Escolar Documentos

Profissional Documentos

Cultura Documentos

General Properties of Pet

Enviado por

pavithraDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

General Properties of Pet

Enviado por

pavithraDireitos autorais:

Formatos disponíveis

General Properties Polyethylene terephthalate (PET) is a hard, stiff, strong, dimensionally stable material that absorbs very little

water. It has good gas barrier properties and good chemical resistance except to alkalis (which hydrolyse it). Its crystallinity varies from amorphous to fairly high crystalline. It can be highly transparent and colourless but thicker sections are usually opaque and off-white. Polyethylene Terephthalate Films It is widely known in the form of biaxially oriented and thermally stabilised films usually referred to by their main brand names Mylar, Melinex or Hostaphan. Strictly speaking, these names should be used only for this type of film whose properties are different from, and in several respects superior to, those of ordinary polyethylene terephthalate (PET) film. Applications These Mylar-type films are used for capacitators, graphics, film base and recording tapes etc. PET is also used for fibres for a very wide range of textile and industrial uses (Dacron, Trevira, Terylene). Other applications include bottles and electrical components. Key Properties

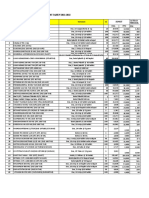

Chemical Resistance Acids concentrated Acids dilute Alcohols Alkalis Aromatic hydrocarbons Greases and Oils Halogens Ketones Electrical Properties Dielectric constant @1MHz Dielectric strength ( kV.mm )

-1

Good Good Good Poor Fair Good Good Good

3.0 17 0.002 1013 >1014

Dissipation factor @ 1kHz Surface resistivity ( Ohm/sq ) Volume resistivity ( Ohm.cm ) Mechanical Properties Coefficient of friction

0.2-0.4

Hardness Rockwell Izod impact strength ( J.m )

-1

M94-101 13-35 0.37-0.44(oriented) 2-4 80, for biax film 190-260

Poissons ratio Tensile modulus ( GPa ) Tensile strength ( MPa ) Physical Properties Density ( g.cm-3 ) Flammability Limiting oxygen index ( % ) Refractive index Resistance to Ultra-violet Water absorption - equilibrium ( % ) Water absorption - over 24 hours ( % ) Thermal Properties Coefficient of thermal expansion ( x10-6 K-1 ) Heat-deflection temperature - 0.45MPa ( C ) Heat-deflection temperature - 1.8MPa ( C ) Lower working temperature ( C ) Specific heat ( J.K .kg )

-1 -1

1.3-1.4 Self Extinguishing 21 1.58-1.64 Good <0.7 0.1

20-80 115 80 -40 to -60 1200 - 1350

Thermal conductivity ( W.m .K )

-1 -1

0.15-0.4 @ 23 115-170

Upper working temperature ( C ) Properties Polyethylene Terephthalate Film Property Dielectric Strength @25m thick Dissipation Factor @1MHz Elongation at Break Initial Tear Strength Permeability to Carbon Dioxide @25C Permeability to Hydrogen @25C Permeability to Nitrogen @25C Permeability to Oxygen @25C Permeability to Water @25C Specific Heat Thermal Conductivity @23C % g.m x10 x10 x10

-1

Value KV.mm-1 300 0.016 60-165 18-54

3 3 3 -2 -2 -2 -1 -1 -1 -1 -1 -1 -1 -1

-13 -13 -13

cm .cm.cm .s .Pa cm .cm.cm .s .Pa cm .cm.cm .s .Pa

3 3 -2 -2 -1 -1

0.07-0.11 0.45 0.0034-0.0038 0.015-0.04 100-115 1.3 0.13-0.15

X10 cm .cm.cm .s .Pa

-13 -13

X10 cm .cm.cm .s .Pa KJ.kg .K

-1 -1

W.m .K

-1

-1

Properties Polyethylene Terephthalate Fibre Property Material Specific Modulus cN/tex Value Medium High tenacity 700-800

Specific Tenacity Density Extension to break Modulus Shrinkage @100C Tenacity

cN/tex g.cm % GPa % GPa

-3

36 1.39 36

70-80 1.39 13-16 9-11

4 0.5

1.5-6 0.9-1.1

Você também pode gostar

- Chlorine: International Thermodynamic Tables of the Fluid StateNo EverandChlorine: International Thermodynamic Tables of the Fluid StateAinda não há avaliações

