Escolar Documentos

Profissional Documentos

Cultura Documentos

Vertical Roller Mill

Enviado por

Chaitanya ChintaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Vertical Roller Mill

Enviado por

Chaitanya ChintaDireitos autorais:

Formatos disponíveis

Vertical roller mill Vertical roller mill Vertical roller mill

Vertical roller mill

Introduction to the Vertical roller mill(grinding mill)

Vertical roller mill(grinding mill) Is a kind of crushing equipment featuring

high-efficient and energy-saving. And Vertical roller mill(grinding mill) have

integrated the crushing and grading into a single whole , which have satisfied the various

requirements of the customers and materials. And at the same time , we company also have the

super thin grinding mill of Vertical roller mill ,which have been catogrized as the

new &high energy-saving products in the eight fifth period by the national cement development

center .

Technical features of Vertical roller mill(grinding mill)

1.The materials will receive the circular crushing process by the crushing and grading. With

no over-grinding phenomenon ,the Vertical roller mill have greatly improved the

powder grinding efficiency .

2. Vertical roller mill is equipped with the grading system and the grading

impeller will adopt the new and high structure design .With high grading precision ,the fine

powder will have no coarse particles by the grading process.

3.The main units of the Vertical roller mill and grading driven electric motor will

be controlled and adjusted by the frequency converter. And with the stable function and

generability, the Vertical roller mill can be used to crush the materials with

various features and the production process and the particle size can be adjustable .

Vertical roller mill Vertical roller mill Vertical roller mill

Vertical roller mill Vertical roller mill Vertical roller mill

Application of the Vertical roller mill(grinding mill)

Vertical roller mill are mainly applied to proceed the powder crushing

manufacturing of the materials such as calcite, limestone, light dry stone coal,

barite, fluorite, glaze, slag, wollastonite, kaolin, vermiculite, mica, feldspar,

brucite, spores, potassium salt slag, garnet , quartz,etc.And the Vertical

roller mill can also be used to the non-metal mining areas with the Mohs

hardness of less than 7degree ,such as mining metallurgy, chemical industry,

electronics, medicine, food, daily chemical, agricultural, building ,and so on.

Working principle of Vertical roller mill(grinding mill)

Flow of material through the Vertical roller mill of the separator

when,the motor wil drive the plate to rotate by the reducer and then

the materials will fall down on the central place of the plate from

the inlet by the qir-locking feeder .While at the same time ,the hot

air will enter the grinder from the air inlet.With the rotation of

the plate ,the materials will move to the edge of the plate by the

centrigugal force and the materials will received the pressure from

the roller and be crushed when it passes the circle ring sink on the

plate.The crushed materials will be brought away by the high speed

air and the big size will fall down on the plate and be reginded .And

the coarse powder will fall down from the cone hopper and then repea t

this kind of process when materials in the air stream passes the

upper seperator by the effect of the rotors.And during the

process ,the fine powder will flow out with the air stream .By the

dust catcher ,the final products will be collected .The materials

with moisture will be dry when it contact with the hot air stream.By

adjusting the temperature of the hot air,we can satisfy materials

with various moisture degree ,thus achieving the required products

moisture.By the seperator ,we can also achieve the required coarse

and fine degree of the products .

Vertical roller mill Vertical roller mill Vertical roller mill

Vertical roller mill Vertical roller mill Vertical roller mill

Main technical parameters of Vertical roller mill

( grinding mill )

Specification Capacity(t/h) Humidity of Fineness of Humidity of Motor

Raw Coal Powder Powder(%) Power(kw)

CLM1250M 7-12 <15% 5-12% ≤1 132

CLM1300M 10-15 <15% 5-12% ≤1 185

CLM1400M 12-17 <15% 5-12% ≤1 200

CLM1500M 16-22 <15% 5-12% ≤1 250

CLM1700M 20-28 <15% 5-12% ≤1 315

CLM1900M 26-35 <15% 5-12% ≤1 400

CLM2200M 35-45 <15% 5-12% ≤1 500

CLM2400M 40-50 <15% 5-12% ≤1 560

CLM2800M 50-62 <15% 5-12% ≤1 710

Shanghai BinQ Mining Equipment Co.,Ltd

South Jinqiao Area,Pudong New Area, Shanghai, China.

