Escolar Documentos

Profissional Documentos

Cultura Documentos

Hard Hat, Safety Glasses, Safety Boots Compulsory: Power

Enviado por

Ebeneshwar AnthonyDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Hard Hat, Safety Glasses, Safety Boots Compulsory: Power

Enviado por

Ebeneshwar AnthonyDireitos autorais:

Formatos disponíveis

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

ACTIVITY OR TASK: General Cutting, welding and grinding Location / Project:

JSA Job Number:

Preparation & JSA Number: G21 JSA Revision:

task work

team:

Competence = Relevant Training/Qualifications + Experience

Competence/ Codes of

Qualific’n req’d Practice &

to complete Legislation

work safely that are

JSA approved Name: Position / Competence/ Date: applicable:

by person License:

responsible i.e.

Team Leader /

Tradesman

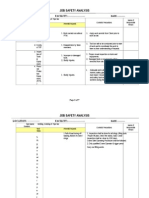

2. HAZARD IDENTIFICATION Identify hazards that may be present by ticking items on the list below.

3. PRECAUTIONS: hard hat, safety glasses, safety boots compulsory

WORK HAZARDOUS HIGH RISK HIGH RISK ADDITIONAL PERMITS

LOCATION AREA PRECAUTIONS

Difficult Hazardous Falling Suspended Gloves: type Hot Work

Entry/Exit Substances Objects loads ………………

- attach MSDS ….

Oxygen to JSA Poor Lighting Poor Goggles Excavation

Deficiency Visibility

Oxygen Working at Slippery Inhalable Full Face Confined

Excess Heights Surfaces Dusts/Fibres Shield Space

Engulfment Remote Area Multiple High Noise High Visibility Hazardous

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

(trench Electrical Levels Vest Work

collapse) Feeds Clearance

Poisonous Motor Room Trip Hazards Use of Harness Access to

Gas Present Hazards Chemicals Area

Temperature Toxic Electrical Elevated Fire High Voltage

Extremes Substances Hazards - LV Work Extinguishers Access

Platform

Defined Potential for Electrical Difficulty to Barricades Scaffolding

Confined Difficult Hazards - HV Communicat

Space Rescue e amongst

Explosive workers Ventilation Other?

Gas Present

Manual Moving Lighting PERMIT

Handling Machinery NUMBER

HAZARDOUS SUBSTANCES in work Sharp Tools & Erect

area / to be used -attach MSDS Materials Equipment Scaffolding to

access

Ladders used Heat/ Respirator or

in the task Sunlight/ Dust mask

Radiation

Working at Traffic Erect Warning

Heights Movement signs

Working near Working near Personal Locks

Crane & Operation or Tag system

Crane Processing Group isolation

Runways Lines

Rail Live Rails Welding screen

Movement

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Pressurised Pneumatics Fall Arrest

Fluids systems

Flamm. Welding Face

Materials Shield

Present

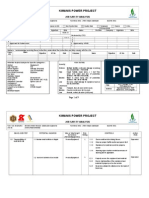

4. ENVIRONMENTAL HAZARDS – (IMPACTS) tick those identified Likelihood: Consequences: how severe an injury?

Medical 1st Aid

Air Pollution Spills to Other: RISK RATING TABLE How likely is it to

be that bad?

Death Serious

Injuries Treatment req’d

Req’d

(dust, fumes) ground This table is used to Almost Certain - 10 9 8 7

Noise (plant & Soil Erosion calculate whether the Expected to Occur

Likely – could

equipment) hazard you have identified happen sometime

9 8 7 6

Spills to Hazard to is Extreme: 9-10 Moderate – could

happen but not likely

8 7 6 5

High: 7-8, Unlikely – could

drains/waterw Flora /Fauna happen but very rare

7 6 5 4

ays Medium: 5-6 or Rare - could happen

6 5 4 3

Low: 3-4 but probably never will

5. EQUIPMENT REQUIRED:

Static Plant & The objective of rating the

Equipment risk is to lower the risk by

Mobile Plant & initiating risk control

Equipment measures. The score is

noted in the JSA risk score

Safety /

column on the next page –

Emergency

both before & after risk

Equip’t

control measures have been

nominated.

