Escolar Documentos

Profissional Documentos

Cultura Documentos

KS-2.328 & KS-2.656 Padrão de Regulador de Voltagem 11kV

Enviado por

fabiano_projeto0 notas0% acharam este documento útil (0 voto)

11 visualizações9 páginasKS-2.328 & KS-2.656 Padrão de Regulador de Voltagem 11kV

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoKS-2.328 & KS-2.656 Padrão de Regulador de Voltagem 11kV

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

11 visualizações9 páginasKS-2.328 & KS-2.656 Padrão de Regulador de Voltagem 11kV

Enviado por

fabiano_projetoKS-2.328 & KS-2.656 Padrão de Regulador de Voltagem 11kV

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 9

‘SPECIFICATION SUBMISSION SHEET

(Attachment to the Tender submission sheet)

om: VotageRaputor xs.2azn a xs.ness) (70 Peed By the Tenderer) sub Package, , Rated range of regulation: TFT TOR of input waliage in 16 steps nether

[a Rated KVA output KS2,328 7 KS-2.656 DOBKVA /416 KVA

fo. = 110KV

fo, Tank: a) Design ‘Seed Tank Design

b) Exterior Colour NEMA grey # 70

Ii: Type of Connectors & Terminal Bolted damp type bronze alloy threaded stud

2. Connector size - 2 Nos. 500 MCM bare 37 strand MHD Cu

No. 4/0 AWG bare stranded MHD Cu

13. Exel power supply voltage to contr} cabinet 240y, 50 Hz

34. a) Position indicator iectromechanical & Sha be on the ront top

) Tap pesiton showing capabilty Present, Minimum & Maximum

15. Height of contol cabinet_— 60" above mounting pad

Sl ESSm Sinner Eas nase Required Yor Regulators having helght less than 5

17. Cooting media Non PCB al (ype nf’ nme tobe mentened )

8, Control settings - -

2) Voltage level 305V -135¥ with @ resolution SV

b) Band with (Min” range) (O.SV SV with 2 resolution 0.5V

€) Time delay (a range) 10 sec 150/sec with a resolution 10 sec (¥in”)

‘LOC settings ‘Shall be capable to set resistance & reactance:

19, Temperature rise Not exceeding 55 deg. C

lou ns

a. eushing peo saan a MS HT

JAuto & Manual control provision, Increased capacty|

2s. Accessories . feature, Multifunction electronic meter to read

incoming & outgoing voltage, load current & PF et

2, Additional Materia requirement for each ‘One fuse foreach type & size

reguator ‘Gneft) face cover for each type of gauge

“Two (2) copies of Instaleton , OSM manual

[23 Test Report of offered em =

2) Name of Testing laboratory "To be mentioned

. ‘berthan ‘Shou beteatonaty recognized epee

1) Stats of the abort, eB spected eerie

©) Routine test

|) Resistance measurements ofall windings Shall be fornished

1 Ratio tests on alltap connection ‘Shall be furshed

Ti) Polarity and Phase relation test Shall be fursshed

Ty) Excaton ls at ted vag & eave ‘Shall be furnished

y) Exton curer tted vag & eave ‘Shall be furhished

1) 96.65 oss a ate erent 8 egue ‘Shall be furnished

wi) Temperature rise test ‘Shall be furnshed

i) Delectic Test

1) Applied Potential test ‘Shall be furnished

i) Induced potential test ‘Shall be furnished

Th inause test using 12/50 nigesee waver Shall be furnished

3) Load Toss ‘Sia be Fumihed

i) Exctavon 1s ; Shall be furnished

a ‘hou Beas per Shipping Box Design NOE of

[24 Packing Se Exhibit -£ of ba document

— REB ITEM: KS-2.328 & KS-2.656

PUBLICATION 916-2000

RURAL ELECTRIFICATION BOARD (REB)

PEOPLES REPUBLIC OF BANGLADESH

STANDARD FOR

11 KV VOLTAGE REGULATORS

1. SCOPE:

This standard establishes the preferred ratings, performance requirements and application

criteria for 11 KV automatic step-voltage regulators.

