Escolar Documentos

Profissional Documentos

Cultura Documentos

Duke Esi/Rm (X) Installation and Operation Manual Duke Part No. 10192 Rev. B

Enviado por

Carlos Salazar ZeladaDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Duke Esi/Rm (X) Installation and Operation Manual Duke Part No. 10192 Rev. B

Enviado por

Carlos Salazar ZeladaDireitos autorais:

Formatos disponíveis

DUKE ESI/RM(x) Installation and Operation Manual Duke Part No. 10192 Rev.

Duke Pro, Inc. 1854-A Hendersonville Rd. PMB 154 Asheville, NC 28803 Phone: 866-587-3853 FAX: 828-684-6044 http://www.dukepro.com

Duke ESI/RM(x) Installation and Operations Manual

TABLE OF CONTENTS

INTRODUCTION...............................................................................................................3 THEORY OF OPERATION...............................................................................................3 TO FIRE ............................................................................................................................3 INSTALLATION.................................................................................................................4 ESI/RM(2, 4, 6) ........................................................................................................................................4 ESI/RM1..........................................................................................................................4 OPERATING INSTRUCTIONS.........................................................................................6 GENERAL.......................................................................................................................6 SEQUENCE CONTROL.................................................................................................6 OPERATION VERIFICATION........................................................................................6 TROUBLESHOOTING and MAINTENANCE...................................................................6 TESTING.........................................................................................................................6 SPECIFICATIONS.............................................................................................................7 ELECTRICAL..................................................................................................................7 MECHANICAL................................................................................................................7 DUKE PRO Replacement Parts List...............................................................................8

Page 2 of 8

10192 Rev B

Duke ESI/RM(x) Installation and Operations Manual

INTRODUCTION

The Duke Model ESI/RMX shock tube initiator is designed to provide EOD robots with a reliable shock tube initiation system for breaching systems and disrupter cannons. It is built to mount directly to the arm of a Remotec Andros Mark 5A, 6A, F6A, and Wolverine robot with minimal interface requirements. This unit utilizes the weapons output terminals, which outputs +24VDC and is controlled at the main or local control panel of the robot.

THEORY OF OPERATION

The ESI/RMX unit is composed of three major modules; 1-Power Auto Polarity and Sequence Control, 2- High Voltage Power Supply, and 3- High Voltage and Low Voltage Relays

TO FIRE

Install switch tip(s) firmly into red/black terminals. Move firing lever to armed position. Test the unit by selecting a weapons platform channel and activating the weapons output (fire control button) continuously for 3 seconds at the main or local control panel for each circuit. If ESI tip is functioning, a loud pop emanating from the initiator tip will be heard approximately 2 seconds after circuit is activated.

Page 3 of 8

10192 Rev B

Duke ESI/RM(x) Installation and Operations Manual

INSTALLATION ESI/RM(2, 4, 6)

For Mark 5A, 6A, F6A and Wolverine: Using the 5/32 allen wrench and mounting brackets supplied, fasten the module on the robots right side as viewed from rear of the 5A, 6A, and Wolverine, or the left side of the F60 of the lower arm. Note that the bracket attached to the box has mounting holes used to either raise or lower the unit by inch. This is done to allow the box to clear the battery cover on the 5A, 6A, and F6A, or the arm motor on the Wolverine. Connect the power connectors to the weapons terminals on the robot, paying careful attention to polarity. Install the shock tube initiator tips on all channels. Test fire each channel. Secure the cables with tie wraps (not supplied), leaving additional slack at arm joints. Move the arm through the entire range of motion to verify that the initiator does not interfere with the arms motion and that the power cable to the initiator is not stretched, kinked, or pinched.

ESI/RM1

For Mark 5A, 6A, F6A and Wolverine: Thread large tie wraps into the bottom of the cradle and over the top of the initiator. Attach unit to lower arm section. Tighten the strap to secure the cradle and initiator. Note that the rubber pads are supplied to prevent the cradle from slipping on the arm. Connect the power connectors to the weapons terminal. Note that the power connector is polarity insensitive on the ESI/RM1. Install firing tip and test operation of the initiator. Secure cable with tie wraps (not supplied), leaving additional slack at arm joints. Move the arm through the entire range of motion to verify that the initiator does not interfere with the arms motion and that the power cable to the initiator is not stretched, kinked, or pinched. If you have any questions on any of the steps above, please dont hesitate to call us. TOLL-FREE 866-587-DUKE (3853)

Page 4 of 8

10192 Rev B

Duke ESI/RM(x) Installation and Operations Manual

STEP ONE Place piercing electrode control level in the load position (away from center electrode hole).