NAME OF TASK: General Cutting, welding and grinding JSA Number: G21

Rev:

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

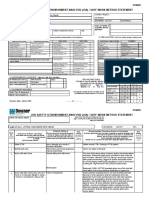

Potential Safety & Risk Recommended Corrective Action or Risk

Ste Sequence of Basic Job Environmental Ratin Procedure Ratin

p Steps Hazards/Impacts g Determine what actions are necessary to g

No. Break down Job into steps. Identify the hazards Use eliminate or minimise all hazards that could Of the

Logi Each step should (health and safety or table lead to an accident, injury, illness or risk

cal accomplish a major task environmental) on the environmental incident. The risk must be followi

sequ and be logical. associated with each previo reduced or controlled to a level that is ng

ence Environmental Aspects step, examine each to us acceptable before work commences. correc

find all possible risk page Indicate who is to perform the action where tive

factors to applicable against each action action

score

risk

1 Determine Location Injury or equipment Toolbox talks before job start, correct

damage as a result of supervision

unfamiliarity with worksite

2 Receive PTW Injury or equipment All personnel working on permit must

damage as a result of understand permit to work system and if in

unfamiliarity with job doubt ask supervisor

scope and permit system

3 Pre-work setup Injury due to fire. Hot work procedure must be adhered to and

Explosion, sparks and permit conditions observed.

flashes, as a result of

poor welding habitat

setup

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

4 Welding, grinding and oxy Injury due to fire. Maintain a visual check of conditions in

cutting Explosion, sparks and welding habitat, fire extinguisher, gas testing,

flashes, as a result of cover drains, use fire spotter

failure to adhere to Ensure adequate fresh air is around weld area

permit conditions. and that fumes are efficiently extracted away

from the local work area.

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Ensure job is set up as per safe welding

procedures.

Only trained personnel to carry out welding.

Fit earth clamp securely to job.

Welders must wear flame resistant work

clothing

and supplied leather PPE where applicable.

Wear gloves to protect hands and arms.

Wear welders shield with filter shade No. 7 to

15 inclusive.

Wear AS1337 safety spectacles under welding

shields.

Use welding screens or blankets to shield arc

from other personnel.

Welders assistants MUST WEAR anti weld

flash eye

protection to AS1337.

If assistant required to look at the arc, then the

sameprotection as welder is required.

5 Clean up worksite Slips trips and falls due Remove tools equipment and rubbish from

to poor housekeeping worksite and maintain a clean work

environment.

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA) / SAFE WORK METHOD STATEMENT

Revision Date: March 2005 ………. of ………….. OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

CONSULTATION & SIGN-OFF RECORD

I confirm by my signature below, that I have attended a briefing on the requirements

of the attached Job Safety & Environment Analysis and agree to perform the work in

the manner detailed on it.

I confirm that copies of the relevant Permits, MSDS's, Isolation Plans etc. have been

reviewed.

JSA JSA Rev:

NAME No:

NAME (Please print) SIGNATURE DATE

Revision Date: March 2005 OHS-03-F01

POWER

JOB SAFETY & ENVIRONMENT ANALYSIS (JSA)

THIS SAFE WORK BRIEFING / TRAINING WAS CARRIED OUT BY (responsible

person at that location) :

Name: Signature: Date:

Client sign off (where applicable)

Site / Project Manager sign off

(document reviewed)

Revision Date: March 2005 OHS-03-F01

Você também pode gostar

- JOB SAFETY ANALYSIS FOR WELDINGDocumento2 páginasJOB SAFETY ANALYSIS FOR WELDINGSravan Dasari100% (3)

- Jsa CraneDocumento3 páginasJsa Cranenattwa201075% (24)

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocumento2 páginasSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- JSA For Cutting, Grinding and WeldingDocumento4 páginasJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Jsa Grinding Welding Gas CuttingDocumento3 páginasJsa Grinding Welding Gas CuttingRana Waseem Khan82% (79)

- JSA Fitting and Welding Work For Pipe Trench InstalationDocumento6 páginasJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Jsa For Lifting (Crane) 016Documento6 páginasJsa For Lifting (Crane) 016aliraza572270% (27)

- JSA Welding Confined SpaceDocumento2 páginasJSA Welding Confined Spacegkmlal100% (4)

- Jsa-Jha For Using of Hand ToolsDocumento2 páginasJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA For Welding GrindingDocumento7 páginasJSA For Welding GrindingBabar78% (9)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocumento7 páginasJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanAinda não há avaliações

- Jsa Installation of Supports and Cable Racks1Documento16 páginasJsa Installation of Supports and Cable Racks1loveson709100% (3)

- Jsa For Arc WeldingDocumento3 páginasJsa For Arc Weldingtnssbhaskar100% (5)

- JSA G20 Scaffolding (Erection, Dismantling)Documento4 páginasJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Erect Steel Structures SafelyDocumento9 páginasErect Steel Structures SafelyLuqman Osman77% (13)

- JSA HandToolsDocumento2 páginasJSA HandToolsCristina Rican100% (3)

- JSA CarpentryDocumento2 páginasJSA Carpentrysubhanmusadiq91% (11)

- Column Erection JSA AnalysisDocumento6 páginasColumn Erection JSA AnalysisRaghava Richhu100% (2)

