Escolar Documentos

Profissional Documentos

Cultura Documentos

Report On Transparent Supply Chain1

Enviado por

Ankit GargTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Report On Transparent Supply Chain1

Enviado por

Ankit GargDireitos autorais:

Formatos disponíveis

1

Project Report

On

Transparent Supply Chain

using

Radio Frequency Identification

Submitted to: Professor S. Chandrashekhar

Submitted by Group 6 (FMG19C):

Ankit Garg(191126) Ankita Garg(191127) Gaurav Sakhuja(191140) Madhur Gautam(191144) Sonal Saraogi(191175) Sudarshan Chitlanga(191177)

Table of Contents

INTRODUCTION ................................ ................................ ................................ .............. 3 REVEALING TECHNOLOGIES................................ ................................ ...................... 4 RFID ................................ ................................ ................................ ................................ .... 5 BASIC COMPONENTS OF AN RFID SYSTEM................................ ................................ ........... 5 READ ONLY , READ/WRITE AND WORM TAGS ................................ ................................ ........ 8 PASSIVE, SEMI-PASSIVE AND ACTIVE TAGS ................................ ................................ .......... 8 PASSIVE VS. ACTIVE RFID COMPARISON ................................ ................................ ............ 8 EPC ................................ ................................ ................................ ................................ . 10 RFID VS. BARCODES COMPARISON ................................ ................................ .................. 10 RFID FREQUENCIES ................................ ................................ ................................ ......... 11 RFID IN THE RETAIL SUPPLY CHAIN ................................ ................................ ...... 14 APPLICATIONS OF RFID................................ ................................ .............................. 18 ADVANTAGES AND DISADVANTAGES OF RFID TECHNOLOGY ....................... 19 ADVANTAGES : ................................ ................................ ................................ ................. 19 DISADVANTAGES : ................................ ................................ ................................ ............ 19 PROBLEMS WITH RFID ................................ ................................ ............................... 21 TECHNICAL PROBLEMS WITH RFID ................................ ................................ ................... 21 SECURITY, PRIVACY AND ETHICS P ROBLEMS WITH RFID ................................ ................... 22 RFID MANUFACTURERS ................................ ................................ ............................. 24 INDIAN COMPANIES IMPLEMENTING RFID ................................ .......................... 25 REFERENCES ................................ ................................ ................................ ................. 27

Introduction

The definition of transparency in supply chain refers to a quality, characteristic, or state in which activities, processes, practices and decisions that take place in the supply chain become open and visible to the outside world. The origins of a companys products used to be pretty murky. Beyond the supply chain function, virtually no one cared. Of course, all thats changed. Consumers, governments, and companies are demanding details about the systems and sources that deliver the goods. They worry about quality, safety, ethics, and environmental impact. Farsighted organizations are directly addressing new threats and opportunities presented by the question, Where does this stuff come from? Consider the trouble an opaque supply chain can cause. Most iPhone owners probably dont think about the provenance of their devices, but worker suicides at Foxconn, one of Apples major Chinese suppliers, forced the company to pull the curtain back on part of its supply chain in 2009. It had to quell claims that it relied on sweatshop labor. Another high-profile case, the toxic drywall scandal, led to class-action lawsuits. The offending product was imported into the United States bearing no readily available information about its source other than a Made in China stamp. And a few years earlier, toy giant Mattel faced a tornado of publicity about lead in toys, which raised questions about how much control it had over its supply chain.

Revealing Technologies

Driven by growing calls for transparency, firms such as Wal-Mart, Tesco, and Kroger are beginning to use new technologies to provide provenance data to the marketplace. In time, customers will perceive easy access to such information as the norm. Revealing origins will become an essential part of establishing trust and securing reputation.

The key technologies are not fundamentally new, but they are evolving and blending to unleash new opportunities and threats. Product labeling has been transformed by microscopic electronic devices, genetic markers for agricultural products, and a new generation of bar codes that can be read with standard mobile phones. Combine these developments with the reach of the internet and virtually unlimited data storage, and firms can now contemplate more-sophisticated ways to trackand to revealthe manufacturing trajectory of their products.

