Escolar Documentos

Profissional Documentos

Cultura Documentos

Civil - Bhel

Enviado por

tiwarivivek2Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Civil - Bhel

Enviado por

tiwarivivek2Direitos autorais:

Formatos disponíveis

A) LIST OF APPROVED MANUFACTURERS (CIVIL, CANOPY, PAVER

& SANITARY WORKS)

S.NO. MATERIAL APPROVED MAKES

1 Vitrous China Sanitary Ware as Parryware, Hindware, Cera, Neycer

per IS:2556-1981 part I to XVII,

as applicable

2 Cistern ( China Ware) Parryware, Hindware, Cera, Neycer

3 Washbasin Parryware, Hindware, Cera, Neycer

4 Cast Iron Pipe(Centrifugally Cast NECO, HEPCO, ACL, BIC, RIF, Varuna,

Spun Pipe - IS 3989:1984)

5 PVC Pipe Supreme, Prince, Jain, Finolex, Prakash, QST

6 G.I. Pipe Jindal, Zenith,Tata, Surya, Tirupati, Rama

7 G.I. Fittings R-Brand, K- Brand, Unik

8 Stone Ware Pipe & Gully Trap Perfect Potteries, Barrow’s & CC

9.1 Ceramic tiles H&R Johnson, Somany, Kajaria , Bell, Navin,

Spartek

9.2 Vitrified Tiles H&R Johnson, Somany, Kajaria , Bell, Marbo

Granito, Navin, Spartek,

9.3 Terracotta Tiles Dazzle Designer

9.4 Chequred Tiles NITCO

9.5 Concrete Tiles EUROCON, NITCO

10 Brass Hardware Saifee, tube & hardware

11 Aluminium Hardware Nov Bharat ,Jayant, E.C.I.E & Zaofa

12 Paint and Varnish Asian Paints, Jenson Nicholson, ICI , Berger

Goodlass Nerolac, SNOWCEM (For Cement

Paint)

13 Glass Modi Guard Glass, AIS Float ,Saint Gobain

,Triveni

14 Water tap (A) Brass (C.P.) Jaquar, Parko, Esso, Marc

(B) P.V.C. Modi Calico Chemical

(C) Rubber Park

15 Waterproofing Compound Acco proof ,Pidilite , Cico ,Impermo

16 UPVC Pipe Finolex, Supreme, Prince, ISI marked

17 Superplasticisers and Concete BASF (Rheobuild SP1), Pidilite , Cico

Admixtures

18 HDPE Water Tank Sintex

19 Stoneware pipe, gully trap Mysore, Perfect, ISI marked

20 C.I. Fittings NECO, BIC

21 Butterfly Valves water type Leader, Audco, IVC, Fludiline

Check Valves, Globe Valves, gm

Gate Valves

22 C.I. Covers NECO, BIC, RIF, SIF

Seal & Signature of Bidder HPCL, NCR Zone, Page 1 of 5

S.NO. MATERIAL APPROVED MAKES

23 C.P. Accessories ESS - ESS, Jaquar, Parko, Hindware

24 C.P. FITTINGS Jaquar, Parko, Marc, Hindware

25 Level Switches Switzer, Placks

26 Dewatering Pumps KSB, Crompton

27 Sensor Faucet Jaquar

28 Hand Dryer Technocrats, Euronics

29 Aerosol Dispenser Technocrats

30 Shoe Shining Machine Technocrats

31 Liquid Soap Dispenser Technocrats, Euronics, Askon

32 Water pumps & motors Kirloskar, KSB, Ujala, Crompton

33 Cement Concrete Pipe Indian Hume Pipes Company

34 Structural Steel and MS Plates/ SAIL, TISCO, IISCO, VSPL, JISCO

Sheets (Except small sections )

35 MS Structural Steel Small Conforming IS:2062 as approved by EIC

sections as specified

36 Anchor Bolts Conforming to IS:2062 as approved by EIC

37 Reinforcement Conforming to IS:1786 as approved by EIC

38 Cement ACC, BIRLA, L&T, JK, JP, LAFARGE, AMBUJA

39 Nuts & bolts TVS, GKW, UNBREAKO

40 Electrodes Conforming to IS as approved by EIC

41 Roofing Material INTERARCH, LLYOD STEEL, HUNTER

DOUGLAS, TIGER STEEL, SPECO, CONWED

MULTICOLOR

42 Ceiling Material Interarch, Luxalon ,Hunter Douglas, Tiger

Steel, Conwed, Speco, Harsons and Metacil

(Mfg. M/s Mascot Overseas Pvt. Ltd.).

