Escolar Documentos

Profissional Documentos

Cultura Documentos

NX100 Robot Controller

Enviado por

Eman GuiruelaDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

NX100 Robot Controller

Enviado por

Eman GuiruelaDireitos autorais:

Formatos disponíveis

SOLUTIONS IN MOTION

OPTIONAL CUSTOM HMI

MULTIPLE ROBOT CONTROL

ROBOT CONTROLLER

NX100

Motoman Robotics NX100 robot controller offers high performance, open communication, and integrated cell control

LADDER EDITOR

FEATURES & OPTIONS

n

Patented multiple robot control capability (up to FOUR robots with one pendant) Windows CE operating system on programming pendant Standard Ethernet communication Compliance with ANSI/RIA R15.06-1999 safety standard Unmatched memory: 60,000 steps (taught points), 10,000 ladder (concurrent I/O) instructions On-board graphical ladder editor Ability to fit up to three external axis servo amplifiers

n n

The revolutionary NX100 controller features a Windows CE programming pendant with color touch screen, highspeed processing, unmatched memory (60,000 steps, 10,000 instructions), built-in Ethernet, and a robust PC architecture. The NX100 features password protection with four levels and up to 100 individual users. The NX100 easily handles multiple tasks, with unmatched ability to control up to four robots (up to 36 axes, including robots and external axes), and I/O devices. Dynamic interference spheres protect the robot arm, providing collision avoidance/arm interference prevention. Advanced Robot Motion (ARM) control provides high-performance path accuracy and vibration control. In addition, the NX100 features best-in-class path planning that dramatically reduces teaching time. The programming pendant features a unique cross-shaped navigation cursor that reduces teaching time by 30 percent. It has full-color touch-screen display and a convenient compact flash slot for easy

memory back-ups. All operator controls are located on the pendant, allowing the control cabinet to be mounted remotely. Dual-channel safety features include enhanced E-Stop functionality, integrated speed monitoring, and manual brake release for the robot. The NX100 also offers unmatched connectivity, highly flexible Fieldbus support, and easy connection to an information infrastructure through standard network options for DeviceNet, ControlNet, Profibus-DP, EtherNet/IP, and many others. An optional web server that allows remote monitoring and diagnosis is available. By eliminating the need for a separate PLC, PC-based human machine interface (HMI), and separate password protection hardware, and by providing a standard Ethernet port, the NX100 delivers significant cost savings at the system level, while also decreasing system complexity and improving overall system reliability.

NX100 Robot Controller

650 650

NX100 ROBOT CONTROLLER SPECIFICATIONS

Dimensions Approximate Mass Cooling System Ambient Temperature Relative Humidity Primary Power Requirements Digital I/O NPN - Standard PNP - Optional Position Feedback Program Memory Interface Multiple Robot Control 650(w) x 1,200(h) x 650(d) mm (25.6" x 47.2" x 25.6") 150-250 kg (330.8-551.3 lbs.) Indirect cooling During operation: 0 C (32 F) to 45 C (113 F) During transport and storage: -10 C (14 F) to +60 C (140 F) 90% max. non-condensing 3-phase, 240/480/575 VAC at 50/60 Hz Standard I/O: 40 inputs/40 outputs consisting of 16 system inputs/16 system outputs, 24 user inputs/24 user outputs Expandable to 1024 inputs/1024 outputs Absolute encoder 60,000 steps and 10,000 instructions Ethernet, RS-232C Dual, triple, and quad

1200

SAFETY FEATURES

All dimensions are metric (mm) and for reference only.

CONTROLLER

Safety Specs Collision Avoidance Collision Detection Machine Lock Safety Interlock

Dual-channel Emergency Stop Pushbuttons, 3-Position Enable Switch built into pendant, Manual Brake Release Meets ANSI/RIA R15.06-1999 safety standard Collision avoidance zones and radial interference zones Protects robot by monitoring torque levels on manipulator Permits testing of peripheral devices without robot operation Prevents robot operation while safety circuit is open

DOOR

PENDANT

Pendant Dimensions Pendant Display Pendant Languages Pendant Weight Coordinate System Windows Menu-Driven Interface Pendant O/S Protection Rating

199 x 338 x 60 mm (7.8" x 13.3" x 2.4") 6.5 inch full color touch screen, 640 x 480 (VGA) English, German, Japanese, Spanish, Chinese 1.34 kg (2.96 lbs.) Joint, rectangular, cylindrical, tool, 24 user-coordinate frames User-selectable touch-screen menu Compact Flash slot for backup Windows CE IP65

Standard I/O - NPN

650

Forty optically isolated inputs, 32 transistor outputs, 8 relay contact outputs (configured to optimize each application), and four break-out cards are provided as standard. For arc welding applications, one XEW01 welder interface board is installed in the cabinet as standard.

