Escolar Documentos

Profissional Documentos

Cultura Documentos

Client Comment Response - DG Foundation

Enviado por

Annelz0 notas0% acharam este documento útil (0 voto)

208 visualizações7 páginasJOB PERTAMINA - TALISMAN JAMBI MERANG DIESEL GENERATOR FOUNDATION DESIGN CALCULATION. 91400 mm PC Spun Pile with 36 m penetration had been used to the design with following capacity:.

Descrição original:

Título original

Client Comment Response -DG Foundation

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoJOB PERTAMINA - TALISMAN JAMBI MERANG DIESEL GENERATOR FOUNDATION DESIGN CALCULATION. 91400 mm PC Spun Pile with 36 m penetration had been used to the design with following capacity:.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

208 visualizações7 páginasClient Comment Response - DG Foundation

Enviado por

AnnelzJOB PERTAMINA - TALISMAN JAMBI MERANG DIESEL GENERATOR FOUNDATION DESIGN CALCULATION. 91400 mm PC Spun Pile with 36 m penetration had been used to the design with following capacity:.

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

JOB PERTAMINA - TALISMAN JAMBI MERANG

DIESEL GENERATOR FOUNDATION DESIGN CALCULATION

Table 2.2 Material Unit Weight

Material

Unit Weight

Reinforced Concrete y",

23.5 kN/m'

Steel y. = 76.9 kN/m'

Soil y",

=

16.5 kN/m'

Water yw

10.0 kN/m'

Sand Gravel y,

17.7 kN/m'

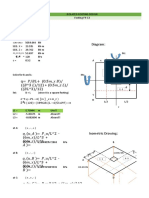

2.4 PILE ALLOWABLE CAPACITY

Refer to Attachment A for the Pile capadty calculation Study extracted from Final

Report of PC! 5011 Investigation for North Geragai Facility Project, Jambi, Sumatera.

91400 mm PC Spun Pile with 36 m penetration had been used to the design with

following capacity:

Table 2.3 Pile Allowable Capacity

Condition of Loading

Qcomp (kN)

SF =3.0

Group

Efficiency

Permanent 725 1.0

Temporary 966 1.0

3 FOUNDATION DESIGN

3.1 DESIGN CRITERIA

Where the centre of mass of the machine is not known, its eccentricity from the

centerline of the foundation is assumed to be zero, and that it would not have

Significant impact on the foundation size and hence cost.

Top of foundation assumed to be 150 mm above the Finish Grade Level (FGL) which

Is higher than top of surface gravel.

The foundation structure Is checkec by :

1. Pile aXial capadty

2. Settlement (fi,,!,+ fW -\-l"iS (A,1c.,,(p,-ho vt U. - ./Or

- Factore oa I rnation Is usee for designing reinforced concrete slab.

Unfactored loading oomblnation is used for checking the pile capacity and punching

shear of the foundation.

3.2 DESIGN LOADS

3.2.1 DEAD LOAD (D)

Dead loads are the self weight of structure of foundation. Unit weights of the major

oonstructlon materials as seen on Table 1.2 Material Unit Weight.

Page 60f9

JOB PERTAMINA - TALISMAN JAMBI MERANG

DIESEL GENERATOR FOUNDATION DESIGN CALCULATION

3.2.2 EQUIPMENT LOAD (E)

The equipment load is the weight of the equipment refers to Doc. No. GD-M-Ll-002

Equipment Ust. The equipment loads are classified as empty [E(E)], and operating

[E(O)] condition.

3.2.3 EARTHQUAKE LOAD (EQ)

The equipment foundation has been designed for earthquake forces in accordance with

USC 1997 with following conditions:

- Seismic zone = 2A

- Seismic Acceleration =0.15 G

- Soil specification =Soft soil

Base Shear (Vs)

Design base snear shall be calculated by using this following equation:

V = C.xI x"w:

, RxT I

The design base shear need not exceed following:

V =2.5 X C

Q

x I x" w: =0.426 x !.W,

sma R I

Also shall be not less than the following formula:

V' mm = O.l1x C

Q

xIxIw; = 0.041 x LW,

where:

!.W, = Weight of equipment and/or structure (kN)

I = Importance factor = 1.25

C

v

=Seismic coeffident = 0.5

C. = Seismic coeffident = 0.3

R = Numerical coeffident = 2.2

h

n

= Total height of equipment = 1.6 m

T = Fundamental Period = 0.0488 (h

n

) 3/. = 0.069 s

C xl "

Design Sase shear: V, = -'-x

RxT

V,= 0.5x1.25 xIw:

2.2 x 0.069 I

V, = 4.117 X LW, kN > Vsmax

Therefore, we use Vsmax as the design base shear: V, = 0.426 X !.W,' kN

For unfactored load combination (Allowable Stress Design Method), the design base

shear should be divided by 1.4 as per USC 1997.

