Escolar Documentos

Profissional Documentos

Cultura Documentos

Saudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 Civil

Enviado por

(*KaT*)Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Saudi Aramco Inspection Checklist: Structural Re-Instatement Punchlisting SAIC-M-1074 18-May-05 Civil

Enviado por

(*KaT*)Direitos autorais:

Formatos disponíveis

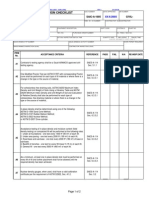

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Structural Re-instatement Punchlisting

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1074

WBS / BI / JO NUMBER

18-May-05

CIVIL-

CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) LAYOUT DRAWING NUMBER SCHEDULED INSPECTION DATE & TIME SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO INSPECTION LEVEL

EQUIPMENT DESCRIPTION REV. NO. PURCHASE ORDER NUMBER

EQPT CODE

SYSTEM ID.

PLANT NO.

EC / PMCC / MCC NO. QUANTITY INSP. MH's SPENT TRAVEL TIME

ACTUAL INSPECTION DATE & TIME SAUDI ARAMCO ACTIVITY NUMBER CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO USE ONLY

WORK PERMIT REQUIRED?

ITEM No. A

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

DOCUMENTATION G.I. 2.710 Para. 4.2.2 G.I. 2.710 Para. 4.1.1.4

A1

Limits of structures for final inspection has been identified. Contractor's QC Inspection Log Book and NCR's were verified for any outstanding open items. (Note: Open items are identified and transferred to the Final System Punchlist Form.) Saudi Aramco Inspection's Log Book and NCR Log were verified for open items. (Note: Open items transferred to Final System Punchlist Form.) QC Documentation on Structural Erection/Alignment complete. (SAIC-M-2007 & SATR-M-2002) (NOTE: In the absence of proof that the Erection Checklist has been completed, this checklist will include all checkpoints contained in SAICM-2007 ). QC Documentation on Structural Bolt Tightening is complete. (SAIC-M-2009) WALKTHROUGH PUNCHLISTING: Main Steel Structure Steel structures are complete (ie: columns, beams, braces, chords, etc) in conformance with the Construction drawings, change orders, and site modifications. A washer shall be furnished with each anchor bolt. Plate washer thicknesses shall be as shown on the design drawings. No section or components of the structure has incurred physical damage during construction/erection. (PIP STS05130, Para. 6.1.1) Field welded connections were completed, tested and accepted through verification of the Weld Summary Report (SATR-W-2008) All field welds shall be continuous weld unless an alternate procedure has been approved by Saudi Aramco. (PIP-STS05130, Para. 6.6.2) All bolted connections using ASTM A325 that were previously tightened and accepted has maintained their tightness condition by verifiying the initial markings (I.E.: color code, die punches) for signs of changes and/or tampering. (PIP STS05130, Para. 6.5.7) All ASTM A307 bolt assemblies are tightened to a snug-tight condition. (PIP STS05130, Para. 6.5.5)

A2

A3

G.I. 2.710 Para. 4.1.1.4

A4

G.I. 2.710 Para. 4.1.1.2

A5

G.I. 2.710 Para. 4.1.1.2

B1

G.I. 2.710 Para. 4.1.1.2 12-SAMSS-007 Para. 6.2.5.21 12-SAMSS-008 Sec. I G.I. 2.710 Para. 4.1.1.2 12-SAMSS-008 Sec. I

B2

B3

B4

B5

B6

12-SAMSS-008 Sec. I

B7

12-SAMSS-008 Sec. I

Page 1 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Structural Re-instatement Punchlisting

