Escolar Documentos

Profissional Documentos

Cultura Documentos

Final ch.2

Enviado por

Akmal AshrafDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Final ch.2

Enviado por

Akmal AshrafDireitos autorais:

Formatos disponíveis

CHAPTER 2 REVIEW OF LITERTURE

2.1- Definition of Algae :

The word ALGAE represent a large group of different organisms from different phylogenetic groups, representing many taxonomic divisions. In general algae can be referred to as plant-like organisms that are usually photosynthetic and aquatic, but do not have true roots, stems, leaves, vascular tissue and have simple reproductive structures. They are distributed worldwide in the sea, in freshwater and in wastewater. Most are microscopic, but some are quite large, e.g. some marine seaweeds that can exceed 50 m in length. The unicellular forms are known as microalgae where as the multicellular forms comprise macroalgae.

Microalgae comprise a vast group of photosynthetic, heterotrophic organisms which have an extraordinary potential for cultivation as energy crops. They can be cultivated under difficult agro-climatic conditions and are able to produce a wide range of commercially interesting byproducts such as fats, oils, sugars and functional bioactive compounds.

Seaweed is a loose colloquial term encompassing macroscopic, multicellular, benthic marine algae. The term includes some members of the red, brown and green algae. They are photosynthetic, like plants, and "simple" because they lack the many distinct organs found in land plants. For that reason they are currently excluded from being considered plants.

The algae have chlorophyll and can process their own food through the process of photosynthesis. Almost all the algae are eukaryotes and conduct photosynthesis within membrane bound structure called chloroplasts. Cyanobacteria are organisms traditionally included among the algae, but they have a prokaryotic cell structure. Algae are an extremely important species. For one, they produce more oxygen than all the plants in the world, put together! For another, they form an important food source for many animals such as little shrimps and huge whales. Thus, they are at the bottom of the food chain with many living things depending upon them. With the recent research and interest into using algae for producing Biodiesel they have the potential to become even more important. Microalgae are small unicellular plants that range in size from 1 to 200 m they are unique organisms in that they can accumulate storage lipids in large quantities within their bodies

The algae can be grown in large outdoor ponds, using the resources of sunlight, saline water, nitrogen, phosphorus, and carbon dioxide. The algae can convert these raw materials into proteins, carbohydrates, and lipids. In the process, they can double their biomass three to five times a day. After a rapid growth phase, the algae are transferred to induction ponds where nutrient limitation is allowed to occur. Under these conditions, many algae stop growth and division and use all their energy to make lipids as storage products to survive. Once the cells have accumulated lipids, they are harvested and the water is recycled back into the growth ponds. The harvested cells then are subjected to an extraction process to remove the lipids. Algal lipids are primarily triglycerides with fractions of isoprenoids, phospholipids, glycolipids, and hydrocarbons. They contain more oxygen and are more viscous than crude petroleum. The two most promising fuel conversion options are transesterification to produce fuels similar to diesel fuels and catalytic conversion to produce gasoline.

2.1.1-Components of algae

There are four components to large scale algal production and conversion into liquid fuels: 1) Microalgae growth and production. 2) Engineering design. 3) Harvesting. 4) Conversion The design of a microalgae mass culture system is a synergistic process. The design must be tailored to the characteristics of the culture organism while species must be selected that contribute to economic construction and operation of the facility. Microalgae must be selected that are environmentally tolerant, have high growth rates, and produce large quantities of lipids. In addition, the choice of a suitable species affects harvesting ease. The types of lipids that the algae produce will determine the conversion methods. Thus, all four areas of development are highly interactive with each other. Each of these four areas of research and technology development will be discussed in detail in the remainder of the paper. To improve lipid yields in microalgae, we must understand the physiological and biochemical basis for partitioning photosynthetically fixed CO2 into lipids. The rate of lipid synthesis and final lipid yield will depend on the availability of carbon for lipid synthesis and the actual levels and activities of the enzymes used for lipid synthesis. Conditions such as nitrogen deficiency that induce the accumulation of lipid by algae often drastically reduce the capacity of photosynthetic CO2 fixation. Low lipid yields could result either from an absence of carbon skeletons or from low levels of enzymes. Improvements in lipid yield can be achieved only when the limiting factors have been determined.