STEP TWO Push shock tube through the loading hole until the center electrode is inside of the shock tube.

SHOCK TUBE

FIRE

LOAD

CENTER ELECTRODE

STEP 3 Move the piercing control arm level to the FIRE position.

STEP 4 *** IMPORTANT *** Always move piercing control lever to the LOAD position before removing shock tube.

ARMED INDICATOR

FIRE PIERCING ELECTRODE

LOAD

FIRE

LOAD

CALIBRATION: Every 1,500 shots, screw the center electrode in until it touches the piercing electrode. Then back off turn to establish the proper gap. 3

CENTER ELECTRODE SCREW HEAD

Page 5 of 8

10192 Rev B

Duke ESI/RM(x) Installation and Operations Manual

OPERATING INSTRUCTIONS

GENERAL

Power is applied from the robots weapons terminals The 24VDC source switching action will occur only when the fire command is actuated at the robot control panel AND held on for at least three seconds. It will not fire again until power switch is released.

SEQUENCE CONTROL

When the power is applied the unit automatically begins a two second charging cycle. After approximately two seconds the power is removed from the high voltage power supply and the initiator tip is connected to the high voltage capacitors, initiating the shock tube. The unit then goes into a standby mode and cannot be recycled until power is removed. If the user wishes to abort during the two-second cycle, simply release the fire switch and power will removed from the weapon terminals used to power to the ESI/RM(X) unit. The high voltage capacitors will discharge internally and the unit will return to an idle state.

OPERATION VERIFICATION

Prior to loading shock tube, verify that unit is functioning by powering up each circuit with the ESI tip in place and armed. A loud pop will be heard, indicating the tip is sparking. For additional verification, a short segment of shock tube (4 inch) may be inserted into tip and fired (please observe safety precautions when performing this test).

TECH TIP!: Improperly shipped or stored shock tube can have dead spots that will

not easily ignite with an electronic initiator. Dangle the ESI tip on the end of a length of shock tube (approx. 3 feet) and thump the tube to get additional RDX around the ignition point for more reliable results.

TECH TIP!: Remember to store and maintain your shock tube reel on its side with a

moisture barrier cap on the end.

TROUBLESHOOTING AND MAINTENANCE TESTING

Test the tip prior to insertion of the shock tube for spark. An audible pop should be heard indicating the tip works. If spark is weak or not present, swap tip with one from a known working channel. If subsequent spark is strong, recalibrate the weak tip. If the tip works on one channel but not the other, verify that +24VDC is present for at least two seconds during firing cycle. If voltage is present, remove ESI tips and listen

Page 6 of 8

10192 Rev B

Duke ESI/RM(x) Installation and Operations Manual

for audible relay clicks two seconds apart internally. This will verify that the electronics are receiving power. If relays are operating but no output is present, return the unit to the factory. The ESI/RMX is equipped with two 5-gram size, molecular sieve desiccant packs, mounted with hook and loop fasteners inside of the unit. These parts should be replaced every 5 years as a general maintenance item.

SPECIFICATIONS ELECTRICAL

Input Voltage: 16 ~ 30 volts D.C. Firing Voltage: 2500 Volts D.C. 2% Charge Time: 2 seconds 200 ms Firing Sequence: Charge time 2 seconds followed 5 milliseconds later by discharge cycle. Peak Current @24 VDC: 0.250 amps Tip Life: 5,000-10,000 shots typical

MECHANICAL

Housing: Weather Resistant, Cast Aluminum Housing (Dimensions : 8.7 L x 4.7 W x 3.25 H ) Weight: 3.5 Lb. Mounting: The ESI/RM 1,2,4, or 6 is designed for Remotec robots and uses two custom clamp assemblies to mount the unit securely to the robot arm. Universal mount for other robots available Available Colors: Unpainted Aluminum or Black . Operating Temperature: -20 ~ 160 F Storage Temperature: -40 ~ 185 F Relative Humidity: 0~95 % NON-CONDENSING

Page 7 of 8

10192 Rev B

Duke ESI/RM(x) Installation and Operations Manual

DUKE PRO REPLACEMENT PARTS LIST

Initiator Module PN 337800A Mounting Brackets PN 337805A 5/32 Allen wrench PN 10007 Shock tube initiator tip Switch Tip PN 1096 Desiccant Pak (includes 2 sealed 1/6 size molecular sieve units and self adhesive loop fastener) PN 10005 Custom Mounting Kit for ESI/RM1 PN 5556