Postcode: 201201

E-mail: mill@raymondgrindingmill.com

E-mail: grinder@raymondgrindingmill.com

Tel:86-21-51890570

http://www.raymondgrindingmill.com/

http://www.grindingmill8.com/

http://www.verticalrollermill8.com/

Vertical roller mill Vertical roller mill Vertical roller mill

Você também pode gostar

- Grinding System and Circuit of VRM Process Data Plant DataDocumento58 páginasGrinding System and Circuit of VRM Process Data Plant DataFasil Ayele60% (5)

- Raw Mill Vertical Roller Mill PDFDocumento58 páginasRaw Mill Vertical Roller Mill PDFManpreetSaran92% (12)

- Vertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsDocumento16 páginasVertical Roller Pre Grinding Mill by AMCLMachinery Limited@ Mangalam CementsRahul RoyAinda não há avaliações

- Vertical Roller MillDocumento42 páginasVertical Roller Milliezanblack_pearl100% (2)

- Active Redundancy ConceptDocumento9 páginasActive Redundancy ConceptRollerJonnyAinda não há avaliações

- LoescheDocumento35 páginasLoescheayaskant751001Ainda não há avaliações

- Vertical Roller Mills 01Documento6 páginasVertical Roller Mills 01Kariem R Noweer100% (1)

- 04 Vertical Roller MillsDocumento12 páginas04 Vertical Roller MillsaktaserdincAinda não há avaliações

- Gebr. Pfeiffer Brochure Passion For Grinding enDocumento28 páginasGebr. Pfeiffer Brochure Passion For Grinding enRollerJonnyAinda não há avaliações

- One Kiln - 13,000 TPD: Cement & MineralsDocumento52 páginasOne Kiln - 13,000 TPD: Cement & MineralsKristínaAinda não há avaliações

- 05 RP - Process Know HowDocumento25 páginas05 RP - Process Know Howaff bear100% (2)

- Loesche Round Table VICATDocumento20 páginasLoesche Round Table VICATrecaiAinda não há avaliações

- Vertical Roller Mill SummaryDocumento20 páginasVertical Roller Mill SummaryPhyo Thura Htay100% (6)

- VRM Hydraulic SystemDocumento2 páginasVRM Hydraulic SystemBhaskar Reddy100% (1)

- Studies of Cement Mill CircuitDocumento3 páginasStudies of Cement Mill CircuitRobson de Freitas Werling100% (1)

- 13-IMS 2021 Roller PressDocumento63 páginas13-IMS 2021 Roller Presshmaza shakeelAinda não há avaliações

- Rotary Kiln Reconditioning Tyre and Roller GrindingDocumento8 páginasRotary Kiln Reconditioning Tyre and Roller GrindingTiago CamposAinda não há avaliações

- A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BDocumento4 páginasA Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 (A+B) C BYhaneAinda não há avaliações

- Loesche Round Table VICATDocumento20 páginasLoesche Round Table VICATFirdaus Azizan86% (7)

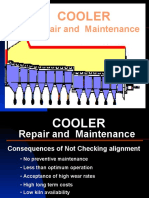

- Repair and Maintenance: CoolerDocumento61 páginasRepair and Maintenance: CoolerYhaneAinda não há avaliações

- VRM Heat and Mass BalanceDocumento1 páginaVRM Heat and Mass BalanceRajeshRockAinda não há avaliações

- Vertical Roller Mill IntroductionDocumento2 páginasVertical Roller Mill Introductionemad sabriAinda não há avaliações

- Mini Plant Training Material: Air SlidesDocumento28 páginasMini Plant Training Material: Air Slidesbulentbulut100% (2)

- VRM - PaperDocumento9 páginasVRM - PaperJoko Dewoto100% (1)

- CoolersDocumento297 páginasCoolersMUNNALURU UMAKANTHA RAOAinda não há avaliações

- Vertical Roller MillDocumento2 páginasVertical Roller MillAhmed Younis0% (2)

- O-Sepa 750 enDocumento29 páginasO-Sepa 750 enEmanuel Widodo50% (2)

- Vertical Mill PDFDocumento15 páginasVertical Mill PDFGregory100% (4)

- Blaine Reference Blaine Required e KDocumento4 páginasBlaine Reference Blaine Required e KNael100% (3)

