Escolar Documentos

Profissional Documentos

Cultura Documentos

Flickering LED Tutorial

Enviado por

Kaw ClericDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Flickering LED Tutorial

Enviado por

Kaw ClericDireitos autorais:

Formatos disponíveis

PERIOD MODEL SHIP LIGHTING WITH LEDs Another Method This article will offer an excellent alternative method

d for installing LED lights on your period model that will accurately replicate the natural color and flickering intensity of oil lanterns. First, I'll respond to sometimes expressed issues on the subject. Problem: Answer: I have no skill with electronics. Ever since the demise of vacuum tubes and the advent of semiconductors, neither have I. The following method is very simple and requires no more than reasonable literacy, soldering ability, and a little money. I promise.

Problem:

Why shouldn't I just buy LED tea lights for a dollar a piece and use the components? I have seen two varieties of these: a fully potted assembly that makes the components difficult or impossible to isolate or identify, or an assembly that consists of the LED and battery only. In the latter instance the current limiting resistance and the flickering program are integrated into the LED Itself. The flickering is unnatural with any of these devices, better described as blinking. In both instances a white LED with a diameter of 5mm is employed. The color is unnatural. The 5mm diameter means a bigger scale problem. If you do the math, that dimension for a model scale of 1/48 will translate to a 9.5 inch or 240mm diameter at full scale, for the light source only, with no consideration for the lantern itself. Of course it's twice the problem at 1/96. The 3mm ones I use here are problem enough.

Answer:

Problem:

I won't be able to get into my completed model to replace failed components. Not a problem at all. All components have expected lifetimes in the order of 100,000 hours or more of continuous use. If you run your lights for five hours continuously every single day, that's 55 years MTBF, at a probable minimum. Half that duty cycle and your component may fail in 110 years. By that time you won't care anyway. At least I won't.

Answer:

Problem: Answer:

This alternative is too expensive. Not really! With all the mistakes and lost material, my prototype set me back about $60US. That's about $5 per lantern for my twelve lights. Yours will cost less.

If you're still with me, let's start with a Bill of Material. In the following table all costs are in US dollars. With apologies to our international members, all sources are North American, simply because I live here, but all items are available for purchase on line. If you re-source any item be aware of the specifications to ensure proper performance. Shipping costs have not been quoted due to the widely separate locations of our members. Any number of lanterns can be planned. The following table lists the material for each THREE LIGHT DEVICE powered by two AAA alkaline batteries located external to the model. There are acceptable alternatives to this power source, which I will discuss.

QTY 1 1 3 3 1 1 ?

ITEM

SOURCE

VENDOR # Velleman MK167 kit Catalog # 270-414

EXT. $ $7.95 $1.79 $1.80 $0.38 $0.00 $2.99

PIC10F200 IC (Programmed) http://www.apogeekits.com 2 Cell AAA Battery Box Yellow LED 47 ohm watt resistor 100K ohm watt resistor Breadboard Consumables http://www.radioshack.com

http://www.superbrightleds.com RL3-Y4545 Anywhere Included in Velleman kit. http://www.radioshack.com Wherever, Whoever, Whatever Any N/A Catalog # 276-1395

Wire, Solder, Flux, Glue, ? potting, batteries, Etc.

Notes on materials The IC chip is part of a DIY kit for a similar application. I had hoped to get a copy of the source code and buy a programmer so that I could get raw chips for much less money. I found a vendor in Australia offering them in small quantities for about $1.50US each. Alas, I've been unsuccessful in getting the program listing, my offer to buy the chip or the source code separately has been refused, the chip is encrypted, and last but not least, I don't have the savvy required to design my own (and at this point don't have the desire to acquire it). So for now, the Velleman chip is it. The kit contains many parts that are of no use for this project. I retain only the chip itself, and the 100K ohm resistor. The chip is somewhat sensitive to static discharge, so take care when handling it. If you shuffle across the carpet on a dry day and pick this chip up in your hand you stand a good chance of zapping it with several thousands of volts. The battery box listed on the BOM will power a three light breadboard (One IC). You need Two AAA alkaline cells for this. You can buy four or eight cell boxes for more lights but they must be rewired to separate the batteries into serially connected pairs, and this is quite difficult. In my experience it's better to use the boxes for two cells and gang them up for more lights. For my twelve light arrangement I glued four of these together with CA (be careful; don't get glue on the removable tops). The 3.2 volts per pair of cells will provide individual power to each one (three light array) of the four chips .

