Escolar Documentos

Profissional Documentos

Cultura Documentos

Tinnerman Nut

Enviado por

Ahmad ShazaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tinnerman Nut

Enviado por

Ahmad ShazaDireitos autorais:

Formatos disponíveis

TINNERMAN FASTENERS

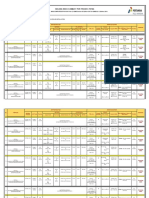

TINNERMAN NUTS FOR INSTRUMENT MOUNTING NUTS

SHEET METAL SCREWS Cage type. Permit mounting of aircraft instruments from

These speed nuts are self-locking steel fasteners.

Locking action is derived from the force exerted by the

the front of the panel. No charge in panel or instrument

design required. Non-magnetic (speed nut is brass; CM

two arched prongs against the root of the screw thread cage is phosphor bronze). Conform to MIL-N-3336.

and by the spring tension of the prongs and base. The Cage is easily compressed with finger-pressure to

combined forces of the thread lock and spring tension allow insertion of legs into clearance holes. When fully

inserted and pressure is released, legs spring apart;

provide a vibration proof fastening. Speed nuts retain

their spring tension and may be used repeatedly with-

out losing their self-locking effectiveness. Suitable for

retain SPEED NUT in screw-receiving position. Turned-

down corners hold firm against force of inserting screw

WP

and screw-tightening torque. All instrument mounting

“B”-type Sheet numerous non-structural applications. nuts listed below take a 6-32 machine screw.

Metal Screw

Finish: Phosphate-coated with three coats of olive

drab paint.

Important: Speed nuts for aircraft are designed to fit standard AN530-

AN531 type B sheet metal screws only. Do not use pointed type A sheet

Tinnerman

Part No.

Our

Part No.

NAS

Part No.

Instrument

Thickness

Price

Ea.

ME

metal screws with aircraft Speed nuts. There is a difference in root diam-

eter and thread pitch. Screw lengths: B type sheet metal screws have a A8938-632-493 MS33737-9C 487-13 .062 $1.19

blunt taper at the end. To be certain the fastener prongs grip on the full A8939-632-493 MS33737-10C 487-14 .091 $1.29

root diameter, the screw should protrude two to three threads beyond

the prongs. See the illustration. A6939-632-493 MS33737-11C 487-15 .125 $1.29 HA

A8940-632-493 MS33737-12C 487-16 .187 $1.26

FLAT TYPE (NAS 446) A8941-632-493 MS33737-13C 487-17 .250 $1.13

Used to replace threaded nuts, lock washers, and spanner washers;

weigh less than other types of self-locking aircraft fasteners. Can be A8942-632-493 MS33737-14C 487-18 .313 $1.28

applied faster, easier, and are vibration resistant. Provide maximum

holding power at minimum cost per fastener. Turned-up ends prevent A8943-632-493 MS33737-15C 487-20 .375 $0.96 AP

scoring of surfaces. Use with type B tapping screws. A8944-632-493 MS33737-16C 487-21 over .375 $1.30

MONADNOCK CLIP NUTS

“U” TYPE

(NAS 395)

High strength Forged hex nuts suitable for structural and non-structural

applications in metal, palstic and composite materials.

LG

Part No. Screw Size Price ea. Edge Part Price

A1776-4Z-1D #4 $0.21 Size Distance

Tkns Number Ea.

A1777-6Z-1D

A1778-8Z-1D

#6

#8

$0.29

$0.19 6-32 .180-.120 .030-.051 04-00151 $1.76 EP

A1779-10Z-1D #10 $0.22 8-32 .310-.500 .020-.090 04-00152 $0.82

10-32 .350-.500 .020-.090 04-00153 $0.79

ANCHOR NUTS (NAS 444)

Riveted or welded in position. Attach access plates, doors or any part

HOW TO APPLY SPEED NUT FASTENERS CS

that must be fastened securely, yet easily removed with fasteners FLAT TYPE “U” TYPE

retained in a blind location. Install with AN426AD-3 rivets. Fastener is positioned Push into position with

over screw clearance thumb until extrusion

Part No. Screw Size Price/Ea. hole with screw- on lower leg snaps into

A6195-6Z-1D

A6195-8Z-1D

#6

#8

$0.36

$0.37

engaging prongs

pointing up or out-

screw hole. The fas-

tener “floats” in screw- IN

ward. Screw is started re ceiv ing position

into nut by hand from to correct for normal

the underside. misalignment in panel

mounting holes.

