Escolar Documentos

Profissional Documentos

Cultura Documentos

300f Overview e

Enviado por

Eng-Mohammed SalemDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

300f Overview e

Enviado por

Eng-Mohammed SalemDireitos autorais:

Formatos disponíveis

Elevator Division

Head Office, Elevators

Switzerland Service Center World Wide

Bucher Hydraulics AG Bucher Hydraulics AG

Industriestrasse 15 Industriestrasse 15

CH-6345 Neuheim CH-6345 Neuheim

Tel.: +41 41 757 03 33 Tel.: +41 41 757 03 33

Fax: +41 41 757 03 17 Fax: +41 41 757 03 19

info.ber@bucherhydraulics.com info.service.ber@bucherhydraulics.com

European contacts

Germany South / Austria Germany West Germany North Service Center Germany

Product Overview

Bucher Hydraulics AG Bucher Hydraulics AG Bucher Hydraulics AG Bucher Hydraulics AG

Josef Sieber Philippe Roose Andreas Nickel Jürgen Zehrer

Rupert Gugg Str. 51 Blumenstrasse 24 Joachim-Ringelnatz-Str. 45 Franz Schubert Strasse 13

AT - 5280 Braunau D-65366 Geisenheim D-12683 Berlin D-90768 Fürth

Tel.: +43 7722 64 715 Tel.: +49 6722 753 72 Tel.: +49 30 547 12377 Tel.: +49 911 72 06 45

Fax: +43 7722 64 716 Fax: +49 6722 753 61 Fax: +49 30 547 12378 Fax: +49 911 72 06 51

Mobile: +49 172 867 84 42 Mobile: +49 172 610 46 36 Mobile: +49 151 152 800 08 Mobile: +49 172 810 51 06

josef.sieber@bucherhydraulics.com philippe.roose@bucherhydraulics.com andreas.nickel@bucherhydraulics.com info.service.ber@bucherhydraulics.com

Finland United Kingdom Hungary Spare Parts Center Germany

Ing. Buero J. Teittinen Ky Bucher Hydraulics Ltd. Olmalift KFT Bucher Hydraulics AG

H. Jukka Teittinen Colin Will Laszlo Lukacs Susanne Sieber

Hatanpään valtatie 34 A Unit 9 Eastboro Fields Üteg Utca 9/A Loferer Weg 3a

FI-33100 Tampere Hemdale, Nuneaton H-1139 Budapest D-82140 Olching

Tel: +358 3 214 08 81 GB-Warwickshire CV11 6GL Tel.: +36 1 339 4308 Tel.: +49 8142 4870 36

Fax: +358 3 214 63 53 Tel.: +44 2476 353 568 Fax: +36 1 320 8256 Fax: +49 8142 4870 37

Mobile: +358 400 637 149 Fax: +44 2476 353 572 olmalift@matavnet.hu susanne.sieber@bucherhydraulics.com

teittinen@yritys.soon.fi Mobile: +44 7721 611 816

info.uk@bucherhydraulics.com

Greece Turkey Bulgaria Service Center Benelux

Minos Ltd. Bucher Hidrolik Sist. Tic. Ltd. Sti. ALEX EA Co. Ltd. Technovice (Service)

T. Gavalas Turhan Altinörs Alexander Alexandrov Ger Snel

22 Kifissou Ave. ISTOÇ 7, Filip Kutev Str. Postbus 225

GR-10442 Athens 5. Ada No. 41 BG-1220 Sofia NL-8250 AE Dronten

Tel.: +30 1 513 49 00 TR-34550 Mahmutbey–Istanbul Tel.: +359 2 931 21 52 Tel.: +31 321 33 66 35

Fax: +30 1 515 02 71 Tel.: +90 212 659 0488 PBX Fax: +359 2 931 21 53 Fax: +31 321 38 13 17

minos_lift@internet.gr Fax: +90 212 659 0489 alex-ea@techno-link.com gs@technovice.nl

Mobile: +90 532 788 0344

info.tr@bucherhydraulics.com

Asia contacts

Japan China Taiwan Iran

Bucher Hydraulics (KK) Suzhou Bucher Hydraulics Co. Ltd. Bucher Hydraulics Co. Ltd. ALMAS NEGIN LIFT CO.

