Escolar Documentos

Profissional Documentos

Cultura Documentos

Mechanical Seal

Enviado por

moonofvuDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Mechanical Seal

Enviado por

moonofvuDireitos autorais:

Formatos disponíveis

Mechanical Seals with Oil as Buffer

in High-Pressure Centrifugal Pumps

High-pressure centrifugal pumps offer such operational advantages as mechanical reliability and

low maintenance cost. Buffer fluid used in most of the pumps is water, which can cause freezing and

pump warping. The operating experience with tandem mechanical seals using oil as a buffer fluid

shows that it is reliable and efficient.

Arif Jamal

Fauji Fertilizer Company Ltd., Goth Machhi, Sadikabad, District Rahim Yar Khan, Pakistan

Plant Ammonia Pump

Fauji Fertilizer Company Ltd. (FFC) operates two Table 1 contains ammonia pump data. To produce

Ammonia I urea plants at Goth Machhi, Pakistan. The urea, liquid ammonia is required at very high pressure.

first plant (Plant I) was commissioned hi early 1982 Liquid ammonia arrives at a urea plant battery limit of

with design capacities of 1,000 metric ton of ammonia about 15 bar and 36°C from the ammonia plant and it

and 1,725 metric ton of urea per day. The plant was is stored in a vessel. Downstream of this vessel, two

successfully revamped to 122% of design capacity in booster pumps increase the ammonia pressure from

1990. The second plant (Plant II) with design capaci- about 15 bar to 23 bar. This low-pressure liquid

ties of 1,100 metric ton of ammonia and 1,925 metric ammonia is then pumped to high-speed, two-stage

ton of urea per day was commissioned in March, centrifugal pumps driven by 6.3-kV electric motors. A

1993. Both plants employ Haldor Tops0e technology gearbox is provided to increase pump speed. Both

for ammonia and the Snamprogetti process for urea. stages operate at the same speed.

FFC opted for use of modern technologies in its Discharge of the second stage at about 223 bar is

plants. High-speed centrifugal ammonia feed pumps sent toward the urea reactor as feed for the urea syn-

were selected for the urea unit of Plant 2. The pump thesis reaction.

model selected was Sundstrand Model HMP 5112, Composition of liquid ammonia is as follows:

similar to high-pressure carbamate pumps which have

been successfully proven in many urea plants through- NH3 99.80 wt. %

out the world. A similar model for carbamate service H20 0.20 wt. %

has been operating virtually troublefree at Plant I. Oil 5 ppm (max.)

AMMONIA TECHNICAL MANUAL 160 1996

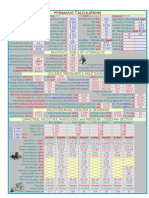

Table 1. Ammonia Pump Data

Fluid handled Liquid Ammonia

Temp, min/oper/max. °C 20/36/40

Density at min/oper/max. Temp. kg/m3 610/586/579

Pump speed rpm 20562

Suction pressure nor/max. bar 23/28

Discharge pressure bar 223

Differential pressure bar 204

Capacity min/nor/rated 67.7/119/127 (152 max.)

N.P.S.H available m 150

Estimated absorbed power kW 1,220

Sealing type Tendern Mechanical

Flushed fluid NH3 + Buffer

No. of impellers 2

Dia. first stage design/max. mm 130.81/136.27

Dia. second stage design/max. mm 158.24/164.5

At any time, one pump shall remain in service while seal chambers of both stages through pressure letdown

the other is on standby. Changeover/startup is only orifices. Low-pressure differential switches monitor-

done in the field after thorough checking. ing the buffer oil flow in seal chambers of first and

Motor/pumps are equipped with various alarms and second stages are set to alarm when flow decreases

trips to safeguard one of the most critical machines of (Figure 1).

the complex. The seal flush is drawn off the first-stage discharge,

filtered and introduced through a pressure control

Seal System valve to the first stage and directly to the second stage.