There are several main groups of microalgae, which differ primarily in pigment composition; biochemical constituents, ultrastructure, and life cycle. There are five groups: diatoms (Class Bacillariophyceae), green algae (Class Chlorophyceae), goldenbrown algae (Class Chrysophyceae), prymnesiophytes (Class Prymnesiophyceae), and the eustigmatophytes (Class Eustigmatophyceae). The blue-green algae, or cyanobacteria (Class Cyanophyceae), were also represented in some of the collections. A brief description of these algal groups follows: Diatoms: Diatoms are among the most common and widely distributed groups of algae in existence; about 100,000 species are known. This group tends to dominate the phytoplankton of the oceans, but is commonly found in fresh- and brackish-water habitats as well. The cells are golden-brown because of the presence of high levels of fucoxanthin, a photosynthetic accessory pigment. The main storage compounds of diatoms are lipids. Another characteristic of diatoms that distinguishes them from most other algal groups is that they are diploid (having two copies of each chromosome) during vegetative growth; most algae are haploid (with one copy of each chromosome) except for brief periods when the cells are reproducing sexually. Green Algae: often referred to as chlorophytes, are also abundant; approximately 8,000 species are estimated to be in existence. . These algae use starch as their primary storage component. However, N-deficiency promotes the accumulation of lipids in certain species. Green algae are the evolutionary progenitors of higher plants, and, as such, have received more attention than other groups of algae. Golden-Brown Algae: This group of algae, commonly referred to as chrysophytes, is similar to diatoms with respect to pigments and biochemical composition. Approximately 1,000 species are known, which are found primarily in freshwater habitats. Lipids and chrysolaminarin are considered to be the major carbon storage form in this group. Prymnesiophytes: This group of algae, also known as the haptophytes, consists of approximately 500 species. They are primarily marine organisms. As with the diatoms and chrysophytes, fucoxanthin imparts a brown color to the cells, and lipids and chrysolaminarin are the major storage products. Eustigmatophytes: This group represents an important component of the Picoplankton, which are very small, cells (2-4 m in diameter). The genus Nannochloropsis is one of the few marine species in this class, and is common in the worlds oceans.

Cyanobacteria: This group is prokaryotic, and therefore very different from all other groups of microalgae. They contain no nucleus, no chloroplasts, and have a different gene structure. There are approximately 2,000 species of cyanobacteria, which occur in many habitats. Although this group is distinguished by having members that can assimilate atmospheric N (thus eliminating the need to provide fixed N to the cells), no member of this class produces significant quantities of storage lipid.

2.2- The Aquatic Species Program

This chapter analyzes each step of the algae to biodiesel process, and begins with a review of previous algae to biodiesel studies. From 1978 to 1996, the United States Department of Energy's Office of Fuels Development funded the Aquatic Species Program (ASP). The focus of the program was to develop renewable transportation fuels from algae. Extensive research was conducted on the production of biodiesel from algae grown in large raceway ponds that use waste CO2 as shown in the following sections.

2.2.1 Algae Classification

The study began by trying to determine which species of algae would be suitable for the purpose of developing transportation fuels. For the production of biodiesel the selected strain of algae must have very high growth rates and a very high lipid or oil content. There are well over 100,000 different species of algae, so the scientists involved in the study had the daunting task of analyzing these species and determining which were most suitable for producing biodiesel. By the end of the study the researchers had identified around 300 strains of algae that are the most suitable for producing biodiesel. They all have high growth rates, oil content, and are capable of growing in harsh climates. These strains of algae are currently housed at the University of Hawaii, and are available to interested researchers (Benemann, 1996).

2.2.2 Biochemistry and Molecular Biology

Next researchers focused their efforts on using biochemistry to manipulate the algae to have higher oil content. The goal of this research was to take advantage of the "lipid trigger", which is the phenomenon that occurs when microalgae are under environmental stress many species go through a metamorphosis and begin producing very large amounts of oil (Benemann, 1996). Researchers thought that this could be done by denying the algae certain nutrients, specifically nitrogen. However in the end the researchers concluded that although the nitrogen deficiency did increase the oil content of the algae it does not lead to increased oil productivity because it reduces the growth rates of the algae. During this time researchers were also attempting to genetically modify the certain algae species so that they would produce more oil and also enable them to grow in very

harsh environments. Although the researchers did make significant discoveries they were unable to demonstrate increased oil production in the cells.

2.2.3 Algae Production Systems

Over the course of the program several test sites were constructed to examine the feasibility of large scale algae production in open ponds. Many different algae growth systems have been studied, for example the Japanese government have developed optical fiber based reactor systems that could dramatically reduce the amount of surface area required for algae production. However while breakthroughs in these types of systems have occurred their costs are prohibitive, especially for the production off uels. The ASP focused on open pond raceway systems because of their relative low cost (Benemann, 1996). The Algae Pond Model, which is a program developed in Matlab to predict the energy use and emissions that result from growing algae in various regions, is based off of the results obtain during the operation of the Microalgae Outdoor Test Facility (OTF) in Roswell, New Mexico.

2.2.4 Microalgae Outdoor Test Facility (OTF)

In 1987 construction began on an algae growth facility consisting of two 1000m2 ponds, one plastic lined and another unlined, and six small, 3m2 ponds. An abandon water research facility in Roswell New Mexico was the site chosen for this operation. Roswell receives large amounts of daily solar radiation and has abundant flat desert land with large supplies of saline groundwater, making it an excellent location for algae growth. One limitation of the site was the low nightly temperatures, which turned out to be to low for many of the more productive species identified. Building the large system required installation of two water pipeline of I, 300m in length. The ponds were 14 x 77 m, with concrete block walls and a central wooden divider. The paddle wheels were approximately 5m wide, with a sump that allowed counter flow injection of C02. One pond was plastic lined; the other had a. crushed rock layer, and the walls were cinder block (Benemann, 1996). Figure 2.1 below shows an overview of the layout of the facility,

Figure 2.1: Schematic of microalgae OTF on Roswell, New Mexico The facility experimented with three different species of algae; first they used C. cryptica CYCLOl. C. cryptica had high productivities in the summer months but reaching 30 g/m2/d but fell off drastically during when the weather became colder. Next M, minutum (MONOR2) Ii more cold-tolerant organism \VIiS used. Even though productivity in the winter was very low 3.5 g/m"/d in December the algae survived despite the ponds freezing over multiple times. Next Amphora sp. was used and although it exhibited growth rates above 40 g/m2/d in the summer it also could not survive in the winter months. Because of its survivability M. minutum was selected as the most suitable strain of algae for the Roswell location (Goebel, 1989).