T. Hirose Timothy Lin Timothy Lin Mohammad Reza Zohrehvandi

Sakae-Cho 723-1-102 No. 168, Shexing Road No. 22 Ding Hwu 5th Street Highway Africa, Street Padidar

Yoshikawa-Shi Lili Town Kuasun Shiang Sharuz Building, 3th floor, no. 10

JP-Saitama-Ken 342-0050 CN-Wujiang City, Jiangsu TW-Taoyuan Taiwan Tehran - Iran

Tel.: +81 48 984 3713 Tel.: +86 512 6 322 1434 Tel.: +886 3 328 77 28 Tel.: +98 21 888 67 14

Fax: +81 48 984 3717 Fax: +86 512 6 322 1033 Fax: +886 3 328 83 89 Fax: +98 21 888 67 15

info.jp@bucherhydraulics.com Mobile: +86 13706 250 579 info.tw@bucherhydraulics.com info@almasliftiran.com

info.sh@bucherhydraulics.com

Middle East contact USA contact

Israel USA

MONDEO (1999) Ltd. Bucher Hydraulics, Inc.

N. Stav 300 North Midland Ave.

Bet Hapa'mon Saddle Brook

20 Hata'as Str. N.J. 07663-5514

IL-44425 Kfar Saba Tel.: +1 201 703 8384

Tel.: +972 9 766 56 32 Fax: +1 201 703 1124

Fax: +972 9 765 45 28 info.us@bucherhydraulics.com

Mobile: +972 52 925 423

mondeo_v@netvision.net.il

© BUCHER HYDRAULICS NEUHEIM - 300-P-9010018-E-04/10.04

www.bucherhydraulics.com motion and progress

Honouring today’s standard … … and presenting tomorrow’s!

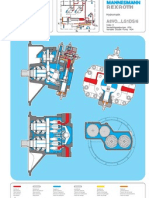

Elevator valve The MRL-System BERIPAC™

Beringer The MRL hydraulic solution for everyone

LRV-1 The electronically controlled valve that has proved its Electrohydraulic drive, car frame kit with side ram 2:1 suspension & pulling

worth thousands of times cylinder - all from one supplier

• Large operating temperature range • Downward speed can be increased • Same, low motor power as traction gency lowering valve)

• Energy losses are reduced by up to 50% without additional costs elevators thanks to the hydraulic co- • Great flexibility in the siting of the

• Lower energy costs or any reduction in comfort unterweight controller cabinet. Even an existing

• Short total travel time due to the short • Insensitive to changes in pressure • Fluid volumes are drastically redu- machine room may be used

distance travelled at creep speed and temperature ced (> 80 % savings compared to • Travel distance up to 15 m, with use-

• No cooling or heating necessary in standard hydraulics) able load capacity of 630 to 1000 kg

many cases • Simplest possible, load-independent

emergency controls can be reached

from outside (handpump or emer-

Power Units

Beringer

SATURN a Frequency-regulated VVVF technology

SATURN b Electronically controlled, proved its worth thousands of times

• Uniform series of standardised mo-

dels

• Optimised filling volume

• Proven technology

The tried-and-tested components

• Minimum space requirement Depending on the country and application, a large pro-

• Optimum heat dissipation portion of new elevator installations are equipped with

• Reduced noise level a hydraulic drive system. These components can also

be applied in a versatile manner when modernizing and

converting existing elevator installations.

Cylinder

Beringer

Application areas

BZG, BZH Plunger cylinder Personnel and freight elevators for airports, train

BZBGL Telescopic cylinder, 2 and 3-stage stations, shopping malls, residential and commercial

BZZ Pulling cylinder buildings up to a travel distance of 25 meters (82 ft.)

We reserve the right of modification without notice. / Detailed information according Product Catalogue.

• Latest state-of-the-art-technology and a useable load capacity ranging from 320 kg to over

40,000 kg (700 lbs to over 88,000 lbs).