Page 8 of 8

10192 Rev B

Você também pode gostar

- LG L194WTDocumento29 páginasLG L194WTqxbgwhvuAinda não há avaliações

- LG L1733TR L1933TR Monitor Service ManualDocumento35 páginasLG L1733TR L1933TR Monitor Service Manualmanlu1001565Ainda não há avaliações

- Color Monitor: Service ManualDocumento20 páginasColor Monitor: Service Manualmalord958Ainda não há avaliações

- Color Monitor: Service ManualDocumento36 páginasColor Monitor: Service ManualelistefanAinda não há avaliações

- Service Manual: /mitsubishiDocumento96 páginasService Manual: /mitsubishiSergio L. SuligoyAinda não há avaliações

- LG Flatron l1753t l1953t-sfs Chassis Lm72a (ET)Documento31 páginasLG Flatron l1753t l1953t-sfs Chassis Lm72a (ET)robermdeaAinda não há avaliações

- LG l1753tr, 1953tr-sf PDFDocumento59 páginasLG l1753tr, 1953tr-sf PDFKartik K BélaAinda não há avaliações

- Color Monitor: Service ManualDocumento35 páginasColor Monitor: Service Manualmoshu_85Ainda não há avaliações

- LG W4320S Service ManualDocumento24 páginasLG W4320S Service ManualeleandrorobertoAinda não há avaliações

- Technical Service Manual Kc186st 256stDocumento41 páginasTechnical Service Manual Kc186st 256stperon6150% (2)

- L196WTQ-S, BFQ eDocumento30 páginasL196WTQ-S, BFQ eadisistemsAinda não há avaliações

- Hr598d-p (Hr500) Bfrallk Lgefs Afn35914271 EvDocumento97 páginasHr598d-p (Hr500) Bfrallk Lgefs Afn35914271 EvfanchheizAinda não há avaliações

- Body Electrical SystemDocumento59 páginasBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Akai Lct26z4ad SMDocumento142 páginasAkai Lct26z4ad SMwifv7enuybyAinda não há avaliações

- LG Flatron Monitor l1918sDocumento44 páginasLG Flatron Monitor l1918sdadogogaAinda não há avaliações

- L194WS SDocumento24 páginasL194WS SpitzubAinda não há avaliações

- DJC 4ManualV1 1Documento22 páginasDJC 4ManualV1 1matyi1Ainda não há avaliações

- Color Monitor: Service ManualDocumento28 páginasColor Monitor: Service ManualUwexAinda não há avaliações

- Service Manual: History Information For The Following ManualDocumento56 páginasService Manual: History Information For The Following ManualMalanie Sriya De SilvaAinda não há avaliações

- Color Monitor: Service ManualDocumento24 páginasColor Monitor: Service Manualmoshu_85Ainda não há avaliações

- LG Flatron l204wt Lm62b SMDocumento27 páginasLG Flatron l204wt Lm62b SMgeofaxxxxxxAinda não há avaliações

- LG w2243c PFVDocumento24 páginasLG w2243c PFValtabebotaAinda não há avaliações

- LG 32CS410 CH LP24B PDFDocumento26 páginasLG 32CS410 CH LP24B PDFLucio Mendoza0% (1)

- Bose 1600VI 1800VI Profesional Service ManualDocumento60 páginasBose 1600VI 1800VI Profesional Service ManualSteven100% (2)

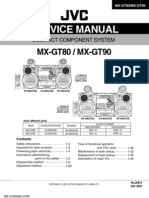

- JVC mx-gt80 gt90 SM No-Sch (ET)Documento48 páginasJVC mx-gt80 gt90 SM No-Sch (ET)Cliffton FilipinoPrd ShraderAinda não há avaliações

- 32ln57xx 32ln570b 32ln571b 32ln572b Chassis lb33bDocumento119 páginas32ln57xx 32ln570b 32ln571b 32ln572b Chassis lb33bJerald D'costaAinda não há avaliações

- LG 32LB550BDocumento39 páginasLG 32LB550BSalvadorRodriguesAinda não há avaliações

- AVR65 Service ManualDocumento89 páginasAVR65 Service ManualTom Ruyle100% (1)

- Service Manual Monitor Fernando MFL30105543 (L17,1952TX-S, BFQ - E (M)Documento36 páginasService Manual Monitor Fernando MFL30105543 (L17,1952TX-S, BFQ - E (M)Jose M. CastilloAinda não há avaliações