43 Door Closer/Floor Spring Everite, Sandhu

44 Flush Door IS 2202 Part 1/ Kitply, Anchor Board, Wonder Wood, Duro,

Particle Board National, Green Ply

45 Lamination Formica, Greenlam, Sundek

46 Aluminium Sections Jindal, Hindalco

47 Gypsum Board Ceiling India Gypsum

48 Acoustic Suspended Ceiling Armstrong

49 Thermoplastic Road Marking Berger

Paint

50 Raised Pavement Markers 3M

51 Linear Delineation Sheeting 3M

52 Polyurethane Based Multi- DEGUSSA (Mastertop 1332)

Component Decking System

53 Waterproofing Felt Shalimar

54 Precast CC, RCC KK Manhole & Gratings Co. Pvt. Ltd.,12/16,

Sarvapriya Vihar, New Delhi-16,

Ph.26969550, 26864895; Surabh Ferro

Concrete Pvt. Ltd., KP-278, Maurya Enclave,

Pitampura, Delhi-88, Ph. 65150887

Seal & Signature of Bidder HPCL, NCR Zone, Page 2 of 5

B) APPROVED MAKE - ELECTRICAL ITEMS

S.NO. MATERIAL APPROVED MAKES

1 Meter Boards / MV panels / MCC CPRI tested Manufacturers

2 High Quality LT panels with Hensel, Rittal, Fibox

Polycarbonate Enclosure/Modules

3 SFU / FSU / HRS Fuses L&T, Havells, Alsthom, Standard

Kopp

4 MCB Distribution Boards MDS, Havells, Indo Asian, Hager,

L&T, Siemens, Hensel

5 MCB / ELCB MDS, Havells, Indo Asian, Hager,

L&T, Standard Kopp, Hensel,

Siemens, Lapp

6 PVC Conduits and Accessories Conforming to IS 9537 as approved

by EIC

7 PVC Insulated Copper Wire Conforming to IS 694, Anchor,

Finolex, Plaza, Polycab, RPG,

Havells, Lapp or as approved by EIC

8 Switch / Sockets Anchor Roma, MK India,crabtree

9 Angle Holder / Batten Holder / Ceiling Conforming to IS as approved by EIC

Rose

10 TV / Telephone Socket Anchor Roma, MK India

11 Telephone wire / Cable Conforming to IS as approved by EIC

12 LT cables CCI, Anchor, Finolex, Universal,

Imperial, Nicco, Polycab, RR ,TCL,

Gemscab, Havells, Industrial, RPG,

Lapp make

13 Luminaries / lamps Philips, Crompton, Bajaj, Osram as

advised by EIC

14 Ceiling Fans (Double Ball Bearing) Crompton, Usha, Khaitan,Polar, Bajaj

15 Exhaust Fans Crompton, Usha, Khaitan, Bajaj

16 Emergency Light Conforming to IS as approved by EIC

17 KWH Meter BHEL, SIMCO, ISI Approved Make

18 Ammeter / Voltmeter L&T, AE, IMP, MECO

19 Indicating Lamps (LED type) Siemens, Technic, ISI Approved

20 GI Pipes Jindal, Zenith, Tata, Surya, Tirupati,

Rama

21 Octagonal GI Yard Light Poles Bajaj, Philips

22 Cable Gland Gripwel, Baliga, FCG, EMI, Hensel,

Lapp

23 Lugs Dowells

24 Junction Box Sudhir, Baliga, CEAG for Flame Proof

and Weather Proof Application /

Hensel, Fibox for Weather Proof

application

Seal & Signature of Bidder HPCL, NCR Zone, Page 3 of 5

C.) SCHEDULE OF RATES:SPECIAL GUIDELINES FOR EXTERNAL PLASTERING

(a) Bricks are tested having Efflorescence as nil/slight only before acceptance.

(b) Before plastering, adequate curing should be done of brick masonry for strength

gain. The efflorescence visible on surface of masonry should be cleaned in dry condition

by wire brush and after that with soft brush to remove any remanant of deposits.

Chemical treatment if required should also be carried out before plastering. Plastering

should be done after this exercise.

( c) Profuse curing of plastering should be done during first 7 days.

(d) External plaster finish should be sand faced and NOT smooth finish. Our SOR also

specifies sand faced finish.

(e) The external plastering should be done invariably in two layers with waterproofing

compound mixed as per manufacturers' recommendations and SOR specifications.

(f) Chicken wire mesh should be used in conjunction with first coat of plastering at all

masonry RCC joints (Minimum 15 cm overlap on each side of joint). The wire mesh

should be fixed on wall and RCC surfaces using small nails. First coat of plaster should

be applied after that.

(g) 53 grade cement should NOT be used in plastering and tile fixing.

(h) Water should be tested and it should be potable with ph nearing 7. On change of

source, water should be again tested for conformity to specifications.