PROGRAMMING

Programming Language Robot Motion Control Speed Adjustment Device Instructions I/O Instructions Operation

INFORM III, menu-driven programming Joint motion, linear, circular, spline interpolation Percentage of maximum for joint motion; mm/sec, cm/min, in/min for displacement; /sec for orientation Application-specific (ARCON, ARCOFF, LASERON, LASEROFF, HANDON, HANDOFF) Discrete I/O, 4-bit and 8-bit manipulation, analog output, analog input, analog scaling, sloping Up to 5 levels of undo/redo

I/O Expansion

MAINTENANCE

The NX100 supports I/O expansion via: Profibus-DP ControlNet Analog I/0 DeviceNet Remote I/0 Discrete I/O, NPN or PNP EtherNet/IP Other networks available

Maintenance Functions Self-Diagnostics User Alarm Display Alarm Display I/O Diagnosis TCP Calibration Tool Weight Calibration

System monitor, internal maintenance clocks Classifies errors and major/minor alarms and displays data Displays alarm messages for peripheral devices Alarm messages and alarm history Permits simulated enabled/disabled input/output Automatically calibrates parameters for end-effectors, optional TCP recovery function Automatically calibrates total weight of tool, center of gravity and inertia for peak performance

www.motoman.com

TECHNICAL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE DS-232-F 2011 yASkAWA AMERICA, INC. JUNE 2011

MOTOMAN ROBOTICS 100 AUTOMATION WAy, MIAMISBURG, OHIO 45342 TEL: 937.847.6200 n FAX: 937.847.6277

MOTOMAN IS A REGISTERED TRADEMARk WINDOWS IS A REGISTERED TRADEMARk OF MICROSOFT ALL OTHER MARkS ARE THE TRADEMARkS AND REGISTERED TRADEMARkS OF yASkAWA AMERICA, INC.

Você também pode gostar

- NXC100 ControllerDocumento2 páginasNXC100 ControllermartinimartiiniAinda não há avaliações

- XRC ControllerDocumento2 páginasXRC ControllersengcyanAinda não há avaliações

- Motoman HP 20Documento2 páginasMotoman HP 20Esteban Quezada NeriAinda não há avaliações

- DENSO Automation Trainer BrochureDocumento8 páginasDENSO Automation Trainer BrochureNascostaAinda não há avaliações

- Motoman-Dx100: Industrial Robot ControllerDocumento4 páginasMotoman-Dx100: Industrial Robot ControllerloreyerneAinda não há avaliações

- Motoman-Dx100: Industrial Robot ControllerDocumento4 páginasMotoman-Dx100: Industrial Robot ControllerIgor GonçalvesAinda não há avaliações

- IRC5Documento2 páginasIRC5Luis Miguel ZapataAinda não há avaliações

- 009-1137-00 HST-SMRTD Savant Smart Host Tech SpecDocumento6 páginas009-1137-00 HST-SMRTD Savant Smart Host Tech Specferna2420Ainda não há avaliações

- FP4030Documento7 páginasFP4030Maitry ShahAinda não há avaliações

- AX 20controller NRSDocumento2 páginasAX 20controller NRSTuan Bu Dich nguyenAinda não há avaliações

- NXC100 Controller PDFDocumento2 páginasNXC100 Controller PDFJose FloresAinda não há avaliações

- DS410Documento2 páginasDS410laratoralAinda não há avaliações

- Infinet IIDocumento4 páginasInfinet IILuis Manuel Perrusquía InfanteAinda não há avaliações

- JOTORON-RRC 7700 VFDocumento4 páginasJOTORON-RRC 7700 VFamir11601Ainda não há avaliações

- Overview of PLC OmronDocumento13 páginasOverview of PLC OmronbejaouiAinda não há avaliações

- E1070 Brochure.30071023Documento2 páginasE1070 Brochure.30071023jariospaAinda não há avaliações

- Exor CP02R-04 SpecsheetDocumento3 páginasExor CP02R-04 SpecsheetElectromateAinda não há avaliações

- FP5043Documento7 páginasFP5043Maitry ShahAinda não há avaliações

- FP5043Documento7 páginasFP5043Parag RekhiAinda não há avaliações

- ControlDocumento5 páginasControlamerquipAinda não há avaliações

- UNV 【Datasheet】VMS-B180-A Datasheet - V1.3-ENDocumento4 páginasUNV 【Datasheet】VMS-B180-A Datasheet - V1.3-ENChristian Hurtado S.Ainda não há avaliações

