Escolar Documentos

Profissional Documentos

Cultura Documentos

CP No.601-Hydraulic Type (Pressure) - Rev

Enviado por

amelchan_tiqueDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CP No.601-Hydraulic Type (Pressure) - Rev

Enviado por

amelchan_tiqueDireitos autorais:

Formatos disponíveis

NIMT-CNL-SP No.

601

S

SSt

tta

aan

nnd

dda

aar

rrd

dd P

PPr

rro

ooc

cce

eed

ddu

uur

rre

ee

f

ffo

oor

rr

C

CCa

aal

lli

iib

bbr

rra

aat

tti

iio

oon

nn

o

oof

ff

P

PPr

rre

ees

sss

ssu

uur

rre

ee M

MMe

eea

aas

ssu

uur

rri

iin

nng

gg

I

IIn

nns

sst

ttr

rru

uum

mme

een

nnt

tts

ss

T

TTy

yyp

ppe

ee]

]]M

MMo

ood

dde

eel

ll :

:: H

HHy

yyd

ddr

rra

aau

uul

lli

iic

cc T

TTy

yyp

ppe

ee

!ssued on January, 200+

First revision on October, 200+

Approved by N!NT

N

I

M

T

-

C

A

L

I

B

R

A

T

I

O

N

N

E

T

W

O

R

K

L

A

B

O

R

A

T

O

R

I

E

S

NIMT-CNL-SP No. 601

Page 2 of 18

HYDRAULIC PRESSURE MEASURING INSTRUMENT

1. Calibration Description:

Parameter Performance Specifications Test Method

Cauge Pressure

Neasurement

Range : 0,1 NPa to 120 NPa

(Note 1)

Uncertainty : Lower than 0,18 kPa

in the range up to 6 NPa

(Note 2)

Lower than 1,18 kPa

in the range up to 120 NPa

Comparison with

Standard Hydraulic

Pressure Balance

2. Equipment Requirements: Note 2, Note 3, Note 5

Equipment used Specifications Requirement Calibration Equipments

1. Pressure Balance,

Nodel AAA with Piston

8 Cylinder

Nodel : xxx

S/N : 111

Range : 0,1 NPa to 6 NPa

Uncertainty (k=2) : 8,0*10

-5

*Pe

Not lower than 0,18 kPa

1 Piston 8 Cylinder

Nodel : xxx

S/N : 111

Nodel : yyy

S/N : 222

Range : 2 NPa to 120 NPa

Uncertainty (k=2): 8,0*10

-5

*Pe

Not lower than 1,18 kPa

2 Piston 8 Cylinder

Nodel : yyy

S/N : 222

Nass set

Nodel : zzz

S/N : 333

Range : 50 kg

Uncertainty (k=2) : 10*10

-6

*m

3 Nass set

Nodel : zzz

S/N : 333

2. Piston 8 Cylinder

!ndicator

(Note +)

Nodel : uuu

S/N : +++

Uncertainty (k=2, for temperature

measurement) : 0,5 C

+ Piston 8 Cylinder !ndicator

Node : uuu

S/N : +++

3. Steel Ruler

S/N : 555 Uncertainty (k=2) : 0,0+ mm 5 Steel Ruler

S/N : 555

+. Pressure Transmitting

(Note 6)

Fluid = Hydraulic oil

Density : (91+ 10) kg/m

3

Surface Tension : (0,031 0,003) N/m

5. Digital Nultimeter

Nodel : mmm

S/N : 666

Range : 0 y 100 vdc

Uncertainty : 10 ppm

Range : 0 y 100 mAdc

Uncertainty : 50 ppm

NIMT-CNL-SP No. 601

Page 3 of 18

3. Preliminary Operation:

3.1 Read the entire procedure before beginning a calibration.

3.2 visual check the Unit Under Calibration (UUC) to ensure that:

3.2.1 The line voltage required of the UUC has bee n set to 220 vAC, 50 Hz. !f the UUC line voltage

cannot be selected to be 220 vAC, the proper adapter is required.

TmPORTAAT AOTE:

- CIEAA GIOVE5 WTTHOOT TAICOm POWOER mO5T BE WORA WHTIE

HAAOITAG PT5TOA & CYITAOER OF THE 5TAAOARO PRE55ORE BAIAACE

AAO OORTAG CAITBRATTOA.

- REFEREACE IEVEI OF THE OOC 5HAII BE TOEATTFTEO.

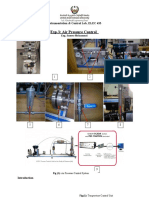

3.3 Connect equipment as shown in figure 1 or figure 2 by using short, clean and appropriate

pressure tubes. The reference level of UUC should be the same level as the reference of the

standard 2 millimeters. !f not the different level shall be measured and taken into

consideration.