2.2.4.1 The OTF facility operated the large scale ponds for two years, by the end of the study they had determined some important parameters for future algae ponds:

1) Power for pond mixing is quiet low around 0.1 kW Il,000 m2 pond. 2) Pond mixing should be in the 15-25 cm/s range, and pond depth 15-25 cm. 3) CO2 utilization efficiencies of near 90% overall should be achievable. 4) Large-scale pond productivities of 70 mt/ha/yr are realistic goals for this process. 5) The small-scale ponds can be used to screen strains and optimize conditions.

2.3 Algae Growth in Outdoor Raceway Ponds

This section is a step by step walk through of the algae to biodiesel process. The size of the algae ponds are 1,OOO m2 the same size studied in the OTF. All of the processes discussed in this section are modeled in the Algae Pond Model. First the algae pond

operations are analyzed, followed by the oil extraction process, and finally transesterification or biodiesel production.

2.4 Microalgae

Micro algae are remarkably efficient biological factories capable of taking a waste (zero-energy) form of carbon (C02) and converting it into a high density liquid form of energy (natural oil). The four most abundant classes of micro algae are diatoms (Bacillariophyceae), green algae (Chlorophyceae), blue-green algae (Cyanophyceae), and golden algae (Chrysophyceae). Diatoms were the only class of micro algae analyzed in this study. They are found in fresh and salt water, and they store carbon in the form of natural oils or as a polymer of carbohydrates. (Benemann, 1996) For the algae to biodiesel cycle to be successful a species of algae that has high growth rates and oil content must be used. The Aquatic Species Program recommends that an effort be made to naturally select strains at the locations that would likely be commercial micro algal production sites. In this manner, the algae would be exposed to the prevailing environmental conditions, particularly the indigenous waters. If a non- native strain of algae is used it is likely that a native species will infiltrate the pond and over time dominate the pond, killing off the desired strain. The Algae Pond Model is based off of the results obtained at the OTF using unicellular green algae called Monoraphidium minutum (M. minutum). Algae reproduce by cellular division. They divide and divide and divide until they fill whatever space they are in or exhaust their nutrients (Tiekell, 2003). There are multiple stages of algae growth that depend on the culture volume and algae density. Assume there is a small batch of algae is placed into a large volume tank mixing tank, and that the tank is supplied with enough C02 and sunlight to generate maximum growth. Some form of agitation, such as shaking or mixing is necessary to ensure nutrient and gaseous exchange. The algae will initially enter an exponential growth phase, where cells grow and divide as an exponential function of time, as long as mineral substrates and light energy are saturated (Richmond. 2003), L~hen the concentration of algae is high enough that light does not penetrate through the entire culture, the algae move into the light limited linear growth phase. which is expressed by the following equation (Richmond, 2003). IA=u"'X"'V/Y J '" Photon flux density (h J ml\2)1\-1 A Illuminated surface area (mI\2) u "'" Specific growth rate (1 hl\-l) X"'" Biomass concentration (grams/liter) V = Culture volume (mI\3) Y;;;;; Growth yield (g/J) Finally if the size of the tank is not increased the algae will eventually reach a terminal density and stop growing, Algae growing in a flowing pond or raceway will operate in the light limited linear growth stage, The exponential growth stage is not

achievable, since the algae are not all subject to the necessary amount of solar radiation. As algae cycle around the race way pond a certain percentage of algae will be harvest leaving the remaining algae room to grow in the linear growth range, maintaining the algae in the linear growth range has allowed the model of algae growth to be controlled by linear relationships.

2.4.1-Algae Pond Operations

Paddle wheel

A scaled version of the 1OOO m2 algae pond is shown in figure 2.2 This is the pond that the APM is modeled after, The pond depth is 20 cm corresponding to a volume of 200 m3 or 200,000 liters, it is unlined and powered entirely by electricity, Many ponds of this size would be fit into a small area along with larger settling ponds and a pumping centrifuge station in order to produce algae on a large scale. Figure 2.3 below is a scaled layout of what one of these facilities might look like,

Centrifuge and pumping station

Settling Ponds (2 total)