LHA 4972 FLOATING CLIPNUT

CADMIUM-PLATED STEEL

Screw can be power-

driven into locked posi-

tion (when base arch

Place second panel EL

in position & drive

of fastener is flat) or a screw. Access to

Part No. Thread Price Each hand screw driver can opposite side is

be used. No wrench is unnecessary. Flush

4972-5-62 6-32 $1.31

4972-6-82

LHA4972-1032

8-32

10-32

$0.89

$0.85

required, finger pres-

sure will prevent it from

turning

mounting can be

made by embossing

either panel.

AV

“U” TYPE (NAS 395)

Snaps over edge of panels or into center hole locations. Holds itself in place for blind assembly. “Floats” free for easy hole alignment.

TO

PS

Part TypeB Design P-panel A B C-max. ctr. G-panel T-mat’l.

Price

Number Scrw Size Variation Thickness Range Length Length hole to edge hole dia. Thkness

A1784-6Z-1D #6 E .025-.051 0.61 0.44 0.281 0.250 0.025 $0.33

A1785-6Z-1D

A1789-8Z-1D

#6

#8

E

E

.025-.064

.025-.051

0.84

0.61

0.44

0.44

0.500

0.281

0.281

0.250

0.025 $0.36

0.028 $0.27

BV

A1787-8Z-1D #8 E .025-.064 0.84 0.44 0.500 0.281 0.028 $0.28

A1788-8Z-1D #8 AE .025-.064 0.84 0.44 0.500 0.170 0.028 $0.24

A1348-8Z-1D #8 AE .025-.064 0.73 0.50 0.343 0.170 0.028 $0.42

A1932-8Z-1D #8 BE .032-.051 0.58 0.50 0.265 0.343 0.025 $0.38

A1786-8Z-1D #8 CEH .040-.051 0.53 0.50 0.218 0.250 0.028 $0.21

A178710Z-1D #10 E .025-.064 0.84 0.44 0.500 0.281 0.031 $0.35

A1758-10Z-1D #10 E .081-.094 0.62 0.44 0.281 0.281 0.031 $0.30

AIRCRAFT SPRUCE WEST AIRCRAFT SPRUCE EAST

Prices Subject to Change Without Notice CORONA, CA • (877) 4-SPRUCE PEACHTREE CITY, GA • (877) 477-7823 73

Você também pode gostar

- Struktur Baja I Sambungan BautDocumento25 páginasStruktur Baja I Sambungan BautYusril MahindraAinda não há avaliações

- Struktur Baja I 7Documento25 páginasStruktur Baja I 7Latifah Meda FerlytaAinda não há avaliações

- Tsubaki Power Lock Ad N SeriesDocumento5 páginasTsubaki Power Lock Ad N SeriesRizal IephoAinda não há avaliações

- Datasheet StrainerDocumento4 páginasDatasheet StrainerTommy ArjanggiAinda não há avaliações

- Non-returns-DampersDocumento1 páginaNon-returns-DampersProject enghvacAinda não há avaliações

- Vertex Hose ClampDocumento8 páginasVertex Hose ClampRamasamy PAinda não há avaliações

- PJU H 9mtr Tunggal PDFDocumento1 páginaPJU H 9mtr Tunggal PDFbgan29Ainda não há avaliações

- LEAD SCREW - p1 - 785Documento1 páginaLEAD SCREW - p1 - 785wawandev7Ainda não há avaliações

- Selection Guide Diaphram Seal 42015Documento2 páginasSelection Guide Diaphram Seal 42015nurahAinda não há avaliações

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Documento14 páginasList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSAinda não há avaliações

