Escolar Documentos

Profissional Documentos

Cultura Documentos

Reinforced BESSER™ Block Retaining Walls

Enviado por

romamanDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Reinforced BESSER™ Block Retaining Walls

Enviado por

romamanDireitos autorais:

Formatos disponíveis

Reinforced BESSER Block Retaining Walls

Contents

Introduction

Preface Introduction 1.0 Retaining walls 1.1 Designs for reinforced retaining wall types 1.2 Loading Conditions 1.2.1 Retaining Walls 1.3 Material Specifications 1.4 Soil Classification 1.5 Wall Foundation 1.6 Infill Soil and Retained Soil 1.7 Drainage Systems 1.8 Water Penetration 1.9 Exploded View of Construction 1.10 How to Build the Wall 1.10.1 Preliminary 1.10.2 Base and Hob 1.10.3 Block Laying 1.10.4 Grouting 1.11 Tanking 1.12 Infill Soil and Drainage 1.13 Design Details for Wall Type 1 1.13.1 Level Surface Wall Layout 1.13.2 Sloping Surface up to 1 in 4 Wall Layout 1.13.3 Base and Key Sizes 1.13.4 Reinforcement Details 1.14 Design Details for Wall Type 2 1.14.1 Level Surface Wall Layout 1.14.2 Sloping Surface up to 1 in 4 Wall Layout 1.14.3 Base and Key Sizes 1.14.4 Reinforcement Details 2.0 Basement Walls 2.1 General 2.2 Drainage 2.3 Tanking 2.4 How to build the wall 2.5 Designs for reinforced basement wall types 2.6 Besser block basement wall design details for supporting a concrete floor 2.7 Besser block basement wall design details for supporting a timber floor 2.8 Basement walls Glossary

2 2 3 3 4 4 4 4 4 4 5 5 5 6 6 6 6 6 6 6 7 7 8 9 9 10 10 11 12 12 13 13 13 13 13 13

Preface

The designs shown in the brochure are based on limit state design in accordance with the provisions of AS4678-2002 Earth retaining structures standard including Amendment 1, 2003. The designs are hereby certified by Adbri Masonry Building Products Pty Ltd ABN 31 009 687 521. The design details provided in this brochure have been prepared by Adbri Masonry specifically for Adbri Masonry blocks and are applicable only to retaining walls using Adbri Masonry products for residential or light commercial applications up to 3.0m high. For higher and/or more complex applications it is recommended reference be made to the Concrete Masonry Association of Australia document Reinforced Concrete Masonry Cantilever Retaining Walls Design and Construction Guide MA51, Amended July 2003.

14

14 15 15

Reinforced BESSER Block Retaining and Basement Walls consist of a reinforced concrete base which anchors the wall against overturning and sliding, and a stem of BESSER blocks. The stem is reinforced with steel bars placed vertically and horizontally, and all cores in the blocks are filled with semi-fluid concrete, known as grout. The vertical reinforcing bars in the cores are lapped with shorter starter bars embedded firmly in the reinforced concrete base using a hob to correctly locate the bars. These short bars allow easier block laying, and the longer bars are put in after all blocks are laid and before grouting. The length of the lap is critically important and must be shown on the drawings.

03

1.0 Retaining Walls

1.1 Designs for Reinforced Retaining Wall Types

Retaining walls up to 3.0m high.

Wall Type 1

Boundary

45 Reinforced block stem Infill soil

Drainage layer Hob Drain Base

Retained soil

Wall Type 2

Boundary

45 Reinforced block stem Infill soil

Drainage layer Hob Retained soil Base Drain

Note: Diagrams not to scale

04

1.2 Loading Conditions 1.4 Soil Classification

1.2.1 Retaining Walls

These tables cover four loading conditions: Level surface with 2.5 kPa surcharge for walls up to 1.5m high. Level surface with 5.0 kPa surcharge for walls over 1.5m high. Sloping surface up to 1:4 with 2.5 kPa surcharge for walls up to 1.5m high. Sloping surface up to 1:4 with 5.0 kPa surcharge for walls over 1.5m high. Notes: 300mm of soil or a private driveway imposes a load of approximately 5 kPa. Sloping surface steeper than 1:4 is not included in this brochure.

1.4 Soil classification

To simplify the following design tables only one type of soil has been used throughout for both infill soil and retained soil. It is classified as an average soil and would be typical of a wide range of insitu soils and would normally include; stiff sandy clays, gravelly clays, compact clayey sand and sandy silts, compacted clay fill (Class II). The characteristic soil property has been reduced by the uncertainty factors below and upon which the designs have been based: Uncertainty factor for drained cohesion, = uc 0.70 Uncertainty factor for drained internal friction angle, ie: * = tan-1 ( u (tan ))

Characteristic soil parameters

= 0.85

Design soil parameters

1.3 Material Specifications

In calculating these tables, the following material specifications were adopted: BESSER Block fuc = 15 MPa in accordance with AS 4455 - 1997 Mortar Class M3 Cement 1 : Lime 1 : Sand 6 OR Cement 1 : Lime 0 : Sand 5 plus cellulose-based water thickener Concrete base fc = 25 MPa Reinforcement Grade 500 N Grout fc = 20 MPa with a pourable consistency and a cement content no less than 300 kg/m3 Where possible, use ready-mixed grout and specify when ordering that it is for filling blockwork. If the grout is mixed on site, use the following proportion: Cement 1 part Hydrated Lime Up to 1/10th part Mortar Sand 3 parts 10mm aggregate Up to 2 parts Notes: 10mm aggregate should be rounded gravel where possible. Grout should be mixed in a tilting drum paddle mixer and should flow freely without separation of the aggregate.