• Complies with current EN81-2 safety regulations

• Two Teflon guide belts guarantee high reliability, excellent sliding characteristics

and a long service life Advantages

• Offers great creative scope to architects

• Low maintenance / long service life

• Flexibility in positioning the machine room

• Highly reliable

• Excellent cost/performance ratio

Car frame kits • More than 100,000 installations in service globally

Beringer

Pluto BR Side ram series, direct/indirect, up to a total weight of 3,500 kg

Jupiter BT Tandem series, direct/indirect up to a total weight of 12,000 kg

Special BT Tandem series, direct/indirect or central arrangement

up to a total weight of 12,000 kg

• Low depth of shaft pit and low shaft • Simple design

head room • Simple construction

• Simple and fast assembly • Good accessibility to all major com-

• Kits for initial assembly and final as- ponents

sembly are separately packaged

• Wide range of variants from the

same car frame kit

Honouring today’s standard … … and presenting tomorrow’s!

Elevator valve The MRL-System BERIPAC™

Beringer The MRL hydraulic solution for everyone

LRV-1 The electronically controlled valve that has proved its Electrohydraulic drive, car frame kit with side ram 2:1 suspension & pulling

worth thousands of times cylinder - all from one supplier

• Large operating temperature range • Downward speed can be increased • Same, low motor power as traction gency lowering valve)

• Energy losses are reduced by up to 50% without additional costs elevators thanks to the hydraulic co- • Great flexibility in the siting of the

• Lower energy costs or any reduction in comfort unterweight controller cabinet. Even an existing

• Short total travel time due to the short • Insensitive to changes in pressure • Fluid volumes are drastically redu- machine room may be used

distance travelled at creep speed and temperature ced (> 80 % savings compared to • Travel distance up to 15 m, with use-

• No cooling or heating necessary in standard hydraulics) able load capacity of 630 to 1000 kg

many cases • Simplest possible, load-independent

emergency controls can be reached

from outside (handpump or emer-

Power Units

Beringer

SATURN a Frequency-regulated VVVF technology

SATURN b Electronically controlled, proved its worth thousands of times

• Uniform series of standardised mo-

dels

• Optimised filling volume

• Proven technology

The tried-and-tested components

• Minimum space requirement Depending on the country and application, a large pro-

• Optimum heat dissipation portion of new elevator installations are equipped with

• Reduced noise level a hydraulic drive system. These components can also

be applied in a versatile manner when modernizing and

converting existing elevator installations.

Cylinder

Beringer

Application areas

BZG, BZH Plunger cylinder Personnel and freight elevators for airports, train

BZBGL Telescopic cylinder, 2 and 3-stage stations, shopping malls, residential and commercial

BZZ Pulling cylinder buildings up to a travel distance of 25 meters (82 ft.)

We reserve the right of modification without notice. / Detailed information according Product Catalogue.

• Latest state-of-the-art-technology and a useable load capacity ranging from 320 kg to over

40,000 kg (700 lbs to over 88,000 lbs).

• Complies with current EN81-2 safety regulations

• Two Teflon guide belts guarantee high reliability, excellent sliding characteristics

and a long service life Advantages

• Offers great creative scope to architects

• Low maintenance / long service life

• Flexibility in positioning the machine room

• Highly reliable

• Excellent cost/performance ratio

Car frame kits • More than 100,000 installations in service globally

Beringer

Pluto BR Side ram series, direct/indirect, up to a total weight of 3,500 kg

Jupiter BT Tandem series, direct/indirect up to a total weight of 12,000 kg

Special BT Tandem series, direct/indirect or central arrangement

up to a total weight of 12,000 kg

• Low depth of shaft pit and low shaft • Simple design

head room • Simple construction

• Simple and fast assembly • Good accessibility to all major com-

• Kits for initial assembly and final as- ponents

sembly are separately packaged

• Wide range of variants from the

same car frame kit

Você também pode gostar

- Sensors, Mechanical SensorsNo EverandSensors, Mechanical SensorsWolfgang GöpelAinda não há avaliações

- Aumund Group Equipment in The Iron and Steel Industry: We Convey QualityDocumento4 páginasAumund Group Equipment in The Iron and Steel Industry: We Convey QualityengfaridmalkAinda não há avaliações

- TODAY Tourism & Business Magazine, Volume 22, November, 2015No EverandTODAY Tourism & Business Magazine, Volume 22, November, 2015Nota: 5 de 5 estrelas5/5 (1)

- Kuhnke Technical Data: Contact DetailsDocumento189 páginasKuhnke Technical Data: Contact Detailsqhdhz8Ainda não há avaliações