3UHVVXUH,QGLFDWRU

8QLW8QGHU&DOLEUDWLRQ

+\GUDXOLF

3UHVVXUH

7UDQVGXFHU

UHIHUHQFHOHYHO

Figure 1

NIMT-CNL-SP No. 601

Page + of 18

AK

8QLW8QGHU&DOLEUDWLRQ

UHIHUHQFHOHYHO

%RXUGRQWXEH

3UHVVXUHJDXJH

Figure 2

3.+ !f the UUC is needed to measure an electrical output, voltage or current ; and the measuring

instrument is not provided. !t can be calibrated using the laboratory digital multimeter.

However it shall be stated in the calibration certificate provided to the customer.

3.5 Care must be taken to ensure that no leakage of pressure between the standard pressure

balance and the UUC which will cause some confusion or incorrect reading.

4. Pressure Cycle Exercise:

Unless otherwise specified, the pressure cycles must be applied to exercise (preloading) the UUC

according to the accuracy class stated in the DKD R 6-1: 2002, pressure calibration guideline. The

pressure cycle must be consisted of starting at zero, going to full scale then back to zero pressure as

described in table 1 below.

NIMT-CNL-SP No. 601

Page 5 of 18

Table 1: Calibration sequences

Calibration

sequence

Neasurement

uncertainty

aimed at, in

of the meas-

urement span

Number of

meas-

urement

points

Number

of

preload-

ings

Load

change +

waiting

time

Waiting time at

upper limit of

measurement

range

Number of

measurement

series

(*) with zero

up/down

(**)

seconds

(***)

minutes

up down

A < 0,1 9 3 >30 2 2 2

B 0,1 h 0,6 9 2 >30 2 2 1

C > 0,6 5 1 >30 2 1 1

(*) Reference to the span was used to allow the sequence (necessary calibration effort) to be

selected from the table, as the accuracy specifications of the manufacturers are usually

related to the measurement span.

(**) One has in any case to wait until steady-state conditions (sufficiently stable indication) of

standard and calibration item are reached.

(***) For Bourdon tube pressure gauges, a waiting time of five minutes is to be observed. For

quasi-static calibrations (piezoelectric sensor principle), the waiting times can be reduced.

TmPORTAAT AOTE:

PRE55ORE 5ORGE5 CAA OAmAGE THE PRE55ORE 5EA5OR, 5mOOTH PRE55ORE CHAAGE5

T5 REOOTREO THROOGHOOT THE CAITBRATTOA.

5. Calibration Procedure:

TmPORTAAT AOTE:

- BEFORE CAITBRATTOA, A ZERO REAOTAG AT THE OOC WHTIE THE HYORAOITC T5

OPEAEO TO AA ATmO5PHERE AFTER EXERCT5E 5HAII BE OB5ERVEO. TF AOT, ZERO

5ET T5 AEEOEO.

- THE AOmBER OF THE PRE55ORE CAITBRATTOA POTAT5 OF THE OOC CAA BE

OETERmTAEO ACCOROTAG TO THE REOOTREmEAT TA THE OKO R J : 2DD2

CAITBRATTOA OF PRE55ORE GAOGE5 GOTOEITAE WHTCH OERCRTBEO TA TABIE J.

NIMT-CNL-SP No. 601

Page 6 of 18

- AFTER APPIYTAG THE TAPOT PRE55ORE AT EVERY mEA5OREmEAT POTAT, 3D

5ECOAO5 mTATmOm ARE AEEOEO TO WATT BEFORE TAKTAG A REAOTAG.

5.1 Cenerate a known pressure, step by step; from the minimum to maximum range which

explained in table 1 to the UUC. An accurate input pressure which being developed by

standard pressure balance can be calculated from the following equation.

@ >

U

W W

F S S

$

F J

D

I

9

L P D

J

L

P

H

3

o + o +

o + p p + p p

=

1

1

where :

P

is the gauge pressure measure at the bottom of the piston, Pa.

m

is the individual mass value of each weight applied on the

piston including all floating elements, kg.

g is the local gravity, m/s

2

.

U

a

is the density of air, kg/m

3

.

U

/

is the density of the measuring fluid, kg/m

3

.

U

m

is the density of each weight, kg/m

3

.

V is the fluid buoyancy correction volume, m

3

.

o is the surface tension of the fluid, N/m.

is the circumference of the piston whe re it emerges from

the pressure fluid, m.

A

p

is the effective area of the piston-cylinder assembly at

a reference temperature I

r

(20 C) and at pressure P m

2

.

However, A

p

can be expressed from the effective area at null pressure A

and the first order

pressure distortion coefficient.

A

p

= A

o

(1+ip)

where :

A

0

= effective area of the piston 8 cylinder unit measured at

atmospheric pressure and at the reference temperature I

r/

, m.

O = elastic distortion coefficient of the piston 8 cylinder unit, Pa

-1

.