Low-pressure differential switches monitor the seal

The Fauji HMP-5112 ammonia pumps incorporate flush flow in both stages (Figure 2).

tandem mechanical seals arrangements, using a seal

flush with process fluid and a seal buffer with oil. Seals

The buffer oil is drawn from the reservoir tank and

pumped to both stages. Prior to entering the seal The process side seals are John Crane Type 8 AB

chambers of both stages, the pressure is monitored by with hydro pads (Figure 3). The hydro pad design pro-

orifices which also are provided at the downstream of vides additional film thickness for sealing light fluids.

buffer seals to prevent ammonia vaporization. These stationary seals are carbon graphite with 78%

The buffer system has a bypass, pressure differential balance face. A retainer material SS 316 retains the

control valve PDCV to reduce the buffer oil pressure face, and four antirotation lugs in the retainer prevent

during startup and shutdown. The valve position is the face rotation. Four springs keep the stationary and

controlled by pressure transmitters which help in rotating faces together. The seal-mating face (rotating

responding to process pressure and buffer oil pressure face) is of tungsten carbide encapsulated by a SS 316

and in maintaining a differential pressure between ring.

process and buffer oil. The buffer oil is introduced in Buffer oil seals are similar in construction except for

AMMONIA TECHNICAL MANUAL 161 1996

ft

*t

AL

n

HM- 'M

M' N

M' -M-

Figure 1. Buffer oil system of Fauji pumps. Figure 2. Seal flush system of Fauji pumps.

RETAINER

STATIONARY FACE

THRUST PUWE RETAINER

ATING FACE

SPRING ^

f_ ANTI-ROTATI0H PIN

STATIONARY fACE

SLEEVE 0-RINGS

PROCESS SEAL

(HYDRO PADS)

ANTI ROTATION LUG AHT1 ROTATION LUG

Figure 3. Seal details. Figure 4. Modification in buffer oil seals.

AMMONIA TECHNICAL MANUAL 162 1996

DISCHARGE UNE

expectations until its root problem was rectified.

Deterioration in the internal parts of its controller and

RECYCLE LINE

transmitters was very frequent. Various attempts were

SUCTION UNE

made to calibrate the controllers and transmitters, but

X results were not positive. This valve had to be operat-

ed manually on a number of occasions when it started

X malfunctioning. During the investigation it was dis-

covered that external vibrations transmitting from pip-

ing was causing distress in the control valve's trans-

mitters. The transmitter was relocated to a more

remote location where vibration could not be induced

from the surroundings. This resolved the problem and

Figure 5. Nitrogen pressurizing. allowed the control valve to be put back in automatic

operation.

hydraulic balance (65%) and face material (graphite Recycle Flow Valves. Fauji pumps are furnished with

with 70% silicon carbide). The hydro pads are not pro- recycle flow valves which help maintain the pump

vided here, since it is sealing viscous oil. operation within the operating range. The pumps

tripped a number of times due to malfunctioning of

Operating Experience these flow valves. These valves were problematic

since the commissioning of the urea plant. It was

During the first year of operation, the buffer seal observed that the buffer oil seal life was shortened fur-

failure incidents were unexpectedly high. All the fail- ther when pumps encountered more startups and shut-

ure incidents were investigated. To address the prob- downs. Extensive work was carried out to rectify the

lem, a modification was also carried out by the manu- abnormal behavior of these valves, but the problem

facturer in buffer seals to improve the reliability of could not be resolved. To avoid such trips, however,

seals. Eventually, all the problems were overcome, and the flow is being controlled using a manual isolating

seal performance is now satisfactory. Following are valve as a recycle control valve.

details of some of the incidents. Process Fluid Temperature Variation. Variation in

ammonia temperatures at pump suction causes

Buffer oil seal failures changes in the axial thrust of the pump rotor. The

rotating seal faces that are mounted on the rotor also

Initially, the average life of seals was about two move axially with rotor axial movement. About 10°C

months. The majority of the failures were of buffer oil temperature variation results in 0.02-0.03 mm of rotor

seals. axial movement. This axial movement aggravated the

Wearing of Antirotation Lugs. Almost all of the deterioration of antirotation lugs of buffer seals.