Eight cell (four pair) AAA battery box 2.5 X 2.5 X 1 or 64 X 64 X 25 mm

With concern for function and local availability, I've determined that AAA alkaline cells or CR2032 coin batteries are the optimum choices for a power source. An alkaline AAA cell has a rated life of 1250 mah (milliampere hours), but this rating can't be taken literally. For one thing, I could find no figure for the level of charge that would define a dead battery. Also, the mah rating is sensitive to the rate of discharge which, of course, will vary with the load. For a test, I ran a six light array on two pair of fresh AAA cells for two months, for five to eight hours a day. At the end of this period the batteries had lost about 20% of their fresh voltage, the array was still functioning normally, and I got tired of running the test. This was in excess of 300 working hours, and it was still working. A CR2032 coin is a lithium anode battery, nominally three volts. This is the battery found on most PC motherboards to power the BIOS chip when the computer is turned off. I would use it in applications where space is a problem. It's rated at 220 mah. I haven't tested it for life, but if the difference in cell life is linear with the difference between the mah of the two sources then the life of the coin might be measured at six weeks or so at five to eight hours a day, or in excess of 55 working hours. If you parallel two or more of these, do the math. CAUTION: don't connect any power source to more than one three light circuit, or you will get EMI (electromagnetic interference) which will definitely shut you down. I wouldn't bother with rechargeable batteries. They're expensive, their fresh voltage is lower, their rate of discharge is higher, and at the low level of consumption of this device they hardly seem necessary. My call out for the LED is the product of a lot of investigation for size, color, intensity, and view angle. It's not ideal in any one of those characteristics, but in combination it beats anything else I've been able to find in an affordable 2-2.5 volt device. There are some alternatives available from Asian manufacturers, but only in buys of 1,000 or more pieces. The breadboard is far larger than needed even for my twelve light array, but you can save the unused remainder for future use. If you plan to buy something different, buy one with no metal plating on the etch side, to avoid solder shorts when hand soldering in these very closely spaces holes.

The twelve light array for my current model. The bare breadboard is 2.75 X 6 or 70 X 152 mm. The array will be cut from the board along the red lines. The finished dimensions of the array will be 1.875 X 2 or 48 X 51 mm. The batteries will be external to the model.

The three light board utilizing AAA cells installed in the model. The device will be cut from the breadboard along the red line. Finished dimension will be 1.125 X 2.75 or 29 X 70 mm. You must supply a two cell AAA battery holder. For more lights simply duplicate this layout.

The three light board utilizing a CR2032 coin battery. The device will be cut from the breadboard along the red lines. Finished dimension will be 1.125 X 1.063 or 29 X 43 mm. For this power source you'll want to save the coin battery holder that's included in the Velleman kit. For more lights simply duplicate this layout.

The board should be potted on both sides with two part epoxy. Don't use CA glue; I've seen reports of interaction problems with it. Before potting all necessary leads should be run from the etch side of the board with 26AWG or smaller stranded wire. Because of space limitations, and the prohibitive cost of 30AWG stranded, 30 gage solid wrapping wire can be used for running the wiring throughout the model. This wiring, in turn, should be liberally potted to avoid any shock or vibration damage, because the whole enchilada may be inaccessible once the model is completed. A word of CAUTION: Don't be a dummy (as I have been) and pot the board before you have checked all function! Nuff said.

An important word about wiring: When running more than one chip (three lights), EMI (electromagnetic interference) is the BBB (Big BugBear) for this device. If you're running wire from your power source to the device(s) i.e. locating your batteries away from the breadboard or external to the model, you need to reduce the chance for EMI between chips by running every pair of power leads twisted together through its length, to as close to its terminations as convenient. The wire shown below is 28 gage stranded pairs, 25 twists per foot, or 82 per meter. The diameter of the pair is 1mm or about .039 inch. This wire can be obtained from kentelectronics, an eBay seller, for about $0.25 per foot. The diameter of my power cable for twelve lights (four twisted pairs in heat shrink tubing) is less than 5mm or about ,196 inch.

If you wish, you can twist your own. As a matter of fact, there's an advantage in twisting your own because you can vary the rate of twists from one pair to another, which does improve the isolation between adjacent pairs. Good luck finding anything smaller than 26 gage in stranded wire, for any price you can afford (or anyway, I can afford). For all wiring use the smallest gage you can find. It will be electrically adequate for this device. And so far as price and availability allow, try to buy stranded wire only; it's much more durable.