NIMT-CNL-SP No. 601

Page / of 18

p is an approximate value of the measured pressure, Pa.

!t can be calculated as the equation below.

A

m

a

J g

m

P

]

]

]

\

|

=

U

U

6

D

p

is the linear thermal expansion coefficient of the piston, K

-1

.

D

is the linear thermal expansion coefficient of the cylinder, K

-1

.

I is the measured temperature of the piston-cyli nder assembly

during its use,

o

C.

When the pressure p

m

is expressed at the reference level of the UUC which may be different

from reference level of the standard. A corrective term (head correction) has to be added to

the pressure P; expressed above.

p

m

= p

e

+ (p

f

- p

a

)gAh

p

m

= the pressure measurand at the UUC's reference-level, Pa.

where:

'n is the difference between the altitude n

J

of the balance reference level and the altitude

n

2

of the point where the pressure has to be measured, m.

Ah = h

1

y h

2

5.2 When the standard pressure balance is obtained at mid float position, the UUC reading has to

be observed and recorded in the table attached in appendix A.

TmPORTAAT AOTE:

OORTAG THE CAITBRATTOA, THE VAIVE V

J

mAY BE O5EO TO PREVEAT HY5TERE5T5

WHTCH mAY BE OCCOREO OA THE OOC WHTIE CHAAGTAG mA55E5 OF THE 5TAAOARO

PRE55ORE BAIAACE.

NIMT-CNL-SP No. 601

Page 8 of 18

5.3 Repeat step 5.1 and 5.2 until the calibration is completed.

5.+ Release all pressure from the measurement system and disconnect all of the equipments.

6. Data Analysis and Uncertainty Calculation

The measurement result and uncertainty of measurement can be calculated by using the method

stated in DKD R 6-1: 2002, Calibration of Pressure Cauges.

NIMT-CNL-SP No. 601

Page 9 of 18

APPENDIX A

Client:

Unit: Type: No.: Date:

Range:

Resolution: Calibration cycle:

Accuracy: Name of Calibrator

Pressure Calibration Table

p t

room

p

amb

t

piston

trim mass plate no. UUC reading

in hh.

in C in bar in C in g

inhhh.

Standard - system

Standard-mass-set

Height difference cm (+when std. is higher)

Pressure medium Calibrator signature

NIMT-CNL-SP No. 601

Page 10 of 18

APPENDIX B

References:

1. BS EN 83/-1: 1998 British Standard vPressure Cauge Part 1. Bourdon tube pressure

gauges-dimensions, metrology, requirements and testing w.

2. DKD R 6-1: 2002 vCalibration of Pressure Cauges w published by the Physikalisch

Technische Bundesanstalt (PTB) in cooperation with the Technical Committee

vPressurew of the Deutscher Kalibrierdienst (DKD), Braunschweig 2002.

3. EAL-C26 vcalibration of Pressure Balance w European cooperation for Accreditation of

Laboratories: Edition 1, July 199/.

+. Cuide to the Expression of Uncertainty in Neasurement 1

st

edition 1993, !SO, Ceneva,

!SBN 92-6/-10188-9.

Note:

1. The pressure range is depended on customer us standard equipment.

2. The uncertainty values are for example. The laboratories shall evaluate by themself.

3. The model and serial numbers are for ex ample.

+. !f available in the laboratory.

5. The standard equipments can be added based on each laboratory.

6. The pressure transmitting fluid property is based on the fluid used in each laboratory.

NIMT-CNL-SP No. 601

Page 11 of 18

Attachment 1

Mathematical model:

'P = P

n

y P

sI

+ 6GP

6GP

= GP

sI

- GP

rsIuIn

- GP

zrvaIn

- GP

rpaIaDIIv

- GP

nvsIrss

- GP

'n

U =

2

n

u

2

nvsIrss

u

2

Iv rpaIaDI

u

2

n zrvaI

u

2

rsIuIn

u

2

ar Ian s

u K

'

+ + + + +

Where:

P

n

= UUC reading, Pa

P

sI

= Pressure standard at the the point to be measured, Pa

GP

sI

= The correction value of pres sure standard, Pa

GP

rsIuIn

= The correction value due to resolution of the UUC reading, Pa

GP

zr vaIn

= The correction value due to the UUC zero reading, Pa

GP

rpaIaDIIv

= The correction value due to the UUC reading repeatability, Pa

GP

nvsIrss

= The correction value due to hysteresis of the UUC reading, Pa

GP

('n!

= The correction value due to the head correction

measurement system, Pa

Since pressure balance is used as a standard equipment.

Therefore:

GP

sI

= GP

rI/aI

- GP

ImpraIur

- GP

gravIv

- GP

(Ua!

