Escolar Documentos

Profissional Documentos

Cultura Documentos

Crackers (FCCS), Cokers and Hydrocrackers. in Addition To Breaking Chains, There Are

Enviado por

Mina Adel0 notas0% acharam este documento útil (0 voto)

29 visualizações2 páginasConversion processes are important in refineries because crude oil naturally contains too little petrol and too much heavy oil compared to consumer demands. The primary purpose of conversion processes is to convert the low valued heavy oil into higher valued petrol using catalysts and heat. Key conversion units include the FCC, coker, and hydrocracker which use catalysts and high temperatures to break the longer hydrocarbon chains in heavy oil into shorter chains for lighter products like petrol.

Descrição original:

Título original

Document

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

RTF, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoConversion processes are important in refineries because crude oil naturally contains too little petrol and too much heavy oil compared to consumer demands. The primary purpose of conversion processes is to convert the low valued heavy oil into higher valued petrol using catalysts and heat. Key conversion units include the FCC, coker, and hydrocracker which use catalysts and high temperatures to break the longer hydrocarbon chains in heavy oil into shorter chains for lighter products like petrol.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato RTF, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

29 visualizações2 páginasCrackers (FCCS), Cokers and Hydrocrackers. in Addition To Breaking Chains, There Are

Enviado por

Mina AdelConversion processes are important in refineries because crude oil naturally contains too little petrol and too much heavy oil compared to consumer demands. The primary purpose of conversion processes is to convert the low valued heavy oil into higher valued petrol using catalysts and heat. Key conversion units include the FCC, coker, and hydrocracker which use catalysts and high temperatures to break the longer hydrocarbon chains in heavy oil into shorter chains for lighter products like petrol.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato RTF, PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Distillation separates the crude oil into unfinished products.

However, the products do not

naturally

exist in crude in the same proportions as the product mix that consumers demand. The biggest

difference is that there is too little petrol and too much heavy oil naturally occurring in crude

oil.

That is why conversion processes are so important. Their primary purpose is to convert low

valued

heavy oil into high valued petrol.

All products in the refinery are based on the same building blocks, carbon and hydrogen

chains,

which are called hydrocarbons. The longer the carbon chain, the heavier the product will be.

Converting heavier hydrocarbons to lighter hydrocarbons can be compared to cutting a link on

a steel chain to make two smaller chains. This is the function of the Fluidised Catalytic

Crackers (FCCs), Cokers and Hydrocrackers. In addition to breaking chains, there are

times when we want to change the form of the chain or put chains together. This is

where the Catalytic Reformer and Alkylation are necessary. Specialised catalysts are

of critical importance in most of these processes.

The FCC is usually the key conversion unit. It uses a catalyst (a material that helps make

a chemical reaction go faster, occur at a lower temperature, or control which reactions

occur) to convert gas oil into a mix of Liquefied Petroleum Gas (LPG), petrol and diesel.

The FCC catalyst promotes the reaction that breaks the heavier chains in the right place

to make as much petrol as possible. However, even with the catalyst, the reactions require a

lot of heat; therefore the FCC reactor operates at about 530 degrees Celsius.

The heaviest material in the refinery is Vacuum Tower Bottoms (VTB) or “resid.” If allowed to

cool to

room temperature, it would become a solid. In Australia resid is sold into the paving asphalt

market

or used as a blend component in fuel oil. Resid is too heavy and has too many contaminants to

process in the FCC. A Delayed Coker can be used to convert this heavy material into more

valuable

products. The delayed coker uses high temperature to break the hydrocarbon chains. Delayed

coking reactions are less selective than FCC reactions. Delayed coking also produces a

relatively

low valued petroleum coke as a by-product. (Delayed coking is not used in Australian

refineries)

In some refineries, the FCC and Delayed Cokers are supplemented by Hydrocracking.

