Escolar Documentos

Profissional Documentos

Cultura Documentos

Supervisor

Enviado por

api-77575086Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Supervisor

Enviado por

api-77575086Direitos autorais:

Formatos disponíveis

Douglas C.

Dever

10507 Millridge North Drive Houston, Tx 77070

Home:(281) 890-1493 Cell: (281) 733-8261

Email: dd7c23e4@westpost.net

.

PROFESSIONAL EXPERIENCE

TOYO INK MFG AMERICA, Bryan, Texas May 2008 June 2010

Production / Safety Manager

Manage all aspects of plant production, quality, maintenance, and logistics for

a small two unit plant producing inks and adhesives.

Managed start up of plant with two production units.

Hired and trained all employees.

Worked with consulting firm on all permits. (air. Storm water, city water, haza

rdous waste NOR)

Set up all Training for safety including OSHA, RCRA, DOT, Shipping and receivin

g and all other requirements.

Set up initial Hazardous Communication, PSM, and emergency procedures

Worked hands on in production as we learned equipment and completed test produc

tion. Work with operators on a daily basis to produce and package products. Unlo

aded tanker trucks, charged chemicals, and preformed minor maintenance.

Met start-up schedule with no incidents or injuries.

KANEKA TEXAS CORPORATION, Pasadena, Texas January 1989 Ma

y 2008

I Worked for KTC for over 19 years from start-up operator to production manage

r. I only left in 2008 due to the immanent end to the product line that I was ma

naging. This unit shut down 6 months after I left. I have listed the various pos

itions and responsibilities that I had while with this specialty chemical facili

ty in Pasadena Texas.

May 2005 May 2008

Eperan Unit Production Manager

Manage all aspects of unit production, quality management and financial planning

.

Managed three production units including polypropylene and polyethylene extrude

rs, plastics expansion and steam molding.

Used lean manufacturing principles and job analysis to reduce total personnel c

ost for three straight years

Work with principles of Operator Excellence (OpX) and 5S to improve operator in

volvement.

Responsible for Unit ISO 9002 Quality program. Leader of nonconformance trackin

g and corrective and preventive actions.

Helped develop Eperan plant PSM program and participate in plant-wide safety an

d environmental audits. Member of Environmental site audit team.

Working as a part of plant Steering Committee to set and improve all plant poli

cies (HR, safety, training, etc.)

Make yearly budgets and track cost using SAP.

2001- April 2005

Production Superintendent

Responsible for unit production employees (4 supervisors, 14 operators, & 18 co

ntractors)

Provide technical support on Honeywell control system.

Set up and Supervised training program and upkeep of ISO 9001/2000 system

Trained operators on Honeywell DCS control

Set up new operator training and qualification system.

Production Day Supervisor

1994-2001

Worked with marketing to create production schedule to meet shipping requiremen

ts.

Scheduled production on three interdependent units. (pellet production-bead pro

duction-parts)

Schedule all production employees for needed staffing.

Perform training and maintain training records for all unit employees.

Process Operator

19891994

Worked on polymerization unit and the started up new unit.

Help write all procedures and commission equipment.

Created equipment verification files.

Lyondell Refinery Pasadena, TX

Process Operator

1984-1989

Monitored conditions and equipment and prepared equipment for maintenance.

Learned operations on large FCCU

EDUCATION

2005 Present Working on an MBA (36 hrs completed) University

of Houston Clear Lake Houston, Tx

2004 B.S., Environmental Science (3.51 GPA) Uni

versity of Houston Clear Lake Houston, Tx

TRAINING

2009 Handling Hazardous Waste (3 Day)

College Station, Tx

2009 Hazardous Materials Technician Training (40hr)

College Station, Tx

2006 Improving and Sustaining Operational Excellence (

OpX) Tampa, Fl

1999 Honeywell Implementation Training

Houston, TX

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Assignment 1Documento13 páginasAssignment 1Muhammad Asim Hafeez ThindAinda não há avaliações

- Joint Venture AgreementDocumento7 páginasJoint Venture AgreementFirman HamdanAinda não há avaliações

- Sarvodaya Public School Azamgarh Class - XI Annual Examination Subject - EconomicsDocumento4 páginasSarvodaya Public School Azamgarh Class - XI Annual Examination Subject - EconomicsAshraf JamalAinda não há avaliações