Radio-frequency identification (RFID) tags, well established for inventory management and other purposes, are becoming smaller, cheaper, and more flexible. New generations of tagssuch as Hitachis sand-grain-size mu-chipcan be used, for instance, to label jewelry inconspicuously. It can even be embedded in paper and plastic, making the products provenance data part of the material itself. And smaller-scale tagslabeled exotically as radio dustare in development. Just like a paper label, a technology tag can be used in two ways. It can store data directly, in some cases even being updated as the item moves through the supply chain. Alternatively, the tag can simply hold a unique identifier, which acts as a pointer to a vast amount of web-based supporting data. The ubiquity of such mobile devices means that consumers can readily access this internet of things, gathering provenance information not just at the generic level of the item category or type but for the specific item. If Im interested in, say, food safety, the technology can tell me not just about this type of chicken, butthis chicken.

RFID

RFID stands for Radio-Frequency Identification. The acronym refers to small electronic devices that consist of a small chip and an antenna. The chip typically is capable of carrying 2,000 bytes of data or less. The RFID device serves the same purpose as a bar code or a magnetic strip on the back of a credit card or ATM card; it provides a unique identifier for that object. And, just as a bar code or magnetic strip must be scanned to get the information, the RFID device must be scanned to retrieve the identifying information.

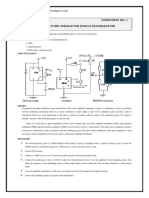

Basic components of an RFID system

A basic RFID system consists of three components:

y y y

An antenna or coil A transceiver (with decoder) A transponder (RF tag) electronically programmed with unique information

Antenna: The antenna emits radio signals to activate the tag and read and write data to it. Antennas are the conduits between the tag and the transceiver, which controls the system's data acquisition and communication. Antennas are available in a variety of shapes and sizes; they can be built into a door frame to receive tag data from persons or things passing through the door, or mounted on an interstate tollbooth to monitor traffic passing by on a freeway. The electromagnetic field produced by an antenna can be constantly present when multiple tags are expected continually. If constant interrogation is not required, a sensor device can activate the field.

Often the antenna is packaged with the transceiver and decoder to become a reader (a.k.a. interrogator), which can be configured either as a handheld or a fixed -mount device. The reader emits radio waves in ranges of anywhere from one inch to 100 feet or more, depending upon its power output and the radio frequency used. When an RFID tag passes through the electromagnetic zone, it detects the reader's activation signal. The reader decodes the data encoded in the tag's integrated circuit (silicon chip) and the data is passed to the host computer for processing.

Tag: Chip tags consist of a microchip and a coupling element an antenna. Most tags are only activated when they are within the interrogation zone of the interrogator; outside they sleep. Chip tags can be both read-only (programmed during manufacture) or, at higher complexity and cost, read-write, or both. Chip tags contain memory. The size of the tag depends on the size of the antenna, which increases with range of tag and decreases with frequency.

Tag shape: RFID tags come in a range of shapes and sizes. The following are the most common:

y y

Label: The tag is a flat, thin, flexible form Ticket: A flat, thin, flexible tag on paper

y y

Card: A flat, thin tag embedded in tough plastic for long life Glass bead: A small tag in a cylindrical glass bead, used for applications such as animal tagging (e.g. under the skin)

Integrated: The tag is integrated into the object it is tagging rather than applied as a separate label, such as moulded into the object

y y

Wristband: A tag inserted into a plastic wrist strap Button: A small tag encapsulated in a ruggesdised, rigid housing

Interrogator: Depending on the application and technology used, some interrogators not only read, but also remotely write to, the tags. For the majority of low cost tags (tags without batteries), the power to activate the tag microchip is supplied by the reader through the tag antenna when the tag is in the interrogation zone of the reader, as is the timing pulse these are known as passive tags. Middleware: Middleware is the interface needed between the interrogator and the existing company databases and information management software.

