Escolar Documentos

Profissional Documentos

Cultura Documentos

Questions Comp

Enviado por

Erdem KundakcıoğluDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Questions Comp

Enviado por

Erdem KundakcıoğluDireitos autorais:

Formatos disponíveis

Question 1 What happens to the material if its degree of polymerization increases? Is it a bad or good thing?

Is there a limit while increasing the DoP of a material?

Question 2

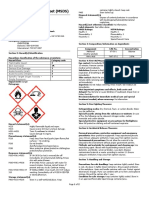

Above figure shows the relation of the epoxy between the viscosity and time After adding the curing agent into the resin during the manufacturing, it is expected that the viscosity of the material increases but instead, it is seen that the viscosity of the polymer is decreased. Why?

Question 3 What does racetracking channel serve for? Why is it used in composite manufacturing? Are there any disadvantages while using racetracking channel?

Question 4

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

An RTM problem is shown above picture, and it is known this problem is not caused by a careless labor. What are the reasons for this manufacturing error?

Question 5 A random mold is used to manufacture a composite. To monitor the process, sensors are used. How(not where) should the sensors be placed on the mold? Explain the logic.

Question 6 In VARTM, only one side mold is used and a vacuum bag is used for the other side. Is it safe to use a bag? Will it contain the resin without a problem? Show it by calculation. (Vacuum pressure is 90%.Vacuum bag should have 10kN force on it to maintain the safety of the process)

Question 7 A circular composite material of a 0.45 Volume fraction is manufactured by VARTM. 5 layers are used in the process. (dfiber =2524 kg/m3, dareal= 0.3 kg/m2 ,dresin= 1094 kg/m3 , r=0.23 m) a) Calculate the thickness of the resin. b) Calculate the the the Mass of the Porous Part. c) Calculate the amount of the resin in the pipe which is used to transfer the resin into the mold.

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

d) Calculate the total amount of the resin required and a filling time (assuming the mold is empty )for a 0,2 cm3/sec flow rate.

% Cobalt (1% Cons) (weight base) 0.6 0.6 0.6 0.6

% Butanox (MEK-P) (weight base) 1 1.2 1.5 2.5

Gelation Time (min) 50 40 30 20

e) After calculating the filling time for the process, choose correct Cobalt-Butanox percentage to add into the resin.

Question 8 a) Write down the pseudo code of a constant flow rate machine for a manufacturing process. The code must prevent the machine exceed 100 kN. Force is a function of flow rate and the volume filled in the mold. b) Draw two graph assuming the force limit is reached in the half of the process time. i) Force versus time ii) Flow rate versus time Hint: Assume the relation between force&time and flowrate&time as linear.

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- INOVYN™ PVC - Emulsion PVCDocumento9 páginasINOVYN™ PVC - Emulsion PVCM Waheed AtharAinda não há avaliações

- Molykote Lubrication BrochureDocumento12 páginasMolykote Lubrication BrochureLiam MoylanAinda não há avaliações

- Composite Materials: Cris Arnold Materials Research Centre J.c.arnold@swansea - Ac.ukDocumento30 páginasComposite Materials: Cris Arnold Materials Research Centre J.c.arnold@swansea - Ac.ukMazin MohammedAinda não há avaliações

- CAT DEO ULS 10W30 - Safety Data SheetDocumento10 páginasCAT DEO ULS 10W30 - Safety Data SheetCorina StanculescuAinda não há avaliações

- Module 2 - Drug AbuseDocumento35 páginasModule 2 - Drug AbuseMark Johnuel DuavisAinda não há avaliações

- Stimulation Manual ONGC 2008Documento306 páginasStimulation Manual ONGC 2008rahul_storm100% (3)

- B40EA - Distillation Unit Operations A PDFDocumento144 páginasB40EA - Distillation Unit Operations A PDFAnonymous vrKMTsa5qAinda não há avaliações

- Catalogue DM AhuDocumento54 páginasCatalogue DM AhurianaAinda não há avaliações

- HKR - Expansion Joints CatalogueDocumento80 páginasHKR - Expansion Joints Cataloguemksingh_22Ainda não há avaliações

- Rapid Fire NewDocumento85 páginasRapid Fire NewvarunsanghiAinda não há avaliações

- Effects of Three Different Dietary Binders On Juvenile Sea CucumberDocumento8 páginasEffects of Three Different Dietary Binders On Juvenile Sea CucumberEnrique MartinezAinda não há avaliações

- ISCRE 24 Lab Scale Up Workshop NotesDocumento2 páginasISCRE 24 Lab Scale Up Workshop NotesSukaran SinghAinda não há avaliações

- Chemistry 12 - Reaction KineticsDocumento16 páginasChemistry 12 - Reaction Kineticscharanbagh6402Ainda não há avaliações

- SF6 Sulfur Hexafluoride PDFDocumento12 páginasSF6 Sulfur Hexafluoride PDFSujit Kumar pahiAinda não há avaliações

- Water Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolDocumento11 páginasWater Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolLeonard PolancoAinda não há avaliações

- Accesorios de Carga CROSBYDocumento52 páginasAccesorios de Carga CROSBYRodolfo AlboresAinda não há avaliações

- Nutrients Deficiency SymptomsDocumento4 páginasNutrients Deficiency SymptomsJodie Mer DayamaAinda não há avaliações

- United States Patent: (45) Date of Patent: Aug - 21, 2018Documento22 páginasUnited States Patent: (45) Date of Patent: Aug - 21, 2018RiskaAinda não há avaliações

- CCWDocumento2 páginasCCWspearboraAinda não há avaliações

- Barbicide MsdsDocumento3 páginasBarbicide MsdstudorcerneaAinda não há avaliações

- Lab Activity 5 - PH of Familiar ProductsDocumento5 páginasLab Activity 5 - PH of Familiar ProductsCharles Reginald K. HwangAinda não há avaliações

- Nital EtchDocumento2 páginasNital EtchJohn GeddesAinda não há avaliações

- BM 12 Uc Usa 2011 08Documento44 páginasBM 12 Uc Usa 2011 08dangomezvAinda não há avaliações

- Selective Oxidation of Secondary AlcoholsDocumento24 páginasSelective Oxidation of Secondary AlcoholsFernando Silva BetimAinda não há avaliações

- Mineralogi 1Documento90 páginasMineralogi 1baihaqiAinda não há avaliações

- Biodegradation of Keratin Waste Theory and Practical AspectsDocumento13 páginasBiodegradation of Keratin Waste Theory and Practical AspectsRodrigo Lara100% (1)

- Group #4: September 25, 2019Documento5 páginasGroup #4: September 25, 2019MIKAYLA ELAINE P. DELA CRUZAinda não há avaliações

- Classification of DyeDocumento6 páginasClassification of DyeSalahuddin SaikotAinda não há avaliações

- Reactions of Organic CompoundsDocumento24 páginasReactions of Organic CompoundsAnis Hanani Abd Mu'minAinda não há avaliações

- As-MS Binding AssayDocumento9 páginasAs-MS Binding AssayAnonymous IGfaYDAinda não há avaliações