Internal friction angle (degrees) 27

Cohesion c (kPa) 3

Internal friction angle * (degrees) 23

Cohesion c* (kPa) 2

1.5 Wall foundation

The tables have been based on a foundation soil as described above and which must be excavated to sufficient depth to expose undisturbed material which is firm and dry. Should a designer wish to analyse a retaining wall built on a different foundation, base dimensions different from the tabulated values could be appropriate. If any of the following foundation conditions exist: softness, poor drainage, filled ground, organic matter, variable conditions, heavily cracked rock, aggressive soils, then experienced professional engineering advice should be obtained.

1.6 Infill soil and retained soil

These tables have been calculated for infill soil and retained soil of soil classification shown above. Note: The following poor quality soils are not allowed for in the tables; soft and firm clay of medium to high plasticity, silty clays, loose variable clayey fill, loose sandy silts. If these soils are considered for use or aggressive groundwater exists an experienced professional engineer should be consulted and separate designs be obtained.

05

1.7 Drainage Systems

It is essential that steps be taken to prevent the soil behind the wall from becoming saturated. These steps should include: Sealing the soil surface this can be done by covering it with a compacted layer of material with low permeability. The surface should be sloped towards an open drain. A drainage system within the soil this should preferably be achieved by placing gravel to a width of approximately 300mm immediately behind the wall with a continuous 100mm diameter slotted pvc agricultural pipe with geo fabric sock located at the base of the wall. The outlets from the pipe must be beyond the ends of the wall unless the pipe is connected to a proper storm water drainage system. For higher walls, or in cases where excessive ground water exists it may be necessary to provide another agricultural pipe drain at mid height of the wall. If it is not possible to discharge the drains beyond the end of the wall, weep-holes may be provided (see items for block laying following). In this case, a collecting system (e.g. spoon drains) must discharge the water into a drainage system to prevent saturation of the ground in front of the wall. A subfloor drainage system is advisable in basements to prevent hydrostatic pressure under the floor slab.

1.8 Water Penetration

If considered necessary to reduce the passage of water through the wall, for aesthetic or other reasons such as aggressive ground water, the earth face of the wall should be treated using appropriate sealing techniques (see notes on tanking.)

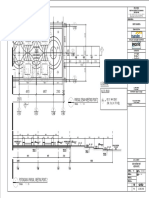

1.9 Exploded View of Construction

Grout all cores Grout Hopper

Note: Where 15.42 or 20.42 blocks are in lieu of 20.48 blocks, lay alternative courses inverted and support horizontal reinforcement in the centre of the wall and 20 mm clear of the webs. Blocks type 20.48

Vertical X-bars (Stem) lapped with and tied to starter Y-bars Horizontal bars in wall can be laid on webs of H-blocks. Wall base

Cleanout Blocks 20.61 or 20.45 Lap Position vertical X and Y-bars to give 55mm clear cover on earth side.

Vertical starter Y-bars cast into base

Cleanout Block 20.45 Hob Base transverse bars Base longitudinal bars Key

Formwork to close cleanout openings. Tie to vertical bars with wire or support with temporary timber struts.

Cleanout Biscuit 20.45A

Note: Diagrams not to scale

06

1.10 How to Build the Wall

1.10.1 Preliminary

Excavate to a satisfactory foundation. Arrange for supply of materials to the specifications given previously.

1.10.2 Base and hob

Form the base and hob to the required dimensions and levels as shown in tables. Place the base reinforcement as shown in the diagrams, securely fix the starter bars for the vertical reinforcement (Y-bars) 55mm from the back face of the wall, in the correct positions relative to the block cores to be reinforced by using the top front edge of the hob as a positioning reference point. Place the base concrete, preferably using ready-mixed concrete, and compact thoroughly by rodding, spading or vibrating. Wood float finish any surface to be exposed permanently. Take care not to dislodge reinforcement.

1.10.3 Block laying

Block laying procedure follows that of the normal practice for building unreinforced walls but, includes the additional requirement of locating the first course directly on top of a hob which is used to accurately locate the starter bars. The mortar mix used should be cement 1 part, lime 1 part, sand 6 parts or cement 1 part, sand 5 parts plus water thickener. These parts should be accurately measured by volume (e.g. a bucket). The sand used should be clean pit sand, masonry or plasterers sand. The use of plasticising additives is permitted. Where they are used, the dosage rate must not exceed that recommended by the supplier as this will drastically reduce the mortar strength. Detergent should never be used. Recommendations specifically applicable to reinforced concrete block retaining walls follow: Cleanout openings should be provided in the bottom course using either 20.61 blocks plus timber formwork at the front or 20.45 blocks plus 20.45 A biscuits to permit removal of mortar fins and other debris, and to allow positioning and tying of vertical reinforcement. These openings must be closed before grouting. Above the first course, the use of 15.48, 20.48 and 30.48 H-Blocks is recommended because they are easier to fill with grout and provide required protection of the reinforcement. 15.42 and 20.42 blocks may be used in lieu of H-Blocks and these blocks require less grout for filling. However, they must be laid with alternative courses inverted so as to provide grout cover to longitudinal reinforcement, which must be lifted 20mm clear of the web of the block by using stirrups or other supports (see diagram). Mortar projecting into the cores should be removed, either as the blocks are laid, or by rodding after the mortar has set. Debris should be removed from the cores through the cleanout openings. When the wall is to be tanked, the mortar joints on that face should be struck flush and cleaned. Weepholes can be providing by passing 50mm diameter upvc pipes holes through the hob at 1200mm centres. Reinforcement must be positioned accurately (refer to above), and tied securely before placing concrete or grout. Vertical reinforcing bars, including starter bars, should be as close to the back face of the wall as possible, consistent with 55mm cover requirements.