2

sI

u =

2

a

2

gravIv

2

ImpraIur

2

rI/aI

u u u u + + +

Where:

GP

rI/aI

= The correction value due to the calibration certificate of the standard Pa

hydraulic pressure balance,

GP

ImpraIur

= The correction value of the piston 8 cylinder temperature measurement, Pa

GP

gravIv

= The correction value due to local gravity acceleration, Pa

GP

(Ua!

= The correction value due to an ambient air density measurement, Pa

NIMT-CNL-SP No. 601

Page 12 of 18

Note:

u

ImpraIur

= - (D-E!x p x

2

I

a

3

J

u

'n

= ('p x g! x

2

h

a

3

1

u

gravIv

=

2

g

a

3

J

g

p

]

]

\

|

u

Ua

=

2

,

,

]

]

\

|

Where:

a

I

, a

n

, a

g

, a

Ua

= Uncertainty attributed to the input quantity

Example

Uncertainty budget for the calibration of a hydraulic pressure transducer

Calibration effort for calibration sequence A

Statement of mean value ( Mw) with measurement deviation ('p), repeatability (DK) and hysteresis (n)

Calibration item

Accuracy stated by manufacturer : 0,0+ Rdg + 0,005 FS

MasurmnI rang : 2UU Dar

Resolution : 0,01 bar

Standard device

Expanded uncertainty (standard) : 0,008 rdg but not smaller than 0,000 + bar

Lnar InrmaI xpansn //nI (D

-D

p

! : U,UUU UU9 K

-J

Temperature of piston (t

piston

) : (20 0,5)C

Density of mass (p

m

) : / 800 kg/m

3

Calibration conditions

Pressure-transmitting medium : Oil

Fluid density (p

f ,20C, 1 bar

) : (91+ 10) kg/m

3

Air density (p

a ,20C, 1 bar

) : (1,199 0,015) kg/m

3

Height different (Ah) : (0 0,002) m

Cravity (g) : (9,/82 9/0 0,000 + 9) m/s

2

Ambient temperature : (20 1)C

Ambient pressure : (1 013 10) mbar

AmDnI numIv . (55 r JU! PH

NIMT-CNL-SP No. 601

Page 13 of 18

*Table 2 : Measurement data

Reading from calibration item

Pn (bar)

P standard

(bar)

M1 M2 M3 M4

0,000 0,00 0,00 0,00 0,00

20,022 19,99 19,99 19,9/ 19,98

+0,030 39,9/ 39,98 39,95 39,9/

59,9/0 59,8/ 59,90 59,86 59,88

/9,9/9 /9,88 /9,90 /9,86 /9,88

99,988 99,88 99,89 99,85 99,8/

119,99/ 119,8/ 119,89 119,85 119,8/

1+0,005 139,8/ 139,89 139,85 139,8/

160,01+ 159,88 159,91 159,8/ 159,89

180,022 1/9,8/ 1/9,91 1/9,8/ 1/9,88

200,031 199,90 199,91 199,88 199,90

*Note:

- All value are presented after normalization.

Table 3: Evaluation

Mean value

Mw

N

i

/+

Deviation

'p

Mw-p

Repeatability

DK

Max(_M3-MJ_,

_M-M2_!

Hysteresis

n

(_M2-MJ_-

_M-M3_!72

Expanded

uncertainty

U

bar bar bar bar bar

0,00 0,00 0,00 0,00 0,013

19,98 -0,0+ 0,02 0,01 0,018

39,9/ -0.06 0,02 0,02 0,020

59,88 -0,09 0,02 0,03 0,023

/9,88 -0,10 0,02 0,02 0,022

99,8/ -0,12 0,03 0,02 0,025

119,8/ -0,13 0,02 0,02 0,023

139,8/ -0,1+ 0,02 0,02 0,02+

159,89 -0,12 0,02 0,02 0,026

1/9,88 -0,1+ 0,03 0,03 0,030

199,90 -0,13 0,02 0,02 0,026

NIMT-CNL-SP No. 601

Page 1+ of 18

Uncertainties distributed

GP

sIanar, r

Width of distribution (k = 2) = ]

\

|

- 031 , 200

100

008 , 0

bar

= 1,60*10

-2

bar

Probability distribution = Normal

Uncertainty, u(x

! =

2

10 * 60 , 1

2

bar

= 8,00*10

-3

bar

Sensitivity coefficient, (

! = 1

?? Uncertainty contribution, u(v! = (

!' u(x

!

= 8,00*10

-3

bar

GP

ImpraIur

Width of distribution (2a) = 0,5 K

Probability distribution = Rectangular

Uncertainty, u(x

! =

3

5 , 0

K

= 2,89*10

-1

K

Sensitivity coefficient, (

! = -(o+|)

*

p

= -9*10

-6

K

-1

*200,031 bar

= -1,80*10

-3

bar/K

Uncertainty contribution, u(v! = (

!' u(x

!