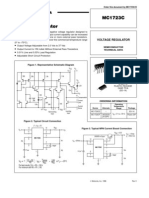

Here is a diagram of a the three LED circuit. A note on the chip polarity: On the diagram of the pin assignments you will note a semicircle drawn at the top of the chip. Also see a smaller full circle near pin #1. These are two markings that the manufacturer will use to orient the chip. With either of these marks at the top the #1 pin will be at the top left, and the pin numbers will increment from there in a counterclockwise direction. The chip is programmed to operate in four optional modes: Flickering, Fade in/out, steady on, and steady off. The modes are toggled by MOMENTARILY applying the +3 volts To the clear line (pin 8). Once set, the mode should not change.

For you techies: The value of the 47 ohm resistors to the LEDs is sensitive to the source voltage, the LED forward voltage, the LED forward current, and the number of LEDs in your array. The LED specified for this device has a forward voltage peaking at 2.2 and a forward current rating of 20ma. Where big variation may occur is at the source. The voltage of my source (The pin 5 Data line actually) peaks at 2.8vdc. I've calculated 33 ohms as a proper value for that source voltage, using either one, two, or three LEDs. However, if the source varies by as little as 0.1 volt the value of the resistor will change substantially. For this reason it is wise to use a higher value than calculated; as much as double the value can't hurt. That's why I'm indicating 47 ohm resistors in my diagram for a three LED array. Be aware that the chip is programmed to turn itself off after a few hours to save the batteries. Toggling the power off and back on will restore function. Now, let's do a checkup on the connections. For EACH chip (three LEDs) on your breadboard, you should have the following: 1 - 100Kohm resistor connected to pin 8 of the chip. 3 - 47 ohm resistors connected in common to pin 5 of the chip. 1 - jumper between Pin 7 and the unconnected end of the 100K resistor. 2 - wires coming from Pin 7, one going to the minus connection on the power source, the other going to the minus side of all 3 LEDs. 1 - wire coming from Pin 2, going to the plus connection on the power source. 1 - wire, coming from the unconnected end of EACH 47 ohm resistor, going to the plus side of each LED. Observe POLARITY; the LED will light only in one direction. About soldering these connections: You can use the much more active acid flux rather than rosin flux, but if you do so you MUST wash the completed assembly in soap and warm water, then thoroughly dry it before applying power. This will prevent otherwise inevitable corrosion of the connections. Don't worry, you can't damage anything; the components are waterproof. Easy peasy, yes? A word on the randomness of the flickering effect: Suppose you're installing nine lights on a three masted model. On each mast you want to install three of the lights, one each on gun deck, spar deck, and top. Don't install all three from one chip to the same mast. Rather, mix & match them so that each mast uses one LED from each chip. Please go to a You Tube video that I shot to demonstrate how this method creates the random effect. http://www.youtube.com/watch?v=iHrdkSv2XiA&feature=player_embedded Finally, I'd like to acknowledge the help and suggestions from other forum members who visited my thread for this subject in the MSW Furniture & Fittings forum. Special thanks to Arthur (aew), Ed (Edrahil), and Fritz (fritzk). And equally, all the others who gave me helpful feedback while the project was in progress. Thanks guys, this article wouldn't work without your invaluable input! Rich (cosmic)

If you have any questions feel free to PM me. Likewise, I would be grateful for feedback on any omission or error I may have made (lately I'm easily confused). N.B. As I become aware of improved availability of material I will update this article. In particular I'm anticipating advancements in LED technology regarding size, view angle, and intensity. Also, possibly a less expensive processor. When I have integrated this feature in actual models, either I will append photos here or I'll give you links to You Tube videos. Your photos or videos of such are also solicited, via posts in the Building a Ship's Deck Furniture, Guns and other Fittings forum. Best of luck!

Copyright 2010 Richard G. Morrison. All rights reserved. Permission is granted by the author to freely distribute or publish this article without modification or omission, for non-commercial use only.