- Catalogo OEMaxDocumento16 páginasCatalogo OEMaxPablo CaroAinda não há avaliações

- Y205 EN2 04 Automation SystemsDocumento63 páginasY205 EN2 04 Automation SystemsAlfredo LauraAinda não há avaliações

- FP4035Documento7 páginasFP4035Maitry ShahAinda não há avaliações

- MOD30 XL+ControllerDocumento6 páginasMOD30 XL+Controllervinodk335Ainda não há avaliações

- PLC Unitronics PDFDocumento12 páginasPLC Unitronics PDFJulio Cesar HdzAinda não há avaliações

- Europe 2012Documento13 páginasEurope 2012muallaktakiAinda não há avaliações

- HW 1010CJDocumento8 páginasHW 1010CJKhalid AminAinda não há avaliações

- Trusted Features1Documento35 páginasTrusted Features1Houssam BahriAinda não há avaliações

- System Control Keyboard: Technical SpecificationsDocumento1 páginaSystem Control Keyboard: Technical Specificationsnk1969Ainda não há avaliações

- Exor eTOP06 SpecsheetDocumento3 páginasExor eTOP06 SpecsheetElectromateAinda não há avaliações

- E1310 Indicator User Manual. EngpdfDocumento37 páginasE1310 Indicator User Manual. Engpdfwilliam SanchezAinda não há avaliações

- 14 - HPL2010-EN. AutomatizaciónDocumento126 páginas14 - HPL2010-EN. AutomatizaciónCesar PomposoAinda não há avaliações

- Fingerprint Access Control Standalone TerminalDocumento7 páginasFingerprint Access Control Standalone TerminalSeftivianiGeaAnandaAinda não há avaliações

- 9 Simatic s5 Catalog St50 enDocumento500 páginas9 Simatic s5 Catalog St50 enНикола КаришикAinda não há avaliações

- User Guide: Read This ManualDocumento112 páginasUser Guide: Read This Manualjulie.garrel94Ainda não há avaliações

- 3 Bse 044080 G en Compact 800 OverviewDocumento12 páginas3 Bse 044080 G en Compact 800 OverviewfibirtAinda não há avaliações

- RDC6334G Biref EnglishDocumento4 páginasRDC6334G Biref EnglishJuanjo AcvdoAinda não há avaliações

- FP4030MT L0808R PDFDocumento6 páginasFP4030MT L0808R PDFmcsecAinda não há avaliações

- Exor eTOP306 SpecsheetDocumento4 páginasExor eTOP306 SpecsheetElectromateAinda não há avaliações

- Genaral Catalog PLC PanasonicDocumento36 páginasGenaral Catalog PLC Panasonicpeter08068350% (2)

- Flaw Detector Sonic1200 PlusDocumento2 páginasFlaw Detector Sonic1200 PlusvrapciudorianAinda não há avaliações

- Weighing Indicator Ind570Documento4 páginasWeighing Indicator Ind570Erivelton AntonioAinda não há avaliações

- 1000MII 1000M4II Milling Machine & Machining Center CNC ControllerDocumento5 páginas1000MII 1000M4II Milling Machine & Machining Center CNC ControllerCNCmakersAinda não há avaliações

- Gridnode-Ips SpecDocumento4 páginasGridnode-Ips SpecMạc DavidAinda não há avaliações

- TechSpec Summit8800 EN Final09b PDFDocumento4 páginasTechSpec Summit8800 EN Final09b PDFautrolAinda não há avaliações

- Programming Manual OptimusDrivePLCDocumento577 páginasProgramming Manual OptimusDrivePLCОлег ЕфимовAinda não há avaliações

- 04 Catalogue ManHinhHienThi IND570Documento4 páginas04 Catalogue ManHinhHienThi IND570Tùng Hồ ThanhAinda não há avaliações

- SpectrumDocumento6 páginasSpectrumBenetton ČačakAinda não há avaliações

- AY-B9350 Datasheet V00 230818 - English - A4Documento2 páginasAY-B9350 Datasheet V00 230818 - English - A4kalkumarmAinda não há avaliações

- Nais Manual BookDocumento20 páginasNais Manual BookAgus Sopyan100% (1)

- 1057 Rev E Amphion Integrated Drilling System - Web PDFDocumento6 páginas1057 Rev E Amphion Integrated Drilling System - Web PDFmr347833% (3)

- 4104euen PLC Overview 0Documento64 páginas4104euen PLC Overview 0ludek_bartakAinda não há avaliações