V, = 0.304 x!.W, kN Whe-re Cv"'1' 0'0"1? (- ....Jt

The total weight of equipment and structures (!.W,) so we get: 0V- (W0. <.l'

V, = 119.02 kN

J-"-b}]< eq \)L ;,-i;u. bll tea \c-IV c..",,p;h.)--9'31--., Ii

. L ,c\-;,lIO ,,-.v Page 7 of 9

\ 'l:-tJ

JOB PERTAMINA- TAUSMAN JAMBI MERANG

DIESEL GENERATOR FOUNDATION DESIGN CALCULATION

3.2.4 WIND LOAD (W)

The foundation will be designed for wind load with following criterion:

Basic Wind Speed V = 28 m/s

Equipment Height H = 1.6 m

- Equipment Width B = 2.8 m

- Velocity pressure exposure coefficient (Exposure C, z=2.4 m) K, = 0.62

- Topographic factor (flat area) K .. =1.00

- Wind directional factor K" = 0.9

- Importance factor (category rrn I... = 1.15

- Gust effect factor G = 0.85

Pressure coeffICient Cp = 1.35

Design wind load shall be calculated by using these following equations:

Velodty Pressure:

q, = 0.613 * K, * K" * K, * Vl * Iw

= 0.308 kN/m2

- Wind Pressure

P =q,*G*C

p

= 0.354 kN/m2

- Wind Pro'ected N

Ar = H * B -------j> I - L ~ '!. .'3"" ov.,.,

- 4.48 m

2

~ ~ L {,"'"

Wind Force

W = P*A,

=1.58 kN < V, =119.02 kN :. Not governing

Therefore, the wind load is not considered in the foundation design load combination.

Page 8 of9

V'

Calculation Sheet

.,."..... ....... ............

......,

Calc no GI}-CL-C-004 File

Elec file location

Project till. EPC Condensat. Metertng Station At North Geragal Project Pro! no

Client JOB PERTAMINA-TALISMAN JAMBI MERANG Phase/CTR

Calculation tille Diesel Generator Foundation Page

5

ot

8

Diesel Generator Foundation

D. Pile Capacity Check

Pile COmpression Capadty

0

0

Iy

0 0

1 1

Y

I I I

Pile quantity (long nx

=

2

PII. quantity (short dir'n) ny

=

2

Total Nos of Pile n

=

4

Pile location x

=

1.00 m

y = 1.10 m

Pile spacing (long Ix = 4.20 m

=

10.5 D

Pile spacing (short Iy

=

2.80 m

=

7 D

Pile EffiCiency Factor

T) =

1.00

Modulus Shape of Pile SX = Lx'i Xm", where: 1:x"

=

1x"/12 x n, x (n! -1)

(x - axis)

=

S.88 m

=

8.82 m'

Xmu

= 1.5

m

pz M PU

max

Case No.

(kN) (kN.m) (kN)

Case 1 471.86 0.00 117.96

Case 2 354.00 0.93 88.66

Case 3 476.13 0.00 119.03

<);e4

357.10 0.93

!r caseS 437.10 CT.OO 109.28)

.)

Pu""" =

pIn + M/Sx

Pile design load (axial) Pu = 238,07 kN (multiplied by 2.0 for' load safety factor)

Pile Allowable Capadty Poop = 725.00 kN @ 36 m pile penetration

Pile Safety Factor SF

=

Pcapl Pu

=

3.05 > 3.0; Hence, pile OK #

[O't.Q. ?

"".

-

1.1 11\

Calculation Sheet

., ................'.........., .......... ""......--,..

........ .....,

Calc no GD-CL-C-004

Elec file location

Project title

Cllant

EPC Condensate Metering StaUon At North Geragai Project

JOB PERTAMINA-TALISMAN JAMBI MERANG

Calculation title Diesel Generator FoundaUon

File

Proj no

Phase/CTR

Page 6 of 8

Diesel Generator Foundation

E. Pllecap Design

L Footing Flexural Reinforcement (Top & Bottom)

Wu = 133.32 kN/m

M max

Pmax

Pmln

fc'

= 23.65

= 666.59

= 424.67

= 2S.00

= 400.00

kNm (Max M from Sect.

kN (Max pz from Sect. C.r,c:.bC-';)' <

5000

Unit Breadth of Slab

Slab Found. Depth

Bar Diameter

Effective Depth

Equivalent uniform load

Bending moment

Strength Reduction Factor

Coeffident of Resistance

Steel Ratio Req'd moment based

Concrete strength redct. Factor

Steel Ratio (balanced Cond.)

