Escolar Documentos

Profissional Documentos

Cultura Documentos

Knife Making Part 1

Enviado por

waltergenkDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Knife Making Part 1

Enviado por

waltergenkDireitos autorais:

Formatos disponíveis

Knife making tutorial [part 1, the knife handle]

Outdoors-Magazine.com

http://outdoors-magazine.com

Amateur

Knife making tutorial [part 1,

the knife handle]

James

- Skills and guides - DYI, Making things. -

Publication: Tuesday 16 May 2006

Description :

Explains in detail how to make a knife from existing parts.

Copyright (c) Outdoors-Magazine.com under a Creative Commons

Attribution-Non-Commercial-Share Alike License

Copyright © Outdoors-Magazine.com Page 1/9

Knife making tutorial [part 1, the knife handle]

I have been for a long time what most people call a knife nut[:-)] After a modest collection, this was prone to lead me

to knife making.

An easy way to start it to buy pieces, or a kit. Brisa.fi by example sell parts, and the blades are relatively cheap. They

also have great tutorials, but you will find mine here. Let's start simple with easily available materials and tools.

We will not cover here how to make a blade from scratch, that will come in the last part of the series and part two will

cover sheath making.

The first thing to do is to gather all the materials and tools needed:

Materials:

• Wood block for the handle

• Blade

• Bolster (preferably pre-pierced and preshaped)

• Spacers, or other material that are used.

• Epoxy glue

• Acetone

• Duct tape

Tools:

• Orbital grinder, or angle grinder with speed control and a rubber disk.

• Sand paper, different grits, the coarser the fastest, the finer for the best finish.

• Drill and long drill bit, 4mm diameter(or adjusted to the tang diameter)

• Thinned chisel (4mm width)

• Mechanical saw blade reground and fitted with a handle in order to make the tang hole)

• Wood saw, mechanical or hand driven

• Metal saw

• Vise

• Little gadgets as shown in the pictures

I have a good selection of mechanical tools, but all this can be done by hand. You will be glad however to have at

least a mechanical drill and sander. I tried to keep this as generic as possible, though indeed the pictures show the

making of one knife, and are therefore more specific.

You can click on the images in order to get a more detailed view.

Preparing materials

Squaring the wood blank For a beginner, it is easier if everything is square.

Copyright © Outdoors-Magazine.com Page 2/9

Knife making tutorial [part 1, the knife handle]

Squaring the wood block can be done by hand or using a bench grinder.

Drilling the block slow speed and care, and a lot of checkings.

Then the block is drilled. Here you see a a press drill, but frankly, I do better by hand. Since a 20 cm x 4mm drill bit is

very flexible, it is easier to drill by hand taking care to compensate and align, than using the press. If you drill using a

press, you'll be glad you squared the block... Mark on the outside of the block the expected path for the bit in the two

dimensions, and check that the bit follows the path.

Cutting and sanding the tang Cut the tang to desired length, and send it using coarse grain.

The tang needs to be cut to the right length. Depending on the assembly type you are planning, it may mean none at

all (tang goes through a butt plate) or a few mm or cm from the handle end. You need to use your hand to decide the

final handle shape and size. Some prefer a drawing, I prefer the intuitive approach, everybody has his own way![;-)]

The coarse grinding of the tang ensures a better adhesion with the glue in the later gluing stage. This Lauri PT blade

also needs the tang to be squared for the bolster to fit properly.

Preparing the tang hole Here we need to check the alignment of block and tang.

Plan the tang hole. It may be interesting at this point to trace on the outside of the block the dimensions of the

channel that will be prepared for the tang.

Sand the bolster We make the pre-pierced bolster flat.

Prepare the bolster. Here I use a pre-shaped bolster, but you may also cut it from a plate of silver-nickel or brass. In

which case you will also have to drill and file the tang hole. The premade bolsters are rather flat, though embossed

so you may need to flatten it. To do this, I use a simple block of wood with two nails planted at strategic distance to

hold the bolster well, and sand either on a sand paper laying flat on the table, or on a machine.

Copyright © Outdoors-Magazine.com Page 3/9

Knife making tutorial [part 1, the knife handle]

Cutting spacers I use wood spacers

Spacers ready different colors.

I use thin wood spacers between the bolster and handle block, so I prepare and cut these to dimension.

Fitting the tang and bolster

Fit bolster to the blade It probably needs to be filed a little, or more.

Check bolster on blade Yes it is perfectly level everywhere. OOps, I cut myself. learn from this and wrap the edge

of the blade in duct tape from the early stages!