1.10.4 Grouting

Close cleanout openings. Place grout. It is recommended that whenever available, ready-mixed grout to workability specifications given in AS3700 2001 should be used. Site-mixed grout, if used, should be mixed thoroughly in a tilting drum type paddle mixer to the same specification as ready-mixed grout. All cores should be filled with grout, whether reinforced or not. This is essential to bond and protect horizontal reinforcement, and to give maximum weight for stability. The grout should be compacted thoroughly so that voids are not left. Compaction may be by rodding with a plain round bar (do not use main vertical reinforcing bars or other deformed bars) or with a high frequency pencil vibrator, used carefully. We recomend using Coremasta for corefilling your walls. Coremasta is a specially formulated block filler that gives superior grout penetration and requires minimal labour hours. Contact Hanson Construction Materials on 132 662 for more details.

1.11Tanking

Where the wall is required to be waterproof, for example a basement wall, various proprietary tanking methods are available. One such method is a three coat liquid rubber compound incorporating a special reinforcing fabric for high stressed areas. Another method is a heavy duty, pliable, waterproof sheet membrane fixed to the wall surface. Surface coatings or sheet membranes must always be used in accordance with the manufacturers specifications.

1.12 Infill Soil and Drainage

Infill soil should not placed behind the wall until at least ten days after grouting. Infill soil should be placed and compacted in layers not more than 200mm deep. The degree and method of compaction depends on the proposed use of the retaining wall. The drainage system should be installed progressively as the infill soil rises. The drainage system behind the wall should be connected to the main drainage system. For the nominated infill soil in this brochure, it is advisable to seal off the top surface of the infill soil with a semi-impermeable layer of soil or earth. Compact and grade to a gutter to provide surface drainage.

07

1.13 Design Details for Wall Type 1

1.13.1 Level Surface Wall Layout

Walls up to 1.2m high Walls over 1.8m and up to 3.0m high

75.10 Capping Tile if required 100

190

140 2.5 kPa surcharge

10.31 Capping Tile if required 100

340 290 190 2.5 kPa surcharge up to 1.5m 5.0 kPa surcharge over 1.5m

N16 top course only 55 cover N12 @ 400 crs H X-bars Note: All cores fully grouted 700 lap 55 cover N16 top course only

N12 @ 400 crs X-bars Note: All cores fully grouted

Y-bars 500 lap 55 cover Cleanout Block 100 200 Y-bars with 55 cover

55 cover to top of Y-bars H N16 @ 300 crs B Y-bars 55 cover N16 @ 400 crs X-bars Cleanout Block 2.5 kPa surcharge up to 1.5m 190 100 5.0 kPa surcharge over 1.5m 100 350 Y-bars with 55 cover Y-bars

Walls over 1.2m and up to 1.8m high

700 lap

240 10.31 Capping Tile if required

N16 @ 300 crs N16 top course only 55 cover X-bars H B

Note: All cores fully grouted

700 lap

Y-bars N12 @ 400 crs 55 cover Cleanout Block Y-bars with 55 cover

100 250

N16 @ 300 crs B

Note: Diagrams not to scale

Wall Type 1

07

1.13.2 Sloping Surface up to 1 in 4 Wall Layout

Walls up to 1.2m high Walls over 1.8m and up to 3.0m high

75.10 Capping Tile if required 100

190 2.5 kPa surcharge 140

340 10.31 Capping Tile if required 100 N16 top course only 55 cover N12 @ 400 crs 290 190

2.5 kPa surcharge up to 1.5m 5.0 kPa surcharge over 1.5m

55 cover N16 top course only Note: All cores fully grouted 700 lap

X-bars Y-bars 55 cover Cleanout Block

X-bars

500 lap

N12 @ 400 crs

Y-bars with 55 cover 100 200 H N16 @ 300 crs B Y-bars 55 cover N16 @ 400 crs X-bars 10.31 Capping Tile if required 2.5 kPa surcharge up to 1.5m 5.0 kPa surcharge over 1.5m 100 Cleanout Block Y-bars 55 cover to top of Y-bars

Note: All cores fully grouted

Walls over 1.2m and up to 1.8m high

700 lap

240

Y-bars with 55 cover

190 100

350

D N16 top course only 55 cover

N16 @ 300 crs

W B

X-bars H Y-bars 700 lap N12 @ 400 crs 55 cover Cleanout Block Y-bars with 55 cover 100 250 D N16 @ 300 crs

Note: All cores fully grouted

W B Note: Diagrams not to scale

Wall Type 1

09

1.13.3 Base and Key Sizes

Base width B Surface slope Wall height H 2.5 kPa surcharge 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Notes: 1. 2. 3. 4. 5.

Key width W

Key depth D

Surface slope Up to 1 in 4 with Up to 1 in 4 with 5.0 kPa surcharge 200 200 300 300 300 300 300 300 200 250 250 300 300 350 350 400

Level with 5.0 kPa surcharge 1300 1450 1650 1800 2000 2100 2250 2450

2.5 kPa surcharge 700 800 1000 1200 1400 -

5.0 kPa surcharge 1800 2200 2400 2700 2900 3200 3400 3700

500 600 700 850 1000 -

No key required for level surface slope walls. All dimensions in millimeters. 300mm of soil or a private driveway imposes a surcharge load of approximately 5 kPa. 2.5 kPa surcharge applies up to 1.5m. 5.0 kPa surcharge applies over 1.5m.