- TODAY Tourism & Business Magazine, Volume 22, May 2015No EverandTODAY Tourism & Business Magazine, Volume 22, May 2015Ainda não há avaliações

- Catalog 1 PDFDocumento19 páginasCatalog 1 PDFtoto-gmbhAinda não há avaliações

- Turck Sensor Katalog PDFDocumento929 páginasTurck Sensor Katalog PDFjuan pablo TurczynAinda não há avaliações

- Byspeed 3015 BA V010 enDocumento524 páginasByspeed 3015 BA V010 enΈλσαΟγκρένιAinda não há avaliações

- Manual Sistem Analiza Clor RezidualDocumento108 páginasManual Sistem Analiza Clor RezidualCatalin CAinda não há avaliações

- Catalog 5 PDFDocumento13 páginasCatalog 5 PDFtoto-gmbhAinda não há avaliações

- 117 12 02 1 10 Przekaźnik 24V Dcac Kuhnke ManualDocumento133 páginas117 12 02 1 10 Przekaźnik 24V Dcac Kuhnke Manualfilisan mirceaAinda não há avaliações

- Foreign ManufacturersDocumento8 páginasForeign ManufacturersHeri SetyantoAinda não há avaliações

- Reovib MFS: Frequency Controllers For Vibratory FeedersDocumento20 páginasReovib MFS: Frequency Controllers For Vibratory FeedersÁron SzárazAinda não há avaliações

- 130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke Manual PDFDocumento133 páginas130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke Manual PDFChawki DerouicheAinda não há avaliações

- 130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke ManualDocumento133 páginas130 2 02 2 30 Przekaźnik 24V Dcac Kuhnke ManualChawki DerouicheAinda não há avaliações

- List of Companies Approved by The Fia For The Calculation of Safety CagesDocumento1 páginaList of Companies Approved by The Fia For The Calculation of Safety CagesAntonio GabrielAinda não há avaliações

- Relee Kuhnke1085974346470a363521c14 PDFDocumento131 páginasRelee Kuhnke1085974346470a363521c14 PDFMuresan SanduAinda não há avaliações

- Kavo Diagnodent 2095 User Guide-1Documento30 páginasKavo Diagnodent 2095 User Guide-1omar shaalanAinda não há avaliações

- Trane Parts Catalogue 2015Documento202 páginasTrane Parts Catalogue 2015Said ZubizaAinda não há avaliações

- Bluetest2: Automated Production Test Software For The Mt8852BDocumento6 páginasBluetest2: Automated Production Test Software For The Mt8852BIvan GomezAinda não há avaliações

- Latest Distributor List 01 13Documento2 páginasLatest Distributor List 01 13andraAinda não há avaliações

- EBRO GROUP COMPANY PROFILE - ProjectsDocumento50 páginasEBRO GROUP COMPANY PROFILE - ProjectsNinh DangAinda não há avaliações

- PF 320 FS 2100N 4x00DN PL UKDocumento9 páginasPF 320 FS 2100N 4x00DN PL UKChad HicksAinda não há avaliações

- Artículo - Separation Technologies in Petroleum Refining - PALLDocumento26 páginasArtículo - Separation Technologies in Petroleum Refining - PALLSteve AvilaAinda não há avaliações

- Enraf Tanksystem - Gtex - WorldwideDocumento2 páginasEnraf Tanksystem - Gtex - WorldwideShanmugamoorthyAinda não há avaliações

- RADAR 10.x Update To 10.0.012Documento6 páginasRADAR 10.x Update To 10.0.012takne_007Ainda não há avaliações

- Helix-Fabricator Licensees (Worldwide) DTD.2-25-09 PDFDocumento6 páginasHelix-Fabricator Licensees (Worldwide) DTD.2-25-09 PDFabhishek kumarAinda não há avaliações

- Alape International 20Documento3 páginasAlape International 20jonAinda não há avaliações

- Grundfosliterature-413755 1940674Documento112 páginasGrundfosliterature-413755 1940674Martin MeynersAinda não há avaliações

- NB, NBG, NK, NKG (Service Kit Instruction)Documento20 páginasNB, NBG, NK, NKG (Service Kit Instruction)Filipe Simoes OliveiraAinda não há avaliações