Good adjustment There are no spaces, the fit is perfect. Avoid dropping blood everywhere!

Adjust the bolster to fit the tang as perfectly as possible, so file it and check the fit often. Invest in a few fine jeweller

files of different sections, it will be well worth it.

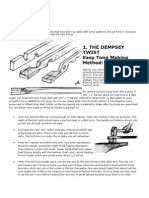

The modidified saws blades Here are the tools I use for enlarging and fitting the tang hole.

These are the most convenient tools in order to enlarge a drilled tang hole. It is a mechanical jigsaw blades ground at

the top and inserted in handles. There is no commercial equivallent, you will need to make these. take care about

heat building in the seteel when you grind them. Please note, on the picture the 3 types of blades, at the top, a model

with straight sharp edged teeth, designed for cutting wood across the grain, very useful to make straight edges and

angles. The two lower models are scrapers, they have wide set teeth, and work marvels in the deep of the hole. The

last model is better for finition and soft metals. Another tool I use often is a thin long chisel, originally 6mm, ground to

4, as it allows fast removal of material when the tang hole is square. Some tangs, on traditional blades taper toward

Copyright © Outdoors-Magazine.com Page 4/9

Knife making tutorial [part 1, the knife handle]

the end in all directions, and these are better fitted using the saw blades.

Fitting the tang - maybe You can use this, but it is a bit violent, and wont got the full length.

Fitting the tang -really Better use this, a 4mm wide chisel, in company of a saw blade will do wonder.

Checking things Well now, we need to check everything fits. Probably the angle of the block at the bloster will need

adaptation.

Then we need to fit the tang. The best way to do this, is either to drill a huge hole, but the adjustments are clumsy,

and a lot of glue will be needed. This requires some work but be patient, the result is well worth doing. This method

allows perfect adjustments, not that important when there is a bolster, but very important when there is no bolster. It

is important to check the angle at which the block of wood meets the bolster. As the block was squared at 90

degrees, there may be some angle where it meets the bolster which will need to be corrected for a perfectly flat fit.

This happens because the bolster may be at an angle slight ly different than 90 degrees with the tang, or that you

made the tang hole asymmetrical in the wood block. No problem either ways, just adjust the angles.

Gluing the tang

Acetone cleaning Acetone is mandatory to remove any grease trace.

Clean every piece to glue in acetone, at least two times. This will remove finger prints. Fingers always leave a greasy

print, even when clean, so do not touch any of the areas of the parts to glue with bare hands once they're cleaned. In

general plan for the smallest thickness of glue as possible. Glues have poor side force strength in large thicknesses.

Doing this and ensuring the surfaces to glue are rough will make an optimal bonding.

Prepare glue I used kevlar in it, but avoid it, simpler to use only epoxy glue.

Prepare the glue. Consider the time the glue takes for hardening. Do not start difficult and complex stacking using a

5 minute glue. Epoxy glues work great. Generally slower epoxy glues provide better bond than faster ones. Respect

Copyright © Outdoors-Magazine.com Page 5/9

Knife making tutorial [part 1, the knife handle]

the proportions of catalyst and resin, and mix well for a few minutes, the bond will be better. Here you can see some

kevlar fibers that will be mixed in to the glue for the tang fitting, avoid fibers for gluing the bolster and spacer stacks,

they are difficult to use.

Gluing Apply the glue everywhere.

Perform the gluing. Apply glue on all surfaces of the stack, fill the tang hole. Do not hesitate to use excess glue. Have

a lot of excess glue squeezing out as you assemble.

Put in the vise A vise is indeed useful in order to maintain the assembly until the glue takes.

Then you need to put your stack under pressure in a bench vise, a hand vise, or any system you may have made.

Make sure whatever system of clamping you use that it also pushes on the blade.

Cleaning the glue Clean the places which needs to be with aceton and cloth before the glue hardens.

We are not yet finished. After the glue has started thickening, but before it is totally hard, clean the parts that needs

to be, using a rag and acetone. You will be happy not to have any hard glue to remove later. You can now let the

glue set until it reaches maximum strength (or close — read the glue specifications).

Gluing result This is what you get once the tang is glued.

And here is the result, A homogeneous block. I had to destroy a few handles made this way, and it is, quite

surprisingly, a tough hammering job.

Shaping

Copyright © Outdoors-Magazine.com Page 6/9

Knife making tutorial [part 1, the knife handle]

Prepare for sanding At that stage the blade (and you) needs protection.

First let's remove the extra glue and make for the right thicknesses.

Grossly cut handle to shape This is done using a saw.