1.13.4 Reinforcement Details

Wall height Total wall height H Height of 150 series block 600 800 1000 1200 Height of 200 series block 1400 1600 1800 1800 1800 1800 1800 1800 1800 Height of 300 series block 200 400 600 800 1000 1200 Surface slope Level X-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 N16 1:4 X-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 N16 Reinforcement Surface slope Level Y-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 @ 200 N16 @ 200 1:4 Y-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 @ 200 N16 @ 200

600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Notes:

1. All bars are to be at 400mm centres unless otherwise stated. 2. All bars to have 55mm cover from outside concrete surface. 3. All dimensions in millimeters.

Wall Type 1

10

1.14 Design Details for Wall Type 2

1.14.1 Level Surface Wall Layout

Walls up to 1.2m high Walls over 1.8m and up to 3.0m high

75.10 Capping Tile if required 100

190 10.31 Capping Tile if required 100

340 290 190 2.5 kPa surcharge up to 1.5m 5.0 kPa surcharge over 1.5m

140

2.5 kPa surcharge

N16 top course only 55 cover N12 @ 400 crs H X-bars Note: All cores fully grouted 700 lap

55 cover N16 top course only

N12 @ 400 crs X-bars Note: All cores fully grouted

500 lap

Y-bars 55 cover Cleanout Block

100 200

SL72 Mesh 55 cover to top of Y-bars H Y-bars with 55 cover Y-bars 55 cover B W Y-bars 55 cover N16 @ 400 crs 700 lap X-bars 240 2.5 kPa surcharge up to 1.5m 190 5.0 kPa surcharge over 1.5m 350 100 Cleanout Block SL72 mesh

N16 @ 300 crs

Walls over 1.2m and up to 1.8m high

10.31 Capping Tile if required 100

D N16 top course only 55 cover 55 cover X-bars H Note: All cores fully grouted

N16 @ 300 crs

Y-bars with 55 cover W

N12 @ 400 crs 700 lap Y-bars 55 cover Cleanout Block

100 250 D

SL72 mesh

N16 @ 300 crs 55 cover B W

Y-bars with 55 cover

Note: Diagrams not to scale

Wall Type 2

11

1.14.2 Sloping Surface up to 1 in 4 Wall Layout

Walls up to 1.2m high Walls over 1.8m and up to 3.0m high

75.10 Capping Tile if required 100

190 2.5 kPa surcharge 10.31 Capping Tile if required 100 N16 top course only 55 cover N12 @ 400 crs

340 290 190

2.5 kPa surcharge up to 1.5m 5.0 kPa surcharge over 1.5m

140

55 cover N16 top course only Note: All cores fully grouted

X-bars

500 lap

Y-bars 55 cover

Note: All cores fully grouted

X-bars 700 lap

Cleanout Block 100 200 D Y-bars with 55 cover W H SL72 Mesh

N12 @ 400 crs

55 cover to top of Y-bars

N16 @ 300 crs 55 cover B

Y-bars Y-bars 55 cover N16 @ 400 crs 700 lap X-bars 2.5 kPa surcharge up to 1.5m 5.0 kPa surcharge over 1.5m 350 100 Cleanout Block

Walls over 1.2m and up to 1.8m high

10.31 Capping Tile if required 100

240

190

SL72 mesh

D N16 top course only 55 cover 55 cover

N16 @ 300 crs

Y-bars with 55 cover W

B X-bars H Note: All cores fully grouted

700 lap

N12 @ 400 crs Y-bars 55 cover Cleanout Block

100 250 D N16 @ 300 crs 55 cover W B

SL72 mesh

Y-bars with 55 cover

Note: Diagrams not to scale

Wall Type 2

12

1.14.3 Base and Key Sizes

Base width B Surface slope Wall height H 2.5 kPa surcharge 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Notes: 1. 2. 3. 4.

Key width W

Key depth D

Surface slope Up to 1 in 4 with

Level with 5.0 kPa surcharge 1600 1900 2000 2200 2400 2700 2900 3100

2.5 kPa surcharge 700 900 1100 1400 1500 -

5.0 kPa surcharge 2200 2400 2600 2900 3200 3500 3700 4000

Level

1 in 4

Level

1 in 4

500 800 800 1000 1100 -

150 200 200 350 400 400 500 550 600 600 700

150 150 200 300 350 500 550 550 600 700 750 800 900

200 300 300 500 600 600 700 800 900 900 1000

100 200 300 400 500 700 800 800 900 1000 1100 1200 1300

All dimensions in millimeters. 300mm of soil or a private driveway imposes a surcharge load of approximately 5 kPa. 2.5 kPa surcharge applies up to 1.5m. 5.0 kPa surcharge applies over 1.5m.

1.14.3 Reinforcement Details

Wall height Total wall height H Height of 150 series block 600 800 1000 1200 Height of 200 series block 1400 1600 1800 1800 1800 1800 1800 1800 1800 Height of 300 series block 200 400 600 800 1000 1200 Surface slope Level X-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 N16 1:4 X-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 N16 Reinforcement Surface slope Level Y-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 @ 200 N16 @ 200 1:4 Y-bar N12 N12 N12 N12 N16 N16 N16 N16 N16 N16 N16 N16 @ 200 N16 @ 200

600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000

Notes:

1. All bars are to be at 400mm centres unless otherwise stated. 2. All bars to have 55mm cover from outside concrete surface. 3. All dimensions in millimeters.