failed seals exhibited a common problem, which was Blockage of Flow Orifices. The flow orifices

premature wearing of the antirotation lugs. Premature installed downstream of buffer oil seal chambers

wearing of antirotation lugs was due to various rea- plugged a number of times. This caused low flow in

sons. the seals which resulted in seal damage. Such plug-

Pressure Differential Control Valve. The buffer oil ging occurred mainly due to small pieces that occa-

seal arrangement is simple and employs flow orifices sionally dislodged from buffer seal faces and choked

for pressure monitor. The pressure differential control the orifices. As a countermeasure, strainers were

valve is the only control valve buffer circuit; however, installed upstream of these orifices. Blockage has not

its malfunction has direct effect on seal life. The been experienced after this modification.

response of the pressure differential control valve Modification in Buffer Oil Seals. To address the fre-

installed at the buffer oil circuit had not been up to quent wearing problem of antirotation lugs, the buffer

AMMONIA TECHNICAL MANUAL 163 1996

seals were modified by the pump manufacture (Figure Conclusion

4). Instead of providing antirotation lugs, an antirota-

tion pin of tungsten carbide was installed. This modifi- Despite the initial seal-related problems, the pump

cation has been proven as the permanent solution of has achieved a high service factor. After overcoming

the problem. To improve the reliability, seal O rings the problems of seal failures, the tandem mechanical

were also changed from neoprene to teflon U cup seals using oil as buffer fluid is now regarded as a reli-

rings. able arrangement in high-pressure ammonia pumps,

Shattering of Rotating Faces. During the initial peri- which can be recommended for urea plant service.

od of commissioning, process seals failed several

times when the pump was shutdown and depressurized Acknowledgment

(Figure 5). In these incidents the rotating faces of

process seals were found shattered. Investigation The author wishes to acknowledge his gratitude to

revealed that rotating faces were damaged due to ther- M/S Adil Bin Rauf and Imran Ghauri, Machinery

mal shock. These faces underwent thermal shocks Engineers of Fauji Fertilizer Company Ltd., Goth

when the seal was hot and exposed to low temperature Machhi, for providing active support during the prepa-

as a result of pump depressurization. The problem was ration of this article.

successfully resolved by depressurizing/pressurizing

under positive nitrogen pressure.

AMMONIA TECHNICAL MANUAL 164 1996

Você também pode gostar

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNo EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNota: 5 de 5 estrelas5/5 (1)

- Why Mech Seal FailDocumento5 páginasWhy Mech Seal FailMunam AhmedAinda não há avaliações

- What Is The Best Silicon Carbide Wear Face Material For My Mechanical SealDocumento3 páginasWhat Is The Best Silicon Carbide Wear Face Material For My Mechanical SealMahmoud Al HomranAinda não há avaliações

- Aes Api682 01Documento9 páginasAes Api682 01meghanahariAinda não há avaliações

- Sealing Extreme Cold Application - FSADocumento3 páginasSealing Extreme Cold Application - FSASulaiman Kadher KAinda não há avaliações

- Dual Gas-Lubricated Seals Provide Energy Efficient SolutionsDocumento2 páginasDual Gas-Lubricated Seals Provide Energy Efficient Solutionssudhindra_tiwariAinda não há avaliações

- John Crane Type FFETDocumento6 páginasJohn Crane Type FFETUntung S PrawotoAinda não há avaliações

- Mechanical Seals for PumpsDocumento5 páginasMechanical Seals for PumpsbryandownAinda não há avaliações

- JC 2648 Seal IOM Manual PDFDocumento4 páginasJC 2648 Seal IOM Manual PDFRené Mora-CasalAinda não há avaliações

- TD 5610V 5610VQ 5620VP 2PG BW Oct2015Documento2 páginasTD 5610V 5610VQ 5620VP 2PG BW Oct2015Pham Thien TruongAinda não há avaliações

