Escolar Documentos

Profissional Documentos

Cultura Documentos

7075

Enviado por

andrewromeoDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

7075

Enviado por

andrewromeoDireitos autorais:

Formatos disponíveis

MatWeb, The Online Materials Database

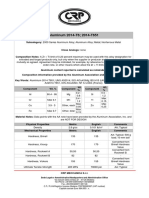

Aluminum 7075-T6; 7075-T651

Subcategory: 7000 Series Aluminum Alloy; Aluminum Alloy; Metal; Nonferrous Metal Close Analogs: Composition Notes: A Zr + Ti limit of 0.25 percent maximum may be used with this alloy designation for extruded and forged products only, but only when the supplier or producer and the purchaser have mutually so agreed. Agreement may be indicated, for example, by reference to a standard, by letter, by order note, or other means which allow the Zr + Ti limit. Aluminum content reported is calculated as remainder. Composition information provided by the Aluminum Association and is not for design. Key Words: Aluminium 7075-T6; Aluminium 7075-T651, UNS A97075; ISO AlZn5.5MgCu; Aluminium 7075-T6; Aluminium 7075-T651; AA7075T6

Component Al Cr Cu Fe Wt. % 87.1 - 91.4 0.18 - 0.28 1.2 - 2 Max 0.5 Component Mg Mn Other, each Other, total Wt. % 2.1 - 2.9 Max 0.3 Max 0.05 Max 0.15 Component Si Ti Zn Wt. % Max 0.4 Max 0.2 5.1 - 6.1

Material Notes:

General 7075 characteristics and uses (from Alcoa): Very high strength material used for highly stressed structural parts. The T7351 temper offers improved stress-corrosion cracking resistance.

Applications: Aircraft fittings, gears and shafts, fuse parts, meter shafts and gears, missile parts, regulating valve parts, worm gears, keys, aircraft, aerospace and defense applications; bike frames, all terrain vehicle (ATV) sprockets.

Data points with the AA note have been provided by the Aluminum Association, Inc. and are NOT FOR DESIGN.

Physical Properties Density Metric 2.81g/cc Mechanical Properties Hardness, Brinell Hardness, Knoop Hardness, Rockwell A Hardness, Rockwell B Hardness, Vickers Ultimate Tensile Strength Tensile Yield Strength Elongation at Break Elongation at Break Modulus of Elasticity Poisson's Ratio Fatigue Strength Fracture Toughness Fracture Toughness Fracture Toughness Machinability Shear Modulus Shear Strength 150 191 53,50 87 175 572MPa 503MPa 11% 11% 71.7GPa 0.33 159MPa 20MPa-m 25MPa-m 29MPa-m 70% 26.9GPa 331MPa Electrical Properties Electrical Resistivity 5.15e-006ohm-cm 5.15e-006ohm-cm Thermal Properties CTE, linear 68F CTE, linear 250C Specific Heat Capacity Thermal Conductivity 23.6m/m-C 25.2m/m-C 0.96J/g-C 130W/m-K 13.1in/in-F 14in/in-F 0.229BTU/lb-F 900BTU-in/hr-ft-F 150 191 53,50 87 175 83000psi 73000psi 11% 11% 10400ksi 0.33 23000psi 18.2ksi-in 22.8ksi-in 26.4ksi-in 70% 3900ksi 48000psi English 0.102lb/in Comments

AA; Typical

AA; Typical; 500 g load; 10 mm ball Converted from Brinell Hardness Value Converted from Brinell Hardness Value Converted from Brinell Hardness Value Converted from Brinell Hardness Value AA; Typical AA; Typical AA; Typical; 1/16 in. (1.6 mm) Thickness AA; Typical; 1/2 in. (12.7 mm) Diameter AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. AA; 500,000,000 cycles completely reversed stress;

RR Moore machine/specimen

K(IC) in S-L Direction K(IC) in T-L Direction K(IC) in L-T Direction 0-100 Scale of Aluminum Alloys AA; Typical

AA; Typical at 68F

AA; Typical; Average over 68-212F range. Average over the range 20-300C AA; Typical at 77F AA; Typical range based on typical composition for

wrought products 1/4 inch thickness or greater. Homogenization may raise eutectic melting temperature 20-40F but usually does not eliminate eutectic melting.