Once this is done, it is good to give the general outlook by sawing the block to the right outlines. I do this by eye,

some may prefer to follow plans.

Coarse shaping Then, making progressive bevels, coarse grind the handle to the desired shape.

Then the shaping takes place, use a bench or orbital grinder, using coarse grit paper, or a set of files, whatever you

have at hand, and feel comfortable with. The shape comes by progressively and symmetrically removing bevels until

the desired curves are reached. I personally use an orbital grinder and a 24 grit paper, which is extremely coarse.

Details of the shape A handle shape is a 3d work, better check often how it fits the hand.

Detail shaping And finish the sanding with finer papers.

The detail shaping takes place using progressively thinner grits and refining the shape. I often check in my hand to

see how it feels, until I am satisfied. It is also time to start rounding things.

Band sanding Block the knife and use a band of paper to finish the round shapes.

A good way to finish the curves is to use a band of sandpaper and pass it around the handle while the blade is held

in a vise.

Copyright © Outdoors-Magazine.com Page 7/9

Knife making tutorial [part 1, the knife handle]

Finishing Finish by hand using very fine sand paper.

A little extra A butt decoration, an insert made of mother of pearl.

The finishing is done using fine sand papers and steel wool, until the right finish is reached. Here I added a little

extra, a mother of pearl insert on the top of the handle.

Protecting

Protect the handle Treat the wood, using your prefered method. Here an hardening oil from brand biofa.

Handle coated in oil Wait some time, to let the oil penetrate.

It is time to add a protective coating to the handle. Some will wax it, some will varnish it, I prefer to oil it. There are

many options: Pure linseed oil, my own mixture of linseed oil and pine pitch, tung oil, all have their uses, Here I use a

commercial hard oil coating based on linseed and pine pitch. I will probably apply a few coats of this. With linseed I

prefer to just drop the handle in the oil for a few days. I wait the proper amount of time for the right penetration and

drying between coatings.

Our efforts show up

Final result Looks good enough to me!

Another view Details.

This is how it looks once finished. The result looks good, and will certainly serve well. Here is a better picture of it:

Copyright © Outdoors-Magazine.com Page 8/9

Knife making tutorial [part 1, the knife handle]

A better picture. A better picture of the finished knife.

Conclusion

I hope this has trigered some envy in our readers to make their own knives . Feel free to ask questions by

commenting the article, or just add your own tips.

In the next part, Knife making tutorial [part 2, the sheath], I will explain how to make a leather sheath for this knife.

Then in the last third part, I will explain an extremely simple forge, and basic technics.

Post-scriptum :15/05/2006 V 1.0, first publication. 18/05/2006 V 1.1, Added tang tools.

Copyright © Outdoors-Magazine.com Page 9/9

Você também pode gostar

- How To Make Your Own Belt SanderDocumento34 páginasHow To Make Your Own Belt Sanderpizzolatto100% (7)

- The Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsNo EverandThe Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsNota: 5 de 5 estrelas5/5 (1)

- DIY Blacksmithing Tempering ChartDocumento1 páginaDIY Blacksmithing Tempering Chartkkd108100% (1)

- Buffalo Portable Forges and Blacksmiths' Hand BlowersDocumento2 páginasBuffalo Portable Forges and Blacksmiths' Hand BlowersJoe LaPenna50% (2)

- Pocketknife Making For BeginnersDocumento114 páginasPocketknife Making For BeginnersMary Robles100% (17)

- DIY PVC Crossbow: Technology Workshop Craft Home Food Play Outside CostumesDocumento14 páginasDIY PVC Crossbow: Technology Workshop Craft Home Food Play Outside CostumesToe100% (1)

- Bladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and FilesNo EverandBladesmithing From Scrap Metal: How to Make Knives With Leaf Springs, Saw Blades, Railroad Spikes, and FilesNota: 4.5 de 5 estrelas4.5/5 (3)

- Japanese Sword Making ProcessDocumento5 páginasJapanese Sword Making ProcessHassam AhmedAinda não há avaliações

- Sword Making by Stock RemovalDocumento24 páginasSword Making by Stock RemovalmeAinda não há avaliações

- HK94, MP5, Parts KitsDocumento6 páginasHK94, MP5, Parts KitsDavid BumbaloughAinda não há avaliações

- Bushcraft PDFDocumento319 páginasBushcraft PDFariakas26Ainda não há avaliações

- 130 Airgun Designs Agd Airgun Designs Agd RT Mag Manual EngDocumento12 páginas130 Airgun Designs Agd Airgun Designs Agd RT Mag Manual Engapi-157888397Ainda não há avaliações