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocumento9 páginasRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariAinda não há avaliações

- Jsa Grinding Welding Gas CuttingDocumento3 páginasJsa Grinding Welding Gas CuttingQomarudin Comenk100% (2)

- JSA G17 Lift Container With CraneDocumento4 páginasJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocumento4 páginasMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- 1 - Scaffolding WorkDocumento16 páginas1 - Scaffolding WorkPerwez21100% (14)

- JSA-Working at HeightDocumento2 páginasJSA-Working at Heightsubhanmusadiq83% (107)

- Crane JSADocumento5 páginasCrane JSAKritsada Tiwutanon100% (1)

- Civil JSA Form Block WorkDocumento3 páginasCivil JSA Form Block Workdrmuhsin86% (7)

- JSA Roof Sheeting V3 16 July 06Documento6 páginasJSA Roof Sheeting V3 16 July 06Walt Flowers80% (5)

- JSA of Loading & Un Loading ActivitiesDocumento3 páginasJSA of Loading & Un Loading ActivitiesMohammed Minhaj100% (1)

- JsaDocumento39 páginasJsajithin shankar100% (3)

- JSA For Material ShiftingDocumento3 páginasJSA For Material ShiftingMohammed Minhaj100% (1)

- Jsa General HousekeepingDocumento2 páginasJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- Jsa Grinding W Angle GrinderDocumento2 páginasJsa Grinding W Angle GrinderMichael Angelo SanteAinda não há avaliações

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocumento17 páginasSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- Job Safety Analysis (Jsa)Documento11 páginasJob Safety Analysis (Jsa)Noraini Binti Osman50% (2)

- Job Safety Analysis For Scaffolding 1Documento3 páginasJob Safety Analysis For Scaffolding 1nasar_mahsood71% (34)

- Jsa ExcavationDocumento33 páginasJsa Excavationlal5012002390782% (17)

- 1installation of Steel Structures JHA 1 (06!06!2015)Documento33 páginas1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- Job Steps, Hazards and ControlsDocumento4 páginasJob Steps, Hazards and ControlsCristina Rican100% (1)

- Hot Works JSA Example - 2Documento2 páginasHot Works JSA Example - 2shaheer79% (33)

- Welding and Grinding HazardsDocumento6 páginasWelding and Grinding HazardsJeremia Samosir100% (2)

- JSA Steel Erection ManliftsDocumento1 páginaJSA Steel Erection Manliftsrudygoot100% (1)

- Jsa For Piping and Erection RevisedDocumento1 páginaJsa For Piping and Erection RevisedAlvin Smith77% (26)

- Draft JSA Levelling & GradingDocumento9 páginasDraft JSA Levelling & GradingAzeem Khan33% (3)

- Aboveground Piping Installation Works 2016Documento7 páginasAboveground Piping Installation Works 2016Aldrin75% (4)

- Petrofac Steel Erection Risk AssessmentDocumento4 páginasPetrofac Steel Erection Risk AssessmentVivek Naik100% (2)

- JHA Civil WorksDocumento2 páginasJHA Civil Worksethelchudi100% (11)

- JSA WeldingDocumento2 páginasJSA WeldingSigint Sides0% (3)

- JSA Cable LayingDocumento2 páginasJSA Cable Layingnishanth100% (2)

- JSA Blasting and Coating KP 69.4Documento5 páginasJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- JSA Shut Down and Tie in Work PDFDocumento6 páginasJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- JSA For False CeilingDocumento4 páginasJSA For False CeilingJaved100% (3)

- Welding, Cutting and GrindingDocumento6 páginasWelding, Cutting and GrindingMohammed MinhajAinda não há avaliações

- Jsa For Scaffolding Erection & DismentlingDocumento7 páginasJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

- JSA G20 Scaffolding Erection DismantlingDocumento4 páginasJSA G20 Scaffolding Erection DismantlingemmyAinda não há avaliações

- Crane Safety TipsDocumento4 páginasCrane Safety Tipssetiawanaji407100% (1)

- JSA G17 Lift Container With CraneDocumento4 páginasJSA G17 Lift Container With Cranesetiawanaji407Ainda não há avaliações

- JSA Safety AnalysisDocumento3 páginasJSA Safety AnalysisLusy Gusti EfendiAinda não há avaliações

- Job Safety Analysis for Instrument Sample Point InstallationDocumento3 páginasJob Safety Analysis for Instrument Sample Point InstallationNasrullah JanAinda não há avaliações

- JSA - Scissor - Lift 2023Documento4 páginasJSA - Scissor - Lift 2023syed khaja misbhuddinAinda não há avaliações

- JSA For Lift Personnel in Scissor LiftDocumento6 páginasJSA For Lift Personnel in Scissor Liftnawalmaftah23Ainda não há avaliações