Similar to the FCC, the Hydrocracker uses high temperature and catalyst to get the

desired reactions. In Hydrocracking, the catalyst stays in one place and the gas oil

passes over the catalyst, whereas in the FCC the catalyst is much finer and moves

together with the gas oil. The catalyst compositions differ. In Hydrocracking, the reactions

take place at high temperatures in the presence of high concentrations of hydrogen.

The Hydrocracker produces products with low sulphur levels. The light liquid product can be

sent directly to Catalytic Reforming and the other liquid products can be blended directly into

jet

fuel and diesel.

The conversion processes that have been discussed up to this point have focused on reducing

the length of some hydrocarbon chains. However, there are other hydrocarbon chains that are

too short. Butane is produced as a byproduct of other conversion units. The Alkylation Unit

(Alky)

takes two butanes and combines them into a longer chain using a catalyst.

The last conversion process to be discussed is Catalytic Reforming. The purpose of the

reformer

is to increase the octane number of petrol blend components and to generate hydrogen for use

in

the refinery hydrotreaters. The same length carbon chains can have very different octane

numbers

based on the shape of the chain. Straight chains, or paraffins, have a relatively low octane

number,

while rings, also called aromatics, have high octane numbers. At high temperatures and in the

presence of hydrogen, the catalyst will “reform” paraffins into aromatics, thus the name

catalytic

reforming. Some of the aromatics produced are sent to petrochemical manufacturers, where

they

are converted to plastics and fabrics.

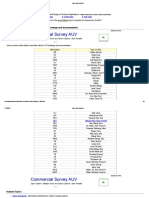

What is made

from a typical

barrel of

crude oil.

Product Litres per barrel

Petrol 70

Distillate Fuel Oil

(Includes both home

heating oil and

diesel fuel) 34

Kerosene-Type Jet Fuels 15

Coke 7

Residual Fuel Oil

(Heavy oils used as fuels

in industry, marine

transportation, and for

electric power generation) 7

Liquefied Petroleum Gases 7

Refinery Fuel Gas 7

Asphalt and Road Oil 5

Petrochemical Feedstocks 4

Lubricants 2

Other 1

C

CONVER SION

onversio

n

Você também pode gostar

- Fluid Catalytic CrackingDocumento10 páginasFluid Catalytic CrackingImran Hanif LubisAinda não há avaliações

- PETROLEUM CRACKING PROCESS GUIDEDocumento23 páginasPETROLEUM CRACKING PROCESS GUIDESrikrishnan KrishAinda não há avaliações

- Fluid Catalytic CrackingDocumento16 páginasFluid Catalytic CrackingArief Maulana IlhamAinda não há avaliações

- Two Phase Relief SizingDocumento9 páginasTwo Phase Relief Sizingashirwad shetty75% (4)

- UZ Petroleum Engineering Catalytic CrackingDocumento9 páginasUZ Petroleum Engineering Catalytic CrackingSaMiHRAinda não há avaliações

- CrackingDocumento32 páginasCrackingMuhammad HAmAd QureshiAinda não há avaliações

- Catalytic Cracking & Hydrocracking Processes ExplainedDocumento96 páginasCatalytic Cracking & Hydrocracking Processes ExplainedSri NivasAinda não há avaliações

- Understanding Powder Flow Properties and Key FactorsDocumento6 páginasUnderstanding Powder Flow Properties and Key FactorsCamii RomeroAinda não há avaliações

- Heavy and Extra-heavy Oil Upgrading TechnologiesNo EverandHeavy and Extra-heavy Oil Upgrading TechnologiesNota: 4 de 5 estrelas4/5 (2)

- Introduction To Petroleum Technology - 3Documento21 páginasIntroduction To Petroleum Technology - 3Anish VazeAinda não há avaliações

- Fluid Catalytic CrackingDocumento9 páginasFluid Catalytic CrackingAntonitoAinda não há avaliações

- Fluid Catalytic CrackingDocumento16 páginasFluid Catalytic Crackingbubalazi100% (1)