- Bytube en PDFDocumento386 páginasBytube en PDFGarry HatteyAinda não há avaliações

- David Brown Pumps 1600-Series PDFDocumento15 páginasDavid Brown Pumps 1600-Series PDFVijay BhureAinda não há avaliações

- Worldwide WiesheuDocumento37 páginasWorldwide Wiesheucheng yifangAinda não há avaliações

- 6 Manual Optibelt F. Sincrónica PDFDocumento74 páginas6 Manual Optibelt F. Sincrónica PDFjesusAinda não há avaliações

- Grundfosliterature 5092Documento20 páginasGrundfosliterature 5092GamberiniAinda não há avaliações

- Topcon GTS-220 PDFDocumento166 páginasTopcon GTS-220 PDFMario CarranzaAinda não há avaliações

- Data Sheet: Proeco Cpdm10Documento6 páginasData Sheet: Proeco Cpdm10George CjrcAinda não há avaliações

- Ba Tube Bender-0210Documento2 páginasBa Tube Bender-0210javier.sm.secundariaAinda não há avaliações

- By Vent Ion 2200 enDocumento482 páginasBy Vent Ion 2200 enjeronimost100% (1)

- Especificação Melservo-J2-C-S100 - Servo - SpindleDocumento71 páginasEspecificação Melservo-J2-C-S100 - Servo - SpindlemiltonrighettoAinda não há avaliações

- ManuliTechnicalManual PDFDocumento168 páginasManuliTechnicalManual PDFYeison Prasca MartinezAinda não há avaliações

- Em17030 Todo Certified Service Centre Leaflet V2 HR PDFDocumento4 páginasEm17030 Todo Certified Service Centre Leaflet V2 HR PDFjohn sinsAinda não há avaliações

- WSM Tool Automatik enDocumento6 páginasWSM Tool Automatik enmuthusamyeeeAinda não há avaliações

- Stromversorgung / Power SupplyDocumento72 páginasStromversorgung / Power SupplyЮлия МайбородаAinda não há avaliações

- Laser Cutting TechnologyDocumento264 páginasLaser Cutting Technologykkangari100% (4)

- 010e Chap-01Documento14 páginas010e Chap-01Mohamed RabeaAinda não há avaliações

- TSCD QDocumento6 páginasTSCD QMon MonAinda não há avaliações

- BER, Controls Motorized Valve Start-Up InstructionsDocumento6 páginasBER, Controls Motorized Valve Start-Up InstructionsJoseph YumulAinda não há avaliações

- AT06 2S Amphenol Sine SystemsDocumento16 páginasAT06 2S Amphenol Sine Systemsfabio coalaAinda não há avaliações

- C517 DarlingtonDocumento8 páginasC517 Darlingtonz3xa5347Ainda não há avaliações

- Technical Publication: Worm Gear Boxes, Mechanical Variators & PC UNITSDocumento16 páginasTechnical Publication: Worm Gear Boxes, Mechanical Variators & PC UNITSConax ChisasaAinda não há avaliações

- SMD SOT89Documento8 páginasSMD SOT89chichedemorenoAinda não há avaliações

- Black and Decker KS531 JigsawDocumento60 páginasBlack and Decker KS531 Jigsawjorge cornejoAinda não há avaliações

- KR THK LM Guide ActuatorDocumento92 páginasKR THK LM Guide ActuatorGiang NguyenAinda não há avaliações

- BC549Documento9 páginasBC549Bg SuelloAinda não há avaliações

- Manual - Leuze - BCL34Documento102 páginasManual - Leuze - BCL34Javier GarcíaAinda não há avaliações

- Cosmetic, Hair, Skin and Dental Products (Importers)Documento4 páginasCosmetic, Hair, Skin and Dental Products (Importers)Ahmet ErdilAinda não há avaliações

- Tank Truck Components Catalogue 2014 UK - ScreenDocumento12 páginasTank Truck Components Catalogue 2014 UK - ScreenMourali ZinAinda não há avaliações

- Shipmate Rs8100Documento38 páginasShipmate Rs8100George MecseryAinda não há avaliações

- Script User's Manual - AbaqusDocumento316 páginasScript User's Manual - AbaqusLvra0% (1)