Figure 2.3: Scaled model of large algae farm for production of biodiesel Algae pond operations are very simple. The algae are introduced into the pond and allowed to grow until they occupy 1 % of the volume of the pond. Very high growth rates are achieved because the pond is constantly mixed by the paddle wheel and it is infused with an ample amount of CO2 and fertilizer. The paddle wheel rotates providing a current of 20 cm/s around the pond. The mixing is required to ensure that all of the algae receive the necessary amounts of solar radiation. C02. and fertilizer required for optimal growth. The C02 is injected into the algae pond in the form of flume gas from a nearby coal fired electric plant. The bubblers are spaced around the pond so that the C02 is evenly dispersed throughout the pond. A 1,000 m2 algae pond operating in Roswell New Mexico consumes around 10,589 kg of CO2 each year. This is a miniscule amount considering that the average ?85 MW power plant produces 19,488 tons of C02 daily, or enough to support about 330,000 algae ponds (Clear the Air, 2000). Algae require a certain amount of phosphorus and nitrogen to grow at optimal rates. The phosphorus and nitrogen are pumped into the ponds along with ground water from the central pumping station shown in figure 2.3. The nitrogen is in the form of ammonia or nitrate and must compose 0.8% of the volume of the pond solution to ensure maximum algae production. Likewise phosphorus is in the form of phosphate and must compose 0.6% of the pond (Benemann, 2006). In the future both of these

nutrients could be supplied in the form of municipal solid waste. Water must also be continuously supplied to the ponds because a certain amount is lost daily due to evaporation and farm operations. The OTF tests recorded an average water loss of 6.2 mm or 6.2 rrr' of water per day. This must be replaced with saline or fresh ground water depending on the species of algae used.

2.4.2 Algae Harvesting

Algae harvesting is one of the major factors that must be overcome in order for algae to be used as a fuel source. The problem is that microalgae mass cultures are dilute, typically less than 500 mgll on a dry weight organic basis, and the cells are very small. Many unicellular species like M. minitum are around 5 micrometers in diameter. In order to be processed into biodiesel the algae must be in the form of a paste that is 15% solids. In the raceway ponds the mixture is about 1 % solids, this mixture must go through a process which will result in a concentration of at least 15%.

2.4.3 Biodiesel Production

In order to be converted into a liquid fuel the oil contained in the algae must be extracted. According to Nick Nagle a senior engineer at the NREL who was a vital part of the ASP, algae oil extraction is similar to soybean oil extraction, and can be modeled the same. The oil is extracted by mixing Hexane, a chemical made from petroleum, with the algae paste. The hexane removes the oil from the algae, this mixture of hexane and oil is distilled leaving pure algae oil. The remaining hexane is recycled through another batch of algae. The algae fiber remaining after this process can be used as fertilizer for the algae farms.

2.4.4 Transesterification

Transesterification is the process that the algae oil must go through to become biodiesel. It is a simple chemical reaction requiring only four steps and two chemicals. 1. Mix methanol and sodium hydroxide creates sodium methoxide 2. Mix sodium methoxide into algae oil 3. Allow to settle for about 8 hours 4. Drain glycerin and filter biodiesel to 5 microns

Figure 2.5: Inputs and outputs of transesteritication reaction The alcohol used in this reaction can be either methanol or ethanol, the catalyst is sodium hydroxide, and the oil is any fat or vegetable oil. The outputs are 86% Methyl Esters or biodiesel, 9% Glycerin which can be used to make soap and other products, 1 % fertilizer, and 4% alcohol which can be recycled back through the process (Tickell,2003)

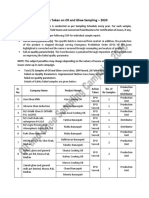

2.5 Collection and Screening Activities

We will describes the research performed at SERI(The Solar Energy Research Institute) they make a program and called it ASP(Aquatic Species Program).Its a research program in the United States launched in 1978 ,which over the course of nearly two decades looked into the production of energy using algae . In addition to performing actual research in this area, SERI personnel were responsible for coordinating the efforts of the many subcontractors performing similar activities, and for standardizing certain procedures and analyses. These efforts ultimately resulted in the development of the SERI Microalgal Culture Collection,

2.5.1 Collection and Screening Activities - 1983

The first collecting trips made by SERI researchers took place in the fall of 1983. Five saline hot springs in western Colorado were selected for sampling because of their abundant diatom populations, and because a variety of water types was represented. Water samples were used to inoculate natural collection site water that had been enriched with N (ammonium and nitrate) and phosphate (P) and then filter sterilized. Water samples were also taken for subsequent chemical analyses. The temperature and conductivity of the site water were determined at the time of collection. Conductivity ranged from 1.9 mmhoscm-2 at South Canyon Spring to 85.0 mmhoscm-2 (nearly three times the conductivity of seawater) at Piceance Spring. Water temperature at the time of collection ranged from 11 to 46C. In the laboratory, researchers tried to isolate the dominant diatoms from the enriched water samples. Cyanobacteria and other contaminants were removed primarily with agar plating. Approximately 125

unialgal diatom strains were isolated. The predominant genera found were Achnanthes, Amphora, Caloneis, Camphylodiscus, Cymbella, Entomoneis, Gyrosigma, Melosira, Navicula, Nitzschia, Pleurosigma and Surirella. A standardized lipid analysis protocol was not yet in place to screen these strains. However, many algal strains were known to accumulate lipids under conditions of nutrient stress. Microscopic analysis of cells grown under N-deficient conditions revealed lipid droplets in several of the strains, particularly in Amphora and Cymbella. .