- Contoh Curriculum Vitae Dokter UmumDocumento2 páginasContoh Curriculum Vitae Dokter UmumPeter HoAinda não há avaliações

- Income CertificateDocumento1 páginaIncome CertificatedeepakbadimundaAinda não há avaliações

- Ministry-Wise Schemes and Developments Prelims 2019 PDFDocumento214 páginasMinistry-Wise Schemes and Developments Prelims 2019 PDFAditya KumarAinda não há avaliações

- Singapore's Development and Achievements Over 50 YearsDocumento1 páginaSingapore's Development and Achievements Over 50 YearsBean LiiAinda não há avaliações

- Travel and Expense Policy: PurposeDocumento9 páginasTravel and Expense Policy: Purposeabel_kayelAinda não há avaliações

- Economic System and BusinessDocumento51 páginasEconomic System and BusinessJoseph SathyanAinda não há avaliações

- CAPE Accounting 2010 U2 P1Documento11 páginasCAPE Accounting 2010 U2 P1jsjkdnckdfcAinda não há avaliações

- Microeconomics ProjectDocumento5 páginasMicroeconomics ProjectRakesh ChoudharyAinda não há avaliações

- Chapter 6Documento26 páginasChapter 6ANGEL MELLINDEZAinda não há avaliações

- RA Maturity ListDocumento30 páginasRA Maturity Listsmasalmeh2872Ainda não há avaliações

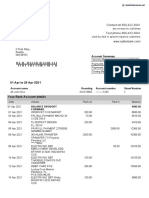

- Statement 20231030161033Documento6 páginasStatement 20231030161033kreetika kumariAinda não há avaliações

- "Training and Action Research of Rural Development Academy (RDA), Bogra, Bangladesh." by Sheikh Md. RaselDocumento101 páginas"Training and Action Research of Rural Development Academy (RDA), Bogra, Bangladesh." by Sheikh Md. RaselRasel89% (9)

- Sutton Bank StatementDocumento2 páginasSutton Bank StatementNadiia AvetisianAinda não há avaliações

- Sample Fryer Rabbit Budget PDFDocumento2 páginasSample Fryer Rabbit Budget PDFGrace NacionalAinda não há avaliações

- Economy of Pakistan Course OutlineDocumento2 páginasEconomy of Pakistan Course OutlineFarhan Sarwar100% (1)

- 2019 Marking Scheme Account PDFDocumento287 páginas2019 Marking Scheme Account PDFsaba alamAinda não há avaliações

- Market Visit Ing ReportDocumento3 páginasMarket Visit Ing ReportMr. JahirAinda não há avaliações

- Ficha Técnica TRIPODE KAYA SAFETY SENTORDocumento1 páginaFicha Técnica TRIPODE KAYA SAFETY SENTORJuan Armas BissoAinda não há avaliações

- Ikhlayel 2018Documento41 páginasIkhlayel 2018Biswajit Debnath OffcAinda não há avaliações

- Contingent Liabilities For Philippines, by Tarun DasDocumento62 páginasContingent Liabilities For Philippines, by Tarun DasProfessor Tarun DasAinda não há avaliações

- February-14 Rural Development SchemesDocumento52 páginasFebruary-14 Rural Development SchemesAnonymous gVledD7eUGAinda não há avaliações

- Application of Memebership Namrata DubeyDocumento2 páginasApplication of Memebership Namrata DubeyBHOOMI REALTY AND CONSULTANCY - ADMINAinda não há avaliações

- Oceanic Wireless Vs CirDocumento6 páginasOceanic Wireless Vs CirnazhAinda não há avaliações

- 140 048 WashingtonStateTobaccoRetailerListDocumento196 páginas140 048 WashingtonStateTobaccoRetailerListAli MohsinAinda não há avaliações

- Apollo Tyre Company: A Project Report ONDocumento55 páginasApollo Tyre Company: A Project Report ONMOHITKOLLI100% (1)

- Voyage Accounting ExampleDocumento4 páginasVoyage Accounting Exampledharmawan100% (1)

- Chapter 6-Household BehaviorDocumento19 páginasChapter 6-Household BehaviorJAGATHESANAinda não há avaliações