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1074

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No. B8

ACCEPTANCE CRITERIA All erection damage caused to hot-dip galvanized coatings are repaired per Inspection Checklist SAIC-H-2089. (PIP-STS05130, Para. 6.12.1) Repairs of damage coating on Steel Structures were completed, accepted and documented in Inspection Checklists SAIC-H-2033 for Alkyd paints, and SAIC-H-2024 for Epoxy coating system. (PIP STS05130, Para. 6.12.2) All galvanized bolt assemblies tightened against shop-applied paint shall be painted. (PIP STS05130, Para. 6.12.2) All non-shop fabricated structural members and appurtenances are painted with the required coating specification and color requirements as per the Paint Schedule and/or Scope of Work. Structural support shall be painted a neutral background color such as aluminum, gray, or black. Consult the Scope of Work for the required color requirement. Structural members which poses as passageway pinch points, unguarded edges, tripping hazards, and obstructions that present bump hazards shall be painted with safety yellow-and-black stripes. The stripes shall be 100 mm wide. Vertical and horizontal members of multi-level equipment structural supports shall be fireproofed at all levels from grade up to the highest level at which any of the following conditions exist: a) Fire hazardous equipment b) Vessels with a minimum gross volume of 2.5 m (15 barrels) that contain flammable liquid, combustible liquid near or above its flash point, combustible gas, or potentially toxic material. Fireproofing when required on structural steel columns and beams supporting Vessels, Equipment, and Piping are complete and accepted. Verify acceptance through completion of the following Inspection Checklists: a. SAIC-B-2010 (Proprietary Fireproofing) b. SAIC-B-1003 & B-1004 (for concrete materials). All cross-bracing shall be bolted at intersections, with one bolt minimum for angles and two bolts minimum for tees. WALKWAYS and HANDRAILS Walkways and handrails were inspected as completed assembly following the Inspection Checklist # SAIC-M-2010 per SATIP-M-001-01. (Note: All inspection checkpoints listed in SAIC-M-2010 shall form part of this checklist if not done otherwise.) All secondary bolted connections using ASTM A307 bolt are tightened to a snug-tight condition. (PIP STS05130, Para. 6.5.5) Field welded attachments and modifications to walkways and handrails are seal welded with a minimum fillet weld size of 3mm and 5mm for strenght welds. (PIP-STS05130, Para. 6.6.4) All erection damage caused to hot-dip galvanized coatings are repaired per Inspection Checklist SAIC-H-2089. (PIP-STS05130, Para. 6.12.1)

REFERENCE 12-SAMSS-008 Sec. I

PASS

FAIL

N/A

RE-INSP DATE

B9

12-SAMSS-008 Sec. I

B10

12-SAMSS-008 Sec. I

B11

SAES-H-001 Para. 5.1

B12

SAES-B-067 Para. 4.1.1

B13

SAES-B-067 Para. 4.2.3a

B14

SAES-B-006 Sec. 5.7

B15

SAES-B-006 Sec. 5

B16

12-SAMSS-007 Para. 6.2.8.2

C1

G.I. 2.710 Para. 4.1.1.2

C2

12-SAMSS-008 Sec. I 12-SAMSS-008 Sec. I 12-SAMSS-008 Sec. I

C3

C4

Page 2 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Structural Re-instatement Punchlisting

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1074

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No.