2. GENERAL

11 KV automatic step-voltage regulators furnished to REB specifications shall conform in all

respects to the performance requirements and other criteria stated in this standard,

3. REFERENCE DATA:

REB designations for Voltage Regulator type are:

kS-2.328: 11,000/6350 volts, 328 amps for 5 MVA sub-station, pad mounted, Single

Phase Regulator.

KS-2,656: 11,000/6350 volts, 656 amps for 10 MVA sub-station, pad mounted, Single

Phase Regulator.

4. PREFERRED RATINGS:

REB automatic step-voltage regulators shall be used in a tropical climate with high annual

rainfall and shall meet the following temperature and altitude conditions:

a. Ambient temperature: 50°C

b. Altitude - up to 1000 meters,

Preferred ratings are defined in USAS C57.15. These preferred ratings, which will be

specified in REB purchase orders are summarized below:

4.1 Rated Frequency: SO HZ.

4.2 Rated Current

The maximum current that the regulator can supply continuously up to the maximum range

of regulation without exceeding the specified operating temperature limits. This shall be

328 A and 656 A for the KS- 2.328 and KS-2,656 respectively

Publication 916-2000, Revision: 0, Date: June, 2000, Page 1 of 8

—134-

43

44

45

46

47

__REB ITEM: KS-2.328 & KS-2.656

Short-Time Rating

‘The maximum constant load that the regulator can supply for a specified interval without

exceeding the’ specified operating temperature limits. Short time rating of the AVR with a

reduced range of regulation shall be 160% of the normal rating with + 5% regulation,

Rated Voltage

‘The maximum voltage for which the step-voltage regulator performance characteristics are

based. This shall be 14.5 KV.

Rated Range of Regulation

‘The amount that the regulator can raise or lower the rated voltage. The range is described

in positive and negative percent of rated voltage. This shall be ( 10%) of the source

voltage.

Rated KVA Output

‘The product of the rated current (amperes) and the rated range of regulation (KV)

BIL: 110 KV

5. DESIGN REQUIREMENTS:

a)

al

a2

The voltage regulators shall be of sealed tank design. The range of regulation shall be plus-

minus ten percent + 10%) of the input voltage in five eighth percent (5/8%) steps of a

total of 16 steps in either direction

Connectors:

Each voltage Regulator will be Supplied with:

Three (3) bolted clamp type bronze alloy threaded stud connectors for 1-1/8-12 threaded

stud type terminals. Two connectors shall accommodate one (1) 500 MCM bare 37 strand

MHD copper conductor (source and load bushings) and one connector shall accommodate

‘one 4/0 AWG bare strand MHD copper conductor (neutral bushing)

Two bolted bronze alloy ground clamps to accommodate one 4/0 AWG bare copper

conductor. These clamps are to be utilised for connecting the voltage regulator tank to the

4/0 bare 19 strand copper substation ground grid system.

Publication 916-2000, Revision: 0, Date: June, 2000, Page 2 of 8

—135-

REB ITEM: KS-2.328 & KS-2.656

b) Control Cabinet:

ba

b2

b3

ba

bs

b6

‘The control cabinet must accept 240 volt, 50 Hertz test input voltage for testing of voltage

regulator with external power supply. The centre of the control cabinet shall be sixty inches

(60") above mounting pad ground level.

All read-out type instruments are to be provided with anti-fungus cover and sealed for

tropical climate.

An electromechanical position indicator shall be installed on the front top of the V.R. to

indicate the present, maximum and minimum tap position to show the regulation by the

V.R. The position indicator shall be provided with a "Raise" & "Lower" limit switch to control

% regulation,

Only non-PCB oil shall be used in the voltage regulators. Specify type and manufacturer of

the oil used.

The exterior colour of the regulators shall be NEMA grey No. 70

Elevating Support Base:

For grounding purposes, the support bases are to be drilled, on opposite base corner legs

and located one foot (1'-0") from the bottom of the base , with two (2) 9/16" round holes

spaced at 1-3/4” centres. Elevating support bases shall be hot- dip galvanised after

fabrication.

The Sub-Station Mounting voltage regulators having a height of less than nine feet (9'-0")

to the lowest part of any live terminal shall be supplied with adjustable elevating support

bases to place them at that minimum height. The bases shall be made of steel to provide a

sturdy, stable foundation for the regulators, and be complete with provisions to secure the

base to regulator concrete foundation plus secure the regulator to the base.