- IBM Think Vision L170 Srvice ManualDocumento28 páginasIBM Think Vision L170 Srvice Manualpocachurio0% (1)

- LG Flatron w1642c Chassis Lm73bDocumento25 páginasLG Flatron w1642c Chassis Lm73bRonan NolascoAinda não há avaliações

- 2LG Flatron W1953TDocumento23 páginas2LG Flatron W1953TelitherhAinda não há avaliações

- 32lg30ra TaDocumento24 páginas32lg30ra TaMikaela MaçkoAinda não há avaliações

- LG 32LB530B CH LA30BDocumento140 páginasLG 32LB530B CH LA30BWilfredo Sanchez TovarAinda não há avaliações

- Samsung Vr22uo Chassis Ltp227wDocumento70 páginasSamsung Vr22uo Chassis Ltp227wArturo Palacios TrejoAinda não há avaliações

- LG 32LN5100 CH LL35BDocumento58 páginasLG 32LN5100 CH LL35Bcandra100% (9)

- Led TV: Service ManualDocumento23 páginasLed TV: Service ManualKiran VeesamAinda não há avaliações

- LG lrm-519 (ET)Documento158 páginasLG lrm-519 (ET)joeblow44Ainda não há avaliações

- 400 TIG - ARC Iwi ManualDocumento13 páginas400 TIG - ARC Iwi ManualnitantharaniAinda não há avaliações

- Lcd+Lg+Flatron+l1753t Chasis+Lm57bDocumento34 páginasLcd+Lg+Flatron+l1753t Chasis+Lm57bIsrael AlexanderAinda não há avaliações

- Color Monitor: Service ManualDocumento36 páginasColor Monitor: Service ManualBorcan CristiAinda não há avaliações

- Service Manual: Xga Color Monitor Model: L700C/L700CM L701C/L701CM L700CAVDocumento75 páginasService Manual: Xga Color Monitor Model: L700C/L700CM L701C/L701CM L700CAVJesus SilvaAinda não há avaliações

- 42LS3450, 345S, 345TDocumento53 páginas42LS3450, 345S, 345TAndres Fermin OchoaAinda não há avaliações

- Led TV: Service ManualDocumento68 páginasLed TV: Service ManualEtu100% (1)

- The IEE Wiring Regulations Explained and IllustratedNo EverandThe IEE Wiring Regulations Explained and IllustratedNota: 4 de 5 estrelas4/5 (14)

- Introduction to Power System ProtectionNo EverandIntroduction to Power System ProtectionNota: 5 de 5 estrelas5/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsNo EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsNota: 3 de 5 estrelas3/5 (2)

- Introduction to Power System ProtectionNo EverandIntroduction to Power System ProtectionAinda não há avaliações

- Ultimate Guide: Wiring, 8th Updated EditionNo EverandUltimate Guide: Wiring, 8th Updated EditionNota: 3.5 de 5 estrelas3.5/5 (4)

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaNo EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaAinda não há avaliações

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Ainda não há avaliações

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationAinda não há avaliações

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Ainda não há avaliações

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationAinda não há avaliações

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNo Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsNota: 4 de 5 estrelas4/5 (1)

- MEITRACK MVT380 User GuideDocumento15 páginasMEITRACK MVT380 User GuideCarlos Salazar ZeladaAinda não há avaliações

- CMJ8-POE Series: Outdoor Gigabit Power-Over-Ethernet (Poe) Surge ProtectorDocumento1 páginaCMJ8-POE Series: Outdoor Gigabit Power-Over-Ethernet (Poe) Surge ProtectorCarlos Salazar ZeladaAinda não há avaliações

- Camp Usa Interview SupplementDocumento1 páginaCamp Usa Interview SupplementCarlos Salazar ZeladaAinda não há avaliações

- COLUCHI!!! BDocumento1 páginaCOLUCHI!!! BCarlos Salazar ZeladaAinda não há avaliações

- Pegasus W200Documento56 páginasPegasus W200Aleixandre GomezAinda não há avaliações

- Frontpage: Don'T Befriend Brutal DictatorsDocumento16 páginasFrontpage: Don'T Befriend Brutal DictatorsFrontPageAfricaAinda não há avaliações

- Technical Analysis CourseDocumento51 páginasTechnical Analysis CourseAkshay Chordiya100% (1)

- Theology NotesDocumento3 páginasTheology NotesNia De GuzmanAinda não há avaliações