ACCEPTANCE CRITERIA Repairs of damage coating on Steel Structures were completed. (PIP STS05130, Para. 6.12.2) NOTE: Acceptance and documentation shall be verified through SAIC-H-2033 for Alkyd paints, and SAIC-H-2024 for Epoxy coating system. All galvanized bolt assemblies tightened against shop-applied paint are painted. (PIP STS05130, Para. 6.12.2) All non-shop fabricated members and appurtenances are painted with the required coating specification and color requirements as per the Paint Schedule and/or Scope of Work. Non-grating walking surfaces including patterned steel plates shall have a non-skid surface, i.e: anti-skid paint per SAES-H-101, APCS-12). Grating fasteners (grating clips/hold down bolts) are tightened and provide firm anchorage of grating. (NAAMM MBG 531-00, Page 14). Grating panels are provided with a minimum of 2 fasteners at each support with a minimum of 4 fasteners per panel. NOTE: The location of the fasteners are: Bearing surface of grating or grating panels on supports shall be 1" (25mm) minimum for bearing bar depths up to 2-". (NAAMM MBG 53100, Page 15). Checkered plate used as floor plates shall be provided with " (12mm) diameter drain holes (when specified on contract drawings) for each 20 ft (2 m) of area, with a minimum of one hole per panel. Grating or checkered plated openings for penetrations are cut and banded as shown on the design drawing. Physical hazards such as stumbling and bump hazards such passageway pinch points, unguarded edges, tripping hazards, and obstructions shall be strip coated with safety yellow-and-black stripes if can not be corrected. The stripes shall be 100 mm wide. STAIRS Stairs were inspected as completed assembly. Note: Verify the inspection record, Inspection Checklist #SAIC-M-2010 per SATIP-M-001-01 for completeness. (NOTE: All inspection checkpoint items listed in SAIC-M-2010 shall form part of this checklist if not done otherwise. ) All ASTM A307 bolt assemblies are tightened to a snug-tight condition. (PIP STS05130, Para. 6.5.5) Field welded attachments and modifications to walkways and handrails are seal welded with a minimum fillet weld size of 3mm and 5mm for strength welds. (PIP-STS05130, Para. 6.6.4) All erection damage caused to hot-dip galvanized coatings are repaired per Inspection Checklist SAIC-H-2089. (PIP-STS05130, Para. 6.12.1) Repairs of damage coating on steel structures were completed. NOTE: Acceptance and documentation shall be verified through SAIC-H-2033 for Alkyd paints, and SAIC-H-2024 for Epoxy coating system. (PIP STS05130, Para. 6.12.2)

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

C5

12-SAMSS-008 Sec. I

C6

12-SAMSS-008 Sec. I SAES-H-001 Para. 5.1 SAES-B-054 Para. 4.9.2 & 4.9.3 12-SAMSS-007 Para. 4.14 12-SAMSS-007 Para. 6.1.16 12-SAMSS-007 Para. 4.14

C7

C8

C9

C10

C11

C12

12-SAMSS-007 Para. 6.1.19 12-SAMSS-007 Para. 6.1.17

C13

C14

SAES-B-067 Para. 4.2.3 a

D1

G.I. 2.710 Para. 4.1.1.2

D2

12-SAMSS-008 Sec. I 12-SAMSS-008 Sec. I 12-SAMSS-008 Sec. I

D3

D4

D5

12-SAMSS-008 Sec. I

Page 3 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Structural Re-instatement Punchlisting

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1074

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No. D6

ACCEPTANCE CRITERIA All galvanized bolt assemblies tightened against shop-applied paint shall be painted. (PIP STS05130, Para. 6.12.2) All non-shop fabricated members and appurtenances are painted with the required coating specification and color requirements as per the Paint Schedule and/or Scope of Work. Base of stair is anhored. Physical hazards such as stumbling and bump hazards such as concrete supports at the base of the stairways shall be stripe coated with safety yellow-and-black stripes. The stripes shall be 100 mm wide. LADDERS and CAGES Ladders were inspected as completed assembly using the Inspection Checklist # SAIC-M-2010 per SATIP-M-001-01. NOTE: Verify/Review the Checklists for completeness. (NOTE: All inspection checkpoint items listed in SAIC-M-2010 shall form part of this checklist if not done otherwise .) All bolt assemblies are tightened to a snug-tight conditions. (PIP STS05130, 6.5.5) All erection damage caused to hot-dip galvanized coatings are repaired per Inspection Checklist SAIC-H-2089. (PIP-STS05130, Para. 6.12.1) Repairs of damage coating on Steel Structures were completed. (PIP STS05130, Para. 6.12.2) NOTE: Acceptance and documentation shall be verified through SAIC-H-2033 for Alkyd paints, and SAIC-H-2024 for Epoxy coating system. All galvanized bolt assemblies tightened against shop-applied paint shall be painted. (PIP STS05130, Para. 6.12.2) All non-shop fabricated members and appurtenances are painted with the required coating specification and color requirements as per the Paint Schedule and/or Scope of Work. Ladder is anchored at the base, intermediate support and at top termination points. (ANSI A14.3, Fig. 8) Safety guards (commonly known as "drop bars" or "safety gates") are provided on fixed ladders serving elevations 1.2 m or more above the ground, existing platform or floor, unless the ladder terminates at a surface without a guard rail such as a building roof or a loading dock Safety guard (drop bar) is self dropping by conforming to Library Drawing DE-950101 or equivalent. Minimum clear space around the ladder is maintained as follows: a. Back side: 7" measured fron centerline of rung, or 1" min. measured from the edge of the side rail for unavoidable obstructions, ie: column or insulated structures. b. Front: 30", or 27" if ladder is facing a smooth wall. c. Sides: 15" from center line of ladder to each sides. (PIP STF05501, Detail Dwg. Page 7 and ANSI A14.3, Para. 5.4.1)