A permanent nameplate detailing all pertinent design and setting information shall be

affixed to the voltage regulator.

Accessories:

Each regulator shall be complete with all standard accessories, such as automatic and

manual control provision, increased capacity feature and a multifunction electronic meter to

read incoming and outgoing voltage, load in ampere and power factor.

Additional Material Requirements:

Each Voltage Regulator shall be supplied with the following additional materials:

a) One (1) fuse for each type and size of fuse in the regular control panel.

b) One (1) face cover for each type of gauge mounted on the voltage regulator.

©) The supplier shall furnish the purchaser with two (2) copies of the Installation,

Operation and Maintenance Manual for each Voltage Regulator with a copy of Voltage

Regulator parts list. The manuals shall be packaged to avold moisture or other types of

damage. The supplier without additional cost to the purchaser shall promptly replace any

damage and/or otherwise non-usable manuals received by the purchaser.

Publication 916-2000, Revision: 0, Date: June, 2000, Page 3 of 8

-136-

REB ITEM: KS-2.328 & KS-2.656

7. PERFORMANCE REQUIREMENTS:

7.1 Insulat

tion Class Designation

‘The insulation class designation indicates the maximum voltage the regulator can withstand

during dielectric tests conducted in accordance with USAS C68.1 and presented in the

following tables.

INSULATION CLASS OF OIL-IMMERSED REGULATORS (USAS C57.15)

Rated Voltage Between Terminals (KV)

L Single - Phase 3-Phase_ |

For Wye Connection | For Delta Connection Delta or Wye Insulation |

on three phase on three phase ‘Connected Class

|____system, system, _

0-0.069 0-0.069 6120 1.20

> _ 2.50 [250

[2.89 2.89 5.00 [ 5.00

8.66 15.00 15.00, 15.00

14.40 25.00 25.00 25.00

19.90 To 34.50 34.50 34.50,

26.60 46.00) 46.00 46.00

39.80 69.00 69.00 69.00

Dielectric Test for Oil Immersed Regulators (USAS C 57.15)

Impulse Tests - 1.2x 50 (Micro-sec wave)

Nominal Chopped Wave

System Insulation Low-Frequency Min Time to

Voltage Class Tests Flashover Full wave

kv kv kv rms KV Crest Micro-sec. KV Crest

1.20 1.20 10 36 1.00 30

2.40 2.50 15 54 1.25 45

4.80 5.00 19 69 1.50 60

8.32 8.66 26 88 1.6 B

14.40 15.00 34 110 1.80 95

23.00 25.00 50 a5 3.00 150

34.50 34.50 70 230 3.00 200

46.00 46.00 95 290 3.00 250

69.00 69.00 140 400 3.00 350

7.2. Accuracy Class of Regulator Control Device

‘The accuracy with which the control device can maintain the desired voltage at the

regulator output, The total error is based upon the sum of errors determined under the

varying conditions listed below with their corresponding reference points.

Publication 91

(6-200, Revision: 0, Date: June, 2000, ~~ Page

—137-

4 0f8

REB ITEM: KS.2.328 & KS-2.656

73

74

75

Publication 916-2000, Revision:

Condition Reference Point

Ambient temperature 25°C

System frequency 50 Hz

Regulator load Rated output voltage,

zero load current

Regulator Position Neutral setting

Accuracy Classes are described as follows:

Accuracy Class Total percent Error

1 +h1

2 442

5 +5

Control Settings

Voltage Level:

The V.R, control circuit shall have the capability to set a voltage level ranging from 105,

volts to 135 volts with a resolution of 5 volts.

Band Width:

The V.R. control circuit shall have the capability to set a band width from 0.5 volts to 5.0

volts (Min. range), with a resolution of 0.5 volts.

Time Delay:

The V.R. control circuit shall have the capability to set a time delay setting from 10.0 sec to

150 seconds (minimum range) with a resolution of 10 seconds (minimum)

LDC Settings:

‘The V.R. control circuit shall have the capability to set Resistance and Reactance settings

equivalent to line impedance of the 11 KV distribution system of a 5/10 MVA 33/11 KV sub-

station.