Melting Point

477 - 635C

890 - 1175F

Solidus Liquidus

477C 635C Processing Properties

890F 1175F

AA; Typical AA; Typical

Annealing Temperature Solution Temperature Aging Temperature

413C 466 - 482C 121C

775F 870 - 900F 250F

References are available for this material.

Copyright 1996-2004 by Automation Creations, Inc. The information provided by MatWeb is intended for personal, non-commercial use.The contents, results, and technical data from this site may not be reproduced either electronically, photographically or substantively without permission from Automation Creations, Inc. No warranty, neither expressed nor implied, is given regarding the accuracy of this information. The user assumes all risk and liability in connection with the use of information from MatWeb.

Você também pode gostar

- Aluminum 2014-T6 Alloy Data SheetDocumento3 páginasAluminum 2014-T6 Alloy Data SheetPrashanthAinda não há avaliações

- Aluminum 7075 Alloy Material Data SheetDocumento2 páginasAluminum 7075 Alloy Material Data Sheetadam.el.polaco7881Ainda não há avaliações

- Aluminum6061DataSheet PDFDocumento2 páginasAluminum6061DataSheet PDFhardik033Ainda não há avaliações

- AL7075T6Documento3 páginasAL7075T6Mohamad Shafiq Ali Mohamed Hassan AliAinda não há avaliações

- Aluminium 7075 t6 7075 t651 PDFDocumento3 páginasAluminium 7075 t6 7075 t651 PDFmenosoftAinda não há avaliações

- 6061 T6 MaterialDocumento2 páginas6061 T6 Materialtravis8zimmermannAinda não há avaliações

- ChithirangaDocumento34 páginasChithirangaP.ArunadeviAinda não há avaliações

- Aluminum 6061 Alloy Material Data SheetDocumento2 páginasAluminum 6061 Alloy Material Data SheetDimazNugraha100% (1)

- Aluminum 7075 SpecsDocumento3 páginasAluminum 7075 SpecsZakaria MuhammadAinda não há avaliações

- ASM Material Data Sheet PDFDocumento2 páginasASM Material Data Sheet PDFanne smithAinda não há avaliações

- Aluminum 6351-T6 6351-T651Documento2 páginasAluminum 6351-T6 6351-T651Mathi Engineers And Builders Private LimitedAinda não há avaliações

- 2024-T3 ASM Material Data Sheet PDFDocumento2 páginas2024-T3 ASM Material Data Sheet PDFAnonymous mq0U43UsPAinda não há avaliações

- Aluminium 2014 t6 2014 t651 PDFDocumento3 páginasAluminium 2014 t6 2014 t651 PDFAbhishek AnandAinda não há avaliações

- Task Report of ARB Blade (Fikan Mubarok R)Documento9 páginasTask Report of ARB Blade (Fikan Mubarok R)fikan mubarokAinda não há avaliações

- Aluminum 2024-O Data SheetDocumento2 páginasAluminum 2024-O Data SheetAnonymous mq0U43UsPAinda não há avaliações

- Matweb:, The Online Materials Database Aluminum 6201-T6Documento2 páginasMatweb:, The Online Materials Database Aluminum 6201-T6Raj PrasanthAinda não há avaliações

- Aluminum 3003 H14Documento2 páginasAluminum 3003 H14mercab15100% (1)

- Aluminum 7175 T736Documento3 páginasAluminum 7175 T736TylerLALA100% (1)

- Aluminum 6351-T6, Aluminium DatasheetDocumento2 páginasAluminum 6351-T6, Aluminium DatasheetvikrantAinda não há avaliações

- Cold Drawn PDFDocumento1 páginaCold Drawn PDFAna Emily PrentissAinda não há avaliações

- Aluminum 5052Documento6 páginasAluminum 5052lalfredoperezAinda não há avaliações

- Aluminum 7005-T6, 7005-T63, and 7005-T6351Documento3 páginasAluminum 7005-T6, 7005-T63, and 7005-T6351Dule JovanovicAinda não há avaliações

- Aluminum 2024 T851Documento2 páginasAluminum 2024 T851Zakaria MuhammadAinda não há avaliações

- Aluminum 6061 T6Documento1 páginaAluminum 6061 T6travis8zimmermannAinda não há avaliações