Read only, read/write and worm tags

y y

Read only tags contain a unique licence plate number which cannot be changed Worm Write Once Read Many enables users to encode tags at the first instance of use, and then the code becomes locked and cannot be changed

Read/write tags allow for updated or new information to be written to the tag

Read only tags can be the cheapest, because they often require the least amount of memory, but they rely on an infrastrucutre and readily available database to retrieve useful information. Where this is not possible, read/write tags, whcih are more expensive (but do not need large infrastructure) and often used. In many cases these functionalities are combined with segmented memories.

Passive, semi-passive and active tags

Passive tags refer to RFID tags which are powered solely by the RFID interrogator. The interrogator emits a radio frequency (RF), which powers the silicon chip on the tag when it is within range of the RF field. When the power to the silicon chip on the tag meets the minimum voltage threshold it require to turn on, the silcion chip can then send back information on the same RF wave. Range is usually limited to several meters. Active tags refer to RFID tags which have their own power source, so they can recieve a weaker signal from the interrogator (i.e. be further away), and the power source on the tag boosts the return signal. These types can have ranges of many tens of meters and even hundreds of meters, but cost more becasue of their size and sophistication. Battery life can also limit the life of the tag. Semi Passive tags refer to tags with a power source (usually a laminar, flexible, low cost battery) which can be used for on tag sensing (e.g. temperature), but not to boost range.

Passive vs. Active RFID Comparison

The primary difference betwee passive and active RFID tags is that active tags are powered by a battery and automatically broadcast their signal, whereas passive tags do not have a power source and only transmit a signal upon receiving RF energy emmited from a reader in proximity of the tag.

Passive Read Range Up to 40 feet (fixed readers) Up to 20 feet (handheld readers)

Active Up to 300 feet or more

Power

No power source

Battery powered

Tag Life

Up to 10 years depending 3-8 years depending upon the upon the environment the tag tag broadcast rate is in

Tag Costs

$.10-4.00 or more depending $15-50 upon quantity, durability, and quantity, form-factor sensor,

depending options tamper

upon (motion

detection, and

temperature form-factor Ideal Use

sensor),

For inventorying assets using For use with fixed RFID handheld (daily, RFID weekly, readers readers to perform real-time monthly asset monitoring at chokeor within necessary zones. when

quarterly, annually). Can also points

be used with fixed RFID Typically readers to track

the security is a requirement.

movement of assets as long as security is not a

requirement. Readers Typically higher cost Typically lower cost

10

EPC

The Electronic Product Code (EPC) is a family of coding schemes created as an eventual successor to the barcode. The EPC was created as a low-cost method of tracking goods using RFID technology. It is designed to meet the needs of various industries, while guaranteeing uniqueness for all EPC-compliant tags. EPC tags were designed to identify each item manufactured, as opposed to just the manufacturer and class of products, as bar codes do today. The EPC accommodates existing coding schemes and defines new schemes where necessary. The EPC was the creation of the MIT Auto-ID Center, a consortium of over 120 global corporations and university labs. The EPC system is currently managed by EPCglobal, Inc., a subsidiary of GS1. The Electronic Product Code promises to become the standard for global RFID usage, and a core element of the proposed EPCglobal Network.

RFID vs. Barcodes Comparison

RFID and barcodes are similar in that they are both data collection technologies, meaining they automate the process of collecting data. However, they also differ significantly in many areas. Although this comparison primarily focuses on the advantages of RFID over barcodes, RFID will not completely replace barcode technology. Barcodes offer some advantages over RFID, most notably their low cost. Comparison Statistics

y

RFID is 15-20 times faster than manual and barcode processes for inventorying IT assets. (Source: RFID Journal)

y y

Some companies experience a 95% reduction in time using RFID (Source: Motorola) The #1 RFID application being deployed is IT asset tracking (Source: Aberdeen) RFID Barcodes Required Several inches up to several

Line of Site Read Range

Not required (in most cases) Passive UHF readers) - Up to 20 feet (handheld readers) RFID:

- Up to 40 feet (fixed feet

11

Active

RFID:

- Up to 100's of feet or more Read Rate 10's, 100's or 1000's Only one at a time

simultaneously Identification Can uniquely identify each Most barcodes only identify item/asset tagged. the type of item (UPC Code) but not uniquely. Read/Write Many RFID Read/Write Technology Interference RF (Radio Frequency) Optical (Laser) cannot covering tags are Read only