- COMPRESOR - Kobelco-Knw-Series-Instruction-Manual-54Documento54 páginasCOMPRESOR - Kobelco-Knw-Series-Instruction-Manual-54YERSONAinda não há avaliações

- My Presentation003 Catalyticcracking SteamcrackingDocumento39 páginasMy Presentation003 Catalyticcracking SteamcrackingAiaru BektemirAinda não há avaliações

- Refining Process-Cataytic CrackingDocumento36 páginasRefining Process-Cataytic CrackingTusenkrishAinda não há avaliações

- Economic Bottom of the Barrel Processing to Minimize Fuel Oil ProductionDocumento5 páginasEconomic Bottom of the Barrel Processing to Minimize Fuel Oil Productionfisco4rilAinda não há avaliações

- Simple Guide To Oil RefiningDocumento5 páginasSimple Guide To Oil RefiningPatel AshokAinda não há avaliações

- Petroleum Technology Two MarkDocumento26 páginasPetroleum Technology Two Markdhanagopal saiAinda não há avaliações

- Thermal and catalytic conversion processes for hydrocarbon crackingDocumento54 páginasThermal and catalytic conversion processes for hydrocarbon crackingSaiPavanAinda não há avaliações

- Coke Steam ReformingDocumento13 páginasCoke Steam ReformingmukthiyarsAinda não há avaliações

- HydrotreatingPoster PDFDocumento1 páginaHydrotreatingPoster PDFekosmind100% (2)

- Hydro ProcessingDocumento56 páginasHydro ProcessinggeorgiadisgAinda não há avaliações

- UOP Fluidized Catalytic Cracking Process: Presented byDocumento31 páginasUOP Fluidized Catalytic Cracking Process: Presented byLaurensAinda não há avaliações

- PETROLEUM REFINING AND PETROCHEMICALS: CATALYTIC CRACKING AND REGENERATIONDocumento6 páginasPETROLEUM REFINING AND PETROCHEMICALS: CATALYTIC CRACKING AND REGENERATIONMilan MoradiyaAinda não há avaliações

- EP422- Hydrocracking Process and CatalystsDocumento26 páginasEP422- Hydrocracking Process and Catalystsazizia harmes0% (1)

- Cracking 151114162534 Lva1 App6891Documento33 páginasCracking 151114162534 Lva1 App6891Truth SeekerAinda não há avaliações

- Spent Catalyst ReportDocumento14 páginasSpent Catalyst Reportstarzgazer100% (1)

- Introduction of Catalytic Reforming ProcessDocumento10 páginasIntroduction of Catalytic Reforming Processsagarchawla13100% (1)

- Overview of Fluid Catalytic Cracking Unit (FCC, Fccu) : Catalyst AluminumDocumento4 páginasOverview of Fluid Catalytic Cracking Unit (FCC, Fccu) : Catalyst AluminumAdemola RabiuAinda não há avaliações

- Catalytic Cracking3Documento12 páginasCatalytic Cracking3Abdurabu AL-MontaserAinda não há avaliações

- Cracking, Visbreaking, Coking and PropertiesDocumento12 páginasCracking, Visbreaking, Coking and Propertiesteyiv23540Ainda não há avaliações

- Project Report On Catalytic CrackingDocumento22 páginasProject Report On Catalytic CrackingAnkit YadavAinda não há avaliações

- CrackingDocumento28 páginasCrackingzaraAinda não há avaliações

- ConocoPhillups GlossaryDocumento7 páginasConocoPhillups GlossaryJesus MoralesAinda não há avaliações

- Catalytic Cracking: Cat Products Become Feed To Other Units, Such As Alkylation andDocumento13 páginasCatalytic Cracking: Cat Products Become Feed To Other Units, Such As Alkylation andPriscilaPrzAinda não há avaliações

- 017 Catalytic CrackingDocumento10 páginas017 Catalytic CrackingJess TobiasAinda não há avaliações

- FALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFDocumento77 páginasFALLSEM2020-21 CHE1014 TH VL2020210101682 Reference Material I 19-Aug-2020 Catalytic Cracking Different Types PDFJateni GedaAinda não há avaliações

- Group WorkDocumento4 páginasGroup WorkRuva Oscass JimmyAinda não há avaliações

- Catalytic CrackingDocumento17 páginasCatalytic Crackingtariq fareedAinda não há avaliações

- Fluid Catalytic Cracking - Wikipedia PDFDocumento9 páginasFluid Catalytic Cracking - Wikipedia PDFSauptik DattaAinda não há avaliações

- Wikiepdia - Cracking Chemistry)Documento6 páginasWikiepdia - Cracking Chemistry)Azrul NizamAinda não há avaliações

- What is Naphtha? Understanding its Properties and UsesDocumento7 páginasWhat is Naphtha? Understanding its Properties and Usesmsabah bugtigAinda não há avaliações

- (79 86) V10N7CTDocumento8 páginas(79 86) V10N7CTertugrul anonymousAinda não há avaliações

- Refinery BasicsDocumento31 páginasRefinery Basicsanurag100% (1)

- Fluid Catalytic Cracking 2Documento27 páginasFluid Catalytic Cracking 2PAWAR ROHAN RAMESHAinda não há avaliações

- Coking and Thermal ProcessesDocumento8 páginasCoking and Thermal ProcessesWulandariAinda não há avaliações

- CrackingDocumento39 páginasCrackingIzziyyahAinda não há avaliações

- Petroleum Fractions (GASOLINE)Documento45 páginasPetroleum Fractions (GASOLINE)Pradeep MunnaAinda não há avaliações

- Unit 3Documento11 páginasUnit 3Shreyash UtekarAinda não há avaliações

- Alhaji Massoud Juma - Petroleum AssignmentDocumento9 páginasAlhaji Massoud Juma - Petroleum AssignmentAlhaj MassoudAinda não há avaliações

- Petroleum Refinery: Soran University Petroleum Engineering DepartmentDocumento24 páginasPetroleum Refinery: Soran University Petroleum Engineering Departmentmustafa sfAinda não há avaliações

- Thermal CrackingDocumento6 páginasThermal CrackingShashank SrivastavaAinda não há avaliações

- Visbreaking, Thermal Cracking, and Coking: Mercaptan ExtractionDocumento4 páginasVisbreaking, Thermal Cracking, and Coking: Mercaptan ExtractionChetan CherryAinda não há avaliações

- Steam ReformingDocumento5 páginasSteam ReformingAshok S. PathakAinda não há avaliações

- 8 Hydrocracking Vs Catalytic CrackingDocumento2 páginas8 Hydrocracking Vs Catalytic CrackingAbhinav ShankarAinda não há avaliações

- Visbreaking, Thermal Cracking, and Coking: ExtractionDocumento4 páginasVisbreaking, Thermal Cracking, and Coking: ExtractionChetan CherryAinda não há avaliações

- Fluid Catalytic Cracking - WikipediaDocumento53 páginasFluid Catalytic Cracking - WikipediaManojkumarAinda não há avaliações

- Chapter-6 Catalytic CrackingDocumento44 páginasChapter-6 Catalytic CrackingVicky TuringAinda não há avaliações

- Module 3: Liquid Fossil Fuel (Petroleum) Lecture 22: Secondary ProcessingDocumento7 páginasModule 3: Liquid Fossil Fuel (Petroleum) Lecture 22: Secondary Processingapi-256504985Ainda não há avaliações

- Catalytic and Thermal Conversion ProcessesDocumento13 páginasCatalytic and Thermal Conversion ProcessesAbdul GhafoorAinda não há avaliações