- Accumulator CatalogueDocumento280 páginasAccumulator CatalogueEdgar Allende ChavezAinda não há avaliações

- Hpwinch 31 1Documento16 páginasHpwinch 31 1Eng-Mohammed SalemAinda não há avaliações

- Integral EquationsDocumento48 páginasIntegral EquationsAnonymous 39lpTJiAinda não há avaliações

- Notes On Differential EquationsDocumento7 páginasNotes On Differential EquationsEng-Mohammed SalemAinda não há avaliações

- Problems in Higher AlgebraDocumento512 páginasProblems in Higher AlgebraEng-Mohammed SalemAinda não há avaliações

- Marine Control BlockDocumento13 páginasMarine Control BlockEng-Mohammed SalemAinda não há avaliações

- CT 198975 PDFDocumento332 páginasCT 198975 PDFRubén PizarroAinda não há avaliações

- Aalco Stainless Steel Tube FlangesDocumento28 páginasAalco Stainless Steel Tube FlangesEng-Mohammed SalemAinda não há avaliações

- Vector and Tensor Analysis With Applications PDFDocumento265 páginasVector and Tensor Analysis With Applications PDFEng-Mohammed SalemAinda não há avaliações

- Four Way Valve (Ac3-1-9)Documento3 páginasFour Way Valve (Ac3-1-9)Eng-Mohammed SalemAinda não há avaliações

- AC 500-2 Training ManualDocumento12 páginasAC 500-2 Training ManualEng-Mohammed SalemAinda não há avaliações

- XyzDocumento2 páginasXyzEng-Mohammed SalemAinda não há avaliações

- Hydraulic System Troubleshooting Guide PDFDocumento13 páginasHydraulic System Troubleshooting Guide PDFWesame Shnoda100% (1)

- ContentsDocumento21 páginasContentsEng-Mohammed SalemAinda não há avaliações

- DOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Documento122 páginasDOE Fundamentals Handbook, Mechanical Science, Volume 1 of 2Bob VinesAinda não há avaliações

- 2009 Handok Ass'yDocumento36 páginas2009 Handok Ass'yEng-Mohammed Salem100% (1)

- A8vo SG1ZDocumento1 páginaA8vo SG1ZEng-Mohammed Salem100% (4)

- A8vo LG1DSDocumento1 páginaA8vo LG1DSEng-Mohammed Salem100% (3)

- JCB Hand Held Hydraulic Equipment: Service ManualDocumento51 páginasJCB Hand Held Hydraulic Equipment: Service ManualEng-Mohammed SalemAinda não há avaliações

- Us 6971375Documento47 páginasUs 6971375Eng-Mohammed SalemAinda não há avaliações

- A8vo 28 SR3CZDocumento1 páginaA8vo 28 SR3CZEng-Mohammed Salem100% (2)

- Electrical MotoreDocumento11 páginasElectrical MotoreEng-Mohammed SalemAinda não há avaliações

- A4vso LR3GNDocumento1 páginaA4vso LR3GNEng-Mohammed SalemAinda não há avaliações

- Belajar Menggambar 3d Dengan Autocad 2007Documento200 páginasBelajar Menggambar 3d Dengan Autocad 2007Iswant MacanAinda não há avaliações

- High Torque Geared Motors: From 70.000 Up To 1.200.000 NM Output Torque (From 52.000 Up To 885.000 LBF - FT)Documento4 páginasHigh Torque Geared Motors: From 70.000 Up To 1.200.000 NM Output Torque (From 52.000 Up To 885.000 LBF - FT)Eng-Mohammed SalemAinda não há avaliações

- AMCA - Special Features APV-16-22 Enz SMDocumento7 páginasAMCA - Special Features APV-16-22 Enz SMEng-Mohammed SalemAinda não há avaliações

- Bomba QC PVHDocumento37 páginasBomba QC PVHJunior Edder Aguilar ApolayaAinda não há avaliações

- Operating Instructions Hydraulic Hammers HM 350 Eco V and HM 580 Eco (V)Documento44 páginasOperating Instructions Hydraulic Hammers HM 350 Eco V and HM 580 Eco (V)Eng-Mohammed SalemAinda não há avaliações

- Amca BP Apv16 BPPSDocumento14 páginasAmca BP Apv16 BPPSEng-Mohammed SalemAinda não há avaliações