= -1,80*10

-3

bar/K*2,89*10

-1

K

= -5,20*10

-+

bar

NIMT-CNL-SP No. 601

Page 15 of 18

GP

gravIv

Width of distribution (2a) = 0,000 +9 ms

-2

Probability distribution = Rectangular

Uncertainty, u(x

! =

3

10 * 9 , +

+

ms

-2

= 2,83*10

-+

ms

-2

Sensitivity coefficient, (

! =

g

p

=

9/ /82 , 9

031 , 200

bar/ m s

-2

= 20,+5 bar/ m s

-2

Uncertainty contribution, u(v! = (

!' u(x

!

= 20,+5 bar/ m

.

s

-2

* 2,83*10

-+

ms

-2

= 5,/9*10

-3

bar

GP

(Ua!

Width of distribution (2a) = 0,015 kg m

-3

Probability distribution = Rectangular

Uncertainty, u(x

! =

3

015 , 0

kg m

-3

= 8,66*10

-3

kg m

-3

Sensitivity coefficient, (

! =

m

p

p

=

800 /

031 , 200

bar/ kg m

-3

= -2,56*10

-2

bar/ kg m

-3

Uncertainty contribution, u(v! = (

!' u(x

!

= -2,56*10

-2

bar/ kg

.

m

-3

*8,66*10

-3

kg

.

m

-3

= -2,22*10

-+

bar

NIMT-CNL-SP No. 601

Page 16 of 18

GP

('n!

Width of distribution (2a) = 0,002 m

Probability distribution = Rectangular

Uncertainty, u(x

! =

3

002 0

m

= 1,15*10

-3

m

p

f(p,t)

= p

f(20C, 1bar)

]

]

]

\

|

]

]

\

|

+

20

2

C) ( t C) ( t

/8 0,000 1

piston room

(1+0,000 08P(bar)) (1)

= 91+

]

]

\

|

\

| +

20

2

20 20

/8 000 , 0 1 (1+0,000 08 * 200,031)

= 928,63 kg m

-3

Note : Equation (1) reference from PTB

Sensitivity coefficient, (

! = Ap * g

= (928,63-1,199) kg m

-3 *

9,/82 9/ m s

-2

= 9,0/*10

-2

bar/m

Uncertainty contribution, u(v! = (

!' u(x

!

= 9,0/*10

-2

bar/m

*

1,15*10

-3

m

= 1,0+*10

-+

bar

GP

rsIuIn

Width of distribution (2a) = 0,01 bar

Probability distribution = Rectangular

Uncertainty, u(x

! =

3 2

01 , 0

bar

= 2,89*10

-3

bar

Sensitivity coefficient, (

! = 1

Uncertainty contribution, u(v! = (

!' u(x

!

= 2,89*10

-3

bar

NIMT-CNL-SP No. 601

Page 1/ of 18

GP

zr vaIn

Uncertainty contribution, u(v! = 0,00 bar

GP

rpaIaDIIv

Width of distribution (2a) = 0,02 bar

Probability distribution = Rectangular

Uncertainty, u(x

! =

3 2

02 , 0

bar

= 5,//*10

-3

bar

Sensitivity coefficient, (

! = 1

Uncertainty contribution, u(v! = (

!' u(x

!

= 5,//*10

-3

bar

GP

nvsIrss

Width of distribution (2a) = 0,02 bar

Probability distribution = Rectangular

Uncertainty, u(x

! =

3 2

02 , 0

bar

= 5,//*10

-3

bar

Sensitivity coefficient, (

! = 1

Uncertainty contribution, u(v! = (

!' u(x

!

= 5,//*10

-3

bar

Expanded uncertainty =

2

hys

2

repeat

2

zero

2

res

2

h

2

a

2

g

2

temp

2

cer

u u u u u u u u u k + + + + + + + +

A

p

= 2

*

0,013

= 0,026 bar

NIMT-CNL-SP No. 601

Page 18 of 18

Table 4: Uncertainty budget for load step p = 200,031 bar

Ouantity

X

Estimate

x

Width of

distribution

2a

Diviso

r

Uncertainty

u(x

!

Sensitivity

coefficient

Uncertainty

contribution

u(v!