- Key to Selection Pages Fluid DataDocumento42 páginasKey to Selection Pages Fluid DataPete PompesAinda não há avaliações

- Technical Specifications Mechanical Seal ComparisonDocumento3 páginasTechnical Specifications Mechanical Seal Comparisonsushant_jhawerAinda não há avaliações

- John CraneDocumento16 páginasJohn CraneMenta Basita Bangun100% (1)

- 2007 The TOYO Urea Granulation TechnologyDocumento14 páginas2007 The TOYO Urea Granulation Technologyaaa206Ainda não há avaliações

- Resources Mechanical AESSEAL Guides PHOSDocumento24 páginasResources Mechanical AESSEAL Guides PHOSAlexandros GiannikosAinda não há avaliações

- Explosive DecompressionDocumento11 páginasExplosive DecompressionAndrey EkkertAinda não há avaliações

- Materials guide with UK and US codesDocumento12 páginasMaterials guide with UK and US codesAan Sarkasi AmdAinda não há avaliações

- 1648 ManualDocumento29 páginas1648 ManualSherif Adel100% (2)

- Eagle Report 4Documento34 páginasEagle Report 4Priya Pawar100% (1)

- KTR Magnetic Coupling CatalogDocumento10 páginasKTR Magnetic Coupling CatalogHyungTae JangAinda não há avaliações

- EagleBurgmann - Competence in Agitator Seals - 2017Documento42 páginasEagleBurgmann - Competence in Agitator Seals - 2017munhAinda não há avaliações

- 100 Mechanical SealsDocumento20 páginas100 Mechanical SealsDeepa VpAinda não há avaliações

- L Uk SugarDocumento16 páginasL Uk SugarnarupvAinda não há avaliações

- Screw Pump HC 232 - 80/2 / N: 1.0 Project DataDocumento1 páginaScrew Pump HC 232 - 80/2 / N: 1.0 Project DataBenicio Joaquín Ferrero BrebesAinda não há avaliações

- FSD101eng FSG Seals Catalog A4Documento64 páginasFSD101eng FSG Seals Catalog A4ASHOKAinda não há avaliações

- Inoxpa - ManualDocumento93 páginasInoxpa - ManualnikitaAinda não há avaliações

- The Dual Seal ArrangementDocumento17 páginasThe Dual Seal Arrangementnyuvaraj1981Ainda não há avaliações

- Roten CatalogDocumento6 páginasRoten Catalogoaves124Ainda não há avaliações

- Mech Seals Selection Guide 2Documento6 páginasMech Seals Selection Guide 2taghdirimAinda não há avaliações

- JOhnCrane Dry Gas Seal Pumps PF - 2874Documento2 páginasJOhnCrane Dry Gas Seal Pumps PF - 2874Mohammed Al-BrashdiAinda não há avaliações

- Mechanical Seals According To StandardsDocumento6 páginasMechanical Seals According To StandardsSunit MishraAinda não há avaliações

- Mechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocusDocumento21 páginasMechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocuspratapAinda não há avaliações

- Next generation materials for pumps and mechanical sealsDocumento3 páginasNext generation materials for pumps and mechanical sealsmadairkifAinda não há avaliações

- Uk Coding ScrewsDocumento14 páginasUk Coding ScrewsAan Sarkasi Amd100% (1)

- 4 Ways To Prevent Seal FailureDocumento5 páginas4 Ways To Prevent Seal FailureGlobe Star Engineers Pvt LtdAinda não há avaliações

- L Uk SulphDocumento24 páginasL Uk SulphypyeeAinda não há avaliações

- m7n Eagle Burgmann Mechancal SealDocumento23 páginasm7n Eagle Burgmann Mechancal SealStathis MoumousisAinda não há avaliações

- JHON CRANE 2152037 Barrier FluidsDocumento19 páginasJHON CRANE 2152037 Barrier Fluidstotalquality100% (2)

