Escolar Documentos

Profissional Documentos

Cultura Documentos

Master Scheduler or Buyer or Planner

Enviado por

api-77621335Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Master Scheduler or Buyer or Planner

Enviado por

api-77621335Direitos autorais:

Formatos disponíveis

David Solodkin Email: ds7ffc80@westpost.

net

4348 North Park Drive Phone: 770-496-1670

Tucker, Georgia 30084 Cell: 678-520-9650

US

QUALIFICATIONS SUMMARY

Progressive experience in all phases of material/inventory control, including ma

ster scheduling and purchasing. Experience in different types of manufacturing r

anging from high volume production to custom made products and service facilitie

s.

PROFESSIONAL Experience

9/2001 - 1/2010 Project Coordinator II EMS Technologies

Norcross, Georgia

Responsible for planning and scheduling of Military and Space jobs, entering BOM

's into computerized system, implementation of engineering changes, control of p

roject / job inventory and project / job material budget. Interfaced with pro

ject managers, design and process engineers, procurement, quality and customer r

epresentatives. Assisted in establishing project budget and producing product w

ith in the budget.

*On one program reduced product cost by establishing floor stock and reducing ma

nufacturing cost by 15%.

*On other programs reduce cost by 20% or 300K by reducing material cost and impr

ove customer delivery by 6 month by establishing material flow and set-up small

dedicated production line which also reduced production cost.

9/1995 - 9/2001 Senior Planner-buyer Nordson Corp

Norcross Ga

Responsible for planning, scheduling and purchasing for a Product line. Schedul

ed work for 20 employees, controlled over 5 million dollars of inventory and pu

rchased over 4 million dollars a year. Interfaced with marketing, engineering,

customer service and field service.

*Participated in conversion to a new computer system (SAP).

*Reduced inventory on one of Product lines from over 1 million to fewer than 30

0K.

*Reduced customer delivery lead-time from 12 weeks to 6 weeks.

3/1994 - 5/1995 Document Control Supervisor Electronic System Intr.

Norcross, Ga

Responsible for conversation of customers BOM's into ESI's, new part number ass

ignment, engineering control. Interfaced with customers, engineering, purchasin

g, production, quality assurance and material control.

*Played a major role in conversion to new computer system (Fourth Shift) *Intro

duced ECN control

*Restructured BOM to reflect manufacturing process

2/1992 - 3/1994 Master Scheduler BTG. Inc

Decatur, Ga

Responsible for document control, ECN control, BOM's, master scheduling, produc

tion scheduling, capacity planning. Interfaced with engineering, marketing, pur

chasing, production and quality control departments.

*Decreased ECN backlog by 80%

*Restructured all planning bills and master schedule

4/1989 - 1/1992 Master Scheduler Mitsubishi Consumer Electroni

cs Braselton, Ga

Responsible for scheduling manufacturing process, Master scheduling of MRP, eng

ineering change

control. Interfaced with engineering, marketing, purchasing, production and qua

lity control departments.

*Assisted introduction of MRP - MPS systems production

*Introduced daily production schedules to the production process

*Assisted the reduction of inventory from $15 Million to $7 Million.

*Established service requirements as part of MRP requirements to improve custom

er service.

5/1981 - 3/1989 Material Analyst Scientific-Atlanta

Norcross, Ga

Responsible for master scheduling, engineering change control, introduction and

scheduling new products through production, interfacing with engineering, mark

eting, sales, quality and materials departments. Performed master scheduling an

d capacity planning in "Product Support" facility with up to 100 employees. Pla

nned for and scheduled work centers for standard and customer production runs.

*Improved Product Services inventory turns from .5 to 2 turns. *Responsible for

over $2 Million in inventory

*Introduced and trained employees in computerized back-order system.

*Improved use of master scheduling and MRP for Product Support group.

*Planned and schedule materials receipts of 6000 distinct components and finish

ed goods necessary to support Product Repair, Customer Service Manufacturing an

d Aftermarket Sales function. Interfaced with outside vendors and purchasing de

partment.

*Reduced inventory by over $300,000 by identification of obsolete or seldom use

d parts, and unnecessary finished goods.