Like the TSA (Transportation Obstructed barcodes Security Administration), be read (dirt

some RFID frequencies don't barcode, torn barcode, etc.) like Metal and Liquids. They can interfere with some RF Frequencies. Automation Most "fixed" readers don't Most barcode scanners

require human involement to require a human to operate collect data (automated) (labor intensive)

RFID Frequencies

Frequency refers to the size of the radio waves used to communicate between the RFID systems components. It is generally safe to assume that a higher frequency equates to a faster data transfer rate and longer read ranges, but also more sensitivity to environmental factors such as liquid and metal that can interfere with radio waves. RFID systems currently operate in the Low Frequency (LF), High Frequency (HF) and Ultrahigh Frequency (UHF) bands. Each frequency has advantages and disadvantages relative to its capabilities. Generally a lower frequency means a lower read range and slower data read rate, but increased capabilities for reading near or on metal or liquid surfaces.

No single frequency is ideal for all applications, even within a single industry. Just as separate bar code symbologies are used at different levels of consumer goods packaging,

12

from U.P.C./EAN symbols at the item level to Code 128 and two-dimensional symbologies on cases and pallets, RFID tags of different frequencies and functionality will be used together within overall supply chain operations.

Frequency Band

Description

Operating Range

Applications

Benefits

Drawbacks

125KHz to Low 134 KHz Frequency

< .5M or Access 1.5ft. Control Animal Tracking Vehicle immobilizers Product Authentication POS applications

Works well around water and metal products.

Short read range and slower read rates

13.56 MHz

High Frequency

< 1M or Smart Cards 3ft. Smart shelve tags for item level tracking Books Airline Library

Low of tags

cost Higher read rate than LF

Baggage Maintenance data logging 860 MHz to Ultrahigh 930MHz Frequency (UHF) 3m or 9ft. Pallet tracking EPC Does not work well around items of high water

Carton standard built this

Tracking toll

Electronic around

13

collection Parking lot access 2.4GHz Microwave 1m or3 ft. Airline Baggage Electronic

frequency

or

metal

content

Most expensive

Fastest read rates

toll collection

14

RFID in the Retail Supply Chain

Wal-Mart and DoD suppliers are moving forward with EPC RFID implementations to gain operational improvements, such as: 100 percent inventory visibility major reduction in losses and shrinkage tracking lot and expiration dates work in process data management enabling tags to carry real-time databases of item information assigning unique serial numbers to items sharing EPC and other product data with partners in the supply chain

Operational Procedure: 1. In the Manufacturing plant, pallets arrive at the dock door where stationery readers pick up EPC numbers and other data about the shipment. 2. Received goods are checked against the Shipping Manifest and will go to one of three areasInventory, Production or Returns. 3. A new shipping smart label is created to ship Returns back to suppliers. 4. Inventory cases are read by a forklift reader that updates the system with product and location data where they will be stored in the Warehouse 5. Production components are read at the case level, updating the system that these goods will be used immediately. Individual components needed to assemble new products are collected into bins at the start of the Production Line, allowing the manufacturer to link EPC data of raw materials with the finished products. A smart label is generated to identify the bin and its contents. 6. As the bins move toward the work-in-process line, they are read into the system by stationary conveyor-belt readers. 7. As workers assemble components into products, a smart label is attached to the product at the outset of Work In Process. Strategically positioned reader/encoders write data about each task that is completed to the read/write tag in the smart label. 8. At Quality Control, a reader picks up EPC numbers of products that have passed inspection. EPC numbers and product data are recorded in the manufacturers database, providing QC documentation as goods move through the supply chain.

15

9. Finished goods go to Packaging and a smart label is created that contains specific new product data. 10. A fork-lift reader is used to update the system with information about the location where finished goods are stored. 11. Inventory is also stored in the warehouse. As cases are removed from shelves and used in manufacturing, a hand-held reader or forklift reader can be used to update the system. 12. In the Warehouse, finished goods destined for a particular Distribution Center are collected into pallets.

