinda não há avaliações

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Documento2 páginasRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoAinda não há avaliações

- Stylus C80 Parts List and Diagram PDFDocumento14 páginasStylus C80 Parts List and Diagram PDFDeniskoffAinda não há avaliações

- Stylus C70Documento10 páginasStylus C70Luis FeijoóAinda não há avaliações

- Feb 5, 2023 - PartsDocumento3 páginasFeb 5, 2023 - PartsMarvie Magante LonggosAinda não há avaliações

- MP-4054 PM PDFDocumento216 páginasMP-4054 PM PDFlaitang100% (2)

- Parts CatalogDocumento254 páginasParts CatalogDavid RochaAinda não há avaliações

- Ricoh mpc307 407 Parts ManualDocumento244 páginasRicoh mpc307 407 Parts Manualmark adams50% (2)

- Ground Effects I SheetDocumento50 páginasGround Effects I SheetEvanAinda não há avaliações

- Remanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Documento2 páginasRemanufacturing Instructions: Oasis Imaging Products Inc. Technical Support (888) 627-6555Hildeu FigueiredoAinda não há avaliações

- d0cc d0cd D0ce Aa Kor IndDocumento177 páginasd0cc d0cd D0ce Aa Kor IndHoang Minh Pham NguyenAinda não há avaliações

- 500 To 510 Upgrade Procedure Low ResDocumento8 páginas500 To 510 Upgrade Procedure Low Resrolando tapiaAinda não há avaliações

- Partes Manual MP C 307 RicohDocumento262 páginasPartes Manual MP C 307 RicohFernando GuarínAinda não há avaliações

- Kyocera ManualDocumento13 páginasKyocera ManualСлободан Ђекић100% (1)

- Neptune 7 - PeçasDocumento39 páginasNeptune 7 - PeçasManuel Pedro InácioAinda não há avaliações

- TROPO Series :: ROAL Living EnergyDocumento1 páginaTROPO Series :: ROAL Living EnergyMinhAinda não há avaliações

- Laser Engraving Machine PDFDocumento24 páginasLaser Engraving Machine PDFJuan Carlos Arroyave PosadaAinda não há avaliações

- Cartridge Information Tools & Supplies: Step 1Documento4 páginasCartridge Information Tools & Supplies: Step 1servicerAinda não há avaliações

- Inside This Issue: Canon Parts Distributor of The YearDocumento12 páginasInside This Issue: Canon Parts Distributor of The YearStefanAinda não há avaliações

- Thomey SP-100 Pachymeter - Service ManualDocumento21 páginasThomey SP-100 Pachymeter - Service ManualPedro Falci PagotoAinda não há avaliações

- Epson LQ2170: Spares Guide Version 3Documento7 páginasEpson LQ2170: Spares Guide Version 3Nma ColonelnmaAinda não há avaliações

- R815 Service ManualDocumento6 páginasR815 Service Manualjackie tannyAinda não há avaliações

- Install MK-738/FK-512 Mount and Fax KitDocumento6 páginasInstall MK-738/FK-512 Mount and Fax KitmfialloAinda não há avaliações

- 198 Stylus Color 300Documento8 páginas198 Stylus Color 300Toma KuckovAinda não há avaliações

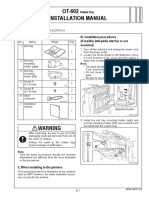

- Installation manual for OT-602 output trayDocumento6 páginasInstallation manual for OT-602 output trayHoussein KachmarAinda não há avaliações

- Ultimaker Original+ Assembly Manual (v3.2)Documento98 páginasUltimaker Original+ Assembly Manual (v3.2)jose maria marin esteveAinda não há avaliações

- Traffic Signal - Operating-InstructionsDocumento4 páginasTraffic Signal - Operating-Instructionsarainzada807Ainda não há avaliações

- Model Cor-C1 Cde (D197/D198/D199/D249/D250/D251) Parts CatalogDocumento194 páginasModel Cor-C1 Cde (D197/D198/D199/D249/D250/D251) Parts CatalogНиколайAinda não há avaliações

- Samsung SC X 4200 TonerDocumento6 páginasSamsung SC X 4200 TonerMarcus RamosAinda não há avaliações

- 1330SE 0407SE PM Rev C Sep 2021Documento217 páginas1330SE 0407SE PM Rev C Sep 2021mehmetAinda não há avaliações

- Cordless Circular Saw Instruction Manual GuideDocumento72 páginasCordless Circular Saw Instruction Manual GuideManuel MpkstroffAinda não há avaliações

- Ardf (D3FE-NA/EU/TWN) Parts CatalogDocumento36 páginasArdf (D3FE-NA/EU/TWN) Parts CatalogBrigitte BardotAinda não há avaliações

- M099/M100 Parts CatalogDocumento82 páginasM099/M100 Parts CatalogChatchawan PhatthanasantiAinda não há avaliações

- Domino - Nozzle RemovalDocumento3 páginasDomino - Nozzle RemovalManutenção eletrônicaAinda não há avaliações

- PC_25,30,35-rfg064473Documento193 páginasPC_25,30,35-rfg064473Ct EntAinda não há avaliações

- FK-506 ImDocumento9 páginasFK-506 ImionutkokAinda não há avaliações

- CX - ABA-1300 LDPE Three Layers Film Blown MachineDocumento6 páginasCX - ABA-1300 LDPE Three Layers Film Blown Machinehoseinifizik1Ainda não há avaliações