Just for fun, here's a photo of my 6 and only successful prototype. I felt like the flea that gave birth to an elephant.

th

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 12 Bit Comparator 32nmDocumento4 páginas12 Bit Comparator 32nm08-Phạm Gia HuyAinda não há avaliações

- Best Electronic Circuit ProjectsDocumento20 páginasBest Electronic Circuit ProjectsGratiela VodaAinda não há avaliações

- (Final)Documento16 páginas(Final)saurabhAinda não há avaliações

- Vijay BTP Report EndSemDocumento46 páginasVijay BTP Report EndSemVijay AjayAinda não há avaliações

- HD8205A Data SheetDocumento6 páginasHD8205A Data SheetFélixAinda não há avaliações

- Atlas: 530-550 W / 144 Cells / 10 Bus Bars Monocristalline ModuleDocumento2 páginasAtlas: 530-550 W / 144 Cells / 10 Bus Bars Monocristalline ModuleJean P SilvaAinda não há avaliações

- Epl Manual (Anna University 2013 Regulation)Documento34 páginasEpl Manual (Anna University 2013 Regulation)Veronica IngramAinda não há avaliações

- 3.2 Inch LCD Shield For MEGA 2560Documento9 páginas3.2 Inch LCD Shield For MEGA 2560detonatAinda não há avaliações

- The Solder Paste Printing Process: Critical Parameters, Defect Scenarios, Specifications, and Cost ReductionDocumento14 páginasThe Solder Paste Printing Process: Critical Parameters, Defect Scenarios, Specifications, and Cost ReductionNurul KhomariyahAinda não há avaliações

- 8051 ApplicationsDocumento5 páginas8051 Applicationsgdreddy25Ainda não há avaliações

- MV Trafo SB - SMC - STP TI US - en 10 PDFDocumento6 páginasMV Trafo SB - SMC - STP TI US - en 10 PDFVictor ToledanoAinda não há avaliações

- Dual Synchronous, Step-Down Controller With 5-V and 3.3-V LdosDocumento31 páginasDual Synchronous, Step-Down Controller With 5-V and 3.3-V Ldosjules eyapAinda não há avaliações

- Datasheet ICL7650 REEMPLAZO PARA EL TC911A DEL INCUBATOR SHAKER PARA PLACAS ELISADocumento12 páginasDatasheet ICL7650 REEMPLAZO PARA EL TC911A DEL INCUBATOR SHAKER PARA PLACAS ELISAJose GodoyAinda não há avaliações

- Module4.Etching - Ee143 f14.CtnDocumento20 páginasModule4.Etching - Ee143 f14.CtnstansilawAinda não há avaliações

- Project Report On Input Power Factor Correction of Ac To DC Converter CircuitDocumento57 páginasProject Report On Input Power Factor Correction of Ac To DC Converter CircuitAkshyat Das100% (7)

- Slides Part3Documento25 páginasSlides Part3shubham singhAinda não há avaliações

- Error CodesDocumento6 páginasError CodesTorozan RomicaAinda não há avaliações

- Vikram BrochureDocumento2 páginasVikram BrochureAmarinder Singh SandhuAinda não há avaliações

- Worked Problem - The I-V CharacteristicDocumento2 páginasWorked Problem - The I-V CharacteristicAndres RojasAinda não há avaliações

- Ra1911004010652 Experiment-1 AdcDocumento12 páginasRa1911004010652 Experiment-1 Adcswagata mandalAinda não há avaliações

- 2.data Acquisition System and 3.virtual InstrumentationDocumento15 páginas2.data Acquisition System and 3.virtual Instrumentationmohammadanas7686Ainda não há avaliações

- BMD101 PDFDocumento14 páginasBMD101 PDFrajAinda não há avaliações

- MDAPPUSGDRM118Documento134 páginasMDAPPUSGDRM118Gemma GarciaAinda não há avaliações

- CT 727 (EDocumento26 páginasCT 727 (EjucatorAinda não há avaliações

- Yx 360 TRDocumento14 páginasYx 360 TRNovian ArmaAinda não há avaliações

- MC1723 PDFDocumento9 páginasMC1723 PDFOsman KoçakAinda não há avaliações

- S600 LatestDocumento98 páginasS600 Latestkar_simAinda não há avaliações

- Solar CellDocumento25 páginasSolar CellfebriAinda não há avaliações

- Tranzistor MOS FET Pentru Cif 250 Tip BSM 181Documento7 páginasTranzistor MOS FET Pentru Cif 250 Tip BSM 181rataion241959Ainda não há avaliações

- Mit 161Documento24 páginasMit 161Santosh Gairhe100% (1)