- DGPS Sensor JLR-4331W Instruction ManualDocumento42 páginasDGPS Sensor JLR-4331W Instruction ManualantonioAinda não há avaliações

- Anxiolytics Sedatives Hypnotics Pharm 3Documento38 páginasAnxiolytics Sedatives Hypnotics Pharm 3Peter Harris100% (1)

- Abundance BlocksDocumento1 páginaAbundance BlockssunnyAinda não há avaliações

- كونكت بلس - 2 ابتدائي - ترم 1 - مذكرة 2Documento86 páginasكونكت بلس - 2 ابتدائي - ترم 1 - مذكرة 2cafubodoAinda não há avaliações

- ARES SC4 Service Manual (HP-300UA)Documento20 páginasARES SC4 Service Manual (HP-300UA)mike_net8903Ainda não há avaliações

- DerbyCityCouncil Wizquiz Presentation PDFDocumento123 páginasDerbyCityCouncil Wizquiz Presentation PDFShubham NamdevAinda não há avaliações

- REMEDIATION-Focus BDocumento13 páginasREMEDIATION-Focus BCharmaine PerioAinda não há avaliações

- IruChem Co., Ltd-Introduction of CompanyDocumento62 páginasIruChem Co., Ltd-Introduction of CompanyKhongBietAinda não há avaliações

- L C R Circuit Series and Parallel1Documento6 páginasL C R Circuit Series and Parallel1krishcvrAinda não há avaliações

- 2 - Alaska - WorksheetsDocumento7 páginas2 - Alaska - WorksheetsTamni MajmuniAinda não há avaliações

- Chapter 4 Cost MinimizationDocumento6 páginasChapter 4 Cost MinimizationXavier Hetsel Ortega BarraganAinda não há avaliações

- Enviroclean 25 LTRDocumento1 páginaEnviroclean 25 LTRMaziyarAinda não há avaliações

- Combustion Cat 2008Documento32 páginasCombustion Cat 2008Miguel LinaresAinda não há avaliações

- Tyfo SDocumento2 páginasTyfo SAndi AsAinda não há avaliações

- Bajaj Auto Company NewDocumento94 páginasBajaj Auto Company Newbhas_786Ainda não há avaliações

- Mitchella Partridge Berry Materia Medica HerbsDocumento3 páginasMitchella Partridge Berry Materia Medica HerbsAlejandra GuerreroAinda não há avaliações

- GERD – Definition, pathophysiology, epidemiology and diagnostic investigationsDocumento132 páginasGERD – Definition, pathophysiology, epidemiology and diagnostic investigationsSorana VasilescuAinda não há avaliações

- Strategic Management Plan analyzing Unilever's macro and micro environmentsDocumento17 páginasStrategic Management Plan analyzing Unilever's macro and micro environmentsMd Moshiul HaqueAinda não há avaliações

- Gps Vehicle Tracking System ProjectDocumento3 páginasGps Vehicle Tracking System ProjectKathrynAinda não há avaliações

- Welcome To International Journal of Engineering Research and Development (IJERD)Documento9 páginasWelcome To International Journal of Engineering Research and Development (IJERD)IJERDAinda não há avaliações

- Screenshot 2023-01-03 at 9.25.34 AM PDFDocumento109 páginasScreenshot 2023-01-03 at 9.25.34 AM PDFAzri ZakwanAinda não há avaliações

- UNIT-2 Design of Spur GearDocumento56 páginasUNIT-2 Design of Spur GearMarthandeAinda não há avaliações

- Coloi Eeml Disease: Original ArticlesDocumento67 páginasColoi Eeml Disease: Original ArticlesLuisAngelPonceTorresAinda não há avaliações

- Navmesh Plus: How ToDocumento7 páginasNavmesh Plus: How TobladimirAinda não há avaliações

- QUESTION A2 and A3 Examples PDFDocumento24 páginasQUESTION A2 and A3 Examples PDFDemian VeAinda não há avaliações

- Lab Manual Cape Bio Unit 1 2023Documento37 páginasLab Manual Cape Bio Unit 1 2023drug123addict25Ainda não há avaliações

- Nakshatra Exaltation DebilitationDocumento3 páginasNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- BiologyDocumento21 páginasBiologyHrituraj banikAinda não há avaliações

- Digital B&W Copiers (D154/D155-NA) Parts CatalogDocumento118 páginasDigital B&W Copiers (D154/D155-NA) Parts Catalogkhoi vuAinda não há avaliações

- Supply Chain Management: Tata Tea's Global OperationsDocumento15 páginasSupply Chain Management: Tata Tea's Global OperationsAmit Halder 2020-22Ainda não há avaliações