- ch1Documento36 páginasch1kakakarlAinda não há avaliações

- Fire Pump Test Meter (6.8)Documento2 páginasFire Pump Test Meter (6.8)Luigi CasamassimaAinda não há avaliações

- Properties of SolutionsDocumento18 páginasProperties of SolutionsstineAinda não há avaliações

- WSHP 36 KBTH - LH - 220V1ph - STD - Tstat - Technical Data SheetDocumento2 páginasWSHP 36 KBTH - LH - 220V1ph - STD - Tstat - Technical Data SheetAilefo DelimaAinda não há avaliações

- James 2020Documento19 páginasJames 2020María Pía Arancibia BravoAinda não há avaliações

- Horner's ApproximationDocumento9 páginasHorner's ApproximationAhmad HussenAinda não há avaliações

- Chapter 4Documento77 páginasChapter 4S S S REDDYAinda não há avaliações

- Hazmat S 23 16698Documento40 páginasHazmat S 23 16698Ngô Ích SơnAinda não há avaliações

- Hydrodynamic Stability of Hagen Poiseuille FlowDocumento2 páginasHydrodynamic Stability of Hagen Poiseuille FlowVijay KumarAinda não há avaliações

- Dae 15 Y764Documento4 páginasDae 15 Y764Gerber GarciaAinda não há avaliações

- Sand Handling Experience in Subsea Processing ApplicationsDocumento18 páginasSand Handling Experience in Subsea Processing ApplicationsLiu MengLongAinda não há avaliações

- Angle Seat Valve Fest Data SheetDocumento41 páginasAngle Seat Valve Fest Data SheetVikk SuriyaAinda não há avaliações

- Unit 5Documento48 páginasUnit 5rathiAinda não há avaliações

- Emission Factors for Municipal Waste CombustorsDocumento44 páginasEmission Factors for Municipal Waste CombustorsMelanie AlejandraAinda não há avaliações

- How AODD pumps can handle high viscosity fluidsDocumento3 páginasHow AODD pumps can handle high viscosity fluidsDarshan PatelAinda não há avaliações

- Chapter 1Documento16 páginasChapter 1Moyikaa MargaaAinda não há avaliações

- Power Production Using Leidenfrost EffectDocumento12 páginasPower Production Using Leidenfrost EffectMini VargheseAinda não há avaliações

- Chemical Equilibrium Updated WorksheetDocumento22 páginasChemical Equilibrium Updated Worksheetmehwish razaAinda não há avaliações

- Sprinkler PresentationDocumento21 páginasSprinkler PresentationRajabu HatibuAinda não há avaliações

- Batch ReactorDocumento4 páginasBatch ReactorHarini BugattiveyronAinda não há avaliações

- Indiabulls Power Limited: SOP/OPNS/10 Operations DepartmentDocumento2 páginasIndiabulls Power Limited: SOP/OPNS/10 Operations DepartmentAmit SoniAinda não há avaliações

- Planning The Wet Scrubber On Auxiliary Boiler Unit at Pt. Indonesia Power Ujp Jabar 2 Pelabuhan RatuDocumento13 páginasPlanning The Wet Scrubber On Auxiliary Boiler Unit at Pt. Indonesia Power Ujp Jabar 2 Pelabuhan RatuYuda HerdiantoAinda não há avaliações

- Protivlomni Ventil Za TGDocumento1 páginaProtivlomni Ventil Za TGStevan SteticAinda não há avaliações

- Commercial Survey AUV: Valve AbbreviationsDocumento8 páginasCommercial Survey AUV: Valve AbbreviationsMario StrašniAinda não há avaliações

- SG1 Final PPT Rev1Documento51 páginasSG1 Final PPT Rev1Swarnim RajAinda não há avaliações

- Introduction To HydrologyDocumento5 páginasIntroduction To HydrologyMark Anthony TajonAinda não há avaliações

- Final Boiling AssignmentDocumento47 páginasFinal Boiling AssignmentBrianRungenAinda não há avaliações