- What Determines Seal Leakage?Documento3 páginasWhat Determines Seal Leakage?Pradeep MotaparthyAinda não há avaliações

- Pressurized Mech Seals Piping PlansDocumento9 páginasPressurized Mech Seals Piping PlanssachinumaryeAinda não há avaliações

- Datum Compressor Cut PDFDocumento1 páginaDatum Compressor Cut PDFJ.SIVIRAAinda não há avaliações

- Resources Mechanical AESSEAL Guides AUTODocumento16 páginasResources Mechanical AESSEAL Guides AUTOmanoAinda não há avaliações

- 6 Reasons Why Mechanical Seals FailDocumento3 páginas6 Reasons Why Mechanical Seals Failgustavo rivaroliAinda não há avaliações

- Double Mechanical Seals, Tandem ArrangementDocumento10 páginasDouble Mechanical Seals, Tandem ArrangementViwek MertiyaAinda não há avaliações

- API Seal Plans 52 and 53 A/BDocumento21 páginasAPI Seal Plans 52 and 53 A/BvenkeekuAinda não há avaliações

- Module 04.4 - Seal ArrangementsDocumento15 páginasModule 04.4 - Seal ArrangementsMostafaAinda não há avaliações

- Seal Material and Arrangement GuideDocumento48 páginasSeal Material and Arrangement Guideleo100% (2)

- Windows-1256 Mechanical Seals For ABS Pumps en PDFDocumento4 páginasWindows-1256 Mechanical Seals For ABS Pumps en PDFaminjolesAinda não há avaliações

- API682 For Mechanical Seal-Rev 00Documento34 páginasAPI682 For Mechanical Seal-Rev 00fahruAinda não há avaliações

- Acoples FLOWSERVE - Instalación PDFDocumento12 páginasAcoples FLOWSERVE - Instalación PDFJenny Cecilia Ureña ZuriAinda não há avaliações

- Mechanical Seal Principles Chesterton)Documento6 páginasMechanical Seal Principles Chesterton)Joon EeoAinda não há avaliações

- Improving Mechanical Seal ReliabilityDocumento4 páginasImproving Mechanical Seal ReliabilityBala MuruganAinda não há avaliações

- 1 Magnetic-Drive-PumpsDocumento19 páginas1 Magnetic-Drive-PumpsMuzammil PiyarjiAinda não há avaliações

- Top Entry Mixer Features For EkatoDocumento2 páginasTop Entry Mixer Features For EkatoShankarAinda não há avaliações

- Safe MaticDocumento4 páginasSafe Maticsulai2000Ainda não há avaliações

- Seal Flushing PlansDocumento11 páginasSeal Flushing PlansSakthikumar ChandrasekaranAinda não há avaliações

- Up-Stream Pumping - Presentation1Documento46 páginasUp-Stream Pumping - Presentation1Chozha RajanAinda não há avaliações

- SUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Documento5 páginasSUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Liz Lynn LimAinda não há avaliações

- Sir Ul AsrarDocumento267 páginasSir Ul AsrarmoonofvuAinda não há avaliações

- HG DS1Documento6 páginasHG DS1moonofvuAinda não há avaliações

- Hydrocarbons LabDocumento10 páginasHydrocarbons LabmoonofvuAinda não há avaliações

- Advanced Supervisory SkillsDocumento378 páginasAdvanced Supervisory Skillsmoonofvu100% (2)

- Estimating Water Requirements For Firefighting Operations Using FIERAsystemDocumento28 páginasEstimating Water Requirements For Firefighting Operations Using FIERAsystemmoonofvuAinda não há avaliações

- PLL 1566Documento12 páginasPLL 1566cuervohijoguachoAinda não há avaliações

- Inpit Tailings Disposal Case History at Marymia Gold OperationDocumento13 páginasInpit Tailings Disposal Case History at Marymia Gold OperationyordyalejandroAinda não há avaliações

- Liebherr Hs DimensionsDocumento12 páginasLiebherr Hs DimensionsLiebherrAinda não há avaliações

