Escolar Documentos

Profissional Documentos

Cultura Documentos

Untitled

Enviado por

api-770063550 notas0% acharam este documento útil (0 voto)

18 visualizações2 páginasSpecial expertise in q uality standards for medical-device, and packaged-goods companies. Designed or suggested many successful product improvements, includ ing a SCSI hard-drive tooling patent. Tasked to implement systems to support a major new medical device customer: main tain ISO 9001 and ISO 13485 registration, and register for multi-state pharmaceuti cal manufacturing-distribution.

Descrição original:

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

TXT, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoSpecial expertise in q uality standards for medical-device, and packaged-goods companies. Designed or suggested many successful product improvements, includ ing a SCSI hard-drive tooling patent. Tasked to implement systems to support a major new medical device customer: main tain ISO 9001 and ISO 13485 registration, and register for multi-state pharmaceuti cal manufacturing-distribution.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato TXT, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

18 visualizações2 páginasUntitled

Enviado por

api-77006355Special expertise in q uality standards for medical-device, and packaged-goods companies. Designed or suggested many successful product improvements, includ ing a SCSI hard-drive tooling patent. Tasked to implement systems to support a major new medical device customer: main tain ISO 9001 and ISO 13485 registration, and register for multi-state pharmaceuti cal manufacturing-distribution.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato TXT, PDF, TXT ou leia online no Scribd

Você está na página 1de 2

Francis ("Andy") Guidry

571 Canterbury Drive * Plover, Wisconsin 54467

Cell: 715-347-7090 * Email: fg551024@westpost.net

Senior Manager, QA Engineering

Manufacturing and Quality Systems: Medical * Electrical * Consumer Goods

Accomplished Quality Manager with exceptional depth and breadth of experience in

high-volume manufacturing and distribution environments. Special expertise in q

uality standards for medical-device, and packaged-goods companies. Exceptional s

trengths in three areas:

* Creativity: Designed or suggested many successful product improvements, includ

ing a SCSI hard-drive tooling patent, which eliminated a repetitive motion probl

em invention.

* Problem Solving: Analyzes and improves process, process control, and quality s

ystems. Develops sampling plans and evaluates manufacturing/quality systems, too

ling and specs.

* Team Leadership: Natural leader who builds and motivates effective teams.

AREAS OF EXPERTISE

* Quality, Engineering, Information Systems & Production Management: Implement D

ivision level quality programs for ISO 9001:2000 and 13485:2003. Direct site Qua

lity Managers and Supplier Quality Engineers. Managed Quality Operations for Pro

duction, Site, and Engineering & Information Systems.

* Procurement Quality / Manufacturing Engineering: Supplier evaluation, Technica

l Interfaces, problem evaluation and resolution, system documentation, and train

ing implementation. Certified ISO 9001:2000 Auditor.

PROFESSIONAL EXPERIENCE

RR DONNELLEY - GLOBAL TURNKEY SOLUTIONS, Plover, WI 1995-Present

Formerly Banta Global Turnkey - a global Supplier Chain Management (SCM) company

that purchases components, assemblies them into packages, and handles logistic

s and distribution. Products include: medical devices, SCSI hard drives, comput

er components, country kits, modems, retail electronics, gift cards, and retail-

marketing displays. Approx. 6,500 employees, $400 million sales, and 10 global s

ites.

Quality & Engineering Manager | Security Manager (2008-Present)

Tasked to implement systems to support a major new medical device customer: main

tain ISO 9001 & ISO 13485 registration, and register for multi-state pharmaceuti

cal manufacturing-distribution licenses. Lead 9 direct reports, including Qualit

y Engineers, Quality Engineering Technician, Quality Supervisor, ISO Administer,

and Device History Recorder Review Clerks. Manage $1.3+ million budget for qual

ity functions such as calibration services, external ISO audit/registration, sec

urity systems, and facility cleaning.