variance

u

2

bar bar

2

P sIanar

200,031

bar

1,60*10

-2

bar

2

8,00*10

-3

bar

1 8,00*10

-3

6,+0*10

-5

GP

sIanar,

ImpraIur

0,5 K \3 2,89*10

-1

K

-1,80*10

-3

bar/K

-5,20*10

-+

2,/0*10

-/

GP gravIv +,90*10

-+

m/s

2

\3

2,83*10

-+

m/s

2

20,+5

bar/ms

-2

5,/9*10

-3

3,35*10

-5

GP (U

a

! 0,015

kg/m

3

\3

8,66*10

-3

kg/m

3

-2,56*10

-2

bar/kg m

3

-2,22*10

-+

+,93*10

-8

''GP ngnI 0,002 m \3

1,15*10

-3

m

9,0/*10

-2

bar/m

1,0+*10

-+

1,08*10

-8

P n,

rsIuIn

199,90

bar

0,01 bar 2\3

2,89*10

-3

bar

1 2,89*10

-3

8,35*10

-6

GP zr

vaIn

0,00 bar 2\3 0,00 bar 1 0,00 0,00

GP

rpaIaDIIv

0,02 bar 2\3

5,//*10

-3

bar

1 5,//*10

-3

3,33*10

-5

GP

nvsIrss

0,02 bar 2\3

5,//*10

-3

bar

1 5,//*10

-3

3,33*10

-5

'P -0,13 bar u = 0,013

u

i

2

=

1,/3*10

-+

'P -0,13 bar U = k.u (k = 2) 0,026 bar

**allowing for the pressure-dependent fluid density

Você também pode gostar

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- CP No.401-IPRT CalibrationDocumento20 páginasCP No.401-IPRT Calibrationsirsa11Ainda não há avaliações

- Calibration Procedure KrissDocumento12 páginasCalibration Procedure KrissALP69Ainda não há avaliações

- Lab3 Temperature and Calibration - FINALrrDocumento6 páginasLab3 Temperature and Calibration - FINALrrDerrick SheeAinda não há avaliações

- SOP-Procedure Calibration of Metal TapesDocumento12 páginasSOP-Procedure Calibration of Metal Tapeshaharamesh100% (1)

- Calibration of AnemometerDocumento4 páginasCalibration of AnemometerAhmet ŞenAinda não há avaliações

- ITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometerDocumento12 páginasITTC - Recommended Procedures: Sample Work Instructions Calibration of A Liquid-in-Glass ThermometertungluongAinda não há avaliações

- Mitutoyo Bore Gauge PDFDocumento12 páginasMitutoyo Bore Gauge PDFAnonymous 8rb48tZSAinda não há avaliações

- 02-Calibration & Control of Measuring & Monitoring DevicesDocumento1 página02-Calibration & Control of Measuring & Monitoring DeviceskitekAinda não há avaliações

- Kosaka Lab Scope CC 2611Documento50 páginasKosaka Lab Scope CC 2611kumarAinda não há avaliações

- EURAMET Cg-4 V 2.0 Uncertainty of Force MeasurementsDocumento23 páginasEURAMET Cg-4 V 2.0 Uncertainty of Force MeasurementsRicarditoAinda não há avaliações

- Fluk Ammeter CalibrationDocumento250 páginasFluk Ammeter CalibrationASHUTOSH BHATTAinda não há avaliações

- Height Gauge Calibration Procedure: 1.0 Standards and EquipmentDocumento2 páginasHeight Gauge Calibration Procedure: 1.0 Standards and EquipmentKiranAinda não há avaliações

- Digital Display Voltmeter (Ammeter) Anual Operational Instruction MDocumento4 páginasDigital Display Voltmeter (Ammeter) Anual Operational Instruction MCaterine CrespoAinda não há avaliações

- NIST Stopwatch & Timer Calibrations 2009Documento82 páginasNIST Stopwatch & Timer Calibrations 2009ririmonir100% (1)

- 1.SOP For Calibratioon of Pressure GaugesDocumento3 páginas1.SOP For Calibratioon of Pressure Gaugesget_engineer05100% (1)

- EURAMET-cg-08 V 2.1 ChangesDocumento18 páginasEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoAinda não há avaliações

- Accreditation No: LAB 131Documento9 páginasAccreditation No: LAB 131Doulat RamAinda não há avaliações

- Method Statement For Conductivity MeterDocumento2 páginasMethod Statement For Conductivity MeterMuhamed RasheedAinda não há avaliações

- 06 Torque ToolsDocumento28 páginas06 Torque Toolselva RfAinda não há avaliações

- Calibration-Fisher Wizards (C1 - Pnuematic Controller) : 1. Check Pressure RangeDocumento3 páginasCalibration-Fisher Wizards (C1 - Pnuematic Controller) : 1. Check Pressure RangeAlbertoAinda não há avaliações

- Digital Multimeter CalibrationDocumento6 páginasDigital Multimeter CalibrationKhalidAinda não há avaliações

- SOP of Calibration of BalanceDocumento3 páginasSOP of Calibration of BalanceYousif100% (1)

- Analytical Balance SOPDocumento2 páginasAnalytical Balance SOPdivine productionAinda não há avaliações

- Certificate of Calibration: HTLS/DPG/04Documento2 páginasCertificate of Calibration: HTLS/DPG/04Umang SOdhiAinda não há avaliações

- 2012 Calibrations in Process Control and AutomationDocumento11 páginas2012 Calibrations in Process Control and AutomationLALIT RAAZPOOTAinda não há avaliações

- Calibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Documento4 páginasCalibration Report For Digital Thermometer: Sample Customer S/N: X-XXXX Report Number: W195839Sherwin John NavarroAinda não há avaliações

- Spectrum Analyzer and Spectrum Analysis: Shimshon Levy October 2012Documento23 páginasSpectrum Analyzer and Spectrum Analysis: Shimshon Levy October 2012Daniel AguilarAinda não há avaliações

- 29-Stop Watch Calibration CartificateDocumento1 página29-Stop Watch Calibration CartificateCustomer SupportAinda não há avaliações

- METHOD STATEMENT PRESSURE SWITCH UAE Univ.Documento2 páginasMETHOD STATEMENT PRESSURE SWITCH UAE Univ.Muhamed RasheedAinda não há avaliações

- Instrument Calibration ProcedureDocumento10 páginasInstrument Calibration ProcedureMohammad Nurayzat JohariAinda não há avaliações

- Terms of Calibration Service (Rev. 7, May 2014)Documento1 páginaTerms of Calibration Service (Rev. 7, May 2014)John Paul RosAinda não há avaliações

- Free Digital Multimeter Calibration ProcedureDocumento12 páginasFree Digital Multimeter Calibration ProcedurejoaoAinda não há avaliações

- UTI Test CertificateDocumento1 páginaUTI Test CertificatePavel ViktorAinda não há avaliações

- 500 104 MTESTQuattroCalibration Rev2Documento5 páginas500 104 MTESTQuattroCalibration Rev2Javier RochaAinda não há avaliações

- Final ReportDocumento53 páginasFinal ReportmirelamanteamirelaAinda não há avaliações

- Iec TS 62492-1 - 2008Documento24 páginasIec TS 62492-1 - 2008mrkAinda não há avaliações

- THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFDocumento7 páginasTHERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDFGustavo SánchezAinda não há avaliações

- Uncertainty in Thermometer CalibrationDocumento6 páginasUncertainty in Thermometer CalibrationJoel Villasanta DeocaresAinda não há avaliações

- DKD Guidance - Calibration of Liquid WaterDocumento14 páginasDKD Guidance - Calibration of Liquid WatergustavoesanchezAinda não há avaliações

- Calibration Thermometer PDFDocumento7 páginasCalibration Thermometer PDFGilberto Andrés Jurado100% (1)

- DKD R 6 2 t5 e PDFDocumento9 páginasDKD R 6 2 t5 e PDFDragan Ilic100% (1)

- Determination of Color by SpectrocolorimeterDocumento11 páginasDetermination of Color by Spectrocolorimeternvithyarajan6872Ainda não há avaliações

- Method Statement Pressure RecorderDocumento2 páginasMethod Statement Pressure RecorderMuhamed RasheedAinda não há avaliações

- KippZonen ISO9847 Calibration StatementDocumento1 páginaKippZonen ISO9847 Calibration Statementmoro1381Ainda não há avaliações

- Dial Indicator Calibration Procedure TS-0051Documento3 páginasDial Indicator Calibration Procedure TS-0051alexrferreiraAinda não há avaliações

- Insulation Tester 1 CI 02 I2Documento13 páginasInsulation Tester 1 CI 02 I2ebbasinghAinda não há avaliações

- Calibration Certificate Basic 315Documento1 páginaCalibration Certificate Basic 315Anonymous xnpIPaMoAinda não há avaliações

- Liquid-in-Glass Thermometer Calibration: Principle of Operation Traceability ChartDocumento1 páginaLiquid-in-Glass Thermometer Calibration: Principle of Operation Traceability ChartbasdownloadAinda não há avaliações

- Stability and UniformityDocumento6 páginasStability and UniformitymegacobAinda não há avaliações

- U 929 RPM MeterDocumento7 páginasU 929 RPM MeterAmit KumarAinda não há avaliações

- X-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersDocumento34 páginasX-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersRahul DubeyAinda não há avaliações

- Stop Watch-ID-23 - 24 To 25Documento2 páginasStop Watch-ID-23 - 24 To 25monwar hosenAinda não há avaliações

- Calibration Certificate - Gas Coriolis - Unit#1Documento2 páginasCalibration Certificate - Gas Coriolis - Unit#1Said100% (1)

- Calibration, American Laboratory: FlijkeDocumento3 páginasCalibration, American Laboratory: FlijkeAMINE MEDDAHIAinda não há avaliações

- Standard Procedure For Calibration of GaugesDocumento12 páginasStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyAinda não há avaliações

- Calibrating Pressure GaugesDocumento4 páginasCalibrating Pressure GaugesRonny AndalasAinda não há avaliações

- Pressure ProcedureDocumento4 páginasPressure ProcedureCitco IdfcAinda não há avaliações