2.5.2 Collection and Screening Activities - 1984

The screening and characterization protocols used by SERI researchers were refined for the 1984 collecting season. Included in these refinements was the development of a modified rotary screening apparatus, a standard type of motorized culture mixing wheel for 16x150-mm culture tubes. The rotating wheel was constructed of Plexiglas to allow better light exposure (see Figure II.A.1). The wheel was typically illuminated with a high-intensity tungsten stage lamp, and could be placed inside a box behind a CuSO4-water heat filter for temperature control. The Plexiglas wheel allowed all the cultures to receive equal illumination. Another technological advance used a temperature-salinity gradient table to characterize the thermal and salinity preferences and tolerances of the isolates.

Figure II.A.1.Rotary screening apparatus used for microalgal screening Collecting trips made by SERI researchers in 1984 focused on shallow saline habitats, including ephemeral ponds, playas, and springs in the arid regions of Colorado and Utah. After collection, the water and sediment samples were kept under cool, dark conditions for 1 to 3 days until they could be further treated in the laboratory. The pH, temperature, conductivity, redox potential, and alkalinity of the collection site waters were determined, and water samples were taken for subsequent ion analysis. In the laboratory, the samples were enriched with 300M urea, 30M PO4, 36M Na2SiO3, 3M NaFeEDTA, trace metals (5 mL/L PII stock, see Figure II.A.2), and vitamins. The enrichment tubes were then placed in the rotary screening apparatus (maintained at 25C or 30C) and illuminated at ~400Em-2s-1. Over a 5day period, the illumination provided by the stage lamp was gradually increased to

1,000Em-2s-1. The predominant strains present in the tubes were isolated as unialgal cultures by agar plating or by serial dilution in liquid media. The isolated strains were then tested for their ability to grow in incubators at 25C at 150-200 Em-2s-1 in the standard media types described above. and in artificial seawater (termed Rila Salts ASW, using Rila Marine Mix, an artificial sea salt mixture produced by Rila Products, Teaneck, NJ. The strains that grew well in at least one of these media were further characterized with respect to growth on a temperature-salinity gradient table at a light intensity of 200 Em-2s-1. Thirty combinations of temperature (10 to 35C) and salinity (10 to 70 mmhocm-1) were included in this analysis, representing the ranges that might be expected in actual outdoor production systems. Once again, the cultures were enriched with nutrients to maximize growth rates. The cultures used to inoculate the test cultures were preconditioned by growth in the media at 17 and 27C. The optical density at 750 nm (OD750) of the cultures was measured twice daily for 5 days, and the growth rates were calculated from the increase in culture density during the exponential phase of growth. A refinement of this method was to measure the growth rates in semicontinuous cultures, wherein the cultures were periodically diluted by half with fresh medium; this method provided more reproducible results than the batch mode experiments. Approximately 300 strains were collected from the 1984 trips to Utah and Colorado. Of these, only 15 grew well at temperatures30C and conductivities greater than 5 mmhocm-1. Nine were diatoms, including the genera Amphora, Cymbella, Amphipleura, Chaetoceros, Nitzschia, Hantzschia,an d Diploneis. Several chlorophytes (Chlorella, Scenedesmus, Ankistrodesmus and Chlorococcum) were also identified as promising strains, along with one chrysophyte (Boekelovia). Two strains isolated as a result of the 1984 collecting effort (Ankistrodesmus sp. And Boekelo via sp.) were characterized in greater detail using the temperature-salinity matrix described earlier. Boekelovia exhibited a wide range of temperature and salinity tolerance, and grew faster than one doublingday-1 from 10 to 70 mmhocm-1 conductivity and from 10 to 32C, exhibiting maximal growth of 3.5 doublingsday-1 in Type II/25 medium. Reasonable growth rates were also achieved in SERI Type I and ASW-Rila salts media (as many as 1.73 and 2.6 doublingsday-1, respectively).Ankist rodesmus was also able to grow well in a wide range of salinities and temperatures, with maximal growth rates occurring in Type II/25 medium (3.0 doubling day.

2.5.3 Collection and Screening Activities - 1985

In 1985, the strain enrichment procedure utilizing the rotary screening apparatus described previously was modified to include incubation of samples in SERI Type I and Type II media (25 and 55 mmhocm-1 conductivity) and in artificial seawater, in addition to the original site water. The cultures that exhibited substantial algal growth were further treated to isolate the predominant strains as unialgal (clonal) isolates. These strains were then tested for growth using the temperature-salinity matrix described earlier.

2.5.4 Collection activities:

Collection efforts by SERI researchers in 1985 again focused on shallow inland saline habitats. This time collecting trips were also made to New Mexico and Nebraska, in addition to Colorado and Utah. Eighty-six sites were sampled during the year, 53 of which were sampled in the spring. From these 53 sites, 17 promising strains were isolated. An analysis was conducted comparing the results of the new protocol with those that would have resulted from the protocol used in prior years. This analysis indicated that the revised protocol was in fact superior to the older protocol. For example, only six of the 17 strains selected via the new protocol would also have been selected using the old protocol. Only three of the 17 strains grew best in the artificial medium type that most closely resembled the collection site water; in fact, only six strains were even considered to grow well in the collection site water relative to growth in at least one of the artificial medium. This analysis clearly indicated the value of performing the initial screening and enrichment in a variety of relevant media. The results suggest that the shallow saline environments sampled probably contain a large number of species whose metabolism is arrested at any given time. In other words, the water quality of such sites varies greatly, depending on precipitation and evaporation, so probably only a few of the many species present are actively growing at any given time. This also may explain the wide range of salinities and temperatures tolerated by many of these strains.