Radio Influence Voltage (RIV)

The RIV levels shail not exceed 100 micro-volts at 1000 KV when measured at 110% of

rated voltage, with the regulator tap set at the neutral position. RIV tests shall conform to

the requirements of NEMA Pub. No. PH107.

Bushing

Regulator bushings shall have an insulation class not less than that of the winding to which

they are attached. These bushings shall be capable of with-standing dielectric test voltages

as follows:

), Date: June, 2000, Page 5 of 8

~ [38-

REB ITEM: KS-2.328 & KS-2.656

Outdoor Bushings

50 Hz Withstand Impulse-Full Wave

Dry Withstand

Insulation 1 Min 10 Sec KV Crest

Class Diy, KV Wet, KV (1.250

kV rms rms Micro-sec)

1.20 10 6 30

2.50 15 B 45

5.00 21 20 60

8.66 7 24 75

15.00 35 30 95

25.00 70 70 150

34.50 95 95 200

46.00 120 120 250

69.00 175 175 350

* Wet withstand values are based on water resistivity of 7.00 Ohm-inches, and

precipitation rate of 0.2 inch per minute.

Requirements and test procedures of outdoor bushings are presented in ANSI C76.1.

7.6 Lock Washers:

Lock Washers shall be required on all electrical connections. Lock washers shall be

fabricated with materials that comply with ANSI B18.21.1

8. TEST REPORTS:

The following routine and type test reports shall be performed in an independent testing

laboratory and submitted with the proposed bids:

Routine tests which include

a) Resistance measurements of all windings on the rated voltage connection.

b) Ratio tests .on all tap connection and the rated voltage connection,

©) Polarity and phase relation tests on the rated voltage connection,

4) Excitation loss at rated voltage and frequency on the rated voltage connection.

¢) Excitation current at rated voltage and rated frequency on the rated voltage

connection.

Impedance and load loss at rated current and rated frequency on the rated voltage

connection.

9) Temperature rise tests.

Publication 916-2000, Revision: 0, Date: June, 2000, - Page 6 of 8

—139-

REB ITEM: KS-2.328 & KS-2.656

lectric tests including

a. Applied potential tests.

b. Induced potential tests.

. Impulse tests using a 1.2/50 microsecond waveform.

Dielectric tests shall be conducted in accordance with USAS C68,1 (IEEE No.4.)

and section 4.3 of USAS C57.15.

Losses

a Load loss.

b. Excitation loss

These tests shall be performed in accordance with the test code procedure/

presented in section 6 of USAS C57.15.

TEMPERATURE RISE LIMITS:

‘The operating temperature limit of an oll-immersed step-voltage regulator is the maximum

winding temperature rise above ambient when the regulator is delivering its rated KVA

output at its rated current.

The limits of temperature rise are presented in Table 4 of USAS C57.15 and summarized

below.

Winding Temperature

Item Apparatus _Rise by resistance (°C) _ Temperature Rise (°C)

a. 55°C Rise 55 65

b. Metallic parts in contact with or adjacent to the insulation shall not attain a

temperature in excess of that allowed for the hottest spot of the windings adjacent

to that insulation. 7

¢. Metallic parts other than those covered in item 2 shall not attain excessive

temperature rises.

d. The regulator shall be equipped with sealed tank. The temperature rise of the

insulating oil shall not exceed 55°C when measured near the top of the main tank.

Publication 916-2000, Revision: 0, Date: June, 2000, ‘Page 7 of 8

= 140-

REB ITEM: KS-2.328 & KS-2.656

10. NAME PLATE:

The following information shall be printed on the nameplate:

1, Manufacturer's name and / or identification mark.

2. Contract number and IFB number.

3. Regulator type and serial number.

4, Diagram of connections.

5. Number of phases.

6. Rated frequency

7. Rated current.

8 Rated Voltage.

9. Rated KVA.

10. Rated range of regulation

11, Impulse level, full wave in KV.

12. Total weight.

11, INSPECTION:

The manufacturer shall perform inspections and tests necessary to determine if the liquid

immersed automatic step-voltage regulator complies with the requirements of this

standards, REB reserves the right to witness factory tests, and shall request test reports.