- Polyethylene TerephthalateDocumento7 páginasPolyethylene Terephthalateapi-3828258100% (1)

- Geotextiles and Geomembranes HandbookNo EverandGeotextiles and Geomembranes HandbookT.S. IngoldNota: 5 de 5 estrelas5/5 (1)

- Seminar 1 (Dhaval Prajapati) (10bpe078)Documento20 páginasSeminar 1 (Dhaval Prajapati) (10bpe078)ajay7892Ainda não há avaliações

- Polystyrene (PS)Documento4 páginasPolystyrene (PS)Joyce LapuzAinda não há avaliações

- Ethylene Glycol PropertiesDocumento5 páginasEthylene Glycol PropertiesPråveen SågittåŕiúśAinda não há avaliações

- Separation Science - Chromatography Unit Thomas Wenzel Department of Chemistry Bates College, Lewiston ME 04240 Twenzel@bates - EduDocumento69 páginasSeparation Science - Chromatography Unit Thomas Wenzel Department of Chemistry Bates College, Lewiston ME 04240 Twenzel@bates - EduthecriticAinda não há avaliações

- Eneral-Purpose Injection Moulding Grade: POKETONE Polymer M630ADocumento2 páginasEneral-Purpose Injection Moulding Grade: POKETONE Polymer M630AmacAinda não há avaliações

- Manufacturing End Uses: Riaz-Ul-Haq 060820-054Documento12 páginasManufacturing End Uses: Riaz-Ul-Haq 060820-054Kasra GolbanAinda não há avaliações

- Nylon FiberDocumento26 páginasNylon FiberA.K.M. Rashedul IslamAinda não há avaliações

- Fydp Proposal by Group b4Documento17 páginasFydp Proposal by Group b4nokhaizAinda não há avaliações

- Spandex YarnDocumento4 páginasSpandex YarnKasra Golban100% (1)

- Polypropylene PP PlasticDocumento8 páginasPolypropylene PP PlasticRyan VasquezAinda não há avaliações

- manualChemicalTechnology6 AlkalIndustry1916Documento122 páginasmanualChemicalTechnology6 AlkalIndustry1916Oth JAinda não há avaliações

- Colloidal Silica Removal in Coagulation - PubMed MobileDocumento1 páginaColloidal Silica Removal in Coagulation - PubMed MobileSandeep MishraAinda não há avaliações

- Clariant FargkartaDocumento10 páginasClariant FargkartaJulia ChouAinda não há avaliações

- Reactol 1717 EDocumento1 páginaReactol 1717 EbuninaAinda não há avaliações

- Mass Transfer DR AurobaDocumento191 páginasMass Transfer DR Aurobaabdukadir442Ainda não há avaliações

- Soda 2520ash Material 2520 BalanceDocumento5 páginasSoda 2520ash Material 2520 BalanceEng RaaAinda não há avaliações

- Chapter 1 DistillationDocumento73 páginasChapter 1 DistillationNUR HIDAYAHAinda não há avaliações

- Lecture 3 - Cellulose Modification PDFDocumento60 páginasLecture 3 - Cellulose Modification PDFSurinder Pal Singh100% (1)

- Carboxymethyl Cellulose - Wikipedia, The Free EncyclopediaDocumento3 páginasCarboxymethyl Cellulose - Wikipedia, The Free EncyclopediaBenni WewokAinda não há avaliações

- Cem Notes by K20ce029Documento75 páginasCem Notes by K20ce029Bilal Ahmed BajkaniAinda não há avaliações

- PolyethyleneDocumento11 páginasPolyethyleneviditghai67% (3)

- DistillationDocumento18 páginasDistillationAbdul RahmanAinda não há avaliações

- Dme Simulation With DwsimDocumento4 páginasDme Simulation With Dwsimingegnere1234Ainda não há avaliações

- Chemicals Based On PropyleneDocumento21 páginasChemicals Based On PropyleneAli aliraqiAinda não há avaliações

- Control de SOXDocumento23 páginasControl de SOXamaguilaAinda não há avaliações

- Production of PolystyreneDocumento56 páginasProduction of Polystyreneيزيد العزانيAinda não há avaliações

- DistillationDocumento15 páginasDistillationSachi DesaiAinda não há avaliações

- Polyethylene Terephthalate (Pet) : HistoryDocumento3 páginasPolyethylene Terephthalate (Pet) : HistoryMaleha SalimAinda não há avaliações