- Conac p69 74 FormWorkDocumento6 páginasConac p69 74 FormWork_at_to_Ainda não há avaliações

- Sherex Brass Insert CatalogDocumento16 páginasSherex Brass Insert CataloggaetAinda não há avaliações

- Power-On Clutches & Brakes Description: Rotor AssemblyDocumento9 páginasPower-On Clutches & Brakes Description: Rotor AssemblycingacAinda não há avaliações

- IWISS Crimping ToolsDocumento66 páginasIWISS Crimping Toolsv.kotekAinda não há avaliações

- Drop-In Anchor in Zinc-Plated Steel For Suitable Hammerset InstallationDocumento2 páginasDrop-In Anchor in Zinc-Plated Steel For Suitable Hammerset InstallationcoolkaisyAinda não há avaliações

- Insulation PinsDocumento2 páginasInsulation PinsChandravadanAinda não há avaliações

- FTRS Threaded Rod AnchorDocumento2 páginasFTRS Threaded Rod AnchorariefAinda não há avaliações

- Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Documento2 páginasPt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Solikhul HarisAinda não há avaliações

- Bolted Connections 1Documento45 páginasBolted Connections 1Nicole ReyesAinda não há avaliações

- Electrical SpecialtiesDocumento1 páginaElectrical SpecialtiessxdcAinda não há avaliações

- f24004001 GCD Ss Flexible HoseDocumento1 páginaf24004001 GCD Ss Flexible Hosepatilshyamkant4Ainda não há avaliações

- Meetering Valves S, M, L &31 Series (MS-01-142) R3Documento8 páginasMeetering Valves S, M, L &31 Series (MS-01-142) R3herysyam1980Ainda não há avaliações

- Distribution Terminal Blocks for Grounding and PhasesDocumento11 páginasDistribution Terminal Blocks for Grounding and PhasesHUGO ANDRÉS CRUZ GONZÁLEZAinda não há avaliações

- MetmachthreadDocumento3 páginasMetmachthreadPatrick - Assist. Técnica - CetemAinda não há avaliações

- InputDocumento5 páginasInputTrần Văn NhânAinda não há avaliações

- D1833 SERIES (NAS1833) : Table 1Documento1 páginaD1833 SERIES (NAS1833) : Table 1blackhawkAinda não há avaliações

- Yarway Wye Type Pipeline StrainersDocumento12 páginasYarway Wye Type Pipeline StrainersLuis CartageneaAinda não há avaliações

- High-tensile steel wire mesh and nail arrangement cross sectionDocumento1 páginaHigh-tensile steel wire mesh and nail arrangement cross sectionReadian FedelinAinda não há avaliações

- WELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEDocumento6 páginasWELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEFerdie OSAinda não há avaliações

- Pt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Documento1 páginaPt. Stainless Steel Primavalve Majubersama: ASME Section IX - 2021 Preliminary Welding Procedure Specification (PWPS)Ilham PaneAinda não há avaliações

- Input ValuesDocumento5 páginasInput ValuesmasoodAinda não há avaliações

- 300 Series PTDocumento2 páginas300 Series PTbhaskarbabaiAinda não há avaliações

- Current Online CatalogDocumento1 páginaCurrent Online CatalogamandaAinda não há avaliações

- Cherry 1900 Bulbing Blind Rivet: SPS Fastener Division, ADocumento4 páginasCherry 1900 Bulbing Blind Rivet: SPS Fastener Division, AДенис СергеевичAinda não há avaliações

- HiltiDocumento5 páginasHilticipsiccAinda não há avaliações

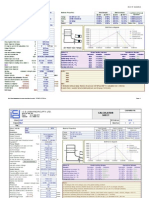

- FlangeCalc AS1210 v1.5Documento28 páginasFlangeCalc AS1210 v1.5Ben100% (1)

- ORIFICE-PLATE-ASSY-BROCHUREDocumento74 páginasORIFICE-PLATE-ASSY-BROCHUREDécio CostaAinda não há avaliações