Job scope

* Assign and approve all Corrective and Preventative Action (CAPA) documents, pr

ocedures, and specifications for the facility. Review product lines by walking t

he production floor and talking to employees.

* Set up all inspection standards by reviewing actual product and making final d

ecisions in accordance with customers' requirements.

* Establish and maintain a Quality Engineering department to support Validation

Master Plans for medical device qualifications, process validation protocols, Fi

rst Article Inspection, component & process deviations systems and process sampl

ing plans.

* Establish and maintain a Quality Inspection department for all processes.

Highlights

* Accomplished medical-device assembly validation for a new customer within a ye

ar:

* Successful validation led to over 150 jobs to the Plover facility.

* Project consisted of 6 assembly lines for over 80 SKUs, including: blood gluco

se meter configuration line, high speed, 125/minute, automatic reagent vial labe

ling system, and a semi-automatic, 35/minute, reagent vial labeling system.

Quality, Engineering & Information Systems Manager (1999-2008)

RR Donnelley Global Turnkey Solutions purchased Banta Corp. in January 2007

Designed and implemented a fully functional site IT Disaster Recovery (DR) progr

am that cost less than $2,000 to implement and less than $300/month to maintain.

Designed quality reports for the facility that met all customer requirements. M

anaged newly hired Quality Engineers and Device History Records (DHR) for every

production lot.

* Co-invented a SCSI Hard Drive Assembly tooling improvement that eliminated a r

epetitive motion problem (U.S. patent 6477764 B1).

* Recognized as one of two employees who played an instrumental role for a major

contract win - a 5 year, worldwide SCSI Hard Drive assembly contract valued ove

r $600 million.

* Achieved ISO 9000:1994 and ISO 13485:2005 registrations that led to a major co

ntract.

* Established supplier-management system. Conducted and approved all supplier su

rveys in conjunction with the Material Manager.

* Moved a major customer's software-assembly process, ordering system (32 differ

ent inputs), and fulfillment process without affecting delivery schedules. Reduc

ed costs and defect rate within 3 months.

Manager of Quality Engineering / Director of Quality (1995-1999)

Banta Global Turnkey, LTD

Improved QA as in-house consultant and tasked to register all four North America

n sites with ISO 9001-1994. Held on-site reviews focused on process, documentati

on, and CAPA systems.

* Established a new facility that supported a start-up program for a major custo

mer. Designed production layouts, trained a new set of employees, established qu

ality standards, and set up reporting to ensure compliance with customer require

ments.

* Set up quality documentation and achieved ISO 9001-1994compliance for 3 site.

* Seamlessly transferred a major customer's program from Europe to the U.S. Esta

blished European program to meet a major customer's needs.

SUMMARY OF ADDITIONAL EXPERIENCE

IBM and IBM/ROLM, Various Locations:

* Advisory Engineer, Procurement Quality (1989-1995): Collaborated closely with

corporate drafting. Directed receiving inspection and process-reliability evalua

tions for printed wiring boards, assemblies (SMT, PTH), and solder ball attach p

rocesses)

* Manufacturing and Quality Engineer-IBM/ROLM (1986-1989): Provided engineering

support for quality compliance and production-process development. Supplier Qual

ity Engineer for PCB assembly processes and components.

EDUCATION

Lincoln College, Liberal Arts Coursework

Santa Barbara Jr. College, Engineering Coursework

AAMI Achievement Certificate for cGMP Training * AMP Institute - Crimp Tooling C

ertified

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCDocumento43 páginas007-013558-001 SAS PCE SPE With Support For HSM PSE2 Integration Feature Documentation RevCpietoeAinda não há avaliações

- RT L2 General Examination PaperDocumento4 páginasRT L2 General Examination PaperdaddadAinda não há avaliações

- Woson 23 Litre B Class Touch AutoclaveDocumento2 páginasWoson 23 Litre B Class Touch AutoclaveBashar MohammadAinda não há avaliações