REFERENCE 12-SAMSS-008 Sec. I SAES-H-001 Para. 5.1 AC-36106 Rev. 4 SAES-B-067 Para. 4.2.3 a

PASS

FAIL

N/A

RE-INSP DATE

D7

D8

D9

E1

G.I. 2.710 Para. 4.1.1.2

E2

12-SAMSS-008 Sec. I 12-SAMSS-008 Sec. I

E3

E4

12-SAMSS-008 Sec. I

E5

12-SAMSS-008, Sec. I SAES-H-001 Para. 5.1 SAES-B-054 Sec. 8

E6

E7

E8

SAES-B-054 Sec. 8 (4.1.7)

E9

SAES-B-054 Sec. 8 (4.1.7)

E10

SAES-B-054 Sec. 8

Page 4 of 5

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO INSPECTION CHECKLIST

Structural Re-instatement Punchlisting

PROJECT TITLE

SAIC NUMBER

DATE APPROVED

QR NUMBER

SAIC-M-1074

WBS / BI / JO NUMBER

18-May-05

Civil

CONTRACTOR / SUBCONTRACTOR

ITEM No. F

ACCEPTANCE CRITERIA

REFERENCE

PASS

FAIL

N/A

RE-INSP DATE

Lifting Structures/Monorails Lifting equipment and devices such as davits, monorails, and lifting beams shall be painted safety yellow. The lifting equipment and devices shall be load tested and certified by Crane Inspection of PID. (ASME B30.11, Para.11-2.2.2a) All lifting equipment and devices shall be clearly marked in black paints with the rated capacity of the equipment in Arabic and English in metric tons. SAES-B-067 Para. 4.2.3 G.I. 7.030 Para. 3.3.1 SAES-B-067 Para. 4.3.6 & 4.4

F1

F2

F3

REMARKS: 1. Any Item marked as "Fail" requires to be identified with the specific description and location of the descripancy/violation and shall be listed in the Contractor's Re-Instatement Punchlist Form. 2. This Checklist along with the Re-Instatement Punchlist, with or with out cleared items, shall be submitted to Saudi Aramco on or before the requested time for Mechanical Completion Punchlisting.

REFERENCE DOCUMENTS: 1- SAES-B-054 -- Access, Egress, and Materials Handling for Plant Facilities, 31 March 2001 2- SAES-B-006 -- Fireproofing for Plants, 30 June 2003 3- 12-SAMSS-007 -- Fabrication of Structural and Miscellaneous Steel, 28 April 2004 4- 12-SAMSS-008 -- Erection of Structural and Miscellaneous Steel, 28 January 2004 5- SAES-H-001 -- Selection Requirements for Industrial Coatings, 30 October 2002 6- SAES-H-101 -- Approved Protective Coating Systems, 31 August 2003

Contractor / Third-Party

Construction Representative*

Work is Complete and Ready for Inspection: Name, Initials and Date: Name, Initials and Date:

Saudi Aramco

PMT Representative

T&I Witnessed QC Record Reviewed Work Verified

QC Inspector

Performed Inspection Name, Initials and Date: Work / Rework May Proceed

PID Representative

T&I Witnessed Name, Initials and Date: QC Record Reviewed Work Verified

QC Supervisor

Quality Record Approved: Name, Sign and Date: *Person Responsible for Completion of Quality Work / Test

Proponent and Others

Name, Organization, Initials and Date: T&I Witnessed QC Record Reviewed Work Verified