- VRM OperationsDocumento35 páginasVRM OperationsJitendra Jangid100% (1)

- PFC - The Great CoolerDocumento47 páginasPFC - The Great CoolerM.IBRAHEEM100% (1)

- Modefied Cooler2Documento71 páginasModefied Cooler21977jul100% (2)

- Cement Mill Shell LinerDocumento7 páginasCement Mill Shell LinerMahaveer SinghAinda não há avaliações

- Cement Mill Control PDFDocumento30 páginasCement Mill Control PDFJackson Vu100% (2)

- Loesche Roller Grinding MillDocumento56 páginasLoesche Roller Grinding MillAdnan rasool100% (1)

- Course Polycom Hydraulic Functionality Specification Components PDFDocumento30 páginasCourse Polycom Hydraulic Functionality Specification Components PDFBruno Cecatto100% (2)

- Quest - Vertical Roller Mill - KM (Rough)Documento6 páginasQuest - Vertical Roller Mill - KM (Rough)Raji SuriAinda não há avaliações

- Cement Mill Calculation DesaignDocumento1 páginaCement Mill Calculation DesaignHilmy MuhammadAinda não há avaliações

- Raw MealDocumento48 páginasRaw Mealrashmiranjan1110Ainda não há avaliações

- 273Documento75 páginas273LabroufiAbdelouahedAinda não há avaliações

- Cement Vertical Mill Vs Ball MillDocumento17 páginasCement Vertical Mill Vs Ball Millanrulo50% (2)

- VRM Drive Unit Ver FJC 2010Documento60 páginasVRM Drive Unit Ver FJC 2010Mujahid Baloch100% (1)

- 05 SeparatingDocumento64 páginas05 Separatingrecai100% (2)

- VRM Operation SOPsDocumento3 páginasVRM Operation SOPsAlaa MaherAinda não há avaliações

- Vertical Roller Mill SummaryDocumento20 páginasVertical Roller Mill SummaryPhyo Thura Htay100% (3)

- RP MaintenanceDocumento31 páginasRP Maintenanceshannu826826100% (2)

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocumento44 páginasGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Raw Mill Vertical Roller Mill PDFDocumento58 páginasRaw Mill Vertical Roller Mill PDFganong itbAinda não há avaliações

- 01.0 - 22146.002E - Hydraulic SystemDocumento126 páginas01.0 - 22146.002E - Hydraulic SystemShariq Khan100% (1)

- Foundation For Roller PressDocumento3 páginasFoundation For Roller PressRollerJonny0% (1)

- Cpi VRMDocumento26 páginasCpi VRMRobert Brown100% (1)

- AirslidesDocumento3 páginasAirslidesVisnu SankarAinda não há avaliações

- Vertical Roller MillsDocumento52 páginasVertical Roller MillsThibaut Leconte50% (2)

- High PressureGrindingMill SDocumento16 páginasHigh PressureGrindingMill SjoyalcrusherAinda não há avaliações

- 3000 Mesh Limestone Super Fine Powder Grinding MachineDocumento9 páginas3000 Mesh Limestone Super Fine Powder Grinding MachineminemillAinda não há avaliações

- VRM PresentationDocumento49 páginasVRM PresentationMKPashaPasha100% (4)

- VRM PresentationDocumento49 páginasVRM Presentationrecai100% (3)

- Gujarat Sidhee Cement Limited-SmitDocumento26 páginasGujarat Sidhee Cement Limited-SmitHimadri MahatoAinda não há avaliações

- Raymond Vertical Mill Technical DatasheetDocumento2 páginasRaymond Vertical Mill Technical DatasheetRaan Mend100% (1)

- AttritorDocumento4 páginasAttritorimrancenakkAinda não há avaliações

- GE Polyamine TechnologyDocumento17 páginasGE Polyamine TechnologyDonatas BertasiusAinda não há avaliações

- Planning For Project Layout ReportDocumento11 páginasPlanning For Project Layout ReportAko C Rence100% (2)

- Petrol Chainsaws: Owner's ManualDocumento4 páginasPetrol Chainsaws: Owner's Manualkatta ngaAinda não há avaliações

- Lockout Tagout ProgramDocumento6 páginasLockout Tagout ProgramYuli AstutyAinda não há avaliações