Steel Ratio (Max)

Steel Ratio (Min)

Steel Ratio (Shrinkage)

Steel Ratio (requined)

Steel area required

Spacing of Rebar

Reinforcement Provided

kN (Min Pz from Sect. - 9..) J

MPa ./

tv

MPa

b = 1 m

h

d",

dOl

=

H ?7

=

=

=

=

h c.." ,,/2 =

Wu = Pm../

L

=

Mu

{1!

=

0.90

Ru = Mu/(llIbd')

=

Preq'd = /

1

_ 2& J

f" 'i

=

= 0.85

Pblnc:

0.85 fc-pc/fyfx600/(600+fyf) =

Pm.. = O.7SX

=

PmIn = Ii) l.4/fyf =

0.600 m

19.050 mm

0.520 m

133.317 kN/m

kN.m

c)rQc.>..I.

C02

0.0303

0.0228

0.0035

kN/m'

govern I

(ii) "rcpclI4 x fyf) = 0.0033

p""

P,OY

=

=

O.OOlS

0.0035

Asr'q'd ::: p.ove.m X b Xdb!:

s =

019@130

pro'" . = n X0.25 7t dlH/

I so: n

As prov"d

= 1822

mm

'

=

130 mm

= 7

=

1988

mm

'

> Asreq'd

okl

1)\L..

., ...... . ... -- ., ......"'",-_....

- -

Calculation Sheet

,

Calc no GD-CL-c-()04 File

Elec file location

Project title EPC Ccndensate Metering Stetion At North Geraga; Project Proj no

Client JOB PERTAMINA-TALISMAN JAMBI MERANG Phase/CTR

Calculation title Diesel Generator Foundation Page 7 01

Diesel Generator Foundation

2, Punching Shear Check

Design compressive strength fc' 28,00 MPa

Foundation slab thickness h 600 mm

Concrete cover cv =

70 ., '!'.'l'

Effective depth db<

=

"lV-

Radius 01 punching shear

=

0/2+ dbt/2

=

415,0 mm

Critical Shear Perimeter b,

=

2608 mm

Pile dimensional ratio

=

1.0

Strength Red'n Factor (shear)

=

0.85

Re-bar vield strength I,

=

400,0 MPa

Constant used to compute Vc a, = 30 (assumed as edge column)

Provisional punching shear cap.

=

$.(l+2/P,),(f J',s.b,.d/6 209 kN

=

242 kN

=

$.(1/3).(fl " .b"d 140 kN

Umltfng punching shear cap.

=

=

70 kN

Punching shear capacity

Design punching load

Utilization ratio

3. Tie Bar

- Tie Bar Requirement

Maximum Actual Shear Vu =

16,97 kN (Max Px Irom Sect C,2)

Allowable Shear for Slab without 2xvfcxBxd

bl

Vc

=

Reinforcement

12

=

157 kN

Strength Reduction Factor ,p

=

0,75

Nominal Shear Strength ,pVc

=

118.08 kN

0.5 ,pVc 59.04 kN > Vu

=

16.97 kN (OK I)

Hence, shear reinforcement caJwlate based on shrinkage requirement only.

- Shear Reinforcement Design

Shear reinforcement Spacing S = Zone 1 , S > 0.5 d, S> 300 = 300 mm

Steel area requ{red A....'d = 1/3 x((dbtx S)ffy) = 130 mm'

Reinforcement Provided +10@300 ,so: n 2

::: n x O.2S1C d

blr

2

= 142 mm'

A"..v

> okl

e>""! "'0- '}-

A....'d

.....

ov....

8

Calculation Sheet

.. ".......... _,_.......""' ..................