- Calcaulation of ResinDocumento1 páginaCalcaulation of ResinThanneeru Naga RajuAinda não há avaliações

- Novatex Limited: Internship ReportDocumento53 páginasNovatex Limited: Internship ReportMuhammad Ayaz0% (1)

- Aniline Point: Fuels and Combustion (Lab)Documento15 páginasAniline Point: Fuels and Combustion (Lab)Zahid Mahmood100% (1)

- What Is Soda Ash?: Flux For Silicate. Moreover, They Are AlsoDocumento5 páginasWhat Is Soda Ash?: Flux For Silicate. Moreover, They Are AlsoOwais KhanAinda não há avaliações

- Styrene - Wikipedia, The Free EncyclopediaDocumento7 páginasStyrene - Wikipedia, The Free EncyclopediaWancianSiaAinda não há avaliações

- Preparation of Zeolites by Different Bases With 1.5 of Initial Ratio Si/Al: The Effect of Crystallization TemperatureDocumento4 páginasPreparation of Zeolites by Different Bases With 1.5 of Initial Ratio Si/Al: The Effect of Crystallization TemperatureIOSRjournalAinda não há avaliações

- Introduction To Ion ExchangeDocumento40 páginasIntroduction To Ion ExchangeMasood AhmedAinda não há avaliações

- D323-15a - Vapor Pressure (Reid Method)Documento11 páginasD323-15a - Vapor Pressure (Reid Method)Johu VeAinda não há avaliações

- The Manufacture of Soda Ash in The Arabian Gulf PDFDocumento9 páginasThe Manufacture of Soda Ash in The Arabian Gulf PDFjustinerose_santosAinda não há avaliações

- Recovery of Ammonia As Struvite From Anaerobic Digester EffluentsDocumento11 páginasRecovery of Ammonia As Struvite From Anaerobic Digester EffluentsYuni Hapsari Nyit IIAinda não há avaliações

- The Manufacture of Soda Ash in The Arabian GulfDocumento10 páginasThe Manufacture of Soda Ash in The Arabian GulfManohkaran VelooAinda não há avaliações

- SAND Study For Orifice PDFDocumento48 páginasSAND Study For Orifice PDFAnoop GeorgeAinda não há avaliações

- R-723 - An Azeotrope On The Basis of AmmoniaDocumento6 páginasR-723 - An Azeotrope On The Basis of AmmoniaevrimkAinda não há avaliações

- Membrane Separation: ProcessesDocumento8 páginasMembrane Separation: ProcessesSaptarshi BhattacharjeeAinda não há avaliações

- Pressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeDocumento13 páginasPressure-Driven Cavitating Flow of Water Through A Sharp-Edged OrificeKaushika Rajapaksha PereraAinda não há avaliações

- Overview of The ProcessDocumento10 páginasOverview of The ProcessChaitanya PottiAinda não há avaliações

- Report On Synthetic FiberDocumento4 páginasReport On Synthetic FiberAnu Yashpal KapoorAinda não há avaliações

- 4 Diffusion+ficks PDFDocumento107 páginas4 Diffusion+ficks PDFYasir AliAinda não há avaliações

- NaphthaleneDocumento7 páginasNaphthalenesudivgulla1100% (1)

- Polyvinyl Chloride (PVC) : A Petrochemical ProductDocumento21 páginasPolyvinyl Chloride (PVC) : A Petrochemical ProductifyAinda não há avaliações

- Adsorption PDFDocumento49 páginasAdsorption PDFMarisol BravoAinda não há avaliações

- Acetylene How Products Are MadeDocumento3 páginasAcetylene How Products Are MadeJoy MukherjeAinda não há avaliações

- Rx-004 CSTR Series CistotransDocumento19 páginasRx-004 CSTR Series CistotransMuhammad Hamza EjazAinda não há avaliações

- SpandexDocumento1 páginaSpandexNavnath PingaleAinda não há avaliações

- Flow Chart of Polyester Fiber ProductionDocumento2 páginasFlow Chart of Polyester Fiber ProductionMuhammad Jafor IqbalAinda não há avaliações

- ArticleDocumento14 páginasArticlejaime100% (1)

- PE Vs XLPEDocumento2 páginasPE Vs XLPEhendrexAinda não há avaliações

- PETDocumento52 páginasPETAkash YadavAinda não há avaliações

- Ens TecDocumento28 páginasEns TecBorja CanalsAinda não há avaliações

- Data Mining HealthDocumento10 páginasData Mining HealthpavithraAinda não há avaliações