16

13. As pallets leave the dock door, stationary readers at Dispatch take take a final reading of the goods and update the system that they have been loaded on to a truck for shipping out. 14. Advance Shipping Manifests give Distribution Centers data about pallets of good that will arrive. Pallets are read by stationary readers that record the shipment and flag duplicate, unordered or suspect items. 15. Forklift readers/encoders update the system with the location of goods that are being stored. At any time, sensors can record conditions in the DC and add data to the smart label, allowing products to carry their own pedigree or history. 16. At the DC, goods from multiple suppliers are collected on pallets and targeted for a particular Retail destination. Pallets are shrink-wrapped to protect contents and keep them stable. A smart label is created to identify the contents of the pallet and encode shipping instructions. Stationary readers at the dock doors update the system about outbound shipments.

17

17. Stationary readers at the dock doors update the system to reflect what types of goods have been received, from whom and when. Again, goods that are accepted will be stored in the Backroom or placed directly onto shelves in-store. 18. Stationary readers or forklift readers update the system as goods transition from the backroom into the Retail Store. 19. Shelf readers report back into the system when items are low and shelves need restocking. 20. EPC numbers become inactive at the end of the supply chain when containers are recycled in Compacting, unless assets, such as pallets or cartons, will be reused.

18

Applications of RFID

Supply Chain Management Thousands of inbound and outbound shipments can be identified with RFID smart labels that enable unattended identification, verification and sortation at different points in the supply chain across trading partners and distribution centers.

Asset Management RFID promises more effective asset management by providing real-time information about location of assets ensuring employees always have equipment, tools and other resources when and where they need them.

Anti-Counterfeiting/Track& Trace Materials authentication is another complementary asset management application. It provides a way to detect counterfeit products and can ensure that only authorized parts and supplies are used with equipment. Many organizations in the life sciences and pharmaceutical industries will use RFID to comply with FDA rules to create pedigrees to support drug traceability and security.

Inventory Control RFID can significantly deliver correct and current information about inventory levels to allow companies to ensure they can deliver what they have promised. In addition better inventory control reduces storage space and labor costs and improves asset utilization as well as enables faster billing cycles and contributes to cash flow.

Work in Process Along the assembly line, tasks associated with WIP can be reported back to the systems with RFID, identifying that each step of the assembly process was completed and ensuring that quality control measures were taken reducing makeovers.

19

Advantages and Disadvantages of RFID Technology

Advantages:

RFID technology has a number of advantages.

y

RFID tags are very simple to install/inject inside the body of animals, thus helping to keep a track on them. This is useful in animal husbandry and on poultry farms. The installed RFID tags give information about the age, vaccinations and health of the animals.

RFID technology is better than bar codes as it cannot be easily replicated and therefore, it increases the security of the product.

Supply chain management forms the major part of retail business and RFID systems play a key role by managing updates of stocks, transportation and logistics of the product.

Barcode scanners have repeatedly failed in providing security to gems and jeweleries in shops. But nowadays, RFID tags are placed inside jewelry items and an alarm is installed at the exit doors.

The RFID tags can store data up to 2 KB whereas, the bar code has the ability to read just 10-12 digits.

Disadvantages:

The RFID technology, though very beneficial, is expensive to install. Small and medium scale enterprises find it costly to use it in their firms and offices.

y

It is difficult for an RFID reader to read the information in case of RFID tags installed in liquids and metal products. The problem is that the liquid and metal surfaces tend to reflect the radio waves, which makes the tags unreadable. The tags have to be placed in various alignments and angles for taking proper reading. This is a tedious task when the work involves big firms.

Interference has been observed if devices such as forklifts and walkie -talkies are in the vicinity of the distribution centers. The presence of mobile phone towers has been found to interfere with RFID radio waves. Wal-Mart, the retail sector giant, has installed billions of RFID tags in their products throughout the world and they have encountered such problems.

20

The USA and Europe, for instance, have different range of frequencies that allow RFID tags to function. This makes it mandatory for international shipping companies and other organizations to be aware of the working pattern of other nations also, which can be very time-consuming.