..-

Calc no GD-CL-G-004 File

Elec fila location

Project tItle

Client

EPC Condensate Melerlng Station At North Geragai Projact Proj no

JOB PERTAMINA-TALISMAN JAMBI MERANG Phase/CTR

calculation UtI. Diesel Generator Foundation Pa e 8 of

8

Diesel Generator Foundation

4. Reinforcement Bar Sketth

Top Flexural Reinforcement

D19@130

Bottom Flexural einforcement

D19@130

5. Maximum Crack WIdth On Tension Area

Effective Tension Area

IJ' ;'\

A.0'" bll,

Is = MPa ,, ')

de = 70 mm

2ds 140 mm

j3 = 1.2 for beam

= 1.35 Ifor slab

= 7 (Ref, Sect E.1)

2 ds

B 1000 mm

Maximum crack width on tension area based on Gergely-Lutz formula.

w 1.11 x 10 " x j3 xfsx 3 Vde x A where : Ae = 2 ds x B

= 1.11 x10-6 x 1.35 x 240 x 30(70 x20000) 140000 mm'

0.0402 mm A = AelN

= 20000 mm'

Allowable crack width W" = 0.4 for interIor exposure (Ref. GL-SP-C-l001

0.33 for exterior exposure (Ref. GL-SP-C-100)

Maximum crack width W 0.040 mm < 0.33 mm (OK!)

Você também pode gostar

- Gantry Girder DesignDocumento6 páginasGantry Girder DesignpandianAinda não há avaliações

- Vertical Equation Foundation-Spread Sheet PDFDocumento6 páginasVertical Equation Foundation-Spread Sheet PDFmassive85Ainda não há avaliações

- ReportTank 12.0m DiaDocumento17 páginasReportTank 12.0m DiasuheilbugsAinda não há avaliações

- AISC 13th Slip Critical Bolt Capacity ASDDocumento1 páginaAISC 13th Slip Critical Bolt Capacity ASDdantevariasAinda não há avaliações

- Buffer Vessel Foundation - LatestDocumento39 páginasBuffer Vessel Foundation - LatestGautam DuttaAinda não há avaliações

- Anchor Chair Design CheckDocumento5 páginasAnchor Chair Design CheckHomer SilvaAinda não há avaliações

- 111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24Documento7 páginas111.872 KN Section Properties B 203.1 D 203.2 T 11 T 7.24ItsmejanuAinda não há avaliações

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Documento7 páginas4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabAinda não há avaliações

- Portal FrameDocumento42 páginasPortal Framesurendra_pangaAinda não há avaliações

- Wind Load Calculations On VesselsDocumento3 páginasWind Load Calculations On VesselssudhakarebvnAinda não há avaliações

- Project: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionDocumento4 páginasProject: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionEr Ravi VishwakarmaAinda não há avaliações

- Embedded PlateDocumento38 páginasEmbedded PlateAnonymous pD2ymRUguAinda não há avaliações

- FinPlate Type Cleat ConnectionDocumento81 páginasFinPlate Type Cleat ConnectionRajveer SinghAinda não há avaliações

- Lifting CalculationDocumento7 páginasLifting CalculationAsaru DeenAinda não há avaliações

- Foundation F1 Design CalculationDocumento30 páginasFoundation F1 Design CalculationvasudhaAinda não há avaliações

- Tank Foundation RingwallDocumento10 páginasTank Foundation RingwallabguyAinda não há avaliações

- Pedestal DesignDocumento11 páginasPedestal DesignNikhil TawadeAinda não há avaliações

- 2 0 Insert Plate Calculations Type 14 PDFDocumento4 páginas2 0 Insert Plate Calculations Type 14 PDFKho C AhlAinda não há avaliações

- 8224 Grating No HeaderDocumento69 páginas8224 Grating No HeadervishalnalwarAinda não há avaliações

- Wind CalculatorDocumento12 páginasWind Calculatorilyasmd7Ainda não há avaliações

- RAM Connection Input With CommentsDocumento6 páginasRAM Connection Input With CommentsAhmed Saeed OokaAinda não há avaliações

- Iito Wall: File:///Conversion/Tmp/Scratch/418555233Documento7 páginasIito Wall: File:///Conversion/Tmp/Scratch/418555233Saurabh GuptaAinda não há avaliações

- Baseplate DesignDocumento14 páginasBaseplate DesignmaheshbandhamAinda não há avaliações

- Calculation For SpliceDocumento15 páginasCalculation For SpliceSandeep Singh0% (1)

- Fdocuments - in Insert Plate Design LugsDocumento8 páginasFdocuments - in Insert Plate Design Lugsarchetype designAinda não há avaliações

- Design of Base Plate & Anchor Bolt (Crusher House)Documento5 páginasDesign of Base Plate & Anchor Bolt (Crusher House)titir bagchiAinda não há avaliações