Education

Master's Degree in Business from Institute of National Economy in Odessa, Ukrai

ne BS Industrial Engineering from Institute of National Economy in Odessa, Uk

raine

Degree conferred in 1977

PERSONAL

Married, 2 children. US citizen

Bilingual: Russian

References upon request

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Learner Guide HDB Resale Procedure and Financial Plan - V2Documento0 páginaLearner Guide HDB Resale Procedure and Financial Plan - V2wangks1980Ainda não há avaliações

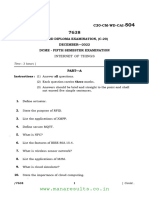

- WWW - Manaresults.co - In: Internet of ThingsDocumento3 páginasWWW - Manaresults.co - In: Internet of Thingsbabudurga700Ainda não há avaliações

- Channel System: Presented byDocumento78 páginasChannel System: Presented bygrace22mba22Ainda não há avaliações

- Common Base AmplifierDocumento6 páginasCommon Base AmplifierMuhammad SohailAinda não há avaliações

- 7933-Article Text-35363-1-10-20230724Documento8 páginas7933-Article Text-35363-1-10-20230724Ridho HidayatAinda não há avaliações

- 1 s2.0 S0304389421026054 MainDocumento24 páginas1 s2.0 S0304389421026054 MainFarah TalibAinda não há avaliações

- Solved - in Capital Budgeting, Should The Following Be Ignored, ...Documento3 páginasSolved - in Capital Budgeting, Should The Following Be Ignored, ...rifa hanaAinda não há avaliações

- CasesDocumento4 páginasCasesNaveen Stephen LoyolaAinda não há avaliações

- Adjectives With Cork English TeacherDocumento19 páginasAdjectives With Cork English TeacherAlisa PichkoAinda não há avaliações

- Installation Manual EnUS 2691840011Documento4 páginasInstallation Manual EnUS 2691840011Patts MarcAinda não há avaliações

- To Syed Ubed - For UpdationDocumento1 páginaTo Syed Ubed - For Updationshrikanth5singhAinda não há avaliações

- Karmex 80df Diuron MsdsDocumento9 páginasKarmex 80df Diuron MsdsSouth Santee Aquaculture100% (1)

- Pie in The Sky 3Documento5 páginasPie in The Sky 3arsi_yaarAinda não há avaliações

- 7373 16038 1 PBDocumento11 páginas7373 16038 1 PBkedairekarl UNHASAinda não há avaliações

- MML3 Journal To CapcomDocumento103 páginasMML3 Journal To CapcomFer BarcenaAinda não há avaliações

- Supply Chain Risk Management: Resilience and Business ContinuityDocumento27 páginasSupply Chain Risk Management: Resilience and Business ContinuityHope VillonAinda não há avaliações

- Stainless Steel 1.4404 316lDocumento3 páginasStainless Steel 1.4404 316lDilipSinghAinda não há avaliações

- BBCVDocumento6 páginasBBCVSanthosh PgAinda não há avaliações

- Strategic Management ModelsDocumento4 páginasStrategic Management ModelsBarno NicholusAinda não há avaliações

- Strength and Microscale Properties of Bamboo FiberDocumento14 páginasStrength and Microscale Properties of Bamboo FiberDm EerzaAinda não há avaliações

- Typical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpDocumento2 páginasTypical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpSabrinadeFeraAinda não há avaliações

- NCR Minimum WageDocumento2 páginasNCR Minimum WageJohnBataraAinda não há avaliações

- Bench VortexDocumento3 páginasBench VortexRio FebriantoAinda não há avaliações

- QuestionDocumento7 páginasQuestionNgọc LuânAinda não há avaliações

- Process Synchronization: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionDocumento26 páginasProcess Synchronization: Silberschatz, Galvin and Gagne ©2013 Operating System Concepts - 9 EditionKizifiAinda não há avaliações

- Divider Block Accessory LTR HowdenDocumento4 páginasDivider Block Accessory LTR HowdenjasonAinda não há avaliações

- SOP No. 6Documento22 páginasSOP No. 6Eli CohenAinda não há avaliações

- EMI-EMC - SHORT Q and ADocumento5 páginasEMI-EMC - SHORT Q and AVENKAT PATILAinda não há avaliações

- Sewing Machins Operations ManualDocumento243 páginasSewing Machins Operations ManualjemalAinda não há avaliações

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocumento45 páginasRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaAinda não há avaliações