- GTC 081001Documento16 páginasGTC 081001Joseph Thomas100% (1)

- Computer Organization and Design: The Hardware / Software InterfaceNo EverandComputer Organization and Design: The Hardware / Software InterfaceNota: 4 de 5 estrelas4/5 (12)

- Time-Sensitive Networking - An IntroductionDocumento5 páginasTime-Sensitive Networking - An Introductionsmyethdrath24Ainda não há avaliações

- The Indonesia National Clean Development Mechanism Strategy StudyDocumento223 páginasThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaAinda não há avaliações

- 3 Carbohydrates' StructureDocumento33 páginas3 Carbohydrates' StructureDilan TeodoroAinda não há avaliações

- AlpaGasus: How To Train LLMs With Less Data and More AccuracyDocumento6 páginasAlpaGasus: How To Train LLMs With Less Data and More AccuracyMy SocialAinda não há avaliações

- LTE Networks Engineering Track Syllabus Overview - 23 - 24Documento4 páginasLTE Networks Engineering Track Syllabus Overview - 23 - 24Mohamed SamiAinda não há avaliações

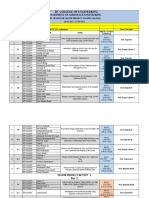

- Review1 ScheduleDocumento3 páginasReview1 Schedulejayasuryam.ae18Ainda não há avaliações

- Lithuania DalinaDocumento16 páginasLithuania DalinaStunt BackAinda não há avaliações

- NDY 9332v3Documento8 páginasNDY 9332v3sulphurdioxideAinda não há avaliações

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterDocumento4 páginasRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviAinda não há avaliações

- Fusion Implementing Offerings Using Functional Setup Manager PDFDocumento51 páginasFusion Implementing Offerings Using Functional Setup Manager PDFSrinivasa Rao Asuru0% (1)

- 3 ALCE Insulators 12R03.1Documento12 páginas3 ALCE Insulators 12R03.1Amílcar Duarte100% (1)

- Equivalent Fractions Activity PlanDocumento6 páginasEquivalent Fractions Activity Planapi-439333272Ainda não há avaliações

- Arnold Ventures Letter To Congressional Social Determinants of Health CaucusDocumento7 páginasArnold Ventures Letter To Congressional Social Determinants of Health CaucusArnold VenturesAinda não há avaliações

- WEB DESIGN WITH AUSTINE-converted-1Documento9 páginasWEB DESIGN WITH AUSTINE-converted-1JayjayAinda não há avaliações

- Azimuth Steueung - EngDocumento13 páginasAzimuth Steueung - EnglacothAinda não há avaliações

- Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingDocumento9 páginasStress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingRory Cristian Cordero RojoAinda não há avaliações

- History of The Sikhs by Major Henry Cour PDFDocumento338 páginasHistory of The Sikhs by Major Henry Cour PDFDr. Kamalroop SinghAinda não há avaliações

- Linguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowDocumento2 páginasLinguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowMonette Rivera Villanueva100% (1)

- IMS Objectives Targets 2Documento2 páginasIMS Objectives Targets 2FaridUddin Ahmed100% (3)

- Mark Garside Resume May 2014Documento3 páginasMark Garside Resume May 2014api-199955558Ainda não há avaliações

- Monergism Vs SynsergismDocumento11 páginasMonergism Vs SynsergismPam AgtotoAinda não há avaliações

- Test Your Knowledge - Study Session 1Documento4 páginasTest Your Knowledge - Study Session 1My KhanhAinda não há avaliações

- CAT 320D2: Hydraulic ExcavatorDocumento5 páginasCAT 320D2: Hydraulic Excavatorhydeer 13Ainda não há avaliações

- Functions in C++Documento23 páginasFunctions in C++Abhishek ModiAinda não há avaliações

- Iec TR 61010-3-020-1999Documento76 páginasIec TR 61010-3-020-1999Vasko MandilAinda não há avaliações

- Leak Detection ReportDocumento29 páginasLeak Detection ReportAnnMarie KathleenAinda não há avaliações

- Technical Bulletin LXL: No. Subject Release DateDocumento8 páginasTechnical Bulletin LXL: No. Subject Release DateTrunggana AbdulAinda não há avaliações

- FM 2030Documento18 páginasFM 2030renaissancesamAinda não há avaliações

- PSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterDocumento3 páginasPSG College of Technology, Coimbatore - 641 004 Semester Examinations, SemesterBabitha DhanaAinda não há avaliações

- Spesifikasi PM710Documento73 páginasSpesifikasi PM710Phan'iphan'Ainda não há avaliações