- 1424-S-RP-002 A Support Reactions and Anchor Bolt DesignDocumento15 páginas1424-S-RP-002 A Support Reactions and Anchor Bolt DesignAmarjit KulkarniAinda não há avaliações

- Neral & Staad Diag.Documento130 páginasNeral & Staad Diag.IkramAinda não há avaliações

- Design of Beam Based On ACI 318-99Documento5 páginasDesign of Beam Based On ACI 318-99Haris AlamAinda não há avaliações

- DG Consulting EngineersDocumento8 páginasDG Consulting EngineersThakshayani SellavelAinda não há avaliações

- Foundation DesignDocumento18 páginasFoundation Designhemantkle2uAinda não há avaliações

- Isolated Footing DesignDocumento14 páginasIsolated Footing DesignDhandapany ArunAinda não há avaliações

- Design of Combined Foundation For Column C7 & C8Documento6 páginasDesign of Combined Foundation For Column C7 & C8Sneha RedkarAinda não há avaliações

- Design Calculation of Security Building at Allipuram: L&T ConstructionDocumento33 páginasDesign Calculation of Security Building at Allipuram: L&T Constructionjuliyet strucAinda não há avaliações

- Gantry Girder DesignDocumento5 páginasGantry Girder DesignDarsHan MoHanAinda não há avaliações

- Seated ConnectionDocumento5 páginasSeated ConnectionMcsSelvaAinda não há avaliações

- Insert Plate DesignDocumento24 páginasInsert Plate Designabhi arote100% (1)

- Welded Splice Connection-R2Documento33 páginasWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- ANCHOR - REINFORCEMENT (Metric)Documento10 páginasANCHOR - REINFORCEMENT (Metric)Tarek AbulailAinda não há avaliações

- Dead Load Only From The PipeDocumento5 páginasDead Load Only From The PipeНемања Караклајић100% (1)

- 98m Stack Design Calculations 4Documento16 páginas98m Stack Design Calculations 4Ouseppachan AmbookenAinda não há avaliações

- Isolated Footing DesignDocumento15 páginasIsolated Footing DesignAzzirrenAinda não há avaliações

- HSS Flange Plate Moment Connection - Temporary SteelDocumento9 páginasHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteAinda não há avaliações

- Beam DesignDocumento8 páginasBeam DesignFaraaz FaisalAinda não há avaliações

- Space 2001Documento43 páginasSpace 2001Nguyen Duc CuongAinda não há avaliações

- Insert Plate DesignDocumento8 páginasInsert Plate DesignPiyushAinda não há avaliações

- Design Basis For Steel Connection of Standard Drawing - Rev Ad PDFDocumento5 páginasDesign Basis For Steel Connection of Standard Drawing - Rev Ad PDFvijaystructuralAinda não há avaliações

- Design of Column: Section ClassificationDocumento4 páginasDesign of Column: Section Classificationvenkatesh19701Ainda não há avaliações

- 1.0bolted Truss ConnectionDocumento7 páginas1.0bolted Truss ConnectionklynchelleAinda não há avaliações

- Design of Ring Girder SupportDocumento3 páginasDesign of Ring Girder Supportvishal guptaAinda não há avaliações

- Foundation Design Philosophy For Horizontal VesselDocumento6 páginasFoundation Design Philosophy For Horizontal VesselKeaten ClaneyAinda não há avaliações

- Steel Beam Design As Per AISC ASDDocumento2 páginasSteel Beam Design As Per AISC ASDAJ NugrohoAinda não há avaliações

- Deisel Tank Foundation 26-10Documento35 páginasDeisel Tank Foundation 26-10Manan MansoorAinda não há avaliações

- Platform Cleat CalculationDocumento1 páginaPlatform Cleat Calculationmiteshpatel191Ainda não há avaliações

- Dome Roof - OutputsDocumento18 páginasDome Roof - Outputszatenne100% (1)

- Gantry CraneDocumento18 páginasGantry Craneamirthraj7494% (16)

- Pile Cap Design 1Documento6 páginasPile Cap Design 1kjpatel2100% (2)

- WarehouseDocumento51 páginasWarehouseAnonymous q0irDXlWAm100% (2)

- Indrumator Metal - EGDocumento37 páginasIndrumator Metal - EGhooky1100% (1)

- Design Calculations For The Dome Structure-Type 1Documento6 páginasDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- ACCX-KITCHENHOODS SPMDocumento36 páginasACCX-KITCHENHOODS SPMDavina FristantryAinda não há avaliações

- Mechanical Engineering Curriculum 2014 Active For 1st and 2nd YearDocumento271 páginasMechanical Engineering Curriculum 2014 Active For 1st and 2nd YearMesafint kassieAinda não há avaliações