RFID technology has been referred to as invasive technology. Consumers are apprehensive about their privacy when they purchase products with RFID tags. Once the radio chips are installed in the product, the customer can be tracked and his personal information can be collected by the RFID reader. However, many stores have a facility that deactivates the RFID tags after the product has been purchased.

RFID technology can be the next tool for success and management of various businesses. With more research, the flaws and limitations of this technology can be removed. This will make RFID technology very useful for diverse sectors like retail, transport and jewelry businesses.

21

Problems with RFID

RFID problems can be divided into several categories:

y y

Technical problems with RFID Privacy and ethics problems with RFID

Technical problems with RFID

Problems with RFID Standards RFID has been implemented in different ways by different manufacturers; global standards are still being worked on. It should be noted that some RFID devices are never meant to leave their network (as in the case of RFID tags used for inventory control within a company). This can cause problems for companies. Consumers may also have problems with RFID standards. For example, ExxonMobil's SpeedPass system is a proprietary RFID system; if another company wanted to use the convenient SpeedPass (say, at the drive-in window of your favorite fast food restaurant) they would have to pay to access it - an unlikely scenario. On the other hand, if every company had their own "SpeedPass" system, a consumer would need to carry many different devices with them. RFID systems can be easily disrupted Since RFID systems make use of the electromagnetic spectrum (like WiFi networks or cellphones), they are relatively easy to jam using energy at the right frequency. Although this would only be an inconvenience for consumers in stores (longer waits at the checkout), it could be disastrous in other environments where RFID is increasingly used, like hospitals or in the military in the field. Also, active RFID tags (those that use a battery to increase the range of the system) can be repeatedly interrogated to wear the battery down, disrupting the system. RFID Reader Collision Reader collision occurs when the signals from two or more readers overlap. The tag is unable to respond to simultaneous queries. Systems must be carefully set up to avoid this problem;

22

many systems use an anti-collision protocol (also called a singulation protocol. Anticollision protocols enable the tags to take turns in transmitting to a reader. RFID Tag Collision Tag collision occurs when many tags are present in a small area; but since the read time is very fast, it is easier for vendors to develop systems that ensure that tags respond one at a time.

Security, privacy and ethics problems with RFID

The following problems with RFID tags and readers have been reported. The contents of an RFID tag can be read after the item leaves the supply chain An RFID tag cannot tell the difference between one reader and another. RFID scanners are very portable; RFID tags can be read from a distance, from a few inches to a few yards. This allows anyone to see the contents of your purse or pocket as you walk down the street. Some tags can be turned off when the item has left the supply chain. RFID tags are difficult to remove RFID tags are difficult to for consumers to remove; some are very small (less than a half-millimetre square, and as thin as a sheet of paper) - others may be hidden or embedded inside a product where consumers cannot see them. New technologies allow RFID tags to be "printed" right on a product and may not be removable at all. RFID tags can be read without your knowledge Since the tags can be read without being swiped or obviously scanned (as is the case with magnetic strips or barcodes), anyone with an RFID tag reader can read the tags embedded in your clothes and other consumer products without your knowledge. For example, you could be scanned before you enter the store, just to see what you are carrying. You might then be approached by a clerk who knows what you have in your backpack or purse, and can suggest accessories or other items.

23

RFID tags can be read a greater distances with a high-gain antenna For various reasons, RFID reader/tag systems are designed so that distance between the tag and the reader is kept to a minimum (see the material on tag collision above). However, a high-gain antenna can be used to read the tags from much further away, leading to privacy problems. RFID tags with unique serial numbers could be linked to an individual credit card number At present, the Universal Product Code (UPC) implemented with barcodes allows each product sold in a store to have a unique number that identifies that product. Work is proceeding on a global system of product identification that would allow each individual item to have its own number. When the item is scanned for purchase and is paid for, the RFID tag number for a particular item can be associated with a credit card number.