- R829 Disassembly ManualDocumento14 páginasR829 Disassembly ManualKo Sai MownlainAinda não há avaliações

- British Commercial Computer Digest: Pergamon Computer Data SeriesNo EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesAinda não há avaliações

- British Commercial Computer Digest: Pergamon Computer Data SeriesNo EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesAinda não há avaliações

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PNo EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PAinda não há avaliações

- Es HpiDocumento48 páginasEs HpidjworkingAinda não há avaliações

- 786.vibration Analysis of Hybrid Composite Leaf SpringDocumento6 páginas786.vibration Analysis of Hybrid Composite Leaf SpringAmaterasu Susanoo TsukuyomiAinda não há avaliações

- ATT03 HTGD690744V0001-B Sequence ValveDocumento8 páginasATT03 HTGD690744V0001-B Sequence ValveEDBAinda não há avaliações

- Sheet Metal Bench Shear PDFDocumento14 páginasSheet Metal Bench Shear PDFmarianrkw100% (1)

- Diaphragm Seals for Food and Pharma IndustriesDocumento4 páginasDiaphragm Seals for Food and Pharma IndustriesJhon Erick Izquierdo SoteloAinda não há avaliações

- Double Cone and Cover GasketsDocumento2 páginasDouble Cone and Cover GasketssubrataAinda não há avaliações

- Filtro Autolimpiante Af 113 MahleDocumento6 páginasFiltro Autolimpiante Af 113 MahleHIDRAFLUIDAinda não há avaliações

- Retrofitting Crude Oil Refinery Heat Exchanger Networks PDFDocumento9 páginasRetrofitting Crude Oil Refinery Heat Exchanger Networks PDFBakti PrasetyoAinda não há avaliações

- Calcul LantDocumento2 páginasCalcul LantDiana Maria CozmaAinda não há avaliações

- DURIT Thermal-CoatingsDocumento8 páginasDURIT Thermal-CoatingsMatheusAinda não há avaliações

- Quotation - 300mm and 250mm Jalan Reko-2Documento11 páginasQuotation - 300mm and 250mm Jalan Reko-2shabow_azwan0% (1)

- Standard Parts and Engineering Design Guide Solution Engineering For Noise Vibration Shock and CushioningDocumento20 páginasStandard Parts and Engineering Design Guide Solution Engineering For Noise Vibration Shock and Cushioningprodn123Ainda não há avaliações

- Nucor Fastener Finished Hex Nuts Are All Formed On PreciDocumento2 páginasNucor Fastener Finished Hex Nuts Are All Formed On PreciJuan DomeAinda não há avaliações

- Aerodynamic principles and equations in Anderson-98101Documento1 páginaAerodynamic principles and equations in Anderson-98101Daniel OrhanAinda não há avaliações

- Catalog Echipamente ServiceDocumento10 páginasCatalog Echipamente ServiceCosmyn IpsilatAinda não há avaliações

- Csi 2130 WP Triaxal AccelerometerDocumento13 páginasCsi 2130 WP Triaxal AccelerometerOrlando MarucaAinda não há avaliações

- CRHV-P600YA-HPB PI Sheet1Documento2 páginasCRHV-P600YA-HPB PI Sheet1vga1234Ainda não há avaliações

- H33 Jet Trajectory Datasheet 0717 PDFDocumento4 páginasH33 Jet Trajectory Datasheet 0717 PDFعبدالمؤمن خالد محمودAinda não há avaliações

- Chapter 4 Input Output DevicesDocumento67 páginasChapter 4 Input Output DevicesM AAinda não há avaliações

- Single Pole Single Throw SwitchDocumento2 páginasSingle Pole Single Throw Switchbernadette domoloan0% (1)

- KIL3012 - WEEK 3 - 24.9.19 (Student Copy)Documento84 páginasKIL3012 - WEEK 3 - 24.9.19 (Student Copy)EdAinda não há avaliações

- Engine Room Simulator ERS 5000: Vessel Model "Tanker LCC" (VERSION 7.2.1100) Trainee ManualDocumento292 páginasEngine Room Simulator ERS 5000: Vessel Model "Tanker LCC" (VERSION 7.2.1100) Trainee Manualalex_alexutzuu100% (1)

- Cmae Prop 3Documento3 páginasCmae Prop 3Mithun Kumar SandaAinda não há avaliações

- Unit 2B Speed and Velocity: Objective(s) : Main Ideas, Key Points, QuestionsDocumento3 páginasUnit 2B Speed and Velocity: Objective(s) : Main Ideas, Key Points, QuestionsHugo ZaldivarAinda não há avaliações

- STD 9th Science and TechnologyDocumento9 páginasSTD 9th Science and Technologyvijay jetnaware52% (48)

- 2.5 GSHP CiatesaDocumento20 páginas2.5 GSHP CiatesaFPrueba1Ainda não há avaliações

- BUFAB Katalog OffshoreDocumento28 páginasBUFAB Katalog Offshoregazwang478Ainda não há avaliações

- Bollhoff Amtec Threaded Inserts For PlasticsDocumento34 páginasBollhoff Amtec Threaded Inserts For PlasticsAce Industrial SuppliesAinda não há avaliações

- Design Strengths For Over Consolidated Clays and Clay Shales Technical PaperDocumento11 páginasDesign Strengths For Over Consolidated Clays and Clay Shales Technical Papermikegibbons27100% (1)