- BCWDocumento13 páginasBCWRohit100% (2)

- 9245 Single Channel On-Line Sodium Analyzer-Operator ManualDocumento130 páginas9245 Single Channel On-Line Sodium Analyzer-Operator Manualdenios09Ainda não há avaliações

- Matrix Coolant Sump CleanerDocumento2 páginasMatrix Coolant Sump Cleaneraditya1759Ainda não há avaliações

- 2011 Sakura WSHP R410A - Installation ManualDocumento12 páginas2011 Sakura WSHP R410A - Installation ManualMaurizio DumitracheAinda não há avaliações

- Dynamic - Absolute and Kinematic ViscosityDocumento5 páginasDynamic - Absolute and Kinematic ViscositySofyan HadiAinda não há avaliações

- Intake StructuresDocumento25 páginasIntake StructuresSalabha TG100% (1)

- B1 OperatingInstructionsDocumento294 páginasB1 OperatingInstructionscengiz kutukcu100% (4)

- B-02 Mechnical Seal For SBPO LubeDocumento8 páginasB-02 Mechnical Seal For SBPO LubeMarvin DuarteAinda não há avaliações

- Udor Pumps Operators Manual MY15 HiResDocumento40 páginasUdor Pumps Operators Manual MY15 HiResjalm66Ainda não há avaliações

- Pipe Vibration Testing and AnalysisDocumento34 páginasPipe Vibration Testing and AnalysisenjoygurujiAinda não há avaliações

- DJ Pump 2021 PDFDocumento20 páginasDJ Pump 2021 PDFManuel Armando Salazar BravoAinda não há avaliações

- Hydraulics CalculationDocumento1 páginaHydraulics CalculationSudish BhatAinda não há avaliações

- Flygt 2201.590: Msha Explosion-Proof Classic Dewatering Pump 60HzDocumento2 páginasFlygt 2201.590: Msha Explosion-Proof Classic Dewatering Pump 60HzricardoAinda não há avaliações

- Wall-hung condensation boiler power and specificationsDocumento94 páginasWall-hung condensation boiler power and specificationsMancasi RazvanAinda não há avaliações

- High Pressure Mud PumpDocumento4 páginasHigh Pressure Mud PumpMihai OpreaAinda não há avaliações

- Part1 Q A Marine EngineerDocumento7 páginasPart1 Q A Marine EngineerSamir Alshaar100% (1)

- 3-A Sanitary Standards - Quick Reference GuideDocumento98 páginas3-A Sanitary Standards - Quick Reference GuideJacques J Pienaar100% (3)

- MacGregor Crane-1 2 GLB2526-3Documento532 páginasMacGregor Crane-1 2 GLB2526-3RusHostel TVAinda não há avaliações

- Retailing Petroleum ProductsDocumento12 páginasRetailing Petroleum ProductsClaudio MacahilosAinda não há avaliações

- Laboratory ExperimentsDocumento70 páginasLaboratory ExperimentsKarl TristanAinda não há avaliações

- Washing Machine EssentialsDocumento52 páginasWashing Machine EssentialsAgustnAinda não há avaliações

- 190 TPH Start Up ProcedureDocumento19 páginas190 TPH Start Up ProcedurepothanAinda não há avaliações

- WAE Assignment 2018 - UpdatedDocumento4 páginasWAE Assignment 2018 - UpdatedCarl MigaelAinda não há avaliações

- 2 Pouces Pompe ChampionDocumento29 páginas2 Pouces Pompe Championclaude northAinda não há avaliações

- Av Series Vane Pumps 182Documento32 páginasAv Series Vane Pumps 182destroAinda não há avaliações

- KMBD Mech BoostersDocumento2 páginasKMBD Mech BoostersMark V FarrellAinda não há avaliações

- Fdocuments - in Eemua-Index PDFDocumento28 páginasFdocuments - in Eemua-Index PDFkapster KannourAinda não há avaliações