- Exp3 - Air Pressure ControlDocumento8 páginasExp3 - Air Pressure ControlDon LawrenceAinda não há avaliações

- t-10 SensusDocumento7 páginast-10 SensusAlam Garcia RodriguezAinda não há avaliações

- ZX400LCH 5GDocumento16 páginasZX400LCH 5Gusmanitp2Ainda não há avaliações

- Raspberry Pi Installing Noobs OSDocumento3 páginasRaspberry Pi Installing Noobs OSEXORCEAinda não há avaliações

- Inkt Cables CabinetsDocumento52 páginasInkt Cables CabinetsvliegenkristofAinda não há avaliações

- Literature Review 2500 WordsDocumento6 páginasLiterature Review 2500 Wordsvvjrpsbnd100% (1)

- OPERATING MANUAL Micro Powder MillDocumento51 páginasOPERATING MANUAL Micro Powder MillSher AhmadAinda não há avaliações

- Tech Bee JavaDocumento57 páginasTech Bee JavaA KarthikAinda não há avaliações

- People/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMDocumento8 páginasPeople/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMPola OsamaAinda não há avaliações

- Mss 202 Practice 19-20Documento2 páginasMss 202 Practice 19-20fayinminu oluwaniyiAinda não há avaliações

- GRE Computer Science SyllabusDocumento2 páginasGRE Computer Science SyllabusSameer Ahmed سمیر احمدAinda não há avaliações

- OSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Documento1.544 páginasOSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Oscar Behrens ZepedaAinda não há avaliações

- International Economics 16Th Edition Thomas Pugel Test Bank Full Chapter PDFDocumento45 páginasInternational Economics 16Th Edition Thomas Pugel Test Bank Full Chapter PDFRebeccaBartlettqfam100% (11)

- 9a Grundfos 50Hz Catalogue-1322Documento48 páginas9a Grundfos 50Hz Catalogue-1322ZainalAinda não há avaliações

- Lich King Chorus PDFDocumento21 páginasLich King Chorus PDFMacgy YeungAinda não há avaliações

- Solved Suppose That The Velocity of Circulation of Money Is VDocumento1 páginaSolved Suppose That The Velocity of Circulation of Money Is VM Bilal SaleemAinda não há avaliações

- Introduction and Instructions: ForewordDocumento20 páginasIntroduction and Instructions: ForewordDanang WidoyokoAinda não há avaliações

- UNIT 6 - Dr. Cemre Erciyes PDFDocumento24 páginasUNIT 6 - Dr. Cemre Erciyes PDFMaries San PedroAinda não há avaliações

- Licensed Practical Nurse, LPN, Nurse Tech, Nurse Aide, Nursing ADocumento4 páginasLicensed Practical Nurse, LPN, Nurse Tech, Nurse Aide, Nursing Aapi-121395809Ainda não há avaliações

- In Coming MailDocumento4 páginasIn Coming Mailpoetoet100% (1)

- Influence of Intellectual Capital in The Organizational InnovationDocumento8 páginasInfluence of Intellectual Capital in The Organizational InnovationsopingiAinda não há avaliações

- Global Review of Enhances Geothermal SystemDocumento20 páginasGlobal Review of Enhances Geothermal SystemKatherine RojasAinda não há avaliações

- PETRO TCS Engineering Manual 682Documento44 páginasPETRO TCS Engineering Manual 682paulm3565Ainda não há avaliações

- Safe and Gentle Ventilation For Little Patients Easy - Light - SmartDocumento4 páginasSafe and Gentle Ventilation For Little Patients Easy - Light - SmartSteven BrownAinda não há avaliações

- Consolidated Digests - Part 2Documento314 páginasConsolidated Digests - Part 2Neil Patrick Pepito ErmacAinda não há avaliações

- 1 General: Fig. 1.1 Industrial RobotDocumento40 páginas1 General: Fig. 1.1 Industrial RobotArunAinda não há avaliações

- Alpine MRV f305Documento2 páginasAlpine MRV f305Luis RrAinda não há avaliações

- Oxford Handbooks Online: From Old To New Developmentalism in Latin AmericaDocumento27 páginasOxford Handbooks Online: From Old To New Developmentalism in Latin AmericadiegoAinda não há avaliações

- ETA-1 Service PDFDocumento44 páginasETA-1 Service PDFgansolAinda não há avaliações

- Vitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenDocumento50 páginasVitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenAnca IscruAinda não há avaliações

- KINDRED HEALTHCARE, INC 10-K (Annual Reports) 2009-02-25Documento329 páginasKINDRED HEALTHCARE, INC 10-K (Annual Reports) 2009-02-25http://secwatch.comAinda não há avaliações

- 4 3 3LeaseLinesignedDocumento42 páginas4 3 3LeaseLinesignedJagat Brahma PatraAinda não há avaliações