- Knife Making Process Photo GuideDocumento18 páginasKnife Making Process Photo GuidePinjaman Peribadi67% (3)

- Bladesmithing: Bladesmithing for Beginners: Make Your First Knife in 7 StepsNo EverandBladesmithing: Bladesmithing for Beginners: Make Your First Knife in 7 StepsNota: 5 de 5 estrelas5/5 (1)

- Custom Knifemaking 10 Projects... Tim McCreight PDF (S)Documento219 páginasCustom Knifemaking 10 Projects... Tim McCreight PDF (S)preceptiveinquirer87% (15)

- Free DIY Bow Plans, Arrow Making Instructions, Crossbow Plans, Archery Info and All About ArcheryDocumento4 páginasFree DIY Bow Plans, Arrow Making Instructions, Crossbow Plans, Archery Info and All About ArcheryNorbelis100% (1)

- How To Make A Bow and Arrow by HandDocumento8 páginasHow To Make A Bow and Arrow by Handpeter TheodAinda não há avaliações

- Bladesmithing: A Step-by-Step Guide to Forging Your Own Knives for BeginnersNo EverandBladesmithing: A Step-by-Step Guide to Forging Your Own Knives for BeginnersAinda não há avaliações

- Basic Guide To Flux Cored Arc MIG WeldingDocumento18 páginasBasic Guide To Flux Cored Arc MIG WeldingHabanabakize Pacis TheophileAinda não há avaliações

- DIY 2x72 Belt Grinder For Knife MakingDocumento4 páginasDIY 2x72 Belt Grinder For Knife MakingJamespagan0% (1)

- Homemade gas cylinder foundryDocumento9 páginasHomemade gas cylinder foundryHerman HeseAinda não há avaliações

- Intermediate Guide to Bladesmithing: Make Knives, Swords and Forge Damascus: Knife Making Mastery, #2No EverandIntermediate Guide to Bladesmithing: Make Knives, Swords and Forge Damascus: Knife Making Mastery, #2Nota: 4.5 de 5 estrelas4.5/5 (2)

- Practical Blacksmithing - A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright": Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex Forgings - Volume IIINo EverandPractical Blacksmithing - A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright": Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex Forgings - Volume IIIAinda não há avaliações

- The Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Home Blacksmith (CompanionHouse Books) Beginner's Guide; Step-by-Step Directions & Over 500 Photos to Help You Start Smithing - Ryan RidgwayDocumento6 páginasThe Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Home Blacksmith (CompanionHouse Books) Beginner's Guide; Step-by-Step Directions & Over 500 Photos to Help You Start Smithing - Ryan Ridgwayzepixife0% (1)

- How To Make An AtlatlDocumento18 páginasHow To Make An Atlatlsoldatbr4183Ainda não há avaliações

- Sheet Metal Bending PlansDocumento11 páginasSheet Metal Bending PlansVivek_subzero100% (1)

- Decorative Wrought Ironwork Projects for BeginnersNo EverandDecorative Wrought Ironwork Projects for BeginnersAinda não há avaliações

- PinzasDocumento9 páginasPinzasjakjuAinda não há avaliações

- Braided Leather Knife Lanyard 2Documento14 páginasBraided Leather Knife Lanyard 2César Zapata R100% (1)

- The Shade Tree Knife MechanicDocumento9 páginasThe Shade Tree Knife MechanicbooghybAinda não há avaliações

- Make Your Own Knife Handles: Step-by-Step Techniques for Customizing Your BladeNo EverandMake Your Own Knife Handles: Step-by-Step Techniques for Customizing Your BladeAinda não há avaliações

- Sharp KnifeDocumento4 páginasSharp Knifegorlan67% (3)

- Bob Engnath Knife PatternsDocumento43 páginasBob Engnath Knife Patternsherpaderpadood100% (13)

- Tennis Ball Launching Crossbow PDFDocumento30 páginasTennis Ball Launching Crossbow PDFMarcelo Rovea SerresAinda não há avaliações

- Knifemaking For Beginners - A ST - W. Smith, ChrisDocumento66 páginasKnifemaking For Beginners - A ST - W. Smith, ChrisXHIXO OOMONAEAinda não há avaliações

- Early Dutch Emigrants To Australia - Les HiddinsDocumento28 páginasEarly Dutch Emigrants To Australia - Les HiddinsBushcraftOzAinda não há avaliações

- Make Your Own Bowie KnifeDocumento5 páginasMake Your Own Bowie Knifegoodsharer100% (1)