Y = YES

N = NO F = FAILED

Page 5 of 5

Você também pode gostar

- Saudi Aramco Concrete Lab InspectionDocumento3 páginasSaudi Aramco Concrete Lab InspectionTayyab AchakzaiAinda não há avaliações

- 09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsDocumento4 páginas09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsFiras AlbaweiAinda não há avaliações

- Saic A 1001Documento2 páginasSaic A 1001Vinayak Vaghe100% (1)

- Saudi Aramco Inspection ChecklistDocumento3 páginasSaudi Aramco Inspection ChecklistZia ur RehmanAinda não há avaliações

- Satip Q 001 03Documento10 páginasSatip Q 001 03munnaAinda não há avaliações

- QMIS RFI RaisedDocumento2 páginasQMIS RFI RaisedSulman YounasAinda não há avaliações

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDocumento3 páginasSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanAinda não há avaliações

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDocumento2 páginasSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- Saic M 1060Documento1 páginaSaic M 1060Hussain Nasser Al- NowiesserAinda não há avaliações

- SATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFDocumento3 páginasSATIP-Q-006-01rev4 (Asphalt Paving - Batch Plant & 3rd Party Lab) PDFRamziAhmedAinda não há avaliações

- SAIC-A-2003 Rev 0Documento3 páginasSAIC-A-2003 Rev 0bluelions_19Ainda não há avaliações

- SAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTDocumento5 páginasSAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTNaushad AlamAinda não há avaliações

- SAIC-A-2016 Rev 0Documento2 páginasSAIC-A-2016 Rev 0philipyapAinda não há avaliações

- SAES-W-012 - Google Search3Documento1 páginaSAES-W-012 - Google Search3fayceal0% (1)

- SAIC-A-1006 - Final Fill InspectionDocumento1 páginaSAIC-A-1006 - Final Fill InspectionwalidAinda não há avaliações

- Saudi Aramco Precast Concrete Installation PlanDocumento10 páginasSaudi Aramco Precast Concrete Installation PlanNaushad AlamAinda não há avaliações

- Saudi Aramco Welding Consumables ChecklistDocumento5 páginasSaudi Aramco Welding Consumables ChecklistAnsuman KalidasAinda não há avaliações

- Saic M 1012Documento2 páginasSaic M 1012Hussain Nasser Al- NowiesserAinda não há avaliações

- Saic-M-1012 Rev 7 (Final)Documento3 páginasSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyAinda não há avaliações

- Satr M 1063Documento3 páginasSatr M 1063jerin100% (1)

- Saic Q 1007Documento2 páginasSaic Q 1007Hussain Nasser Al- NowiesserAinda não há avaliações

- Saic-Q-1035 Sub-Base & Base CourseDocumento4 páginasSaic-Q-1035 Sub-Base & Base CourseAbdul HannanAinda não há avaliações

- SATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsDocumento2 páginasSATIP-Q-001-03 Pre-Cast Concrete Fence Posts at Fabrication YardsAbdul HannanAinda não há avaliações

- Saic A 1005.Documento5 páginasSaic A 1005.Fazal HaqAinda não há avaliações

- Presentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)Documento55 páginasPresentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)kbldamAinda não há avaliações

- AEP1152Documento10 páginasAEP1152walitedisonAinda não há avaliações

- Satip M 100 07Documento10 páginasSatip M 100 07munnaAinda não há avaliações

- Saudi Aramco waterproofing inspectionDocumento3 páginasSaudi Aramco waterproofing inspectionSatheesh Rama SamyAinda não há avaliações

- 175 022503Documento2 páginas175 022503Abu Anas M.SalaheldinAinda não há avaliações

- QC and QA standards for construction materialsDocumento1 páginaQC and QA standards for construction materialsMuhammad Arif KhanAinda não há avaliações

- Saudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 WeldDocumento1 páginaSaudi Aramco Inspection Checklist: Buttering and / or Weld Build-Up - Offshore Structures SAIC-W-1311 Weldkartik_harwani4387Ainda não há avaliações