- Integration of Nonlinear Crude Distillation Unit Models in RefineryDocumento11 páginasIntegration of Nonlinear Crude Distillation Unit Models in RefineryNông DânAinda não há avaliações

- Topic 1 Electrical Installation System in The BuildingDocumento96 páginasTopic 1 Electrical Installation System in The Buildingnabilnash21100% (5)

- Bi Toroid Transformer DiscussionDocumento781 páginasBi Toroid Transformer DiscussionLuisLazoAinda não há avaliações

- BA-AR-G1 900 540X270 TW: Product DatasheetDocumento5 páginasBA-AR-G1 900 540X270 TW: Product DatasheetAl AmosAinda não há avaliações

- AUMA (Ba Sar2!07!16 Amb1 En)Documento60 páginasAUMA (Ba Sar2!07!16 Amb1 En)cuongnammuAinda não há avaliações

- Industrial Asd 75 132kw Operating InstructionDocumento4 páginasIndustrial Asd 75 132kw Operating InstructionRinda_RaynaAinda não há avaliações

- FB Aqua Feed Technologies en DataDocumento8 páginasFB Aqua Feed Technologies en Datasarah ahmedAinda não há avaliações

- Panolin Biomot LD 10W/40: Diesel Engine Oil - Fully Synthetic, Rapidly BiodegradableDocumento1 páginaPanolin Biomot LD 10W/40: Diesel Engine Oil - Fully Synthetic, Rapidly Biodegradablerobertoalfaro492023Ainda não há avaliações

- q1 m6 Heat Temperature Activity Sheet Summative TestDocumento5 páginasq1 m6 Heat Temperature Activity Sheet Summative TestALLYSA JANE SIAAinda não há avaliações

- Daylighting IN Underground Buildings: Ashraf Ali Ibrahim NessimDocumento365 páginasDaylighting IN Underground Buildings: Ashraf Ali Ibrahim NessimthabisAinda não há avaliações

- 2 Pipe - Hot Water Only Direct Drive - Draw Through DesignDocumento2 páginas2 Pipe - Hot Water Only Direct Drive - Draw Through DesignwipiriAinda não há avaliações

- Simufact BR Rolling 2015 E Web PDFDocumento2 páginasSimufact BR Rolling 2015 E Web PDFSamir KhAinda não há avaliações

- Physical ChenistryDocumento146 páginasPhysical ChenistrychemasimAinda não há avaliações

- Presentation GrihaDocumento60 páginasPresentation GrihaTimila Dangol100% (1)

- Catálogo MultiV IV 2013 EngDocumento110 páginasCatálogo MultiV IV 2013 EngANDERSON HERRERAAinda não há avaliações

- 5.4.1 Arenes635464Documento6 páginas5.4.1 Arenes635464ArchitAinda não há avaliações

- Design of CFBC BoilerDocumento86 páginasDesign of CFBC Boilerhalder.kalyan88% (8)

- Coulson MethodDocumento17 páginasCoulson MethodSanjeeb SutradharAinda não há avaliações

- Single Wire Earth Return (SWER) : Course Instructor: Peter ArmstrongDocumento16 páginasSingle Wire Earth Return (SWER) : Course Instructor: Peter ArmstrongnambaccucAinda não há avaliações

- STPM Trials 2009 Chemistry Answer Scheme KelantanDocumento11 páginasSTPM Trials 2009 Chemistry Answer Scheme Kelantansherry_christyAinda não há avaliações

- Question and Answers Electrical MaintenaDocumento416 páginasQuestion and Answers Electrical MaintenaimranAinda não há avaliações

- Crouse Hinds Area10425Documento5 páginasCrouse Hinds Area10425Pablo MarajAinda não há avaliações

- Chapter 28 Ground GRDocumento3 páginasChapter 28 Ground GRmanirup_tceAinda não há avaliações

- Open Ended LabDocumento6 páginasOpen Ended LabVishal DhimanAinda não há avaliações

- Fahrzeugverdichter / Vehicle Compressor / Compresseur Pour AutomobilesDocumento1 páginaFahrzeugverdichter / Vehicle Compressor / Compresseur Pour AutomobilesZoraida100% (1)

- Stress Analysis of PSV Connected Piping Systems Using Caesar IIDocumento6 páginasStress Analysis of PSV Connected Piping Systems Using Caesar IIwisesaAinda não há avaliações