2.5.5 Growth rates:

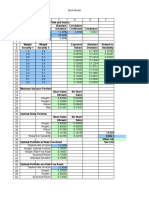

Six promising strains were analyzed in SERI Type I, Type II, and ASW (Rila) using the temperature-salinity gradient described previously. These included the diatoms Chaetocers muelleri(C H A E T 1 4 ), Navicula(N AV IC 1 ), Cyclotella(C Y C LO 2 ), Amphora (AMPHO1 and AMPHO2), and the chlorophyte Monoraphidium minutum (MONOR2). (NAVIC1 and CYCLO2 were actually collected from the Florida Keys; the remaining strains were collected in Colorado and Utah.) All strains exhibited rapid growth over a wide range of conductivities in at least two media types. Furthermore, all strains exhibited temperature optima of 30C or higher. Maximal growth rates of these strains, along with the optimal temperature, conductivity, and media type determined in these experiments are shown in Table II.A.1. (Higher growth rates were determined for some of these strains in subsequent experiments; see results presented in Barclay et al. [1987]). Temperature-salinity growth contours are provided for these strains in the 1986 ASP Annual Report (Barclay et al. 1986).

Strain m

Maximu Growth Rate (doublin gsday-1

Optimal Conducti vity (mmhocm-1

Optim al Temperature

Optimal Medium Type (dependent on temperature and conductivity used) Type I, ASW Type I, Type II Type II, ASW Type I, ASW Type I, II, ASW Type I, Type II

AMPHO 1 AMPHO 2 CHAET1 4 CYCLO 2 MONOR 2 NAVIC1

1.7 2.48 2.87 1.63 2.84 2.77

10-25 40-70 25-70 10-70 25 10-40

30 30-35 35 30-35 25-30 30

Experiments were also conducted in an attempt to identify the chemical components of SERI Type I and Type II media most important for controlling the growth of the various algal strains. Bicarbonate and divalent cation concentrations were found to be important determinants in controlling the growth of Boekelovia sp. (BOEKE1) and Monora phidium (MONOR2). The growth rate of MONOR2 increased by more than five-fold as the bicarbonate concentration of Type II/25 medium was increased from 2 to 30 mM and the growth of BOEKE1 by approximately 60% over this range. These results make sense, since media enriched in bicarbonate would have more dissolved carbon available for photosynthesis. An unexpected finding was that there was a decrease of nearly 50% in the growth rate of BOEKE1 as the divalent cation concentration increased from 5 mM to 95 mM (in Type I/10 medium containing altered amounts of calcium and magnesium). The effects of magnesium and calcium concentration on the growth of MONOR2 were less pronounced. These results indicate that matching the chosen strain for a particular production site to the type of water available for mass cultivation will be important.

2.5.6 Lipid content:

The lipid contents of several strains were determined for cultures in exponential growth phase and for cultures that were N-limited for 7 days or Si-limited for 2 days. In general, nutrient deficiency led to an increase in the lipid content of the cells, but this was not always the case. The highest lipid content occurred with NAVIC1, which increased from 22% in exponential phase cells to 49% in Si-deficient cells and to 58% in N-deficient cells. For the green alga MONOR2, the lipid content increased from

22% in exponentially growing cells to 52% for cells that had been N-starved for 7 days. CHAET14 also exhibited a large increase in lipid content in response to Si and N deficiency, increasing from 19% to 39% and 38%, respectively. A more modest increase occurred for nutrient-deficient AMPHO1 cells, whereas the lipid content of CYCLO2 was similar in exponential phase and nutrient-deficient cells, and actually decreased in AMPHO2 as a result of nutrient deficiency. These results suggested that high lipid content was indeed achievable in many strains by manipulating the nutrient levels in the growth media. However, these experiments did not provide information on actual lipid productivity in the cultures, which is the more important factor for developing a commercially viable biodiesel production process. This lack of lipid productivity data also occurred with most of the ASP subcontractors involved in strain screening and characterization, but was understandable because the process for maximizing lipid yields from microalgae grown in mass culture never was optimized. Therefore, there was no basis for designing experiments to estimate lipid productivity potential.

2.5.7 Collection and Screening Activities - 1986 and 1987

SERI in-house algal strain collection and screening efforts during 1986-1987 were focused in three separate areas. First, detailed characterization of previously collected strains continued. Second, because the desert southwest sites targeted for biodiesel production facilities can be quite cool during the winter, a new effort to collect strains from cold-water sites was initiated. Finally, a strategy was developed and implemented to reduce the number of strains that had accumulated as a result of in-house and subcontracted research efforts, which allowed researchers to focus on the most promising strains.