24

RFID Manufacturers

AeroScout - Leading manufacturer - Private firm - Headquarters in Redwood City California, USA - Offices in Europe, Middle East, Asia, Australia and Latin America - Revenues: $14.1 M - Employees: 150

Alien Technologies - Private firm - Headquarters in Margan Hill, CA and RFID solutions center in Dayton, Ohio - Offices in US, Europe, Australia and Asia - Employees: 235 - Clientele: WalMart, IBM, HP, Microsoft, Philips, US DOD

25

Indian Companies implementing RFID

Pantaloon Retail (India) Limited Headquarter - Mumbai (Bombay) Over 1000 stores across 73 cities in India and employs over 30,000 people. Operating Profit(2010): 600.44 crores

Pantaloon's experiment with RFID The main objective was to smoothen the entire product lifecycle, introduce item-level tagging for identification, and track the entire RFID roadmap with Pantaloon. Pantaloon went in for RFID for its simplicity of tagging, efficacy of use, product buffering, ability to keep track of over-produced items, and ability to monitor productline lead time at the warehouse and fast-moving product-lines. The company selected a few lines of apparel, primarily shirts and trousers, for its RFID pilot. Developed by :Wipro Infotech Oracle database 10g, middleware along with an implementation of the RFID hardware It integrates with the existing IT infrastructure, the in-house developed Retail Enterprise Manager (a special variety of ERP package). Efficiency and accuracy: After the RFID implementation, the time saved on the same is about 80 percent in inward warehouse processing and 12 percent in outward. Real-time visibility of items during all stages of the supply chain improved to 98 percent.

Ashok Leyland Ashok Leyland, a Hinduja group company Manufacturer of commercial vehicles and diesel engines Deployed RFID technology within its assembling centers. Ashok Leyland has seven manufacturing plants - the mother plant at Ennore near Chennai, three plants at Hosur , the assembly plants at Alwar, Bhandara and state-ofthe-art facility at Pantnagar. The total covered space at these seven plants exceeds 650,000 sq m and together employ over 11,500 personnel. Operating Profit in March,2010 is Rs.423.67 crores

26

Benefits of RFID in Engine Assembly The parts received from the supplier are scanned at assembly shops and the database is updated automatically. The objective of implementing RFID in engine assembly application is: To avoid mismatch of critical components that are to be assembled in the engine To improve quality control To facilitate JIT inventory To facilitate automation To facilitate genealogy tracking of critical engine components. Implementation: As a proof of concept, RFID was implemented at Instrumentation department of Technical Centre. Features of an RFID enabled Instrument transaction system: Real - time availability of information about Instrument status through ERP Availability of Instrument calibration information through ERP Instrument requisition through ERP Indication of Instruments going out of Instrumentation department With the RFID enabled Instrument transaction system, users will have access to the information regarding Instrument availability through ERP. As soon as the user requests for the Instrument, the concerned person at Instrumentation department gets an email. The authorized person at the Instrumentation department approves the request and the Instrument is issued. When the Instrument is issued to the user, the issue information is fed in the ERP, which sends it to the RFID reader, disabling the beep. If the Instrument is taken out of the Instrumentation department without being issued, the RFID system raises an alarm to indicate this.

27

References

http://www.inlogic.com/rfid/rfid_vs_barcode.aspx http://www.buzzle.com/articles/passive-vs-active-rfid-tags.html http://www.technovelgy.com/ct/Technology-Article.asp?ArtNum=2 http://www.howstuffworks.com/ http://www.expresscomputeronline.com/

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Portable Spirometer Using Air Pressure Sensor MPX5500DP Based On Microcontroller Arduino UnoDocumento10 páginasPortable Spirometer Using Air Pressure Sensor MPX5500DP Based On Microcontroller Arduino UnoBiomed TAinda não há avaliações

- EE462L, Spring 2014 DC DC Buck ConverterDocumento37 páginasEE462L, Spring 2014 DC DC Buck ConverterprateekAinda não há avaliações

- Automated Billing SystemDocumento24 páginasAutomated Billing SystemjamesAinda não há avaliações

- Fireclass Overview Presentation PDFDocumento34 páginasFireclass Overview Presentation PDFRamon Mendoza PantojaAinda não há avaliações