- Discuss Both Views Introduction PracticeDocumento3 páginasDiscuss Both Views Introduction PracticeSang NguyễnAinda não há avaliações

- Nonviolent Communication Lessons 2-20-18Documento210 páginasNonviolent Communication Lessons 2-20-18Ice George100% (1)

- Essay On Stamp CollectionDocumento5 páginasEssay On Stamp Collectionezmt6r5c100% (2)

- Exception Aggregation in Sap Bi PDFDocumento2 páginasException Aggregation in Sap Bi PDFPamela0% (1)

- Dior Product Development PresentationDocumento59 páginasDior Product Development PresentationSade WycheAinda não há avaliações

- Introduction To Human Resources ManagementDocumento14 páginasIntroduction To Human Resources ManagementEvan NoorAinda não há avaliações

- Lease of Playground To A SchoolDocumento2 páginasLease of Playground To A SchoolSutapaAinda não há avaliações

- Services Marketing-Unit-Ii-ModifiedDocumento48 páginasServices Marketing-Unit-Ii-Modifiedshiva12mayAinda não há avaliações

- Em Swedenborg THE WORD EXPLAINED Volume IX INDICES Academy of The New Church Bryn Athyn PA 1951Documento236 páginasEm Swedenborg THE WORD EXPLAINED Volume IX INDICES Academy of The New Church Bryn Athyn PA 1951francis batt100% (2)

- Constantin Floros, Kenneth Chalmers - New Ears For New Music-Peter Lang GMBH, Internationaler Verlag Der Wissenschaften (2014)Documento242 páginasConstantin Floros, Kenneth Chalmers - New Ears For New Music-Peter Lang GMBH, Internationaler Verlag Der Wissenschaften (2014)paperocamillo100% (3)

- RightShip Inspections Ship Questionaire RISQ 3.0Documento207 páginasRightShip Inspections Ship Questionaire RISQ 3.0Philic Rohit100% (1)

- Tectos Falsos Stretch Caracteristicas TecnicasDocumento37 páginasTectos Falsos Stretch Caracteristicas TecnicasVadymAinda não há avaliações

- Sample CVDocumento3 páginasSample CVsam_mad00Ainda não há avaliações

- CV BTP AhokDocumento2 páginasCV BTP AhokDiah Purwati N.Ainda não há avaliações

- The Basics of Effective Interpersonal Communication: by Sushila BahlDocumento48 páginasThe Basics of Effective Interpersonal Communication: by Sushila BahlDevesh KhannaAinda não há avaliações

- Introduction To Mechanical Engineering Si Edition 4Th Edition Wickert Lewis 1305635752 9781305635753 Solution Manual Full Chapter PDFDocumento36 páginasIntroduction To Mechanical Engineering Si Edition 4Th Edition Wickert Lewis 1305635752 9781305635753 Solution Manual Full Chapter PDFwilliam.munoz276100% (13)

- Principle of ManagementsDocumento77 páginasPrinciple of ManagementsJayson LucenaAinda não há avaliações

- PMMSI Vs CADocumento1 páginaPMMSI Vs CAFermari John ManalangAinda não há avaliações

- HG G2 Q1 W57 Module 3 RTPDocumento11 páginasHG G2 Q1 W57 Module 3 RTPJennilyn Amable Democrito100% (1)

- Revilla Law IRRDocumento2 páginasRevilla Law IRRPaulAinda não há avaliações

- Individual Assignment 1 (TPT630)Documento7 páginasIndividual Assignment 1 (TPT630)MUHAMMAD HABIB HARRAZ ABDUL RAHMANAinda não há avaliações

- (Downloadsachmienphi.com) Bài Tập Thực Hành Tiếng Anh 7 - Trần Đình Nguyễn LữDocumento111 páginas(Downloadsachmienphi.com) Bài Tập Thực Hành Tiếng Anh 7 - Trần Đình Nguyễn LữNguyên NguyễnAinda não há avaliações

- Paras Vs ComelecDocumento2 páginasParas Vs ComelecAngel VirayAinda não há avaliações

- Tazkira Mujaddid AlfesaniDocumento53 páginasTazkira Mujaddid AlfesanisayedAinda não há avaliações

- School of The Scripture PreviewDocumento10 páginasSchool of The Scripture PreviewJoseph Chan83% (6)

- ch27 Matrices and ApplicationsDocumento34 páginasch27 Matrices and Applicationschowa fellonAinda não há avaliações