Wall Type 2

13

2.0 Basement Walls

2.1 General

The foundation slab of a basement can be modified to provide an efficient footing for a retaining wall. In addition, a concrete floor slab will provide a prop to the top of the wall, simplifying the wall details compared to a timber floor. All infill materials must be with granular material. Details of typical basement walls are shown in the following figures.

2.2 Drainage

As with all retaining walls it is critical that the soil is prevented from becoming saturated. Steps to be taken to achieve this include: A drainage system within the soil. This should preferably take the form of a 300 mm width of gravel immediately behind the wall with a continuous agricultural pipe located at the base of the wall. The pipe must discharge beyond the ends of the wall. Sealing the soil surface. This can be done by placing a compacted layer of low-permeability material over the soil and sloping the surface away from the house. It is also important to prevent hydrostatic pressure under the floor slab. Where there is the possibility of groundwater under the slab, then a subfloor drainage system is advisable.

2.3 Tanking

Where it is required that the basement be kept dry, a proper tanking system needs to be installed behind the wall before backfilling (refer Chapter 10). An alternative to this is to provide a drain and a false wall in front of the wall (refer alternative detail).

2.4 How to Build the Wall

Building a Basement wall is essentially the same as building a retaining wall. Please refer to section 1.10 for details on how to build a basement wall.

2.5 Basement Walls

Unpropped or partially propped wall Basement walls up to 2.7m high. Propped wall

Timber floor

Concrete floor

45 Infill soil Drainage layer Infill soil

45

Reinforced block stem

Reinforced block stem

Drainage layer Retained soil

Basement

Retained soil Basement

Base

Drain

Base

Drain

Note: Diagrams not to scale

14

2.6 BESSER Block Basement Wall Design Details For Supporting a Concrete Wall

Typical details - Fully-propped walls Alternative details

Starter bar to match wall reinforcement above One-course bond beam with N12 bar 20.20 knock-out block saw-cut at floor soffit level

Floor slab reinforcement

N12 at 200 crs

20.48 H blocks

Horizontal reinforcement N12 at 400 crs Tanking to back face of wall

2700 max. 190 thick blockwork Vertical reinforcement N16 at 400 crs, central

Note: Wall blocks and reinforcement as for Typical Details - fully propped walls

Note: N12 at 200 crs may be used instead of N16 at 400 crs

Note: No tanking required

False wall Ag. drain Floor slab reinforcement N16 at 400 crs Drained cavity Ag. drain 200 200 N12 at 400 crs 55 cover 1000

2.7 BESSER Block Basement Wall Design Details For Supporting a Timber Floor

Typical details - Unpropped or partially-propped walls Alternative details

Timber floor

140-thick blockwork

Timber floor One-course bond beam using 20.20 knock-out block with 1-N12 bar Pole plate fixed to bond beam Vertical reinforcement N16 at 400 crs, central Horizontal reinforcement N12 at 400 crs 55 cover to back face

190-thick blockwork

20.48 H blocks

2700 max. to ground level

190 thick blockwork

Note: Reinforcement as for Typical Details

290-thick blockwork

290 thick blockwork

Tanking to back face of wall

55 cover to back face

Note: N20 at 400 crs may be used instead of N16 at 200 crs

1200 30.48 H blocks Floor slab reinforcement N16 at 200 crs 300 N12 at 400 crs 1500 Ag. drain

False wall

Note: No tanking required

Drained cavity Ag. drain

300

55 cover

Note: Diagrams not to scale

Glossary

2.8 Basement Walls

These designs are based on a level surface with 5 kPa surcharge. Walls designed as propped must not be backfilled before the concrete floor at the top of the wall is in place.

Load and Limit States:

Dead load* The self-weight of the structure, infill soil, retained soil or rock. Live load* Loads that arise from the intended use of the structure, including distributed, concentrated, impact and inertia loads. It includes construction loads, but excludes wind and earthquake loads. Surcharge A uniformaly distributed external load. For retaining walls under 1.5m a minimum load of 2.5 kPa. For retaining walls over 1.5m a minimum load of 5 kPa. Stability limit state A limit state of loss of static equilibrium of a structure or part thereof, when considered as a rigid body. Strength limit state A limit state of collapse or loss of structural integrity of the components of the retaining wall. Serviceability limit state A limit state for acceptable in-service conditions. The most common serviceability states are excessive differential settlement and forward movement of the retaining wall.

Important Notes

No loadings should be applied (e.g. from footings), within the area of infill soil other than those loadings referred to above. The area of infill soil is bounded by a line at 45 to the rear of the base as illustrated in chapter 1. Only one typical soil case is presented. These tables may not provide an ideal solution in a particular case. For situations other than those covered by the tables, or if there is doubt as to: The strength and stability of the foundation material the drainage system needed An experienced professional engineer should be consulted for advice.

Components:

Concrete masonry units Concrete blocks manufactured to provide an attractive, durable, stable face to a retaining wall. The recommended block types are the 15.48, 20.48 and 30.48 H blocks. Retained soil The natural soil, intended to be retained by a retaining wall. Foundation soil The natural soil material under a retaining wall. Infill soil The soil material placed behind the retaining wall facing. Often retained soil is used for this purpose.