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocumento2 páginasSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanAinda não há avaliações

- SATIP Q 006 02 (Recovered)Documento10 páginasSATIP Q 006 02 (Recovered)Abdul HannanAinda não há avaliações

- Saic M 2021Documento6 páginasSaic M 2021Hussain Nasser Al- NowiesserAinda não há avaliações

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocumento3 páginasSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalAinda não há avaliações

- Saudi Aramco refractory installation checklistDocumento3 páginasSaudi Aramco refractory installation checklistAnonymous S9qBDVkyAinda não há avaliações

- SATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFDocumento2 páginasSATIP-Q-001-04rev4 (Structural Precast-Prestressed Conc.) PDFRamziAhmedAinda não há avaliações

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocumento5 páginasTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcAinda não há avaliações

- Saes R 004Documento8 páginasSaes R 004Shahzad HussainAinda não há avaliações

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Documento2 páginasSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesAinda não há avaliações

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocumento2 páginasSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.Ainda não há avaliações

- Saudi Aramco Inspection ChecklistDocumento5 páginasSaudi Aramco Inspection ChecklistAbdul HannanAinda não há avaliações

- Weekly Welder ReportDocumento2 páginasWeekly Welder Reportkarthi51289Ainda não há avaliações

- SaicDocumento8 páginasSaicKhurram Shehzad100% (1)

- SAIC-Q-1044 Asphalt Paving Final InspectionDocumento3 páginasSAIC-Q-1044 Asphalt Paving Final InspectionAbdul HannanAinda não há avaliações

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDocumento2 páginasSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanAinda não há avaliações

- Saic A 1002Documento2 páginasSaic A 1002Sajid ShaikhAinda não há avaliações

- Saic M 1006Documento2 páginasSaic M 1006Hussain Nasser Al- NowiesserAinda não há avaliações

- IP02-Bend Check List 01Documento1 páginaIP02-Bend Check List 01Laith SalmanAinda não há avaliações

- SAIC-A-1005 Rev 3 Compaction TestingDocumento2 páginasSAIC-A-1005 Rev 3 Compaction Testingimrankhan22Ainda não há avaliações

- 00 Saip 10aDocumento1 página00 Saip 10amalika_00Ainda não há avaliações

- Saudi Aramco Typical Inspection PlanDocumento10 páginasSaudi Aramco Typical Inspection Plankarthi51289Ainda não há avaliações

- Rfi FormDocumento2 páginasRfi Formmuhammedemraan0% (1)

- 175 091300Documento2 páginas175 091300Abu Anas M.SalaheldinAinda não há avaliações

- Saep 321Documento25 páginasSaep 321AbdullahAinda não há avaliações

- Saes Q 001Documento22 páginasSaes Q 001irfan hussainAinda não há avaliações

- Saic Q 1017Documento1 páginaSaic Q 1017Hussain Nasser Al- Nowiesser100% (2)

- SAIC-D-2022 Rev 2Documento5 páginasSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுAinda não há avaliações

- Handling and Storage of FBE Coated BarsDocumento2 páginasHandling and Storage of FBE Coated BarsMo'tasem SerdanehAinda não há avaliações

- Receiving Inspection of Pressure VesselsDocumento5 páginasReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுAinda não há avaliações

- Dashboard Produccion Historica PPGDocumento132 páginasDashboard Produccion Historica PPGdoyola grupoppgAinda não há avaliações

- Act 1947 2018Documento81 páginasAct 1947 2018HirakAinda não há avaliações

- JazzDocumento2 páginasJazzมาย มาน์ยAinda não há avaliações

- Bruce Lee Abs RoutineDocumento2 páginasBruce Lee Abs RoutinebabagazeboAinda não há avaliações

- 5a8fbc22d0ce57481 PDFDocumento80 páginas5a8fbc22d0ce57481 PDFMahendra SofyanAinda não há avaliações

- NBA 2K12 Manual PC FinalDocumento14 páginasNBA 2K12 Manual PC FinalJohn BrennanAinda não há avaliações