- SK350 / SK200 Software Manual: 1 How To Upload New Software For The SK350 / SK200Documento8 páginasSK350 / SK200 Software Manual: 1 How To Upload New Software For The SK350 / SK200Ray PutraAinda não há avaliações

- Fsuipc User GuideDocumento54 páginasFsuipc User GuideKAPTAN XAinda não há avaliações

- Introduction To Computing To FASADocumento118 páginasIntroduction To Computing To FASAabdoulayAinda não há avaliações

- MGT382-2 Coursework Specification (Individual Report) 2022-2023Documento4 páginasMGT382-2 Coursework Specification (Individual Report) 2022-2023Darshil D ShethiaAinda não há avaliações

- Effects of Customer Relationship Management On Market Performance: A Comparative PerspectiveDocumento94 páginasEffects of Customer Relationship Management On Market Performance: A Comparative PerspectiveMelesse MisganawAinda não há avaliações

- PVI-134.0-400.0 BCD.00382 EN RevB PDFDocumento4 páginasPVI-134.0-400.0 BCD.00382 EN RevB PDFbacuoc.nguyen356Ainda não há avaliações

- RS900G DatasheetDocumento9 páginasRS900G DatasheetsamuelpemonAinda não há avaliações

- 9.13 Surge Protection For PROFIBUS FMS, PROFIBUS DP, and Profibus PaDocumento4 páginas9.13 Surge Protection For PROFIBUS FMS, PROFIBUS DP, and Profibus PaRodrigoBurgosAinda não há avaliações

- Ict in Language TeachingDocumento25 páginasIct in Language TeachingJulie Ann GernaAinda não há avaliações

- Us06-201 843 01 01 02 PDFDocumento12 páginasUs06-201 843 01 01 02 PDFF2CANALESAinda não há avaliações

- Service Oriented ArchitectureDocumento418 páginasService Oriented ArchitectureTsiory HeriniavoAinda não há avaliações

- CISA Domain 2 QuestionsDocumento14 páginasCISA Domain 2 QuestionseliAinda não há avaliações

- PAMDocumento11 páginasPAMMarco Alejandro Teran AguilarAinda não há avaliações

- Management PricipalDocumento7 páginasManagement PricipalmdivyalakshmiAinda não há avaliações

- VB Chapter 9Documento47 páginasVB Chapter 9KybeleAinda não há avaliações

- Associative Learning PresentationDocumento9 páginasAssociative Learning PresentationMairos Kunze BongaAinda não há avaliações

- Kanban Excercise-1Documento2 páginasKanban Excercise-1Viraj vjAinda não há avaliações

- Edc PDFDocumento7 páginasEdc PDFKarim SamhyAinda não há avaliações

- Common Core Grade 5 Math Printable WorksheetsDocumento3 páginasCommon Core Grade 5 Math Printable WorksheetsJessicaAinda não há avaliações

- ONLINE LAB - Encrypting A VM Data Disk PDFDocumento9 páginasONLINE LAB - Encrypting A VM Data Disk PDFNghĩa NgôAinda não há avaliações

- ZVP2106A ZVP2106A: Typical CharacteristicsDocumento3 páginasZVP2106A ZVP2106A: Typical CharacteristicsMuhammad ZahidAinda não há avaliações

- Purchasing Presentation 11iDocumento59 páginasPurchasing Presentation 11iadityakhadkeAinda não há avaliações

- CCNP 300 410 Enarsi Networktut May 2020Documento65 páginasCCNP 300 410 Enarsi Networktut May 2020Pak ChannAinda não há avaliações

- DX360LC-7M Dx360lca-7m enDocumento20 páginasDX360LC-7M Dx360lca-7m enmsegundomoraleslagosAinda não há avaliações

- Algorithmic Advances in Riemannian Geometry and ApplicationsDocumento216 páginasAlgorithmic Advances in Riemannian Geometry and ApplicationsasgfsagAinda não há avaliações

- Lab Manual Windows PowerShell ScriptingDocumento21 páginasLab Manual Windows PowerShell ScriptingffAinda não há avaliações