- IEEE Paper - SecurityDocumento10 páginasIEEE Paper - Securitynarendarreddym100% (1)

- Instruction Hazard11Documento9 páginasInstruction Hazard11pavithraAinda não há avaliações

- Bhakranangal Dam-Power Distribution: HistoryDocumento5 páginasBhakranangal Dam-Power Distribution: HistorypavithraAinda não há avaliações

- Analytic FunctionsDocumento5 páginasAnalytic Functionspavithra0% (1)

- Mega Structures of Civil Engineering World's Tallest Hotel: Burj Al-ArabDocumento10 páginasMega Structures of Civil Engineering World's Tallest Hotel: Burj Al-ArabpavithraAinda não há avaliações

- Formation of BogDocumento6 páginasFormation of BogpavithraAinda não há avaliações

- Medical Uses of UltrasoundDocumento3 páginasMedical Uses of UltrasoundpavithraAinda não há avaliações

- Cylinder Manufacturers Marks (Non Statutory)Documento26 páginasCylinder Manufacturers Marks (Non Statutory)srkmAinda não há avaliações

- Experiment 2 Introduction and ConclusionDocumento4 páginasExperiment 2 Introduction and ConclusionMaiSakurajimaAinda não há avaliações

- Harga Ekatalog 2021-2022 UpdateDocumento1 páginaHarga Ekatalog 2021-2022 Updatesury astikaAinda não há avaliações

- PPT1 - Chemistry 1Documento27 páginasPPT1 - Chemistry 1mmsoledadAinda não há avaliações

- Experiment 5 - PLAHDocumento24 páginasExperiment 5 - PLAHJena CamangegAinda não há avaliações

- Acidity Guide A4 en LRDocumento21 páginasAcidity Guide A4 en LRHeriberto GonzalezAinda não há avaliações

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Documento2 páginasEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoAinda não há avaliações

- Experiment 5a Pre Post LabDocumento9 páginasExperiment 5a Pre Post LabRue Cheng Ma100% (1)

- Report: My Favorite ElementDocumento1 páginaReport: My Favorite ElementDiego RoeschAinda não há avaliações

- 1 Manufacture: A Typical Analysis of Commercial Chlorosulfonic Acid Would Be AsDocumento6 páginas1 Manufacture: A Typical Analysis of Commercial Chlorosulfonic Acid Would Be Asapi-19738746Ainda não há avaliações

- Ullmann's Enc. of Industrial ChemistryDocumento72 páginasUllmann's Enc. of Industrial ChemistrySlim Toumi50% (2)

- Effect of The Superplasticizer Type On The Properties of The Fly Ash Blended CementDocumento6 páginasEffect of The Superplasticizer Type On The Properties of The Fly Ash Blended CementKaraline MarcesAinda não há avaliações

- 209th Meeting (R-II North)Documento110 páginas209th Meeting (R-II North)Sarfarazpk10% (1)

- Chemistry Project Report Class XIIDocumento3 páginasChemistry Project Report Class XIIRohitKumar50% (2)

- IncinerationDocumento30 páginasIncinerationOMSAIRAMAAinda não há avaliações

- Nicotine ProductionDocumento10 páginasNicotine Productionkyungsoo's death glareAinda não há avaliações

- 20electrochemistry Best Slides 2Documento145 páginas20electrochemistry Best Slides 2Muhammad Nauman KhalidAinda não há avaliações

- Section A - Sprinklers Standard Coverage, Standard Response: Pendent/Upright (Glass Bulb)Documento18 páginasSection A - Sprinklers Standard Coverage, Standard Response: Pendent/Upright (Glass Bulb)José marinAinda não há avaliações

- Physical and Chemical Change Virtual Lab ST Lesson Santellano Victoria ADocumento3 páginasPhysical and Chemical Change Virtual Lab ST Lesson Santellano Victoria Aapi-255434272Ainda não há avaliações

- Carbon CompoundsDocumento22 páginasCarbon CompoundsJaechel Vhien TatuAinda não há avaliações

- Exp 16-FR 3 SudanDocumento14 páginasExp 16-FR 3 Sudanherbie_wanAinda não há avaliações