- Sae 5160 VBDocumento2 páginasSae 5160 VBBarron ValentinAinda não há avaliações

- Aluminio 3105 H16Documento2 páginasAluminio 3105 H16Cesar Zarate100% (1)

- AISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessDocumento2 páginasAISI 1012 Steel, Cold Drawn Bar, 19-32 MM (0.75-1.25 In) Round or ThicknessdavmedclAinda não há avaliações

- Bronze c54400 SpecificationsDocumento3 páginasBronze c54400 SpecificationsRam Parimalam100% (1)

- MaterialData 6937Documento1 páginaMaterialData 6937Cristobal Gutierrez CarrascoAinda não há avaliações

- AISI 1050 Steel, As RolledDocumento2 páginasAISI 1050 Steel, As RolledCristobal Gutierrez CarrascoAinda não há avaliações

- Aluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloyDocumento3 páginasAluminum 6061-T6 6061-T651: Metal Nonferrous Metal Aluminum Alloy 6000 Series Aluminum AlloySaad SaudAinda não há avaliações

- Al 7075 T651Documento2 páginasAl 7075 T651Michael HarrellAinda não há avaliações

- Titanium alloy propertiesDocumento3 páginasTitanium alloy propertiesMarcionilo NeriAinda não há avaliações

- Astm A572 Steel, Grade 50 DurezaDocumento1 páginaAstm A572 Steel, Grade 50 DurezaMaikol Chino100% (1)

- AISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) TemperDocumento1 páginaAISI 4620 Steel, Direct Quench From Pot, Carburized, Oil Quenched, 150°C (300°F) Temperapurv bhartiAinda não há avaliações

- Mil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322Documento2 páginasMil-Spec Mil-S-6049, Sae J404, Sae J412, Sae J770, Uns G87400, Ams 6322, Ams 6323, Ams 6325, Ams 6327, Ams 6358, Astm A322FlavioAinda não há avaliações

- AISI 4340 Steel properties and usesDocumento2 páginasAISI 4340 Steel properties and usesJoko TriwardonoAinda não há avaliações

- S 45 CDocumento1 páginaS 45 CFahmi IrmanshahAinda não há avaliações

- AISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1Documento2 páginasAISI 1141 Steel, Hot Rolled, 19-32 MM (0.75-1PrasadAinda não há avaliações

- Aluminium A380Documento1 páginaAluminium A380Ashokkumar VelloreAinda não há avaliações

- (Discontinued ) : ASTM A353 Alloy SteelDocumento1 página(Discontinued ) : ASTM A353 Alloy SteelDhanyajaAinda não há avaliações

- A21 Ex Rect eDocumento1 páginaA21 Ex Rect ededosimoesAinda não há avaliações

- ASTM A516 Carbon Steel, Grade 70 Material PropertiesDocumento1 páginaASTM A516 Carbon Steel, Grade 70 Material Propertiesdeyanshu7Ainda não há avaliações

- 4130 Data SheetDocumento1 página4130 Data SheetcarlottiAinda não há avaliações

- Aisi 1030 SteelDocumento2 páginasAisi 1030 SteelKhairul KaiAinda não há avaliações

- ASTM A202 Low Alloy Steel PropertiesDocumento1 páginaASTM A202 Low Alloy Steel PropertiesDhanyajaAinda não há avaliações

- Aluminum 6063Documento2 páginasAluminum 6063Laurence SarmientoAinda não há avaliações

- AISI 1010 steel bar properties and dataDocumento2 páginasAISI 1010 steel bar properties and dataIan KellyAinda não há avaliações

- ASM Material Data Sheet 304Documento2 páginasASM Material Data Sheet 304.xAinda não há avaliações

- Aluminium 7075 t6 7075 t651Documento3 páginasAluminium 7075 t6 7075 t651VassiliNikolaiWolnitzkyElguetaAinda não há avaliações

- A95_EX_EDocumento1 páginaA95_EX_Emarceloalves.dsAinda não há avaliações

- Cusn8 Industrial RolledDocumento4 páginasCusn8 Industrial RolledPrakash MakadiaAinda não há avaliações

- Sheet Coil & Plate Alloy 6061: Technical DataDocumento2 páginasSheet Coil & Plate Alloy 6061: Technical DataSarat SrinivasAinda não há avaliações