- 11 Lakh Classified DBDocumento246 páginas11 Lakh Classified DBasidique5_292665351Ainda não há avaliações

- Xabcdefghy 8Rsnlwqkvlntr ( (7Zpp+-Zppzpp' 6-+P+-+-+& 5+-+P+-+-% 4-+-+-+-+$ 3+-+P+-Zp-# 2Pzpp+Pzplzp" 1Trnvlqmk-Snr! XabcdefghyDocumento5 páginasXabcdefghy 8Rsnlwqkvlntr ( (7Zpp+-Zppzpp' 6-+P+-+-+& 5+-+P+-+-% 4-+-+-+-+$ 3+-+P+-Zp-# 2Pzpp+Pzplzp" 1Trnvlqmk-Snr! XabcdefghyJames NeoAinda não há avaliações

- Spanish Academy Soccer Coaching Passing DrillDocumento2 páginasSpanish Academy Soccer Coaching Passing DrillLucian Nicolau50% (2)

- Rise Up Boat Landing - TLD - Rev.0 - LatestDocumento12 páginasRise Up Boat Landing - TLD - Rev.0 - LatestSendy MaulanaAinda não há avaliações

- Lesson 3:: Safety Protocol To Avoid Emergencies During An ExerciseDocumento3 páginasLesson 3:: Safety Protocol To Avoid Emergencies During An ExerciseJerwin SamsonAinda não há avaliações

- 25.04 101490900101 101490900144 Hydr - Motor, VibrationDocumento15 páginas25.04 101490900101 101490900144 Hydr - Motor, Vibrationangga setyawanAinda não há avaliações

- DYNA-CAT(PLC)-AMTRAK Quick Reference GuideDocumento653 páginasDYNA-CAT(PLC)-AMTRAK Quick Reference GuideSteven James Capuano100% (5)

- LinksDocumento3 páginasLinksblytzAinda não há avaliações

- Data Sheet Low Drag Ellipsoid Buoy 16 Rev 4Documento1 páginaData Sheet Low Drag Ellipsoid Buoy 16 Rev 4Arthur Antônio MachadoAinda não há avaliações

- Sierra 7mm08 Reloading DataDocumento9 páginasSierra 7mm08 Reloading DataBIBI1978Ainda não há avaliações

- Ut 4Documento4 páginasUt 4Johnny OzaltunAinda não há avaliações

- Video Games Sales AnalysisDocumento20 páginasVideo Games Sales AnalysisChristianGrayAinda não há avaliações

- Manual Book VibroDocumento157 páginasManual Book Vibrodirma wansyahAinda não há avaliações

- Tong-Its - Wikipedia, The Free EncyclopediaDocumento3 páginasTong-Its - Wikipedia, The Free EncyclopediaAnsel SotnasAinda não há avaliações

- Cifra Club - ABBA - WaterlooDocumento3 páginasCifra Club - ABBA - WaterlooLuán AcevedoAinda não há avaliações

- Grade 8 Science Forces and Motion Multiple ChoiceDocumento1 páginaGrade 8 Science Forces and Motion Multiple ChoiceIan Gabriel Oliquiano83% (6)

- Fostech Product Catalog 2017Documento24 páginasFostech Product Catalog 2017KenshironokenAinda não há avaliações

- 7 SwordsDocumento4 páginas7 SwordsShady OwlAinda não há avaliações

- 2047681-Chesters Holiday SublassesDocumento11 páginas2047681-Chesters Holiday SublassesHamio DracnyAinda não há avaliações

- Cricket Infrastructure BangladeshDocumento23 páginasCricket Infrastructure BangladeshShakil AlamAinda não há avaliações

- My Day ScheduleDocumento3 páginasMy Day ScheduleMarta CabaçoAinda não há avaliações

- 359566-2linde 11.5 Meter R16 PDFDocumento1 página359566-2linde 11.5 Meter R16 PDFASIFAinda não há avaliações

- catcrochets.com-Moomin PatternDocumento5 páginascatcrochets.com-Moomin PatternDebra EdelmannAinda não há avaliações