- US6196109Documento10 páginasUS6196109Eng-Mohammed SalemAinda não há avaliações

- GC Series Hydraulic PumpsDocumento10 páginasGC Series Hydraulic PumpsdjenanAinda não há avaliações

- CrafcoDocumento59 páginasCrafcofersigalAinda não há avaliações

- MSDocumento12 páginasMSM.Ainda não há avaliações

- Catalogo 312DDocumento24 páginasCatalogo 312DMarioAinda não há avaliações

- Bobkat 435 6902331 enUSDocumento1.537 páginasBobkat 435 6902331 enUSviktorAinda não há avaliações

- Hydraulic Power Unit PDFDocumento8 páginasHydraulic Power Unit PDFAriel DimacaliAinda não há avaliações

- Powertrim PumpeDocumento26 páginasPowertrim PumpeBilly12369Ainda não há avaliações

- Zmywarka Moduł STEROWANIA PB100 PB200 Aeg Service Manual 2Documento39 páginasZmywarka Moduł STEROWANIA PB100 PB200 Aeg Service Manual 2Jan DettlaffAinda não há avaliações

- 29.5in-500psi Diverter Operation ManualDocumento16 páginas29.5in-500psi Diverter Operation ManualIskander KasimovAinda não há avaliações

- UntitledDocumento395 páginasUntitledvaishnavi sharmaAinda não há avaliações

- Single and Double Acting CylindersDocumento41 páginasSingle and Double Acting CylindersDavid SteainsAinda não há avaliações

- Mechanical Chart.01.Documento25 páginasMechanical Chart.01.sri7877Ainda não há avaliações

- StellarHookliftBooklet PDFDocumento99 páginasStellarHookliftBooklet PDFabdul aziz AzizAinda não há avaliações

- 100-510-45436 - H Hpt-06-Mb1-Eb1 O&m ManualDocumento15 páginas100-510-45436 - H Hpt-06-Mb1-Eb1 O&m ManualMiki 40Ainda não há avaliações

- Documentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS RomaniaDocumento80 páginasDocumentatie GRUNDFOS 3 7 Pompa Dozatoare Membrana Hidromecanica DMHQ 1500 LH H 200 Bar Sialco Distribuitor GRUNDFOS Romaniajoko setiawanAinda não há avaliações

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocumento24 páginasTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanAinda não há avaliações

- s650 It4 Maintenance ChartDocumento2 páginass650 It4 Maintenance ChartEdmundas ŽemaitisAinda não há avaliações

- Boom Hydraulic System CAT 330Documento17 páginasBoom Hydraulic System CAT 330hectorAinda não há avaliações

- A4 G930 - G960 Product Brochure enDocumento24 páginasA4 G930 - G960 Product Brochure endalibor_bogdanAinda não há avaliações

- Lift Emergency RescueDocumento29 páginasLift Emergency RescuebugseAinda não há avaliações

- TOSC 004 ManguerasDocumento21 páginasTOSC 004 ManguerasAkaalj Inspeccion100% (1)

- Zoomlion K8JBW BetoneiraDocumento2 páginasZoomlion K8JBW BetoneiraRonaldo FernandesAinda não há avaliações

- Fluid CircuitsDocumento189 páginasFluid CircuitsM.Saravana Kumar..M.E100% (1)

- Bypass Check ValveDocumento2 páginasBypass Check Valvealsief1951Ainda não há avaliações

- M60es44 N449XL TX Man 001Documento27 páginasM60es44 N449XL TX Man 001Riski Kurniawan100% (2)

- Filtro Hidraulico AC80 2Documento2 páginasFiltro Hidraulico AC80 2Jhousep steven Mesia gonzalesAinda não há avaliações

- Instruction Allied W6GDocumento82 páginasInstruction Allied W6G180976Ainda não há avaliações

- Operating Manual: H40-60XT (A380)Documento180 páginasOperating Manual: H40-60XT (A380)mohamed100% (1)

- TransRec 125 SpecDocumento15 páginasTransRec 125 SpecDavid HenrionAinda não há avaliações

- Work Boats Waflaf 2346 - 7760Documento8 páginasWork Boats Waflaf 2346 - 7760Adhietama SumarsonoAinda não há avaliações