- ID Pengaruh Temperatur Cetakan Pada Cacat VDocumento10 páginasID Pengaruh Temperatur Cetakan Pada Cacat VDetri Yoga AdhiAinda não há avaliações

- Chemistry 12: JUNE 1994 Provincial ExaminationDocumento27 páginasChemistry 12: JUNE 1994 Provincial ExaminationCát TriệuAinda não há avaliações

- Bpharm 3 Sem Pharmaceutical Organic Chemistry 2 Bp301t 2020Documento1 páginaBpharm 3 Sem Pharmaceutical Organic Chemistry 2 Bp301t 2020ABHISHEK YADUVANSHIAinda não há avaliações

- Atomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFDocumento16 páginasAtomic Spectroscopy - A Guide To Selecting The Appropriate Technique and System PDFAdamu OnakpaAinda não há avaliações

- A4-Transporter August 31, 2015Documento25 páginasA4-Transporter August 31, 2015Paolo Q. SangalangAinda não há avaliações

- IMO55 2021 T1 Solutions EngDocumento11 páginasIMO55 2021 T1 Solutions EngLazar SavicAinda não há avaliações

- Kami Export - John Daniel Silvestre - 26 Strength of Acids - SDocumento6 páginasKami Export - John Daniel Silvestre - 26 Strength of Acids - SJohn Silvestre0% (1)

- Tutorial 8 502Documento21 páginasTutorial 8 502jamesAinda não há avaliações

- Chemical Technology Self Study Topic: Polyvinyl Chloride (PVC)Documento11 páginasChemical Technology Self Study Topic: Polyvinyl Chloride (PVC)Paridhi GargAinda não há avaliações

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindAinda não há avaliações

- Hero Found: The Greatest POW Escape of the Vietnam WarNo EverandHero Found: The Greatest POW Escape of the Vietnam WarNota: 4 de 5 estrelas4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonNo EverandSully: The Untold Story Behind the Miracle on the HudsonNota: 4 de 5 estrelas4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldNo EverandThe Fabric of Civilization: How Textiles Made the WorldNota: 4.5 de 5 estrelas4.5/5 (58)

- Highest Duty: My Search for What Really MattersNo EverandHighest Duty: My Search for What Really MattersAinda não há avaliações

- The End of Craving: Recovering the Lost Wisdom of Eating WellNo EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellNota: 4.5 de 5 estrelas4.5/5 (81)

- A Place of My Own: The Architecture of DaydreamsNo EverandA Place of My Own: The Architecture of DaydreamsNota: 4 de 5 estrelas4/5 (242)

- The Knowledge: How to Rebuild Our World from ScratchNo EverandThe Knowledge: How to Rebuild Our World from ScratchNota: 3.5 de 5 estrelas3.5/5 (133)

- Pale Blue Dot: A Vision of the Human Future in SpaceNo EverandPale Blue Dot: A Vision of the Human Future in SpaceNota: 4.5 de 5 estrelas4.5/5 (588)

- System Error: Where Big Tech Went Wrong and How We Can RebootNo EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootAinda não há avaliações

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNo EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestNota: 4 de 5 estrelas4/5 (28)

- The Future of Geography: How the Competition in Space Will Change Our WorldNo EverandThe Future of Geography: How the Competition in Space Will Change Our WorldNota: 4 de 5 estrelas4/5 (5)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaAinda não há avaliações

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyAinda não há avaliações

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNo EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNota: 4.5 de 5 estrelas4.5/5 (122)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterNo EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterAinda não há avaliações

- Packing for Mars: The Curious Science of Life in the VoidNo EverandPacking for Mars: The Curious Science of Life in the VoidNota: 4 de 5 estrelas4/5 (1395)

- Reality+: Virtual Worlds and the Problems of PhilosophyNo EverandReality+: Virtual Worlds and the Problems of PhilosophyNota: 4 de 5 estrelas4/5 (24)

- The Weather Machine: A Journey Inside the ForecastNo EverandThe Weather Machine: A Journey Inside the ForecastNota: 3.5 de 5 estrelas3.5/5 (31)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreNo EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreNota: 4.5 de 5 estrelas4.5/5 (33)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterNo EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterNota: 5 de 5 estrelas5/5 (3)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNo EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerNota: 4.5 de 5 estrelas4.5/5 (54)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationNo EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationNota: 4.5 de 5 estrelas4.5/5 (46)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureNo EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureNota: 5 de 5 estrelas5/5 (125)