- Bladesmithing: 101 Bladesmithing Secrets: What Every Bladesmith Should Know Before Making His Next KnifeNo EverandBladesmithing: 101 Bladesmithing Secrets: What Every Bladesmith Should Know Before Making His Next KnifeNota: 5 de 5 estrelas5/5 (1)

- Casted Lathe PDFDocumento27 páginasCasted Lathe PDFFIREREALM66100% (1)

- Knife Making 101 - Stock Removal Method GuideDocumento19 páginasKnife Making 101 - Stock Removal Method Guiderace egrAinda não há avaliações

- Traditional Metal SmithDocumento6 páginasTraditional Metal Smithmanevem75% (4)

- Butterfly KnifeDocumento5 páginasButterfly KnifeYousef Al HessiAinda não há avaliações

- Usa Knife Maker CatalogDocumento104 páginasUsa Knife Maker Catalogsalenka71100% (2)

- Knife Making Tutorial Part 2 TheDocumento9 páginasKnife Making Tutorial Part 2 TheBushcraftOz100% (1)

- The Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Blacksmith HobbyistNo EverandThe Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Blacksmith HobbyistAinda não há avaliações

- Knife Grinder - PlansDocumento21 páginasKnife Grinder - PlansRodney SmithAinda não há avaliações

- Building A Home Made Belt SanderDocumento10 páginasBuilding A Home Made Belt SanderCiprian Cociuba100% (1)

- Making A KnifeDocumento12 páginasMaking A KnifeAurel Garceava100% (2)

- Folding Blade Knife With Spring Assisted Pivoting Feature (US Patent 6959494)Documento13 páginasFolding Blade Knife With Spring Assisted Pivoting Feature (US Patent 6959494)PriorSmartAinda não há avaliações

- DIY Angle Grinder Pipe SanderDocumento14 páginasDIY Angle Grinder Pipe SanderEdmar DL100% (1)

- How To Make A Chainmail Coif: by Theodore SchuermanDocumento23 páginasHow To Make A Chainmail Coif: by Theodore SchuermanSergioOmarMachucaAinda não há avaliações

- Weedeater Trolling MotorDocumento16 páginasWeedeater Trolling MotorJames McEwenAinda não há avaliações

- Blacksmith Knife TutorialDocumento18 páginasBlacksmith Knife TutorialAndre Balen100% (2)

- Notes for Forge Shop Practice - A Course for High SchoolsNo EverandNotes for Forge Shop Practice - A Course for High SchoolsAinda não há avaliações

- Making Folding Knives by Harold Hoffman (Action Book Publishers)Documento78 páginasMaking Folding Knives by Harold Hoffman (Action Book Publishers)vbamain100% (3)

- Knife AnatomyDocumento7 páginasKnife AnatomyErwin BergsAinda não há avaliações

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.No EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Nota: 5 de 5 estrelas5/5 (1)

- Basic Plane Blade Sharpening in MinutesDocumento3 páginasBasic Plane Blade Sharpening in MinutesJoshua HAinda não há avaliações

- Forging Process: Madan Lal Chandravanshi Assistant Professor Department of Mechanical Engineering I S M DhanbadDocumento77 páginasForging Process: Madan Lal Chandravanshi Assistant Professor Department of Mechanical Engineering I S M DhanbadNiharika RawatAinda não há avaliações

- From Flat To Fab: Pattern Metals With The Economy Compact Rolling MillDocumento30 páginasFrom Flat To Fab: Pattern Metals With The Economy Compact Rolling MillWiredlotus100% (7)

- Tying It All TogetherDocumento2 páginasTying It All TogetherBushcraftOzAinda não há avaliações

- Who Tracked That Track - Student NotesDocumento4 páginasWho Tracked That Track - Student NotesBushcraftOzAinda não há avaliações

- Point Stuart Info SheetDocumento2 páginasPoint Stuart Info SheetBushcraftOzAinda não há avaliações

- Kamminga TimberDocumento53 páginasKamminga TimberBushcraftOzAinda não há avaliações

- John McDouall Stuart and The Great North RoadDocumento9 páginasJohn McDouall Stuart and The Great North RoadBushcraftOzAinda não há avaliações

- Higher Algebra - Hall & KnightDocumento593 páginasHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Bush Tucker Survival Guide: by Koa WindsongDocumento10 páginasBush Tucker Survival Guide: by Koa Windsongash121Ainda não há avaliações

- Basic Blacksmithing - David Harries PDFDocumento132 páginasBasic Blacksmithing - David Harries PDFMichele Perrone FilhoAinda não há avaliações