* This brochure uses the terminology dead load to indicate permanent loads and live load to indicate imposed loads. This terminology is consistent with the convention adopted in AS 4678-2002.

Adbri Masonry Reinfroced BESSER Block Retaining Walls 1st Edition Apr 2009 - Adbri Masonry Pty Ltd

Landscape Solutions: AB.RBBRWD0109 BESSER is a trade mark of Adbri Masonry Pty Ltd or its related entities. Adbri Masonry is Australias largest supplier of quality masonry products. Adbri Masonry manufactures a large range of concrete products such as; bricks, block and architectural coloured block, decorative wall claddings, retaining wall systems, concrete and wetcast pavers as well as an exceptional range of environmental products. These products are used in many large scale civil projects as well as in thousands of backyards throughout Australia. Adbri Masonry is a wholly owned subsidiary of Adelaide Brighton Ltd, a top 200 ASX listed public company. Adbri Masonry was formed in July 2008, bringing together two reputable brands, C&M Brick and Hanson Building Products. Both Hanson Masonry and C&M Brick boast proud histories and both have been foundation companies whose products have helped to build the face of the Australia we now know. From Hanson pavers in Cairns Airport to C&M Bricks paving in the Homebush Olympic village, many of Australias iconic projects have utilised the quality products from these two trusted companies. For further advice, talk to your local Adbri Masonry Landscaping Solutions Specialist.

For more information call: 1300 365 565 Adbri Masonry Pty Ltd ABN: 31 009 687 521

www.adbrimasonry.com.au

Você também pode gostar

- Brick Veneer/Concrete Masonry Walls: Technical Notes 28DDocumento19 páginasBrick Veneer/Concrete Masonry Walls: Technical Notes 28DKen SuAinda não há avaliações

- 29.moisture BarriersDocumento31 páginas29.moisture BarriersraviciviltAinda não há avaliações

- Tek 14-08BDocumento14 páginasTek 14-08BMuhammad ImranAinda não há avaliações

- CONCRETE SUPPLIESDocumento8 páginasCONCRETE SUPPLIESSherazAinda não há avaliações

- Post-Installed Rebar.: in Compliance With AS 3600-2009Documento38 páginasPost-Installed Rebar.: in Compliance With AS 3600-2009caner_kurtoglu-1Ainda não há avaliações

- Bridge Types and StructuresDocumento55 páginasBridge Types and StructuresRuben MunteanuAinda não há avaliações

- Retrofitting of Columns by Steel Jackets-8cccDocumento7 páginasRetrofitting of Columns by Steel Jackets-8cccsecond2nonnAinda não há avaliações

- Technical Data Sheet For Post-Installed Rebar Technical Information ASSET DOC 2331222Documento39 páginasTechnical Data Sheet For Post-Installed Rebar Technical Information ASSET DOC 2331222Nyan OoAinda não há avaliações

- Construction Joints: 1:3 SlopeDocumento13 páginasConstruction Joints: 1:3 Slopecharles_hutabarat_2007Ainda não há avaliações

- Welcome To The Presentation On "One Way Slab Design: Md. Asif Rahman 10.01.03.108 Dept. of CeDocumento29 páginasWelcome To The Presentation On "One Way Slab Design: Md. Asif Rahman 10.01.03.108 Dept. of CeadnanAinda não há avaliações

- Sika & Tricosal WaterstopsDocumento52 páginasSika & Tricosal WaterstopsJoAinda não há avaliações

- Ces 3 Reinforced Concrete Design Bond, Development Lengths, and SplicesDocumento10 páginasCes 3 Reinforced Concrete Design Bond, Development Lengths, and SplicesInglis, Carell Erica P.Ainda não há avaliações

- Underwater Concrete Anti-Washout AdmixturesDocumento10 páginasUnderwater Concrete Anti-Washout AdmixturesAhmed MohammedAinda não há avaliações

- AWC NDS2015 Commentary PrintableDocumento107 páginasAWC NDS2015 Commentary PrintableTerry TriestAinda não há avaliações

- Understanding Steel Fiber Reinforced ConcreteDocumento87 páginasUnderstanding Steel Fiber Reinforced ConcreteHardiantoAinda não há avaliações

- BCM - Unit 4 - PadDocumento79 páginasBCM - Unit 4 - PadPallavi DeotaleAinda não há avaliações

- 2000 - Novo Esquema de Design - Elimination of Flat Plate Punching Failure Mode - BromsDocumento8 páginas2000 - Novo Esquema de Design - Elimination of Flat Plate Punching Failure Mode - BromswhitepeteAinda não há avaliações

- Staircases: Download Civil Engineering EbookDocumento38 páginasStaircases: Download Civil Engineering EbookYudirwan TanjungAinda não há avaliações

- A 949 - A 949M - 01 Qtk0os9botq5tqDocumento4 páginasA 949 - A 949M - 01 Qtk0os9botq5tqsachinguptachdAinda não há avaliações

- Analysis and Design of Circular Prestressed Concrete Storage TanksDocumento22 páginasAnalysis and Design of Circular Prestressed Concrete Storage Tankschondroc11Ainda não há avaliações

- PDFsam TMPbuffer HRHPR1Documento58 páginasPDFsam TMPbuffer HRHPR1ryan rakhmat setiadiAinda não há avaliações

- Shapes and Sizes of Web Opening Effects On Bending Behaviour of I-Beam With Web OpeningDocumento9 páginasShapes and Sizes of Web Opening Effects On Bending Behaviour of I-Beam With Web OpeningKousalya MkAinda não há avaliações