(i) Each and every lot of sand brought to site should be field tested for silt content. Any

lot having more than 5% silt content should be rejected and should not be allowed at

site. Lab tests for conformity to grading requirements and for parameters in line with

SOR specifications should be done in addition to field tests.

(j) The mortar should preferably be machine mixed.

Kindly ensure that the job is done as per SOR specifications. Please ensure strict

compliance.

D.) SCHEDULE OF RATES: MODERNISATION / CONSTRUCTION OF RETAIL

OUTLETS UNDER

NORTH CENTRAL RETAIL ZONE

NOTES:

1 Quoted rate shall be applicable for any height, depth, level and thickness of wall

etc unless otherwise specified.

2 Samples of all materials will have to be approved by Engg.-In-Charge before

using the same.

3 All IS Codes referred to shall be of Latest Edition only.

4 List of approved make/brand is attached to technical/commercial bid and

decision of HPCL with regard to selection of make/brand of material to be used

shall be final.

5 All jobs to be carried out as per technical specification attached to

technical/commercial bid.

Seal & Signature of Bidder HPCL, NCR Zone, Page 4 of 5

6 For all cutting/excavation and filling jobs, it will be the responsibility and duty of

the contractor to take joint initial levels with Engg.-In-Charge in all cases before

commencing the work.The joint levels should be certified by the contractor as

well as HPCL Engg.-In-Charge.The payments will be made basis the initial levels

and final levels taken jointly and certified. The pay-ment for all cutting /

excavation will be made at the lower rate applicable for 0 to 3 m and the higher

rate will be paid only for the portion beyond 3 m depth.If the contractor fails to

take jointly certified levels, the levels as taken by HPCL Engg.-In-Charge shall be

treated as final and all payments will be released basis the levels so taken by the

HPCL Engg.-In-Charge.

7 Purchase proof of any material may be asked by HPCL from the contractors.

HPCL reserves right to approach to original manufacturers, authorised

dealers/resellers or any other agency/laboratory for verification of

quality/purchase of materials and documents submitted by contractor.

Appropriate penal action will be taken against the contractor found defaulting

including deductions of amount whole or in part as per discretion of HPCL and

also may result in removal of name of the contractor from approved vendors list

of HPCL.

8 The RCC for all foundation/ D/Way/ Slabs shall have exposed RCC finish i.e. no

plastering shall be done on finished surface of RCC except in case when written

permission has been granted by Engg.-In-Charge, at no extra cost.

9 WBM wherever carried out should be with murrum or stone dust as binder. In no

case mud, soil, sand etc shall be used as binder till written approval of EIC is

obtained..

1 For all mortar/mix preparation mechanical / hand mixer usage is mandatory. In

0 no case hand mixing shall be permitted. Written approval from EIC or for jobs

involving less than one bag cement consumption may be exempted.

1 In no case any welding/hot work shall be carried out at any of the retail outlet

1 premises unless and untill special hot work permit/written approval is sought

from the EIC.

1 Proper formwork as specified in the specifications has to be used in all

2 PCC/RCC works. In no case brick/unfinished planks OR make shift

arrangements shall be accepted as shuttering.

1 Technical specifications and specifications given under job schedule are

3 complimentary to each other. In case of any difference between the two,

specifications given under job schedule will govern.

Seal & Signature of Bidder HPCL, NCR Zone, Page 5 of 5

Você também pode gostar

- Exim Policy 2009-14 HighlightsDocumento8 páginasExim Policy 2009-14 HighlightsSvvs ReddyAinda não há avaliações

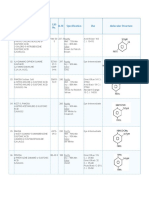

- Sr. No. Commercial Name Chemical Nomenclature Empirical Formula CAS No. M.W. Specification Use Molecular StructureDocumento12 páginasSr. No. Commercial Name Chemical Nomenclature Empirical Formula CAS No. M.W. Specification Use Molecular Structuretiwarivivek2Ainda não há avaliações

- Open Access (Power Trading) PresentationDocumento38 páginasOpen Access (Power Trading) Presentationtiwarivivek2100% (1)

- Purchase PresentationDocumento6 páginasPurchase Presentationtiwarivivek2Ainda não há avaliações

- HRMDocumento104 páginasHRMsreedevi_sree58Ainda não há avaliações

- Exim Policy 2009-14 HighlightsDocumento8 páginasExim Policy 2009-14 HighlightsSvvs ReddyAinda não há avaliações

- Improving Personality Through HandwritingDocumento2 páginasImproving Personality Through Handwritingankita dablaAinda não há avaliações

- Stainless Steel Pressure RatingsDocumento7 páginasStainless Steel Pressure RatingsNauman KhanAinda não há avaliações