- Good Practices in Government Resource Planning, Developed Vs Developing CountriesDocumento11 páginasGood Practices in Government Resource Planning, Developed Vs Developing CountriesFreeBalanceGRPAinda não há avaliações

- Estimate SR 14-15 02 KHANDEKARDocumento5 páginasEstimate SR 14-15 02 KHANDEKARAkshay SavvasheriAinda não há avaliações

- Jerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransDocumento1 páginaJerry Hill's Letter To Bijan Sartipi, Director, District 4 CaltransSabrina BrennanAinda não há avaliações

- Q3 NSP - SLP - RLPDocumento41 páginasQ3 NSP - SLP - RLPRushi RavalAinda não há avaliações

- VXN150 Vixion Fuel Tank PDFDocumento3 páginasVXN150 Vixion Fuel Tank PDFHarris Jum'aniandaAinda não há avaliações

- EMOC 208 Installation of VITT For N2 Cylinder FillingDocumento12 páginasEMOC 208 Installation of VITT For N2 Cylinder Fillingtejcd1234Ainda não há avaliações

- Lesson Plan 2 Road FurnitureDocumento4 páginasLesson Plan 2 Road FurnitureShahbaz SharifAinda não há avaliações

- 701.ssvseat 1.04Documento2 páginas701.ssvseat 1.04Cosmin MuscaluAinda não há avaliações

- Chapter 19A ConcreteDocumento10 páginasChapter 19A ConcreteMofasa EAinda não há avaliações

- How To Measure MTFDocumento64 páginasHow To Measure MTFamtcorporationAinda não há avaliações

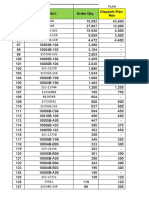

- Order Qty Vs Dispatch Plan - 04 11 20Documento13 páginasOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPAinda não há avaliações

- Turbin 1Documento27 páginasTurbin 1Durjoy Chakraborty100% (1)

- High Integrity Aluminum (GENERAL)Documento140 páginasHigh Integrity Aluminum (GENERAL)Kmilo Giraldo100% (3)

- Colchicine - British Pharmacopoeia 2016Documento4 páginasColchicine - British Pharmacopoeia 2016Social Service (V)100% (1)

- ED ProcessDocumento9 páginasED ProcesskhanasifalamAinda não há avaliações

- Jacky Smith Resume Project ManagerDocumento1 páginaJacky Smith Resume Project ManagerGrey GrayAinda não há avaliações

- IEM PI A401 - ANNEXE - Design & Site ExperienceDocumento5 páginasIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaAinda não há avaliações

- Le22a1321 AocDocumento130 páginasLe22a1321 AocEchefisEchefisAinda não há avaliações

- Estimation Software For Presure VesselDocumento36 páginasEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- " " Reach: Ordering InformationDocumento8 páginas" " Reach: Ordering InformationTrong TranAinda não há avaliações

- 21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilDocumento4 páginas21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilJose ManzanarezAinda não há avaliações

- PBLauncherDocumento50 páginasPBLauncherborreveroAinda não há avaliações

- 3310 ATF DEXRON III H PDS Vesion 3Documento2 páginas3310 ATF DEXRON III H PDS Vesion 3luayhabibbAinda não há avaliações

- RT 8090 TDocumento40 páginasRT 8090 TManuel100% (1)

- Skytrain Avia Services: Emergency Procedures ManualDocumento32 páginasSkytrain Avia Services: Emergency Procedures ManualEndro RastadiAinda não há avaliações

- Ultra Petronne Interior Supply Corp.: Manufacturer of Light Metal FramesDocumento1 páginaUltra Petronne Interior Supply Corp.: Manufacturer of Light Metal Framesjun vincint geleraAinda não há avaliações

- Ultrasonic Mixer: Project 99.11Documento11 páginasUltrasonic Mixer: Project 99.11Febri SandiAinda não há avaliações