Escolar Documentos

Profissional Documentos

Cultura Documentos

Fanuc 6m

Enviado por

Zaheer Iqbal0 notas0% acharam este documento útil (0 voto)

3K visualizações1 páginaThe following information comes from our many years of experience in setting up RS-232 communications with this CNC. However, our experience also has taught us that many controls do not necessarily match the standard. If you must change a parameter you must set the toggle switch on the bottom of the master pcb to the Enable position.

Descrição original:

Título original

fanuc 6m

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe following information comes from our many years of experience in setting up RS-232 communications with this CNC. However, our experience also has taught us that many controls do not necessarily match the standard. If you must change a parameter you must set the toggle switch on the bottom of the master pcb to the Enable position.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

3K visualizações1 páginaFanuc 6m

Enviado por

Zaheer IqbalThe following information comes from our many years of experience in setting up RS-232 communications with this CNC. However, our experience also has taught us that many controls do not necessarily match the standard. If you must change a parameter you must set the toggle switch on the bottom of the master pcb to the Enable position.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

TECHNOTE!

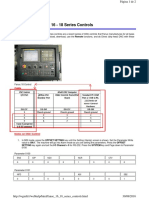

CNC RS-232 Parameters Fanuc 6M

Please note! The following information comes from our many years of experience in setting up RS-232 communications with this CNC. However, our experience also has taught us that many controls do not necessarily match the standard. So, please double check this information in the Operator or Maintenance or Parameter manual that came with your machine. 1. Put the CNC in MDI mode. 2. Select the Setting(Handy) screen by pressing the Setting button. Set TV Check to OFF. Make sure both input and output devices are set to RS-232. Set Punch code to ISO. 3. Select the Parameter screen by pressing the Parameter button. Set the following parameters: (Parameter bits not related to RS-232 communications are represented by an x and should not be changed.) 340 =2 Input device 341 =2 Output device 311=xx001010 Use control codes, 1 stop bit, 9600 baud. Note if 340 and 341 are set to 3 then 312 is used or if set to 4 then 313 is used to set the baud rate. If you must change a parameter you must set the toggle switch on the bottom of the Master Printed Circuit Board to the Enable position (right.) You will get an alarm code 100. Select Parameters. Cursor to the parameter. Type in P followed by the new number Press INPUT. When done set the toggle switch back to disable (left) and press Reset to clear the alarm. 4. Set the DNC machine properties to 9600, Even, 7 bits, 1 stop bit, both-no-wait. The protocol is Generic RS-232.

Wiring

Use 24 AWG stranded, low capacitance computer cable with an over shield (foil is fine and easier to work with.) CNC DNC COM port (25 pin plug) (25 pin socket) 1--------------------shield 2------------------------3 3------------------------2 4------------------------5 5------------------------4 7------------------------7 6---------| 8---------| 20------- |

RHL 1/24/2001

Você também pode gostar

- Fanuc RS232 Internal Connections and Parameters: OM ControlDocumento5 páginasFanuc RS232 Internal Connections and Parameters: OM ControlLio SnAinda não há avaliações

- Fanuc: 0 Series ControllerDocumento16 páginasFanuc: 0 Series ControllerHoangvinh Duong100% (1)

- Fanuc PM PDFDocumento26 páginasFanuc PM PDFnamnp2007Ainda não há avaliações

- Fadal Zero Memory ProcedureDocumento2 páginasFadal Zero Memory Procedureavalente112Ainda não há avaliações

- Fanuc 6 Alarm Codes System Fanuc 6 AlarmsDocumento16 páginasFanuc 6 Alarm Codes System Fanuc 6 AlarmsPham LongAinda não há avaliações

- Fanuc 6mDocumento3 páginasFanuc 6mLưu QuýAinda não há avaliações

- Fanuc 16i 210i Ts AlarmsDocumento109 páginasFanuc 16i 210i Ts AlarmstugskulAinda não há avaliações

- Fanuc Series 16 Backup ProcedureDocumento4 páginasFanuc Series 16 Backup ProcedureYael Abraham GutiérrezAinda não há avaliações

- Fanuc 0 C BACKUP PDFDocumento2 páginasFanuc 0 C BACKUP PDFsunhuynhAinda não há avaliações