- Chapter-1 Door and WindowsDocumento66 páginasChapter-1 Door and WindowsDawit TesfayAinda não há avaliações

- 21castellated Steel BeamDocumento11 páginas21castellated Steel BeamHozaifaAinda não há avaliações

- Ardex Tiling Systems PDFDocumento76 páginasArdex Tiling Systems PDFjoe briffaAinda não há avaliações

- Elastomeric Bearings: Background Information and Field StudyDocumento106 páginasElastomeric Bearings: Background Information and Field StudyBahram HabibiAinda não há avaliações

- Rail-Steel and Axle-Steel Deformed Bars For Concrete ReinforcementDocumento5 páginasRail-Steel and Axle-Steel Deformed Bars For Concrete ReinforcementWashington JorgeAinda não há avaliações

- Cost-Effective Inspection of Rebar Spacing and Cle-BolehDocumento17 páginasCost-Effective Inspection of Rebar Spacing and Cle-BolehAlfadinAzzahrawaaniElNauvalAinda não há avaliações

- NDS Drainage Catalog Apr 2010Documento52 páginasNDS Drainage Catalog Apr 2010Jason BrownAinda não há avaliações

- Edge-Supported Two-Way Slabs AnalysisDocumento11 páginasEdge-Supported Two-Way Slabs AnalysisGirma FikreAinda não há avaliações

- Plate Dowels: An Innovation Driven by Industrial Concrete PavingDocumento6 páginasPlate Dowels: An Innovation Driven by Industrial Concrete PavingRizaam Nafiz100% (1)

- The Study of The Effects of Web Openings On The Concrete BeamsDocumento10 páginasThe Study of The Effects of Web Openings On The Concrete BeamsChetan ToliaAinda não há avaliações

- HEC 20 HydrologyDocumento193 páginasHEC 20 Hydrologycarmona.eitAinda não há avaliações

- Captura de Tela 2023-06-07 À(s) 16.30.51Documento6 páginasCaptura de Tela 2023-06-07 À(s) 16.30.51Gon FreecsAinda não há avaliações

- Investigation of The Oppening Effects On The Behavior of Concrete Beams Without Additional Reinforcement in Opening Region Using Fem MethodDocumento12 páginasInvestigation of The Oppening Effects On The Behavior of Concrete Beams Without Additional Reinforcement in Opening Region Using Fem MethodHamza MsatatAinda não há avaliações

- Survey II: Control Surveying MethodsDocumento99 páginasSurvey II: Control Surveying MethodsMigaeaAinda não há avaliações

- Metal WindowsDocumento21 páginasMetal Windowsshubhankar mishraAinda não há avaliações

- Jurutera April 2013Documento56 páginasJurutera April 2013adzhouAinda não há avaliações

- 10.1016 J.jue.2007.08.004 A Game Theoretic Analysis of SkyscrapersDocumento16 páginas10.1016 J.jue.2007.08.004 A Game Theoretic Analysis of SkyscrapersAr SoniAinda não há avaliações

- Strengthening On RC SlabsDocumento16 páginasStrengthening On RC SlabsHarshAinda não há avaliações

- Geodetic Leveling: Manual NOS NGS 3Documento162 páginasGeodetic Leveling: Manual NOS NGS 3HazelMaeJoseRicoAinda não há avaliações

- Analysis of Wooden Curved Beams Using SCAD OfficeDocumento64 páginasAnalysis of Wooden Curved Beams Using SCAD OfficeJoão DiasAinda não há avaliações

- BadmintonDocumento45 páginasBadmintonRose ObnialaAinda não há avaliações

- AWC SDPWS2015 Commentary PrintableDocumento52 páginasAWC SDPWS2015 Commentary PrintableTerry TriestAinda não há avaliações

- Nonlinear Dynamics of Discrete and Continuous Systems: Andrei K. Abramian Igor V. Andrianov Valery A. Gaiko EditorsDocumento284 páginasNonlinear Dynamics of Discrete and Continuous Systems: Andrei K. Abramian Igor V. Andrianov Valery A. Gaiko EditorsFlávio AugustoAinda não há avaliações

- Numerical Study of R.C. Beams Strengthening by External Steel PlateDocumento9 páginasNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALAinda não há avaliações

- Leveling Explained: Measure Heights and ElevationsDocumento110 páginasLeveling Explained: Measure Heights and ElevationsIsmael Wael SobohAinda não há avaliações

- Hybrid Paper 2Documento222 páginasHybrid Paper 2prabindp100% (1)

- Basic Skills in Badminton Group 2Documento46 páginasBasic Skills in Badminton Group 2alexandravisteriaAinda não há avaliações

- UNIT 2 SurveyingDocumento217 páginasUNIT 2 SurveyingSHAIK MURTHUJAVALIAinda não há avaliações

- Infiltration Characteristics, Performance, and Design of Storm Water FacilitiesDocumento48 páginasInfiltration Characteristics, Performance, and Design of Storm Water FacilitiesDavidAinda não há avaliações

- Motion Based Seismic Design and Loss Estimation of Diagrid StructuresDocumento83 páginasMotion Based Seismic Design and Loss Estimation of Diagrid StructuresSaba 2413Ainda não há avaliações

- Bending of Plates - Wikipedia, The Free EncyclopediaDocumento11 páginasBending of Plates - Wikipedia, The Free Encyclopediaakhilesh120Ainda não há avaliações