2.5.8 Strain characterization:

Eight additional strains collected previously from warm-water sites that grew well during the initial screening procedures were characterized with respect to temperature and salinity tolerances, growth rates, and lipid content under various conditions. These strains were Chaetoceros muelleri (strains CHAET6, CHAET9, CHAET10, CHAET15, and CHAET39), Cyclotella cryptica(C Y C LO4), Pleurochrysis carterae (PLEUR1), and Thalassiosira weissflogii (THALA2). Each strain was grown in a variety of temperature-salinity combinations by the use of a temperature-salinity gradient table. The maximal growth rate achieved under these conditions occurred with CHAET9, which exhibited a growth rate of 4.0 doublingsday-1. The remaining strains all had maximum growth rates that exceeded 1.4 doublingsday-1, and several grew at rates exceeding 2.5 doublingsday-1 (i.e., CHAET6, CHAET10, and CHAET39). All had an optimal temperature of 30C or higher, except for PLEUR1 and THALA2, which had optimal temperatures of 25C and 28C, respectively. Most of the strains grew well in a wide range of salinities (e.g., five of the eight strains exhibited a growth

rate greater than one doublingday-1at conductivities between 10 and 70 mmhocm-1). With respect to the effect of water type on growth, CHAET39, CYCLO4, and PLEUR1 grew best on SERI Type I medium. On the other hand, CHAET6, CHAET9, and CHAET10 grew best in SERI Type II medium, but also exhibited good growth on Type I medium and artificial seawater. CHAET15 and THALA2 achieved maximal growth rates on artificial seawater, and, along with PLEUR1, grew very poorly on Type II medium. These results again highlight the need to have a variety of algal strains available for the specific water resources that would be available for mass culture in various locations. The lipid contents of these 10 strains were also determined for exponentially growing cells, as well as for cells that were grown under nutrient-limited conditions. Nitrogen deficiency led to an increase in the lipid contents of CHAET6, CHAET9, CHAET10, CHAET15, CHAET39, and PLEUR1. The mean lipid content of these strains increased from 11.2% (of the total organic mass) in nutrient-sufficient cells to 22.7% after 4 days of N deficiency. Silicon deficiency led to an increase in the lipid content of all strains (although in some cases the increase was small and probably not statistically significant). The mean lipid content of the eight strains increased from 12.2% in nutrient-sufficient cells to 23.4% in Si-deficient cells. A few strains were poor lipid producers, such as CHAET6, CYCLO4, and PLEUR1, which did not produce more than 20% lipid under any growth conditions. In conclusion, the work carried out by Tornabenes laboratory provided a detailed characterization of the lipids present in a variety of microalgae. No general conclusions could be made from the work except that the lipid composition of various microalgal strains can differ quite substantially. Because the nature of the lipids can have a large impact on the quality of the fuel product, characterizing the potential production strains is important to ensure that deleterious lipids (e.g., highly polyunsaturated fatty acids in the case of biodiesel fuel) are not present at high levels.

2.6 Algae - A source of biofuel

2.6.1 Algae as a source of Biofuel possess certain advantages: Algae produce oil, and because of their growth rate and yields, they could produce a lot more than other energy crops. Some estimates suggest that microalgae are capable of producing up to 15,000 gallons of oil per Hectare a year. This could be converted into fuels, chemicals and more. Microalgae, specifically, possess several attractive characteristics in the context of energy and biofuels: 1. They provide much higher yields of biomass and fuels, 10-100 times higher than comparable energy crops. 2. They can be grown under conditions which are unsuitable for conventional crop production.

3. Microalgae are capable of fixing CO2 in the atmosphere, thus facilitating the reduction of increasing atmospheric CO2 levels, which are now considered a global problem. 4. Algae biofuel is non-toxic, contains no sulfur, and is highly biodegrada. Origin of some types of Microalgae: Color Genus Alga name Green Dunaliella Dunaliella Chlamydomonus Scenedesmus Dunaliella bardawil Dunaliella salina Chlamydomonus sp.

Origin Bardawil Lake Qaron Lake and Egyptial costal shores Swiss government

Scenedesmus obliquus Germany Scenedesmus sp. El-Fayoum, El-Rayan Scenedesmus sp. Valley Saudi Arabia kingdom Chlorella sp. Spirulina sp. El-Qalubia governorate Most Egyptian lakes specially ,those at Natron valley

Chlorella Blue Green Spirulina

Comparison between open ponds and photo bioreactor: Item Cost Space Growth volume Running cost Maintenance Purity Specification Light harvesting Harvesting cost Open pond Low Short High Low Low Low Low Low High Photo bioreactor High Long Low High High High High High Low Oil% 72 28.7 35-65 27.8 25.9 20-30 16-40 12-14 19.9 21.7 19.7 6-7 16.6 33 3 15-23

Percentage of oil contents in Microalgae : Algae Oil% Algae Anabaena cylindrica 4-7 Monallantus salina Ankistrodesmus species 28-40 Nannochloropsis species Botryococcus braunii 25-86 Neochloris oleoabundans Chaetoceros muelleri 24.4 Nitschia closterium Chlamydomonas species 23 Nitschia frustulum Chlorella emersonii 63 Phaeodactylum tricorunutum Chlorella minutissima 57 Scenedesmus dimorphus Chlorella protothecoides 15-55 Scenedesmus obliquus Chlorella sorokiana 22 Scenedesmus quadricauda Chorella vulgaris 14-56 Selenastrum species Cyclotella species 42 Skeletonema costatum Dunaliella bioculata 8 Spirulina maxima Dunaliella salina 28.1 Spirulina plantensis Dunaliella tertiolecta 36-42 Stichococcus species Hantzschia species 66 Tetraselmis maculate Isochrysis galbana 21.2 Tetraselmis suecia