- Stainless Steel Pressure RatingsDocumento7 páginasStainless Steel Pressure RatingsNauman KhanAinda não há avaliações

- CMAI - Paul Blanchard - Nylon ABS Review 5.12Documento42 páginasCMAI - Paul Blanchard - Nylon ABS Review 5.12tiwarivivek2Ainda não há avaliações

- Improving Personality Through HandwritingDocumento2 páginasImproving Personality Through Handwritingankita dablaAinda não há avaliações

- Air ConditioningDocumento54 páginasAir Conditioningtiwarivivek2100% (1)

- ISMBDocumento1 páginaISMBtiwarivivek2Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- Nursing Care Plan For Readiness For Enhanced Sleep NCPDocumento4 páginasNursing Care Plan For Readiness For Enhanced Sleep NCPderic100% (2)

- Separating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationDocumento4 páginasSeparating Mixtures: Techniques and Applications: Evaporation, Distillation and FiltrationAndrea SobredillaAinda não há avaliações

- Matriculation Chemistry Amino Acids-Part-1Documento24 páginasMatriculation Chemistry Amino Acids-Part-1iki292Ainda não há avaliações

- Bubba - S Food MS-CDocumento2 páginasBubba - S Food MS-CDũng Trần QuốcAinda não há avaliações

- Fan Adta-En-50hz-March-2018 - 20180315Documento52 páginasFan Adta-En-50hz-March-2018 - 20180315Andi JatmikoAinda não há avaliações

- Corp Given To HemaDocumento132 páginasCorp Given To HemaPaceAinda não há avaliações

- Urie BronfenbrennerDocumento27 páginasUrie Bronfenbrennerapi-300862520100% (1)

- Shelf Life ControlDocumento7 páginasShelf Life ControlRushikesh Deshpande100% (1)

- Pre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka byDocumento41 páginasPre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka by12mchc07Ainda não há avaliações

- SiUS121602E Service ManualDocumento222 páginasSiUS121602E Service ManualpqcrackerAinda não há avaliações

- 3926 An Premium DxiDocumento400 páginas3926 An Premium DxiMartin Bugár100% (2)

- Clobazam For The Treatment ofDocumento3 páginasClobazam For The Treatment ofpronto4meAinda não há avaliações

- QuestionnaireDocumento2 páginasQuestionnaireMili Gada100% (8)

- Case Study MMDocumento3 páginasCase Study MMayam0% (1)

- Significant Supreme Court RulingsDocumento5 páginasSignificant Supreme Court Rulingsapi-307941674Ainda não há avaliações

- Calamity and Disaster Preparedness Chapter IXDocumento34 páginasCalamity and Disaster Preparedness Chapter IXANGEL ALBERTAinda não há avaliações

- Hazard Risk Assessment of Roof of The Mazanine Floor..Documento15 páginasHazard Risk Assessment of Roof of The Mazanine Floor..Akhtar BahramAinda não há avaliações

- Microbiiology Lab LayoutDocumento9 páginasMicrobiiology Lab LayoutNageswara raoAinda não há avaliações

- Envirotainer RKN E1 Operations ManualDocumento46 páginasEnvirotainer RKN E1 Operations ManualJorge de oliveiraAinda não há avaliações

- Solid Dosage Form Part 1Documento48 páginasSolid Dosage Form Part 1Claire Marie AlvaranAinda não há avaliações

- Future Proofing Cities Toolkit by Craig Applegath 2012-03-01sm PDFDocumento20 páginasFuture Proofing Cities Toolkit by Craig Applegath 2012-03-01sm PDFJorge Fernández BaluarteAinda não há avaliações

- Elasticity, Plasticity Structure of Matter: by DR R. HouwinkDocumento9 páginasElasticity, Plasticity Structure of Matter: by DR R. HouwinkKhlibsuwan RAinda não há avaliações

- Indian MaDocumento1 páginaIndian MaAnass LyamaniAinda não há avaliações

- Jurnal RustamDocumento15 páginasJurnal RustamRustamAinda não há avaliações

- YuzurtDocumento2 páginasYuzurtFranco Ascari100% (1)

- Steen Kamp 2021Documento16 páginasSteen Kamp 2021LARANSA SOLUNA GOGO SIMATUPANGAinda não há avaliações

- Pulverizers: By: G. RamachandranDocumento140 páginasPulverizers: By: G. Ramachandranshivshankar prajapatiAinda não há avaliações

- Job Vacancy Kabil - Batam April 2017 RECARE PDFDocumento2 páginasJob Vacancy Kabil - Batam April 2017 RECARE PDFIlham AdeAinda não há avaliações

- Labour Laws in India FINALDocumento55 páginasLabour Laws in India FINALSneha Periwal0% (1)

- P13Documento21 páginasP13Saeful AzizAinda não há avaliações