- Fuseclips For A480r5r-1 and A480t2eDocumento2 páginasFuseclips For A480r5r-1 and A480t2eM. Taufik HidayatAinda não há avaliações

- Turn Buckle Safety WireDocumento1 páginaTurn Buckle Safety WireJohn Adrian RoceroAinda não há avaliações

- Evinru 1Documento2 páginasEvinru 1Marine Parts ChinaAinda não há avaliações

- Bellows Sealed Matering Valves BM Series (Ms-01-23) R3Documento4 páginasBellows Sealed Matering Valves BM Series (Ms-01-23) R3herysyam1980Ainda não há avaliações

- D1836 Series (Nas1836)Documento1 páginaD1836 Series (Nas1836)blackhawkAinda não há avaliações

- Thread Length Verification for 1-1/8Documento2 páginasThread Length Verification for 1-1/8PravinAinda não há avaliações

- Esp 141028Documento2 páginasEsp 141028Mai Thế ToanAinda não há avaliações

- IKO Bearing CatalogueDocumento18 páginasIKO Bearing Cataloguenurek2100% (2)

- M6 8ST PDFDocumento1 páginaM6 8ST PDFHung Cuong PhamAinda não há avaliações

- Cutmaster 42 Cutmaster True Series: Light Duty Plasma Cutting SystemsDocumento1 páginaCutmaster 42 Cutmaster True Series: Light Duty Plasma Cutting SystemsLeonardo Martínez LópezAinda não há avaliações

- 2018 Stonage Fittings and Accessories WebDocumento35 páginas2018 Stonage Fittings and Accessories WeblupiAinda não há avaliações

- Terminal block accessory essentialsDocumento10 páginasTerminal block accessory essentialsismuAinda não há avaliações

- Draft Wps Astm A 743 GR - Ca6nmDocumento2 páginasDraft Wps Astm A 743 GR - Ca6nmIlham PaneAinda não há avaliações

- Post+order+documents+ - Electrical+junction+box 0 1 PDFDocumento9 páginasPost+order+documents+ - Electrical+junction+box 0 1 PDFElwyn DavidAinda não há avaliações

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Documento12 páginasPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXAinda não há avaliações

- Mark Piece Information: For Weld Details, See Sheet: 3Documento5 páginasMark Piece Information: For Weld Details, See Sheet: 3Proorocu MikyAinda não há avaliações

- Ripper PDFDocumento52 páginasRipper PDFСергей Горовой100% (3)

- Submittal Data Information: KV Series Vertical Close Coupled PumpsDocumento3 páginasSubmittal Data Information: KV Series Vertical Close Coupled PumpsSneyder MontoyaAinda não há avaliações

- Klippon Connect Selection GuideDocumento2 páginasKlippon Connect Selection Guideanoop2010Ainda não há avaliações

- Visual 23 Januari 24Documento1 páginaVisual 23 Januari 24Abd Chalik Faja Dawani SiraitAinda não há avaliações

- Ylon Insert: Revised 406Documento6 páginasYlon Insert: Revised 406williaqAinda não há avaliações

- Size #8 Concentric Twinax Socket For MIL-DTL-38999 Series I, III and IV ConnectorsDocumento1 páginaSize #8 Concentric Twinax Socket For MIL-DTL-38999 Series I, III and IV ConnectorsYounes AlzyoudAinda não há avaliações

- AirframeDocumento149 páginasAirframeAhmad ShazaAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 2042 2003 enDocumento165 páginas2042 2003 enAhmad ShazaAinda não há avaliações

- ANNEX III Part-66 Aircraft Maintenance Licence RequirementsDocumento78 páginasANNEX III Part-66 Aircraft Maintenance Licence Requirementschutia88Ainda não há avaliações

- Production: Material or Process IndicatorDocumento48 páginasProduction: Material or Process IndicatorCosmin DumitraAinda não há avaliações

- Lecture-5: Technological Properties of Metals Steel and Its ClassificationDocumento51 páginasLecture-5: Technological Properties of Metals Steel and Its ClassificationSarojKumarSinghAinda não há avaliações