Scope of present work

As a result from the previous discussion; we choose Dunaliella Salina as a source of oil as the algae exist in Egypt at Qaron Lake and Alex. and its lipid content is somehow high 10-30%. The oil is then extracted from the algae by the help of professional botanist, after we get the oil it would be treated chemically with adding some additives to get the biodiesel, then we will make sure that this biodiesel can work as fuel in engines, has no side effects on the engine, livings and environment, measure some of the main properties as flash point, toxicity, cetane number and etc. Then we will measure its performance on the engine. In the end we will study how it could be used in large scale production.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Marketing Study of Mango JuiceDocumento18 páginasMarketing Study of Mango JuiceVijay ArapathAinda não há avaliações

- Safety Tips in Playing ArnisDocumento2 páginasSafety Tips in Playing ArnisDensyo De MensyoAinda não há avaliações

- Lecture 8 - ThermodynamicsDocumento65 páginasLecture 8 - ThermodynamicsHasmaye PintoAinda não há avaliações

- Hemostatic AgentsDocumento18 páginasHemostatic AgentshariAinda não há avaliações

- SA01 GENXXX SDIN BSDS 0001 B04 A - Instrumentation Design Basis Sazeh CommentedDocumento31 páginasSA01 GENXXX SDIN BSDS 0001 B04 A - Instrumentation Design Basis Sazeh Commentedamini_mohiAinda não há avaliações

- NTJN, Full Conference Program - FINALDocumento60 páginasNTJN, Full Conference Program - FINALtjprogramsAinda não há avaliações

- A.8. Dweck (2007) - The Secret To Raising Smart KidsDocumento8 páginasA.8. Dweck (2007) - The Secret To Raising Smart KidsPina AgustinAinda não há avaliações

- Improving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionDocumento2 páginasImproving The Livelihoods of Smallholder Fruit Farmers in Soroti District, Teso Sub Region, Eastern Uganda RegionPatricia AngatoAinda não há avaliações

- Probni Test 1. Godina - Ina KlipaDocumento4 páginasProbni Test 1. Godina - Ina KlipaMickoAinda não há avaliações

- Issue of HomosexualityDocumento4 páginasIssue of HomosexualityT-2000Ainda não há avaliações

- The Impact Behaviour of Composite MaterialsDocumento6 páginasThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- Missoula County Fairgrounds Phase 2Documento10 páginasMissoula County Fairgrounds Phase 2Olivia IversonAinda não há avaliações

- BKM 10e Ch07 Two Security ModelDocumento2 páginasBKM 10e Ch07 Two Security ModelJoe IammarinoAinda não há avaliações

- Tackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavDocumento9 páginasTackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavMalcolm PintoAinda não há avaliações

- Action Taken On Oil and Ghee Sampling - 2020Documento2 páginasAction Taken On Oil and Ghee Sampling - 2020Khalil BhattiAinda não há avaliações

- Hodgkin LymphomaDocumento44 páginasHodgkin LymphomaisnineAinda não há avaliações

- Remote Control Unit Manual BookDocumento21 páginasRemote Control Unit Manual BookIgor Ungur100% (1)

- Biology Q PDFDocumento9 páginasBiology Q PDFsumon chowdhuryAinda não há avaliações

- PulpectomyDocumento3 páginasPulpectomyWafa Nabilah Kamal100% (1)

- Borelog CP.101Documento1 páginaBorelog CP.101radixkusumaAinda não há avaliações

- AGIP STD - Valves Specification SheetDocumento1 páginaAGIP STD - Valves Specification Sheethalim_kaAinda não há avaliações

- BHP Billiton Petroleum Contract Letter For ABDUL SATTARDocumento5 páginasBHP Billiton Petroleum Contract Letter For ABDUL SATTARAbdul SattarAinda não há avaliações

- Case StudyDocumento7 páginasCase StudyLeighvan PapasinAinda não há avaliações

- 8 Categories of Lipids: FunctionsDocumento3 páginas8 Categories of Lipids: FunctionsCaryl Alvarado SilangAinda não há avaliações

- 21 05 20 Montgomery AssocDocumento1 página21 05 20 Montgomery AssocmbamgmAinda não há avaliações

- Onuaguluchi1996 1Documento10 páginasOnuaguluchi1996 1IkaSugihartatikAinda não há avaliações

- Bioplan Nieto Nahum)Documento6 páginasBioplan Nieto Nahum)Claudia Morales UlloaAinda não há avaliações

- Energy Optimization of A Large Central Plant Chilled Water SystemDocumento24 páginasEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002Ainda não há avaliações

- NURTURE Module-V 11 1 en PDFDocumento4 páginasNURTURE Module-V 11 1 en PDFJorge SingAinda não há avaliações

- Chi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillDocumento32 páginasChi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillNaresh GillAinda não há avaliações