- SMP For Supply Water PumpDocumento13 páginasSMP For Supply Water PumpSonratAinda não há avaliações

- Deaeration Technique DT199505 - A01Documento3 páginasDeaeration Technique DT199505 - A01smallik3Ainda não há avaliações

- Lathe PresentationDocumento130 páginasLathe Presentationrahul k.kAinda não há avaliações

- 800D SeriesDocumento3 páginas800D Seriesvkeie0206Ainda não há avaliações

- Ig Rj45 Push-Pull Connector 39680 en 1512Documento1 páginaIg Rj45 Push-Pull Connector 39680 en 1512Henry WoartAinda não há avaliações

- Basf Masterprotect 180 TdsDocumento3 páginasBasf Masterprotect 180 TdsHoang An ViAinda não há avaliações

- P No-Goat Shed Pig Shed Poultry Shed BOQDocumento9 páginasP No-Goat Shed Pig Shed Poultry Shed BOQEstate BASUAinda não há avaliações

- MOD 005 Stainless SteelsDocumento6 páginasMOD 005 Stainless SteelsDu Xuan BinhAinda não há avaliações

- Printing On Proteinic FabricsDocumento10 páginasPrinting On Proteinic FabricsDÃljït Sīñgh100% (1)

- Clg855h (Gcic t2) Service Manual 202007002-EnDocumento642 páginasClg855h (Gcic t2) Service Manual 202007002-EnRicky Safira zahiraAinda não há avaliações

- Specifications: PartsDocumento1 páginaSpecifications: PartsJohn reinaAinda não há avaliações

- Expansion ThermometersDocumento28 páginasExpansion ThermometersKevin Nelson LoboAinda não há avaliações

- Eset 211 Lab 08 InverterDocumento3 páginasEset 211 Lab 08 InverterPhan HiếuAinda não há avaliações

- Ime34070m 2 Far FR2835SDocumento80 páginasIme34070m 2 Far FR2835Ssrinu1984Ainda não há avaliações

- Canal Trough DesignDocumento18 páginasCanal Trough DesignGarg Tj100% (1)

- Sonalika Training ReportDocumento64 páginasSonalika Training Report3drohit100% (4)

- Oscillating Magnetos Jack Beater 1940Documento3 páginasOscillating Magnetos Jack Beater 1940Steven Howell0% (1)

- Ecoclean (TM) HSDI 653.af - PDS (2381)Documento1 páginaEcoclean (TM) HSDI 653.af - PDS (2381)Sony HartonoAinda não há avaliações

- Specification ☆客户名称 Customer: 立创: Jimson Electronics (Xiamen) Co.,LtdDocumento9 páginasSpecification ☆客户名称 Customer: 立创: Jimson Electronics (Xiamen) Co.,LtdVALTERAinda não há avaliações

- ZJP Roots Vacuum Pump - Manual - 1ED.20200422.ENDocumento17 páginasZJP Roots Vacuum Pump - Manual - 1ED.20200422.ENLuisAngelChavezAinda não há avaliações

- F 34145Documento143 páginasF 34145María Gómez ZerpaAinda não há avaliações

- SDMyers Test Packages BrochureDocumento4 páginasSDMyers Test Packages BrochureYesid FigueroaAinda não há avaliações

- Pipe Roofing SolutionsDocumento12 páginasPipe Roofing SolutionsSubhash KediaAinda não há avaliações

- Chromium-Nickel-Molybdenum-Iron (UNS N08366 and UNS N08367) Plate, Sheet, and StripDocumento6 páginasChromium-Nickel-Molybdenum-Iron (UNS N08366 and UNS N08367) Plate, Sheet, and StripGreg YeeAinda não há avaliações

- Building RepairsDocumento8 páginasBuilding RepairsRenuka ChalikwarAinda não há avaliações

- Do - 026 - s2023 (Item 624 Roadway Lighting)Documento13 páginasDo - 026 - s2023 (Item 624 Roadway Lighting)QWERTY YUYUPAinda não há avaliações

- Boston Gear Worm Gear Speed Reducers: Installation and OperationDocumento24 páginasBoston Gear Worm Gear Speed Reducers: Installation and OperationJuan Alejandro Jurado de la RosaAinda não há avaliações

- Hix HTM (Heat Transfer Machine) BookletDocumento8 páginasHix HTM (Heat Transfer Machine) BookletHIX CorporationAinda não há avaliações