- Draft WPS For Carbon Steel PipeDocumento2 páginasDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Effect of D.C. Polarity On SMAWDocumento9 páginasEffect of D.C. Polarity On SMAWhp PCAinda não há avaliações

- Lagro High School - SMAW Unit Test in 3rd GradingDocumento4 páginasLagro High School - SMAW Unit Test in 3rd GradingLunilyn Ortega100% (1)

- Forging Process Audit Check ListDocumento15 páginasForging Process Audit Check ListKeerthivasan NAinda não há avaliações

- Welding PresentationDocumento18 páginasWelding PresentationFasil ParuvanathAinda não há avaliações

- Powder Metallurgy - Wikipedia, The Free EncyclopediaDocumento11 páginasPowder Metallurgy - Wikipedia, The Free EncyclopediazidaaanAinda não há avaliações

- All AlloysDocumento74 páginasAll AlloyswmkaneAinda não há avaliações

- Astm A 240-18Documento12 páginasAstm A 240-18Giann' Andreh'xd100% (2)

- CH 05Documento11 páginasCH 05chaitanyachegg100% (2)

- Black Crown Diamond WatchesDocumento22 páginasBlack Crown Diamond WatchesJasmine Al NuamaiAinda não há avaliações

- Production and Manufacturing of Automotive Engine ComponentsDocumento24 páginasProduction and Manufacturing of Automotive Engine ComponentsMr. Jerome Nithin Gladson100% (1)

- LG, Sharp, and Toshiba TV Parts ListDocumento27 páginasLG, Sharp, and Toshiba TV Parts ListAsep ZaenalAinda não há avaliações

- 201172711456351Documento9 páginas201172711456351Ferlie IndrapatiAinda não há avaliações

- CP 00143-15-1973 (2007) PDFDocumento34 páginasCP 00143-15-1973 (2007) PDFStanislav PerevezentsevAinda não há avaliações

- Corrosion of MartensiticDocumento40 páginasCorrosion of MartensiticDinta PratiwiAinda não há avaliações

- JSL Brochure - CorpDocumento20 páginasJSL Brochure - Corpdoctorcarbon100% (1)

- Grating and Expanded Metal CatalogDocumento68 páginasGrating and Expanded Metal CatalogsivaAinda não há avaliações

- Applecarbide Catalogue For Metric EndmillsDocumento42 páginasApplecarbide Catalogue For Metric EndmillsAlex Kiko VillalobosAinda não há avaliações

- Material para BombasDocumento3 páginasMaterial para BombasPeñaloz GustavoAinda não há avaliações

- Study of Titanium in SeawaterDocumento36 páginasStudy of Titanium in SeawaterJorge CarreñoAinda não há avaliações

- Asirusa WPS-P-002 1FDocumento5 páginasAsirusa WPS-P-002 1FWalter RuedaAinda não há avaliações

- Steel Fence Posts and Assemblies, Hot Wrought: Standard Specification ForDocumento4 páginasSteel Fence Posts and Assemblies, Hot Wrought: Standard Specification ForManuel IbarraAinda não há avaliações

- Powder Standerd & CodeDocumento9 páginasPowder Standerd & CodeAbhijeet AnkushAinda não há avaliações

- Directory of Rolling Mill Cluster JaipurDocumento5 páginasDirectory of Rolling Mill Cluster JaipurShabbir Moizbhai100% (2)

- CLASS-10TH - CHAPTER - 3 Metals and Non-MetalsDocumento3 páginasCLASS-10TH - CHAPTER - 3 Metals and Non-MetalsTanmay LahaAinda não há avaliações

- Hardness Conversion Chart: ConversionsDocumento1 páginaHardness Conversion Chart: ConversionsQuốc Trí LêAinda não há avaliações

- Welding Wire Diameter CHART PDFDocumento1 páginaWelding Wire Diameter CHART PDFFerhat KahveciAinda não há avaliações

- Phase Diagrams For Metallic SystemsDocumento5 páginasPhase Diagrams For Metallic SystemsZesi Villamor Delos SantosAinda não há avaliações