12, OTHER STANDRDS:

‘The preferred. ratings and performance requirements of the liquid immersed automatic

step- voltage regulator based on other internationally recognized standards are acceptable

only if the requirements of this document are met.

13. BIBLIOGRAPHY OF REFERENCE STANDARDS: Latest Edition

1. USAS C57 - 1!

Voltage and Induction- Voltage Regulators.

2. USAS C 68-1: USA and IEEE Standard Techniques for Dielectric Tests.

3. NEMA Pub-PH 107: NEMA Standards Publication-Methods of Radio Influence Voltage

(RIV) of high-Voltage Apparatus.

4. ANSI B 18.21.1: American National Standard for Lock Washers.

ISA Standard Requirements, Terminology and Test Code for Step-

‘Publication 916-2000, Revision: 0, Date: June, 2000, Page 8 of 8

149

Você também pode gostar

- Tabelas de conversão e fórmulas para roscas NPT, UNF, BSP e métricasDocumento1 páginaTabelas de conversão e fórmulas para roscas NPT, UNF, BSP e métricasJoenewwave100% (1)

- Norma técnica CELG para transformadores de potênciaDocumento91 páginasNorma técnica CELG para transformadores de potênciafabiano_projetoAinda não há avaliações

- IEC 60255-22-2 (Ed3.0)Documento30 páginasIEC 60255-22-2 (Ed3.0)fabiano_projetoAinda não há avaliações

- K-1 & K-2 Modelo para Reguladores de VoltagemDocumento9 páginasK-1 & K-2 Modelo para Reguladores de Voltagemfabiano_projetoAinda não há avaliações

- OHSAS18001-2007 Versao PTDocumento35 páginasOHSAS18001-2007 Versao PTSandro VieiraAinda não há avaliações

- IEC 60255-22-4 (Ed3.0) BDocumento30 páginasIEC 60255-22-4 (Ed3.0) Bfabiano_projetoAinda não há avaliações

- Determinação do índice de refraçãoDocumento3 páginasDeterminação do índice de refraçãofabiano_projetoAinda não há avaliações

- AterramentoDocumento27 páginasAterramentoJonis SantosAinda não há avaliações

- Impulso AtmosfericoDocumento3 páginasImpulso Atmosfericofabiano_projetoAinda não há avaliações

- Fispq Lava Loucas RegularDocumento15 páginasFispq Lava Loucas Regularfabiano_projeto100% (1)

- W1943 CFGDocumento1 páginaW1943 CFGgabrielslacerdaAinda não há avaliações

- Material Sobre Oleo VegetalDocumento13 páginasMaterial Sobre Oleo Vegetalfabiano_projetoAinda não há avaliações

- Conversão de potência HP em KVA para motores trifásicos e monofásicosDocumento1 páginaConversão de potência HP em KVA para motores trifásicos e monofásicosfabiano_projetoAinda não há avaliações

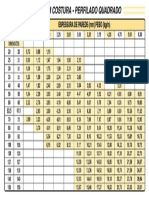

- Tubos - Costura Perfilado QuadradoDocumento1 páginaTubos - Costura Perfilado Quadradofabiano_projetoAinda não há avaliações

- N-381 - Execução de Desenhos e Outros Documentos Técnicos em GeralDocumento19 páginasN-381 - Execução de Desenhos e Outros Documentos Técnicos em Geralfabiano_projetoAinda não há avaliações

- Curso de Fotografia National GeographicDocumento71 páginasCurso de Fotografia National GeographicAnnelise Grottker de OliveiraAinda não há avaliações

- Simulação dos regimes operacionais térmicos de transformadoresDocumento25 páginasSimulação dos regimes operacionais térmicos de transformadoresfabiano_projetoAinda não há avaliações

- Manual Tel Sem Fio KX-TG4011LBTDocumento52 páginasManual Tel Sem Fio KX-TG4011LBTDezirèè Bregano33% (3)

- Mestrado RT22008 MarianaDocumento83 páginasMestrado RT22008 MarianaAlessandro_Mac_3991Ainda não há avaliações