- Fapt Ladder PDFDocumento302 páginasFapt Ladder PDFMichael KennaAinda não há avaliações

- 3760 PC FAPT Ladder SetupDocumento2 páginas3760 PC FAPT Ladder SetupQuy QuyAinda não há avaliações

- M100741H MAI Memex Memory Upgrade For Fanuc 16 182Documento32 páginasM100741H MAI Memex Memory Upgrade For Fanuc 16 182Nica BogdanAinda não há avaliações

- Option Ordering Information (5-21-08) PDFDocumento6 páginasOption Ordering Information (5-21-08) PDFVicshannAinda não há avaliações

- Yasnac J300 PLC Programming ManualDocumento224 páginasYasnac J300 PLC Programming Manualsunhuynh100% (1)

- Fanuc: Spindle ControlDocumento8 páginasFanuc: Spindle ControlTony AntonyAinda não há avaliações

- Fanuc Program Transfer Tool Operator's Manual B-64344en - 02Documento192 páginasFanuc Program Transfer Tool Operator's Manual B-64344en - 02alexandreAinda não há avaliações

- Dan's Fanuc Spindle InfoDocumento13 páginasDan's Fanuc Spindle InfoPham LongAinda não há avaliações

- BNP b2267 (Eng) CDocumento317 páginasBNP b2267 (Eng) CibraheemAinda não há avaliações

- Fanuc 10 Fanuc 11 Memory Backup ProceduresDocumento1 páginaFanuc 10 Fanuc 11 Memory Backup ProceduresLeonardusAinda não há avaliações

- Okuma Howa Spindle Drive AlarmsDocumento3 páginasOkuma Howa Spindle Drive AlarmsAnonymous wBxc1VGtAinda não há avaliações

- 04 - Fanuc - PLC - EN PDFDocumento45 páginas04 - Fanuc - PLC - EN PDFGuillermo RamirezAinda não há avaliações

- A-65623EN Manual Setting of Parameters Related To FSSB - TMN11062E - 02 PDFDocumento15 páginasA-65623EN Manual Setting of Parameters Related To FSSB - TMN11062E - 02 PDFGuillermo Ramirez100% (1)

- Miyano-BNC-34T Fanuc OT G M Codes 1Documento13 páginasMiyano-BNC-34T Fanuc OT G M Codes 1Nguyễn Khắc LợiAinda não há avaliações

- CN 0 Leds PLACASFanuc Manuals 2731Documento34 páginasCN 0 Leds PLACASFanuc Manuals 2731AntonioCanestriJúniorAinda não há avaliações

- Cyclone Fanuc OTADocumento68 páginasCyclone Fanuc OTAPham LongAinda não há avaliações

- Setting The CNC RS232Documento4 páginasSetting The CNC RS232Maleš DejanAinda não há avaliações

- 64113EN1Documento1.224 páginas64113EN1João Paulo Moreira Santos BarbosaAinda não há avaliações

- Fanuc-Page-7 (Pluse @i64)Documento13 páginasFanuc-Page-7 (Pluse @i64)Hoangvinh DuongAinda não há avaliações

- Fanuc Model C Serial RS232 Connection GuideDocumento6 páginasFanuc Model C Serial RS232 Connection GuideSanchai ProgaeewAinda não há avaliações

- Fanuc Tape Drill Mate Data SheetDocumento12 páginasFanuc Tape Drill Mate Data SheetIvan Jesus Castilla Carrillo100% (2)

- Maza Trol M 2 Operator ManualDocumento5 páginasMaza Trol M 2 Operator Manualcamb2270100% (1)

- Fanuc 10 Alarm ListDocumento8 páginasFanuc 10 Alarm ListRevolusiSoekarno0% (1)

- 54765e PDFDocumento152 páginas54765e PDFCristobal PerezAinda não há avaliações

- I80 Maintenance ManualDocumento226 páginasI80 Maintenance ManualsunhuynhAinda não há avaliações

- Fanuc RS232 SettingDocumento2 páginasFanuc RS232 SettingThk Bao HanhAinda não há avaliações

- Doosan MX Series Alarm ListDocumento7 páginasDoosan MX Series Alarm ListRevolusiSoekarnoAinda não há avaliações