- Warping Displacement of Skew Box Girder BridgesDocumento9 páginasWarping Displacement of Skew Box Girder BridgesmasterumAinda não há avaliações

- Structural Analysis and Design of Long Span Suspension Bridges With Regards To Nonlinearities, Uncertainties, Interactions and SustainabilityDocumento9 páginasStructural Analysis and Design of Long Span Suspension Bridges With Regards To Nonlinearities, Uncertainties, Interactions and SustainabilityArunesh AzadAinda não há avaliações

- Structures Detailing Manual: Florida Department of TransportationDocumento327 páginasStructures Detailing Manual: Florida Department of TransportationmirzaAinda não há avaliações

- FR 491Documento126 páginasFR 491RAJENDRA PRASADAinda não há avaliações

- Besser block retaining wallsDocumento16 páginasBesser block retaining wallsSergio MarkAinda não há avaliações

- Reinforced BESSERTM Block Retaining and Basement Wall GuideDocumento16 páginasReinforced BESSERTM Block Retaining and Basement Wall GuideA NT LeilyAinda não há avaliações

- ECE 2101 ENGINEERING DRAWING II Notes pt3Documento11 páginasECE 2101 ENGINEERING DRAWING II Notes pt3John Ng'ang'aAinda não há avaliações

- Ijciet 09 02 089Documento8 páginasIjciet 09 02 089Xahid UsmanAinda não há avaliações

- Marker Post Installation JSADocumento10 páginasMarker Post Installation JSAShahid BhattiAinda não há avaliações

- Non-Loadbearing TimberDocumento13 páginasNon-Loadbearing TimberSanjay KumarAinda não há avaliações

- CE DRAWING TITLEDocumento54 páginasCE DRAWING TITLEgeos100189% (9)

- 04 Kemcure WDocumento2 páginas04 Kemcure WMohamed Osama AshmawyAinda não há avaliações

- Install MCC Method StatementDocumento59 páginasInstall MCC Method StatementDawoodAinda não há avaliações

- CPCCBC5004A Student Assessment Task 2B - Word - LockDocumento3 páginasCPCCBC5004A Student Assessment Task 2B - Word - LockShah ZeeshanAinda não há avaliações

- Dream House Writing StrategiesDocumento26 páginasDream House Writing StrategiesAngela MariaAinda não há avaliações

- Spec 079219 - Acoustical Joint SealantsDocumento5 páginasSpec 079219 - Acoustical Joint Sealantsداروین پرزAinda não há avaliações

- Tos Assignment No 3Documento22 páginasTos Assignment No 3Daljeet ThethiAinda não há avaliações

- MEETING POINT 2-Layout1Documento1 páginaMEETING POINT 2-Layout1Tri AriantoAinda não há avaliações

- MEP Grouping: 1st, 2nd & Final Fix WorksDocumento2 páginasMEP Grouping: 1st, 2nd & Final Fix WorksVelmurugan SelvanAinda não há avaliações

- Design and Construction of Skyscraper: Fig 1. Burj KhalifaDocumento19 páginasDesign and Construction of Skyscraper: Fig 1. Burj Khalifaವಿನಯ್ ಎಮ್. ಆರ್100% (1)

- Week 5 To 6 Lecture - Walls and PartitionsDocumento120 páginasWeek 5 To 6 Lecture - Walls and PartitionsPeng XunAinda não há avaliações

- Gyproc - Product GuideDocumento8 páginasGyproc - Product Guidereyl espirituosoAinda não há avaliações

- Nomenclature (Peb)Documento4 páginasNomenclature (Peb)Santhosh ChandramAinda não há avaliações

- LONG SPAN ROOFS: Steel Trusses: MMBC V SEM 2020 Online SessionDocumento62 páginasLONG SPAN ROOFS: Steel Trusses: MMBC V SEM 2020 Online SessionPrajna R SimhaAinda não há avaliações

- Final - Inspection Report - Fog HornDocumento16 páginasFinal - Inspection Report - Fog HornmillimeterAinda não há avaliações

- Marine Tools and Equipments On BoardDocumento8 páginasMarine Tools and Equipments On BoardIsea MarineAinda não há avaliações

- Estimating Architectural Materials and FinishesDocumento3 páginasEstimating Architectural Materials and FinishesHana YeppeodaAinda não há avaliações

- 6 List of Supplier (1-28)Documento6 páginas6 List of Supplier (1-28)Joseph IngramAinda não há avaliações

- Forms, Scaffolding and StagingDocumento39 páginasForms, Scaffolding and StagingKemuel TabamoAinda não há avaliações

- IspeesifikeeshiniiDocumento28 páginasIspeesifikeeshiniisolomonAinda não há avaliações

- June 2023 HeraldDocumento45 páginasJune 2023 HeraldHighland Lakes CondominiumsAinda não há avaliações

- Liapor - Lagani BetonDocumento8 páginasLiapor - Lagani BetonNenadAinda não há avaliações

- 699752.construction Materials Roadmap For Research and DevelopmentDocumento22 páginas699752.construction Materials Roadmap For Research and DevelopmentFarjallah Al-AssãadAinda não há avaliações

- How To Calculate Fastener PulloutDocumento6 páginasHow To Calculate Fastener PulloutCarlos SilvaAinda não há avaliações

- Structured PackingDocumento8 páginasStructured Packingtarangx12100% (1)

- PWD Schedule of Rates for Civil Works 10th EditionDocumento87 páginasPWD Schedule of Rates for Civil Works 10th EditionQamrul HasanAinda não há avaliações