- M-Servo Batt Drop - 5066.17Documento1 páginaM-Servo Batt Drop - 5066.17David Cruz100% (1)

- Al-12 Spindle AlarmDocumento20 páginasAl-12 Spindle AlarmPhong HuynhAinda não há avaliações

- Fanuc 0i - Model FDocumento16 páginasFanuc 0i - Model FAlex Kiko VillalobosAinda não há avaliações

- 205 V358%20CompleteOperationManual PDFDocumento182 páginas205 V358%20CompleteOperationManual PDFLê Thanh NgọcAinda não há avaliações

- TNC430 Technical Manual PDFDocumento1.108 páginasTNC430 Technical Manual PDFNenad Jarakovic100% (1)

- ES400 F 21iMB Mag Zero Set 033007Documento3 páginasES400 F 21iMB Mag Zero Set 033007Julián MorelosAinda não há avaliações

- FANUC 18P Communications Revision 5 1Documento23 páginasFANUC 18P Communications Revision 5 1Pham LongAinda não há avaliações

- Meldasmagic Monitor Operation Manual: BNP-B2192 (ENG)Documento14 páginasMeldasmagic Monitor Operation Manual: BNP-B2192 (ENG)Durairaj TAinda não há avaliações

- Fanuc OiMC RS232 PIN DiagramDocumento3 páginasFanuc OiMC RS232 PIN Diagramamdobedb100% (1)

- BNP b2215 (Eng) ZDocumento138 páginasBNP b2215 (Eng) ZRuslanAinda não há avaliações

- Heidenhain TNC Machine DataDocumento8 páginasHeidenhain TNC Machine DataDörky LefieuwAinda não há avaliações

- Main Card 3 E48090-450-38-C Opus 5000 1911-1103 Okuma Datasheet PDFDocumento7 páginasMain Card 3 E48090-450-38-C Opus 5000 1911-1103 Okuma Datasheet PDFaaamil13Ainda não há avaliações

- Yasnac J50L Upgrading Function ManualDocumento76 páginasYasnac J50L Upgrading Function ManualsunhuynhAinda não há avaliações

- Ncboot 32Documento12 páginasNcboot 32Hà ChínhAinda não há avaliações

- Parametros Fanuc OmDocumento19 páginasParametros Fanuc OmJuan Fernando Salazar100% (2)

- Yasnac J50L Descriptive Information For TurningDocumento47 páginasYasnac J50L Descriptive Information For TurningsunhuynhAinda não há avaliações

- Trouble Alarm 900 Rom Parity: Move M/C Jog M/C Macro ROM Module No Software M/C Can Move and Jog Macro ROM ModuleDocumento2 páginasTrouble Alarm 900 Rom Parity: Move M/C Jog M/C Macro ROM Module No Software M/C Can Move and Jog Macro ROM ModuleWazabi MooAinda não há avaliações

- 1 Program Errors Alarms On Program and OperationDocumento78 páginas1 Program Errors Alarms On Program and Operationsssf-doboj100% (2)

- Okuma Osp5000Documento2 páginasOkuma Osp5000Zoran VujadinovicAinda não há avaliações

- DNC 6MDocumento4 páginasDNC 6MtuAinda não há avaliações

- Conexiones de ComunicacionDocumento2 páginasConexiones de ComunicacionAlejandro DuranAinda não há avaliações

- 51 52 25 123 enDocumento2 páginas51 52 25 123 enNicole StewartAinda não há avaliações

- proDNC EDocumento24 páginasproDNC EFaizan HamiedAinda não há avaliações

- Turning Catalog INCH 2022 - LR - P1-112Documento114 páginasTurning Catalog INCH 2022 - LR - P1-112ElmeysAinda não há avaliações

- XOS Tutorial: Auto Surfacing:Air BagDocumento13 páginasXOS Tutorial: Auto Surfacing:Air BagElmeysAinda não há avaliações

- A05 PDFDocumento8 páginasA05 PDFElmeysAinda não há avaliações

- 02 2014 Oscillating Mountings AK EN Low PDFDocumento5 páginas02 2014 Oscillating Mountings AK EN Low PDFElmeysAinda não há avaliações

- RS 232 Parameters Fanuc 6mDocumento1 páginaRS 232 Parameters Fanuc 6mElmeysAinda não há avaliações